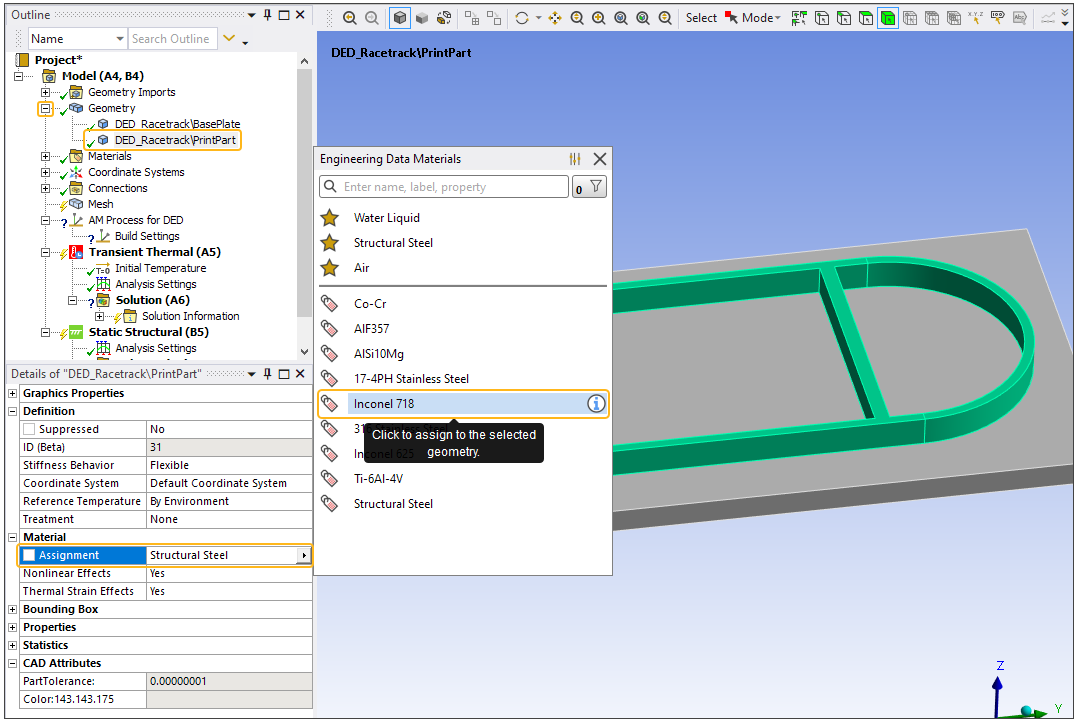

Assign a material to each geometry body. The build and the base plate can be a different material.

The reference temperature is the temperature at which thermal strains do not exist in a material. We recommend you set the reference temperature value to be the melting temperature of your chosen material. In the simulation of the DED process, our assumption is that each finite element cluster is added (with the element birth and death technique) at or above the melting temperature for the material and is initially strain-free. As the build cools, thermal strains develop. The static structural analysis will use the temperature results of the transient thermal analysis to compute the displacements, stresses, strains, and forces due to these induced thermal strains.

As its name implies, the reference temperature is used as a reference value to determine the state of the material - whether it is melted or not. It is also used as a criterion in the simulation to determine whether elements should be alive (activated) or dead (deactivated). The remelting phenomenon can be captured in the simulation by distinguishing between process temperature and reference temperature (melting temperature). Because the process temperature can be higher than the reference temperature, newly activated elements in the build (prior to the current cluster) might still be at a temperature higher than the reference temperature (melting temperature). Consequently, these elements will be deactivated to emulate remelting and prevent the accumulation of strain. This distinction becomes particularly crucial in the case of power-based temperature solutions (Heating Method = Power Based), as the maximum temperature can be significantly higher than the material's melting temperature.

Procedural Steps

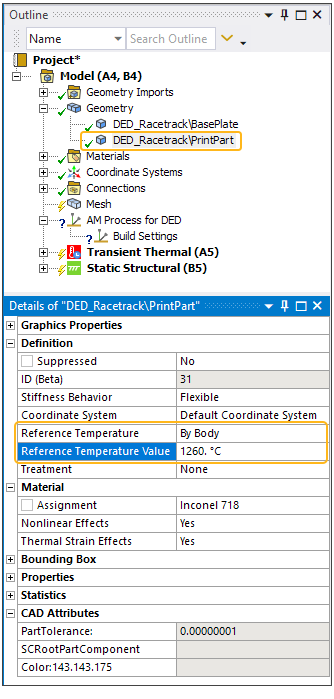

When you select a geometry entity in the project tree, the Details view lists all the settings associated with that body.

In the project tree under Model, expand the Geometry object to see its child objects below it. Select the geometric entity that is the Print /part geometry and, in Details view, under Material, change the Assignment to be an additive manufacturing material.

