VM201

VM201

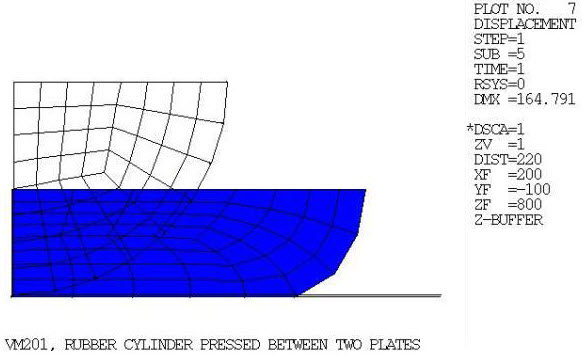

Rubber Cylinder Pressed Between Two Plates

Overview

Test Case

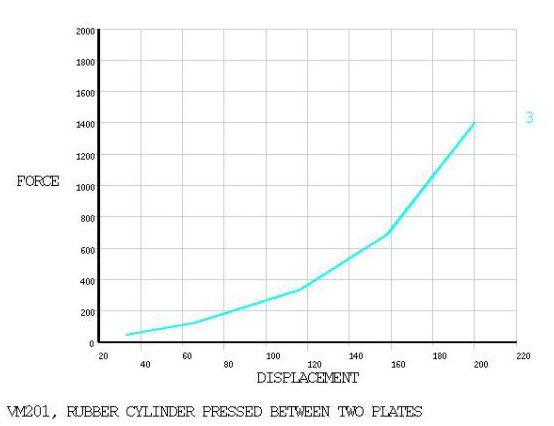

A long rubber cylinder is pressed between two rigid plates using a maximum imposed displacement of δmax. Determine the force-deflection response.

| Material Properties | Geometric Properties | Loading | |||||

|---|---|---|---|---|---|---|---|

|

|

|

Analysis Assumptions and Modeling Notes

A plane strain solution is assumed based on the geometry of the problem. Due to geometric and loading symmetry, the analysis can be performed using one quarter of the cross section. All nodes on the left edge (X = 0) are constrained, UX = 0. All nodes on the top edge (y = 0) are coupled in UY. An imposed displacement of -0.1 m acts upon the coupled nodes.

This problem was solved in several ways:

In the 3D case, a MESH200 element is used as the target face for the automatic generation of contact elements. The target surface is given a high contact stiffness (KN = 2000 MPa) to model a rigid surface and no contact stiffness is required to be specified while performing the solution using Lagrange Multipliers method.

Results Comparison

| Target[1] | Mechanical APDL | Ratio | |

|---|---|---|---|

| PLANE182 with 2D CONTA175 | |||

| Force at Displacement = 0.1 (N) | 250.00 | 266.05 | 1.064 |

| Force at Displacement = 0.2 (N) | 1400.00 | 1397.06 | 0.998 |

| SOLID185 with 3D CONTA175 | |||

| Force at Displacement = 0.1 (N) | 250.00 | 266.33 | 1.065 |

| Force at Displacement = 0.2 (N) | 1400.00 | 1398.79 | 0.999 |

| PLANE182 with 2D CONTA175 with KEYOPT (2) = 3 | |||

| Force at Displacement = 0.1 (N) | 250.00 | 266.20 | 1.065 |

| Force at Displacement = 0.2 (N) | 1400.00 | 1400.42 | 1.000 |

| SOLID185 with 3D CONTA175 with KEYOPT (2) = 4 | |||

| Force at Displacement = 0.1 (N) | 250.00 | 266.40 | 1.066 |

| Force at Displacement = 0.2 (N) | 1400.00 | 1400.48 | 1.000 |