This example demonstrates the static analysis of a compressor multistage system. Specifically, it demonstrates the following key points:

Static analysis of a multistage system

Use of only base sectors for static, HI = 0 cases

Axial multistage modeling with more than 2 stages

Mismatched interstage boundaries requiring mapping

Offset cyclic edge starting points

Expansion

The example problem is presented in the following sections:

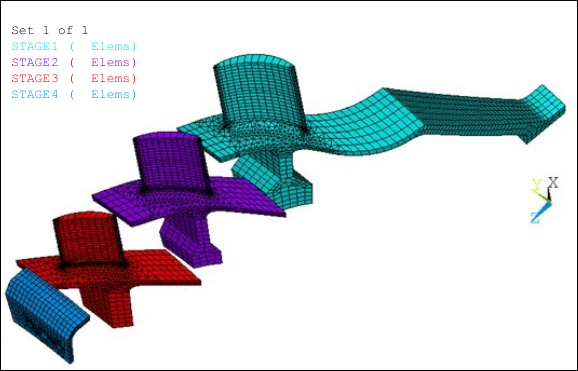

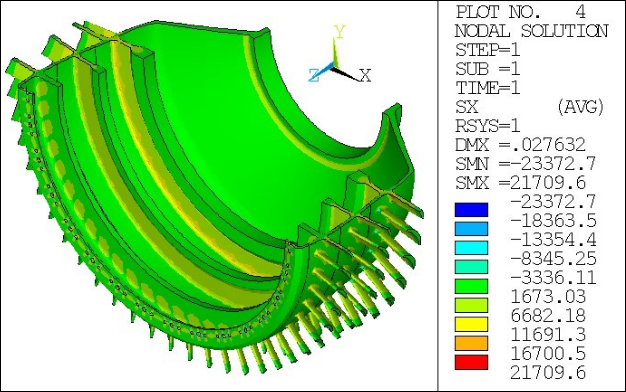

The multistage system consists of 4 axially aligned cyclic stages merged at 3 interstage boundaries. There are 3 blade rows and a rim modeled using SOLID186 and SOLID187 elements as shown in Figure 7.1: Compressor Model with 4 Axial Stages . The model is fixed along the hoop of the upstream hub. The stages have the following sector counts:

| Stage | Sector Count |

|---|---|

| 1 | 43 |

| 2 | 48 |

| 3 | 54 |

| 4 | 30 |

The finite element models of the four stages in axial alignment are shown below.

The following table describes the key steps and related commands used for the example analysis. See Input for the Analysis for the detailed command listing.

| Step | Description | Mechanical APDL Commands |

| 1. | Create base sector for each stage. | CDREAD,... |

| 2. | Create stage components for each stage. | CM,... |

| 3. | Create sector low/high edge components for each stage. | CM,... |

| 4. | Create stages and apply cyclic constraints for harmonic index 0. |

MSOPT,NEW,... CECYCMS,... |

| 5. | Set analysis type (static). | ANTYPE,STATIC |

| 6. | Apply multistage constraints. | CEIMS,... |

| 7. | Apply other boundary conditions. | D,.... |

| 8. | Apply external loading in the form of rotational velocity. | OMEGA,... |

| 9. | Solve the analysis. | SOLVE,... |

| 10. | Enter POST1 postprocessor. | /POST1 |

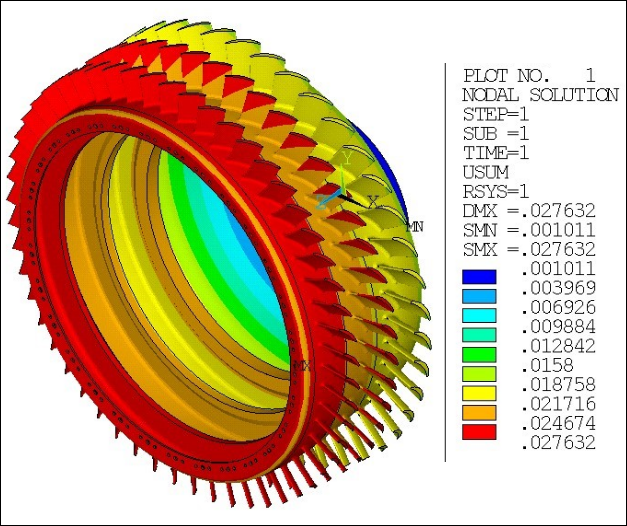

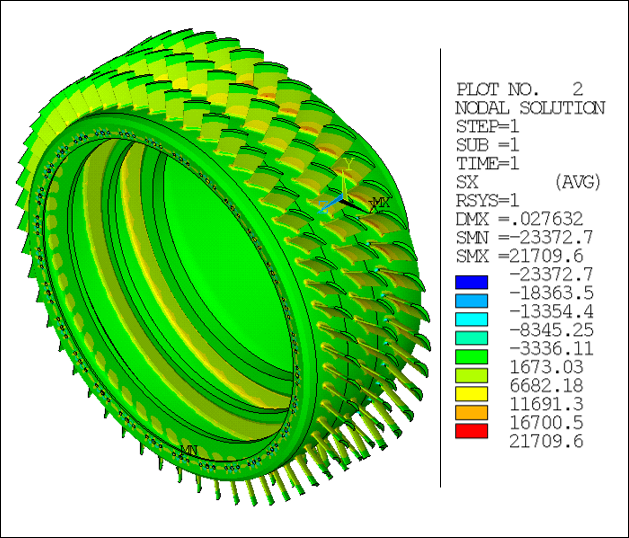

| 11. | Set expansion parameters to expand all stages and sectors. | MSOPT,EXPA,ALL,ALL |

