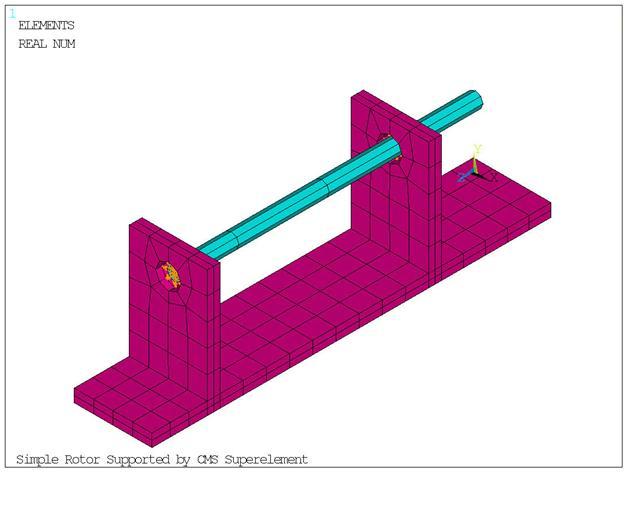

A rotating shaft is supported by two symmetric bearings and a foundation structure. This foundation is reduced to a Component Mode Synthesis (CMS) superelement. A Campbell diagram analysis is performed on the model.

Problem Specifications:

| Shaft length | = 0.595 m |

| Shaft diameter | = 0.015 m |

| Support block length | = 0.79 m |

| Support block height | = 0.25 m |

| Support block width | = 0.154 m |

| Support block thickness | = 0.025 m |

| Bearing stiffness | = 5E+07 N/m |

The inertia properties of the disks are:

| Disc No | Mass [kg] | Ixx [kg-m2] | Iyy [kg-m2] | Izz [kg-m2] |

| 1 | 0.334 | 2.688e-4 | 2.688e-4 | 1.360e-4 |

| 2 | 0.782 | 7.02e-4 | 7.020e-4 | 4.310e-4 |

| 3 | 4.390 | 1.39e-2 | 1.194e-2 | 8.809e-3 |

The material properties for this analysis are:

| Structure | Material | Young's modulus [N/m2] | Density [kg/m3] | Poisson's ratio |

| Shaft | Steel | 2 E+11 | 7850 | 0.3 |

| Support | Aluminum | 7 E+10 | 2710 | 0.3 |

!** parameters

fl=0.79 ! foundation length

fw=0.154 ! foundation width

ft=0.025 ! foundation thickness

ex_f=70e9 ! foundation young's modulus

dens_f=2710 ! foundation density

fsh=0.25 ! support height

fst=0.025 ! support thickness

sch=0.2 ! shaft centre height

bor=0.025 ! bearing or =0.025 m

bs=5e7 ! bearing stiffness n/m

!** disc 1

m1=0.334

j1=2.688e-4

i1=1.36e-4

!** disc 2

m2=0.782

j2=7.02e-4

i2=4.31e-4

!** disc 3

m3=4.39

ix3=1.39e-2

iy3=1.194e-2

iz3=8.809e-3

ex_s=200e9

dens_s=7850

s_or=0.015

/prep7

!** foundation

block,0,fw,0,ft,0,fl

block,0,fw,0,fsh,(0.23-fst/2),(0.23+fst/2)

block,0,fw,0,fsh,(0.668-fst/2),(0.668+fst/2)

