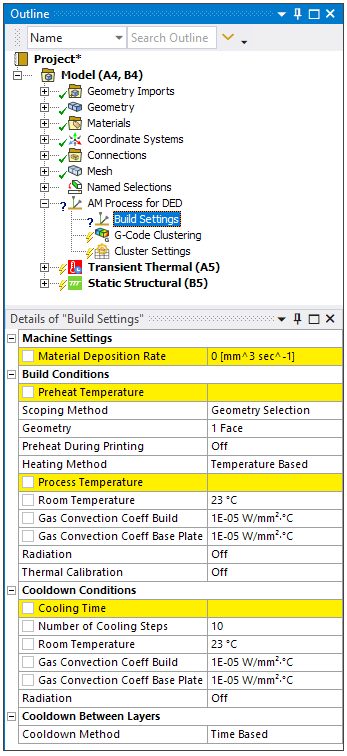

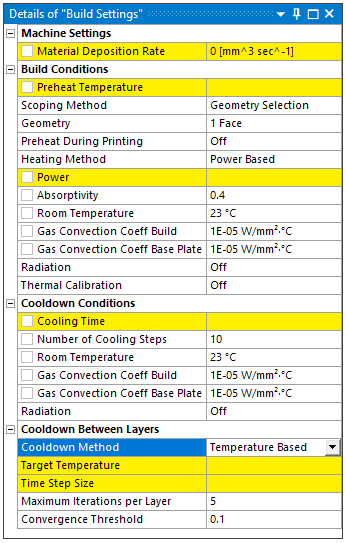

Establishes settings and conditions related to a DED additive manufacturing process and machine.

|

| Category | Description and Settings |

| Machine Settings | Process parameters that vary for each DED machine and deposition material. |

| Material Deposition Rate: The feeding rate of the melted material, in mm3/sec. This value can be determined by multiplying layer thickness (mm) x weld width (mm) x deposition speed (mm/sec). | |

| Build Conditions | The environment in the build chamber around the part as it is being printed, including the preheat temperature. |

| Preheat Temperature: The starting temperature of the base plate. | |

| Scoping Method: Choose Geometry Selection or Named Selection to identify the bottom face of the base plate that is preheated. | |

| Preheat During Printing: Off/On - If set to Off (default), the preheat temperature is applied in only the first load step. On maintains the preheat temperature throughout the complete build process. | |

| Heating

Method: The method used to heat up the material.

Choose Power Based or Temperature Based (default). Power Based: Heating is based on laser power and material absorptivity.

Temperature Based: Heating is based on the process temperature.

| |

| Room Temperature: Temperature of the gas in the build chamber during the build. | |

| Gas Convection Coefficient Build: Convection coefficient from the part to the surrounding gas in the chamber during printing. Convection is applied to the element surfaces of every element cluster, which can be especially relevant in the case of a bulky structure. | |

| Gas Convection Coefficient Base Plate: Convection coefficient from the base plate to the surrounding gas in the chamber during printing. | |

Radiation: Off/On - If set to

Off (default), the radiation effect between the build/base and

surrounding environment is not considered during printing. Setting

the option to On enables the radiation effect between the build/base

and surrounding environment during printing.

| |

Thermal Calibration: Off/On - If

set to Off, default heating and cooling behavior is used for cluster

deposition. Setting the option to On allows you to change the

Cluster Cooling Time Ratio, essentially using it as a calibration factor.

| |

| Cooldown Conditions | The environment in the build chamber around the part in the cooldown step after the last layer is printed. |

| Cooling Time: The duration of the cooldown process, in seconds. | |

| Number of Cooling Steps: The number of substeps within the cooldown calculation. Defaults to 10. | |

| Room Temperature: Temperature of the gas in the build chamber during cooldown. | |

| Gas Convection Coefficient Build: Convection coefficient from the part to the surrounding gas in the chamber during cooldown. | |

| Gas Convection Coefficient Base Plate: Convection coefficient from the base plate to the surrounding gas in the chamber during cooldown. | |

Radiation: Off/On - If set to

Off (default), the radiation effect between the build/base and

surrounding environment is not considered during cooldown. Setting

the option to On enables the radiation effect between the build/base

and surrounding environment during cooldown.

| |

| Cooldown Between Layers | Options to automatically adjust the dwell time between layers as measured after the last cluster in a layer is deposited. |

| Cooldown Method: Choose Time Based or

Temperature Based. Time Based: The dwell time between layers is read from the Cluster Settings table. Temperature Based: Uses a Target Temperature together with time step and convergence options to automatically adjust dwell time. As soon as one of the convergence options is achieved, deposition of the next layer is started. When this method is chosen, the Dwell Time column is set to Off in the Cluster Settings table before and during the transient thermal solution. Once the thermal solution is completed, the table is updated to reflect the calculated dwell times.

|

Valid Parent Tree Object: AM Process for DED

Valid Child Tree Objects: None

Relevant right-click options include:

Save Build Settings: Saves the configuration of your build settings as an XML file. The property values are always saved in Consistent MKS Unit System.

Load Build Settings: Imports a build settings XML file. Once loaded, the settings populate the properties of the Details pane. Sample build settings XML files are available in: [Ansys Installation Directory]\aisol\DesignSpace\DSPages\SampleData\AdditiveManufacturing.

Reset to Default: Resets build settings to default values.