VM314

VM314

Stresses of UHMWPE under Uniaxial Tension

Test Case

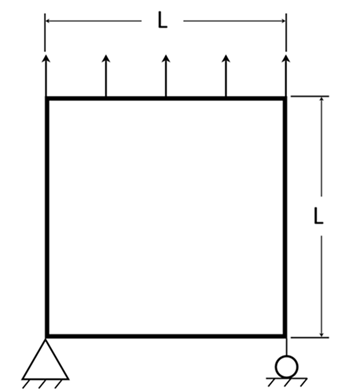

A block of UHMWPE (ultra-high-molecular-weight polyethylene) is under tension in the

vertical direction as shown in the problem sketch. The displacement loading is applied slowly

with an engineering strain rate of 0.007/s. The body temperature is kept constant at

300 K throughout the loading process. The reference temperature

0 and material parameter

are both selected as 300 K to remove temperature effect. The

final stress is obtained and compared against the reference solution.

| Material Properties | Geometric Properties | Loading | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Refer to Defining a TNM in the Material Reference

|

| Uniaxial tension to 260 mm in Y within 372 seconds. The body temperature is kept constant at 300 K. |

Analysis Assumptions and Modeling Notes

The problem is solved using 3D SOLID185 elements. UHMWPE is modeled by the Three Network Model (TB,TNM). The block is stretched in the Y direction. The constant body temperature 300 K is defined by command BFUNIF. Large deflection effect is enabled (NLGEOM,ON). The final stress is obtained in /POST1.