- Assembly and Selpart

Select which parts and assembly to display, delete.

- Keyword Manager

providing access to keyword editing and search interface.

- Create Entity

Generate entities, and use the drawing area to visualize entities while working on them

- Display Entity

Display LS_DYNA entities such as sets, contacts, rigidwalls, boundary, etcetera .

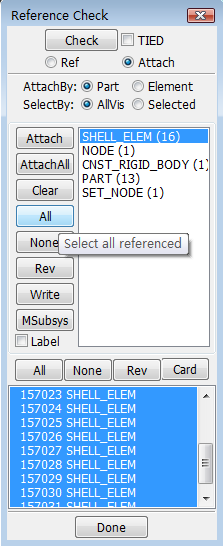

- RefCheck

Identify unreferenced, undefined, or attached entities.

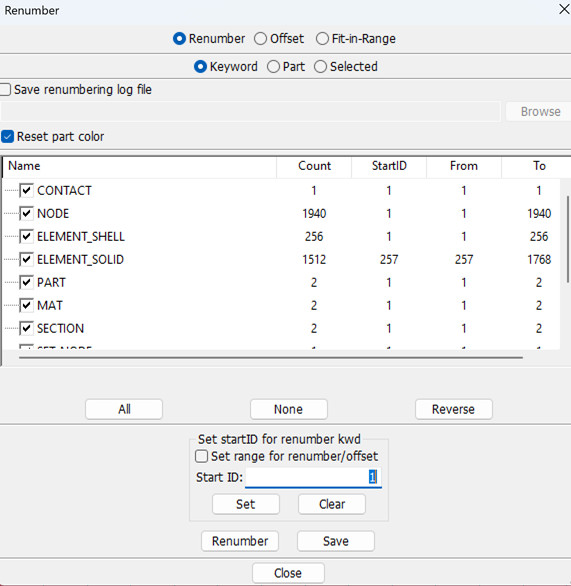

- Renumber

Renumber IDs of model entities.

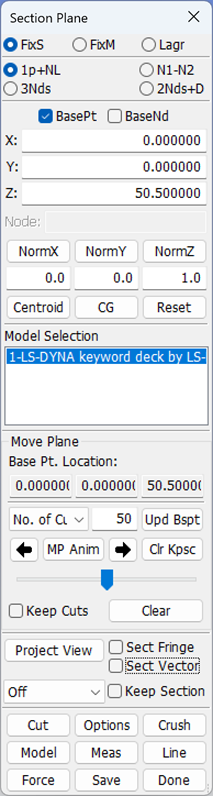

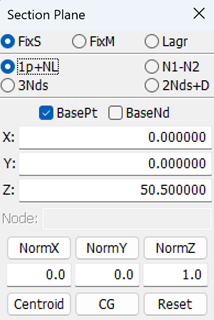

- Section Plane

Create cross sections of the model.

- Subsystem

Interact with an manage sub-systems.

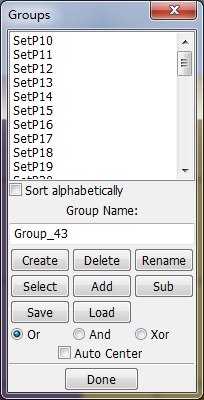

- Group

Create and manipulate groups of parts

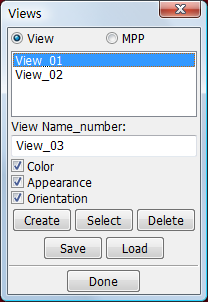

- View

Save and retrieve appearance, color, and orientation settings.

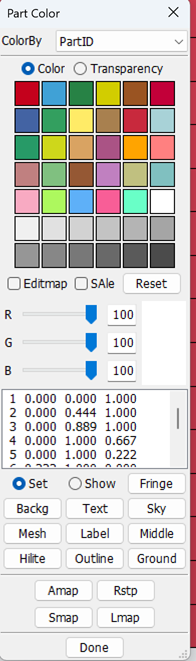

- Part Color

Apply different colors and transparency levels to selected parts.

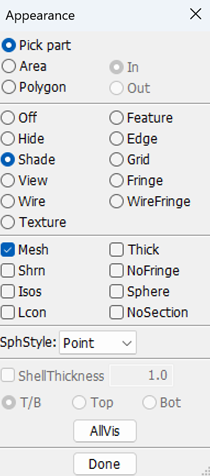

- Appear

Change the appearance of selected parts.