For the print/part geometry, set the Reference Temperature to be By Body, and enter a Reference Temperature Value to be the melting temperature. This step is very important to ensure that the proper birth and death behavior occurs in the simulation. See Methodology and Abstractions.

Note: If the Reference Temperature for the print/part geometry is set to By Environment, or set to By Body but the Reference Temperature Value is left as the default of 22°, you may see odd behavior in the structural results, such as missing elements.

Select the entity that is the base plate body and change its material Assignment, as desired. Leave the Reference Temperature option to be By Environment (default).

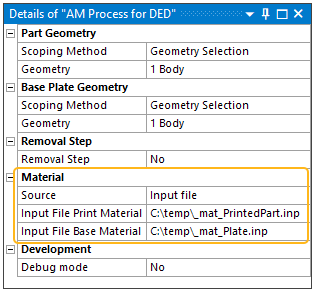

Custom Material Files

Alternatively, advanced users may want to define text files containing material data for the build part and base plate, useful for sensitivity analysis of material properties, perhaps. (See example files _mat_Plate.inp and _mat_PrintedPart.inp that show examples of the required definitions.) Define the custom material files on the Details view of the AM Process for DED object.

Example files are shown here for reference.

_mat_Plate.inp:

/nopr !++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ ! ! Bodenplatte AL-2 ( Isotropic Hardening ) DHV ! !++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ ! ! Reference Temperature [C] ! MP,REFT, matpoi, 20, ! ! Thermal Expansion Coefficient [mm/mm C] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,ALPX, matpoi, 1, 2.3860E-05, 2.6843E-05 ! !---------------------------------------------------------------------------------------------------- ! ! Thermal Conductivity [mW/mm C] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,KXX , matpoi, 1, 122.50, 147.00 !---------------------------------------------------------------------------------------------------- ! ! Thermal Heat Capacity [mW s/ton C] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,C , matpoi, 1, 9.00000E+08, 10.1000E+08 ! !---------------------------------------------------------------------------------------------------- ! ! Mass Density [t/mm*mm*mm] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,DENS, matpoi, 1, 2.66000E-09, 2.53000E-09 ! !---------------------------------------------------------------------------------------------------- ! ! Young's Modulus [MPa] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,EX , matpoi, 1, 70400.0, 56320.0 ! !---------------------------------------------------------------------------------------------------- ! ! Poisson's Ratio [-] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,PRXY, matpoi, 1, 0.30, 0.30 ! !---------------------------------------------------------------------------------------------------- ! ! Plastic Stress Strain Curves [C] ; [-] ; [MPa] ! TB,PLASTIC,matpoi,2,2,MISO TBTEMP, 20.0 TBPT,,0.0 , 123.64 TBPT,,0.1325, 246.40 TBTEMP,250.0 TBPT,,0.0 , 100.0 TBPT,,0.2875, 160.0 ! !++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

_mat_PrintedPart.inp:

/nopr /com, /com,!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! /com,--------------------------------------------------------------------------- /com, /com, Units: [mm-t-s] --> [MPa-N] /com,--------------------------------------------------------------------------- /com,!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !/gopr ! /nopr !++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ ! ! Bodenplatte AL-2 ( Isotropic Hardening ) ! !++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ ! ! Reference Temperature [C] ! MP,REFT, matpoi, 210, ! ! Thermal Expansion Coefficient [mm/mm C] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,ALPX, matpoi, 1, 2.3860E-05, 2.6843E-05 ! !---------------------------------------------------------------------------------------------------- ! ! Thermal Conductivity [mW/mm C] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,KXX , matpoi, 1, 122.50, 147.00 !---------------------------------------------------------------------------------------------------- ! ! Thermal Heat Capacity [mW s/ton C] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,C , matpoi, 1, 9.00000E+08, 10.1000E+08 ! !---------------------------------------------------------------------------------------------------- ! ! Mass Density [t/mm*mm*mm] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,DENS, matpoi, 1, 2.66000E-09, 2.53000E-09 ! !---------------------------------------------------------------------------------------------------- ! ! Young's Modulus [MPa] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,EX , matpoi, 1, 70400.0, 56320.0 ! !---------------------------------------------------------------------------------------------------- ! ! Poisson's Ratio [-] ! MPTEMP MPTEMP, 1, 20.0, 250.0 MPDATA,PRXY, matpoi, 1, 0.30, 0.30 ! !---------------------------------------------------------------------------------------------------- ! ! Plastic Stress Strain Curves [C] ; [-] ; [MPa] ! TB,PLASTIC,matpoi,2,2,MISO TBTEMP, 20.0 TBPT,,0.0 , 123.64 TBPT,,0.1325, 246.40 TBTEMP,250.0 TBPT,,0.0 , 100.0 TBPT,,0.2875, 160.0 ! !++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++