The model is a simply supported shaft. A rigid disk is located at 1/3 of its length. A bearing is located at 2/3 of its length. The rotational velocity varies with a constant slope from zero at t = 0 to 5000 RPM at t = 4 s.

The geometric properties of the shaft are as follows:

| Length: 0.4 m |

| Radius: 0.01 m |

The inertia properties of the disk are:

| Mass = 16.47 kg |

| Inertia (XX,YY) = 9.47e-2 kg·m2 |

| Inertia (ZZ) = 0.1861 kg·m2 |

The material properties for this analysis are as follows:

| Young's modulus (E) = 2.0e+11 N/m2 |

| Poisson's ratio (υ) = 0.3 |

| Density = 7800 kg/m3 |

The mass unbalance (0.1 g) is located on the disk at a distance of 0.15 m from the center line of the shaft. The mass unbalance transient forces are input using table array parameters. See Mass Unbalance Transient Forces in the Theory Reference for details of the equations. Note that the unbalance phase is 90 degrees in this example.

/prep7

! ** parameters

length = 0.4

ro_shaft = 0.01

ro_disk = 0.15

md = 16.47

id = 9.427e-2

ip = 0.1861

kxx = 2.0e+5

kyy = 5.0e+5

beta = 2.e-4

! ** material = steel

mp,ex,1,2.0e+11

mp,nuxy,1,.3

mp,dens,1,7800

! ** elements types

et,1,188

sect,1,beam,csolid

secdata,ro_shaft,20

et,2,21

r,2,md,md,md,id,id,ip

et,3,14,,1

r,3,kxx,beta*kxx

et,4,14,,2

r,4,kyy,beta*kyy

! ** shaft

type,1

secn,1

mat,1

k,1

k,2,,,length

l,1,2

lesize,1,,,9

lmesh,all

! ** disk

type,2

real,2

e,5

! ** bearing

n,21,-0.05,,2*length/3

type,3

real,3

e,8,21

type,4

real,4

e,8,21

! ** constraints

dk,1,ux,,,,uy

dk,2,ux,,,,uy

d,all,uz

d,all,rotz

d,21,all

finish

! ** transient tabular force (unbalance)

pi = acos(-1)

spin = 5000*pi/30

tinc = 0.5e-3

tend = 4

spindot = spin/tend

nbp = nint(tend/tinc) + 1

unb = 1.e-4

f0 = unb*ro_disk

*dim,spinTab,table,nbp,,,TIME

*dim,rotTab, table,nbp,,,TIME

*dim,fxTab, table,nbp,,,TIME

*dim,fyTab, table,nbp,,,TIME

*vfill,spinTab(1,0),ramp,0,tinc

*vfill,rotTab(1,0), ramp,0,tinc

*vfill,fxTab(1,0), ramp,0,tinc

*vfill,fyTab(1,0), ramp,0,tinc

tt = 0

*do,iloop,1,nbp

spinVal = spindot*tt ! omega use to compute coriolis force and omega^2

spinTab(iloop,1) = spinVal ! table of omega vs time

spin2 = spinVal**2 ! omega^2 used to compute centrifugal force

rotVal = spindot*tt**2/2 ! total rotation in radians

rotTab(iloop,1) = rotVal ! table of rotation vs time

sinr = sin(rotVal) ! direction of force based on rotVal

cosr = cos(rotVal)

fxTab(iloop,1)= f0*(-spin2*sinr + spindot*cosr) ! centrifugal force plus

! tangential force due to

fyTab(iloop,1)= f0*( spin2*cosr + spindot*sinr) ! rotation acceleration

tt = tt + tinc ! time used to compute omega

! and rotation

*enddo

fini

! ** transient analysis

/solu

antype,transient

time,tend

deltim,tinc,tinc/10,tinc*10

kbc,0

coriolis,on,,,on

omega,,,spin

f,5,fx,%fxTab%

f,5,fy,%fyTab%

outres,all,all

solve

fini

! ** generate response graphs

/post26

nsol,2,5,U,X,UXdisk

prod,3,2,2

nsol,4,5,U,Y,UYdisk

prod,5,4,4

add,6,3,5

sqrt,7,6,,,Ampl_At_Disk

/axlab,y,Displacement (m)

/show,JPEG

plvar,7

EXTREME,7

/show,CLOSE

esol,8,4,5,smisc,32,Sy_At_Disk

esol,9,4,5,smisc,34,Sz_At_Disk

/axlab,y,Bending Stresses (N/m2)

/show,JPEG

plvar,8,9

EXTREME,8,9

/show,CLOSE

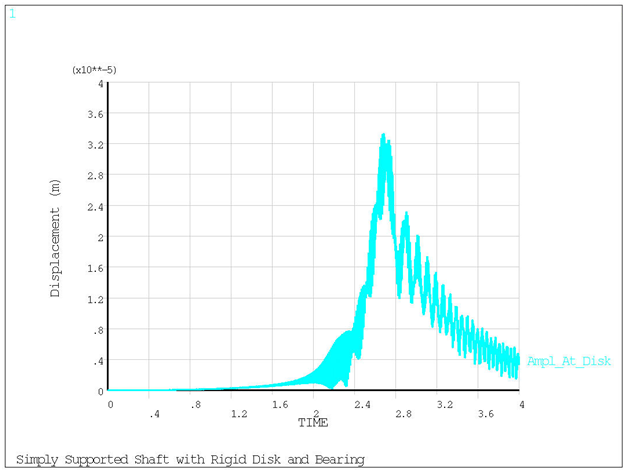

Figure 7.5: Transient Response – Displacement vs. Time shows displacement vs. time.

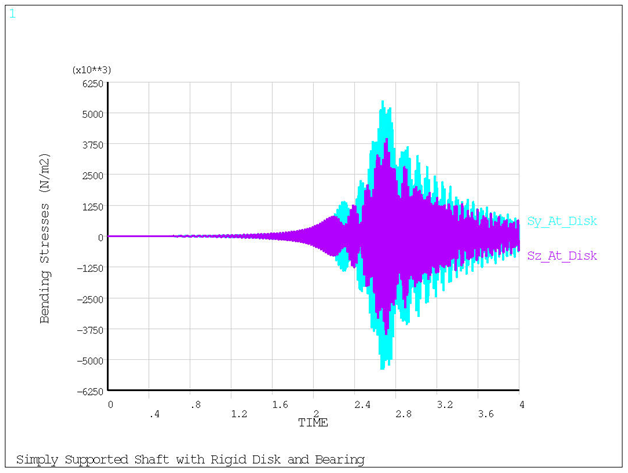

Figure 7.6: Transient Response - Bending Stress vs. Time shows bending stress vs. time.