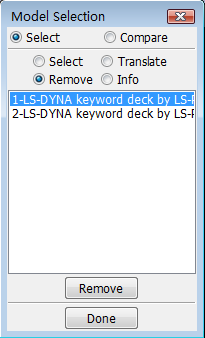

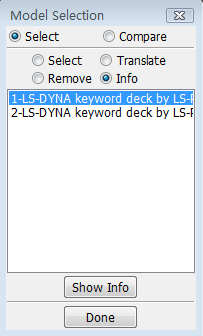

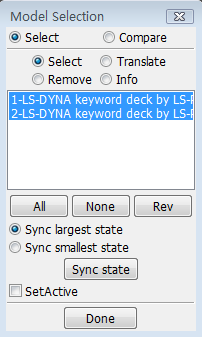

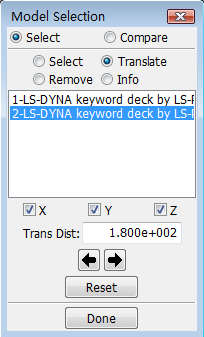

- Model Selection

Open and select multiple models.

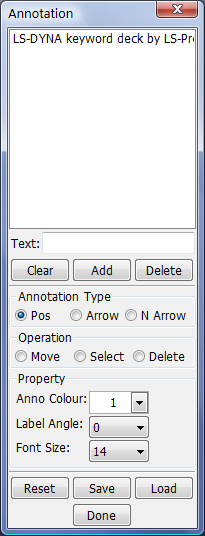

- Annotation

Add annotations to a model.

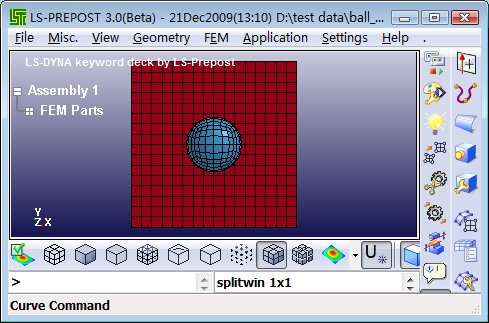

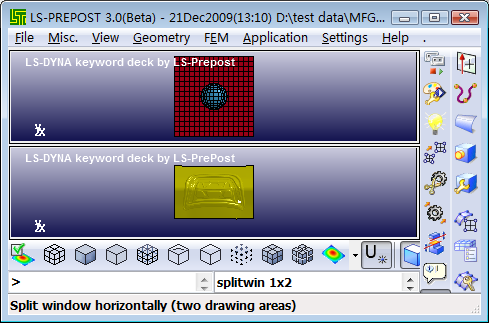

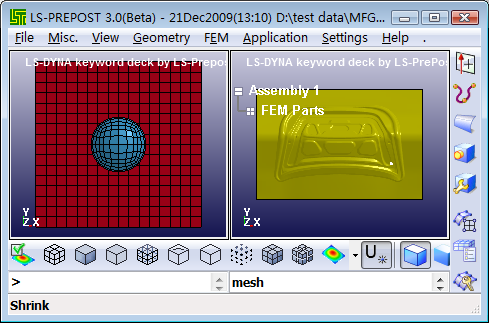

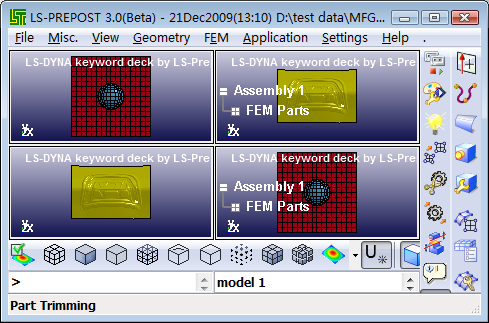

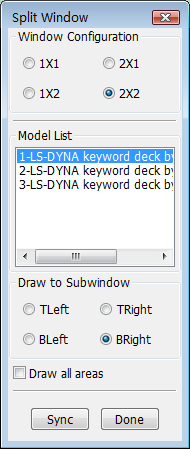

- Split Window

Split graphics region into multi-view.