| 12. | Read results, expand database and expand results. | SET,... |

| 13. | Plot expanded displacements. | PLNSOL |

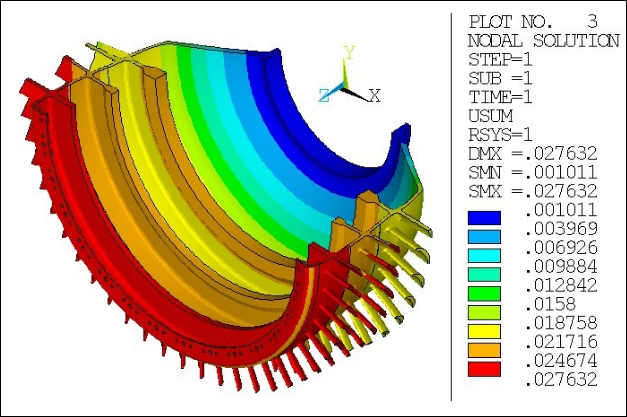

| 14. | Define cutting plane. | /CPLANE,... |

| 15. | Plot same expanded displacements with different cut view. | PLNSOL |

Download the zipped .cdb files used for this example problem.

/batch,

/com ===============================================================

/com Multistage static analysis - compressor

/com ===============================================================

! define stage information

!--------------------------

NumStages = 4 ! Number of stages

NS1 = 43 ! Stage1 number of sectors

NS2 = 48 ! Stage2 number of sectors

NS3 = 54 ! Stage3 number of sectors

NS4 = 30 ! Stage4 number of sectors

HI1 = 0 ! Stage 1 harmonic index

HI2 = 0 ! Stage 2 harmonic index

HI3 = 0 ! Stage 3 harmonic index

HI4 = 0 ! Stage 4 harmonic index

! create multistage components

!-----------------------------

*do,iter,1,NumStages

! Read in stages in reverse order

filenum=NumStages-Iter+1

cdread,db,Stage%filenum%,cdb

! Create stage components

cm,_Stage%filenum%_base_elm,elem

nsle

cm,_Stage%filenum%_base_nod,node

cmsel,s,Stage%filenum%_Low

cm,_Stage%filenum%_cyclow_nod,node

cmsel,s,Stage%filenum%_High

cm,_Stage%filenum%_cychigh_nod,node

cmsel,u,_Stage%filenum%_base_elm

*enddo

alls

/prep7

! rotate nodes into cylindrical system

!-------------------------------------

alls

csys,1

nrot,all

! setup selection parameters for later use

!-----------------------------------------

cmsel,s,stage1

nsle

*get,_RBC,NODE,0,MNLOC,X ! BC radius

allsel

*do,iter,1,NumIntfs

cmsel,s,INT%iter%_LARGE

*get,_Int%iter%Ax,NODE,0,MXLOC,z ! MS interface axial location

*get,_Int%iter%RadMax,Node,0,MXLOC,x !Max Radial Location

*get,_Int%iter%RadMin,Node,0,MNLOC,x !Min Radial Location

allsel

*enddo

! create multistage settings for each stage

!------------------------------------------

*do,iter,1,NumStages

msopt,new,Stage%iter%,NS%iter%,HI%iter%

cecycms

*enddo

allsel

msopt,list,all

finish

seltol

/solu

antype,static

outres,erase

outres,all,none

outres,nsol,all

outres,etmp,all

outres,strs,all

! apply interstage constraints between 1-2

!------------------------------------------

cmsel,s,int1_large

cm,Int1_intf_nod,node

cmsel,s,int1_small

esln

cm,Int1_intf_elm,elem

allsel

cmsel,,Int1_intf_nod

cmsel,,Int1_intf_elm

ceims,,,stage1,stage2

allsel

! apply interstage constraints between 2-3

!------------------------------------------

cmsel,s,int2_large

cm,Int2_intf_nod,node

cmsel,s,int2_small

esln

cm,Int2_intf_elm,elem

allsel

cmsel,,Int2_intf_nod

cmsel,,Int2_intf_elm

ceims,,,stage2,stage3

allsel

! apply interstage constraints between 3-4

!------------------------------------------

cmsel,s,int3_large

cm,Int3_intf_nod,node

cmsel,s,int3_small

esln

cm,Int3_intf_elm,elem

allsel

cmsel,,Int3_intf_nod

cmsel,,Int3_intf_elm

ceims,,,stage4,stage3

allsel

! apply fixed support boundary conditions

!-----------------------------------------

cmsel,s,_Stage1_base_elm

nsle

seltol,0.001

nsel,r,loc,x,_RBC

d,all,uy

d,all,uz

allsel

seltol

! apply rotational load

!-----------------------

omega,,,1000

solve

finish

/post1

! expand all stages and sectors

!-------------------------------

msopt,expa,all,all

set,first

rsys,1

/show,png,rev

/view,1,1,1,1

! show all stages and sectors

!-----------------------------

plns,u,sum

*get,usummax,plnsol,0,max

plns,s,x

*get,sxmax,plnsol,0,max

! show cut of all stages and sectors

!------------------------------------

wprot,0,-90,0

/type,1,5

/cplane,1

/shade,1,1

/hbc,1,0

plns,u,sum

plns,s,x

/show,close