VM315

VM315

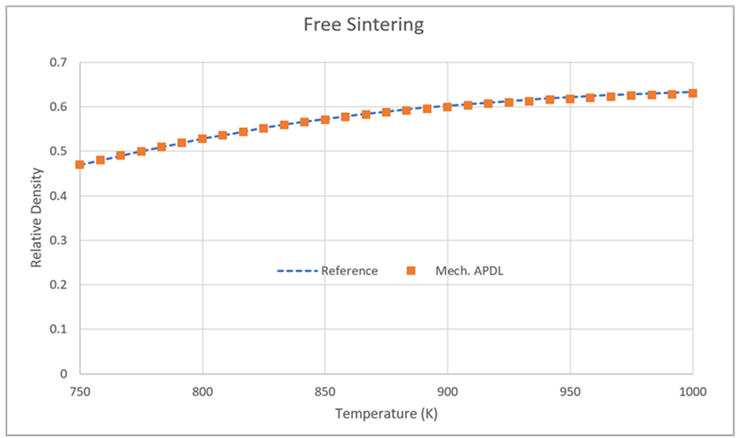

Simulation of Free Sintering

Overview

| Reference: | Arguello, J., Reiterer, M., & Ewsuk, K. (2009). Verification, Performance, Validation, and Modifications to the SOVS Continuum Constitutive Model in a Nonlinear Large‐Deformation Finite Element Code. Journal of the American Ceramic Society, 92(7): 1442-1449. |

| Analysis Type(s): | Static (ANTYPE = 0) |

| Element Type(s): |

3-D Structural Solid Elements (SOLID185) |

| Input Listing: | vm315.dat |

Test Case

A uniaxial bar composed of 0.2 µm ZnO powder stands freely without any constraints. The bar is loaded with temperature. Temperature increases linearly to 1000 K. At 750 K, the sintering process is activated, and the body starts to shrink. The temperature loading speed is 5°C/min during the sintering process. The relative density of the bar is obtained and compared against the reference.

| Material Properties | Geometric Properties | Loading | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Elastic parameters

Sintering transition temperature

Initial parameters

Sintering stress

SOVS coefficients

Viscocity

| Bar is cubic with length 1 mm |

1) Apply body temperature of 750 K. 2) Increase body temperature to 1000 K. |

Analysis Assumptions and Modeling Notes

The sintering material is defined by TB, SINT. The temperature is loaded in two steps, 750 K in the first step and from 750 K to 1000K in the second step. The first step is solved in one substep and the second step takes 30 substeps. The sintering process occurs in the second step, and its relative density is obtained using *GET in /POST1 and ESOL in /POST26. See the figure below.