wpcsys,-1,0

wpoff,fw/2,sch

cswpla,11,1,1,1,

cyl4, , ,bor, , , ,fl

vsbv,2,4,,,keep

vsbv,3,4,

vovlap,all

wpcsys,-1,0

csys,0

n,1,fw/2,0.2,0.073

n,2,fw/2,0.2,0.23

n,3,fw/2,0.2,0.23+0.147

n,4,fw/2,0.2,0.23+0.147+0.179

n,5,fw/2,0.2,0.23+0.147+0.179+0.112

!** shaft

et,1,188

keyopt,1,3,3

sectype,1,beam,csolid,shaft, 0

secoffset,cent

secdata,s_or

ex,1,ex_s

nuxy,1,0.3

dens,1,dens_s

r,1,

e,1,2

*repeat,4,1,1

et,2,21

r,2,m1,m1,m1,j1,i1,i1

r,3,m2,m2,m2,j3,i2,i2

r,4,m3,m3,m3,ix3,iy3,iz3

type,2 ! motor

real,4

e,1

real,2 ! disc 1

e,3

real,3 ! disc 2

e,4

et,5,185

keyopt,5,2,3

ex,5,ex_f

nuxy,5,0.3

dens,5,dens_f

r,5

type,5

mat,5

real,5

csys,11

lsel,s,loc,x,0.025

lesize,all,,,4

csys,0

lsel,s,loc,y,0.1*ft,0.9*ft

lesize,all,,,2

lsel,s,loc,z,(0.23-fst/3),(0.23+fst/3)

lesize,all,,,2,,1

lsel,s,loc,z,(0.668-fst/3),(0.668+fst/3)

lesize,all,,,2,,1

allsel

esize,0.05

vsweep,all

*get,maxnode,node,,num,max

!** bearings radial stiffness modeling

et,7,14

r,7,bs/4

type,7

real,7

csys,11

nsel,s,loc,x,0,bor

nsel,r,loc,z,0.23

e,2,node(bor,0,0.23)

e,2,node(bor,45,0.23)

e,2,node(bor,90,0.23)

e,2,node(bor,135,0.23)

e,2,node(bor,180,0.23)

e,2,node(bor,225,0.23)

e,2,node(bor,270,0.23)

e,2,node(bor,315,0.23)

nsel,s,loc,x,0,bor

nsel,r,loc,z,0.668

e,5,node(bor,0,0.668)

e,5,node(bor,45,0.668)

e,5,node(bor,90,0.668)

e,5,node(bor,135,0.668)

e,5,node(bor,180,0.668)

e,5,node(bor,225,0.668)

e,5,node(bor,270,0.668)

e,5,node(bor,315,0.668)

allsel

!** components

esel,s,ename,,188

esel,a,ename,,21

cm,rotor,elem ! rotating parts

esel,a,ename,,14

nsle,s,1

cm,rotor_bear,elem ! rotor+bearings (non se)

esel,inve

cm,support,elem ! foundation (se)

allsel

save,rotor_supp_full,db

finish

!***************************

! superelement generation

!***************************

/filname,support

/solu

antype,substr

ematwrite,yes

seopt,support,2,

cmsopt,fix,4

nsel,s,loc,x,bor

m,all,all

csys,0 ! fix bottom of the support structure

nsel,s,loc,y,0

d,all,all

cmsel,s,support,elem

nsle,s

solve ! generate superelement "support.sub"

fini

save

!**********************************************

! rotor+bearings+superelement modal analysis

!**********************************************

/clear, nostart

/filname, rotor_use

resume, rotor_supp_full,db ! resume original assembly model

/prep7

vclear,all ! delete foundation elements to be replaced by superelement

et,10,matrix50

type,10

se,support ! read in superelement from file "support.sub"

allsel

/solu

pi=acos(-1)

rpmtorps=2*pi/60

antype,modal

modopt, qrdamp,6,1,0,1,on

mxpand,6, , ,1

coriolis,on,,,on

beta,1e-6

cmomega,rotor,0*rpmtorps,,,fw/2,sch,0.073,fw/2,sch,0.668

solve

cmomega,rotor,1000*rpmtorps,,,fw/2,sch,0.073,fw/2,sch,0.668

solve

cmomega,rotor,5000*rpmtorps,,,fw/2,sch,0.073,fw/2,sch,0.668

solve

cmomega,rotor,10000*rpmtorps,,,fw/2,sch,0.073,fw/2,sch,0.668

solve

save, rotor_use,db

finish

! **********************************

! expand results for superelement

! **********************************

/clear, nostart

/filname, support

resume, support,db

/solu

expass,on

seexp, support, rotor_use,

numexp,all, , , yes

solve

finish

! **********************

! review the results

! **********************

/clear, nostart

resume, rotor_use,db

/post1

cmsfile,clear

file, rotor_use,rst

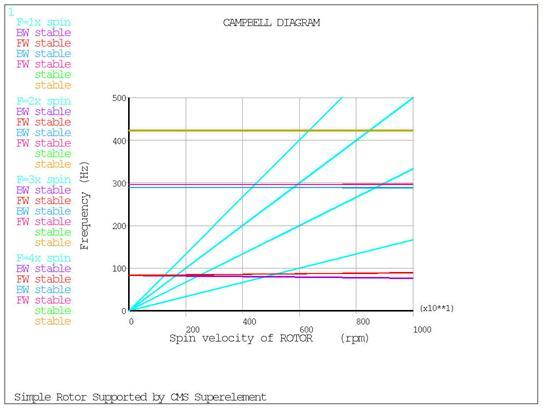

/gropt,divx,5

/gropt,divy,5

/yrange,0,500,1

/show,jpeg

plcamp,on,1,rpm,,rotor ! plot campbell diagram with 1st order excitation

prcamp,on,1,rpm,,rotor

/noerase

plcamp,on,2,rpm,,rotor ! plot campbell diagram with 2nd order excitation

prcamp,on,2,rpm,,rotor

plcamp,on,3,rpm,,rotor ! plot campbell diagram with 3rd order excitation

prcamp,on,3,rpm,,rotor

plcamp,on,4,rpm,,rotor ! plot campbell diagram with 4th order excitation

prcamp,on,4,rpm,,rotor

/show,close

/erase

fini

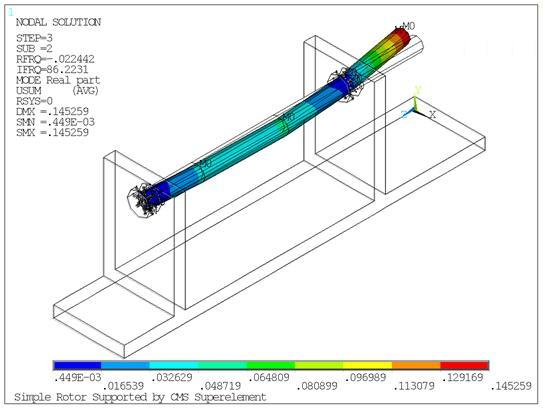

!** combined results of foundation and rotor

/clear, nostart

/verify

resume, rotor_use,db

/post1

/eshape,1

cmsfile,clear

file, rotor_use,rst

set,3,2

/show,jpeg

plnsol,u,sum,2

*get, umax,plnsol,0,max

*stat,umax

/show,close

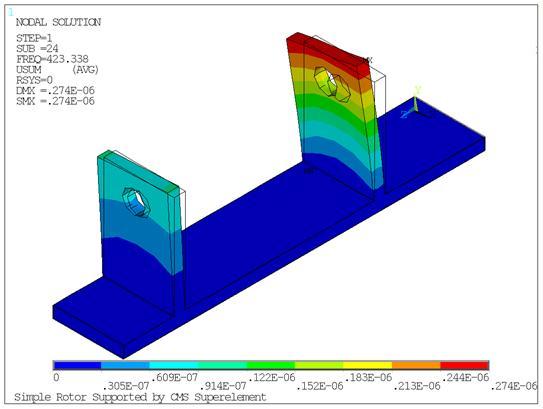

cmsfile,add,support.rst

set,last

esel,s,ename,,185

/show,jpeg

plnsol,u,sum,2

*get, umax,plnsol,0,max

*stat,umax

/show,close

finish