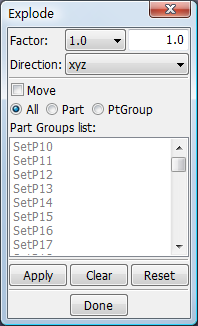

- Explode

Explode/separate parts so that they can be viewed more easily.

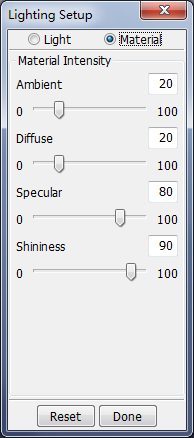

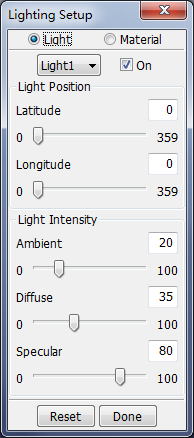

- Light

Apply effects using up to ten independent light sources.

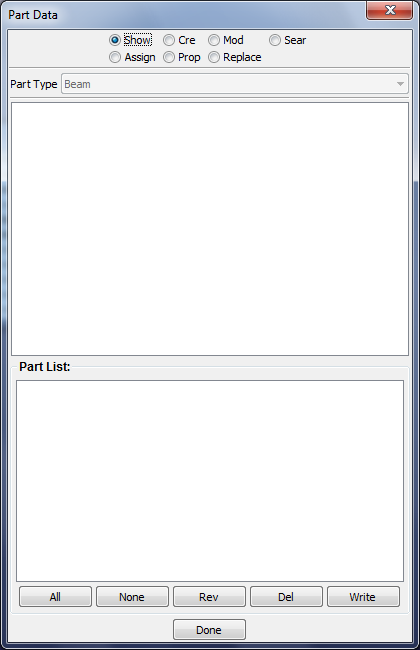

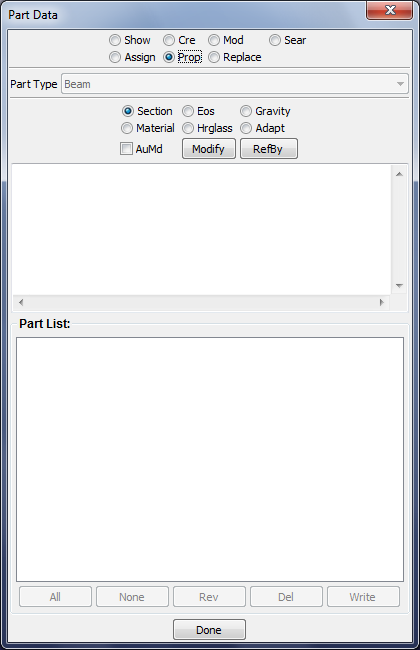

- PartD

operate part data.

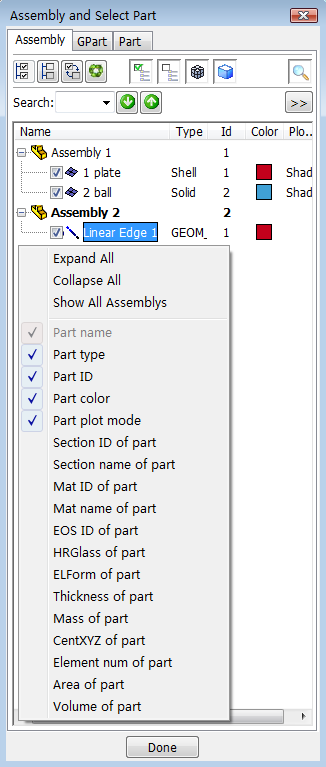

This interface is used for general managment of parts, include FE parts, Geometry parts and part display set.

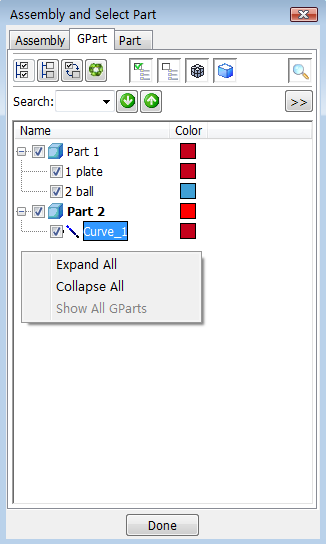

- Assembly

Integrated manage tool for FE parts and Geometry parts.

- GPart

Manage tool for Geometry parts.

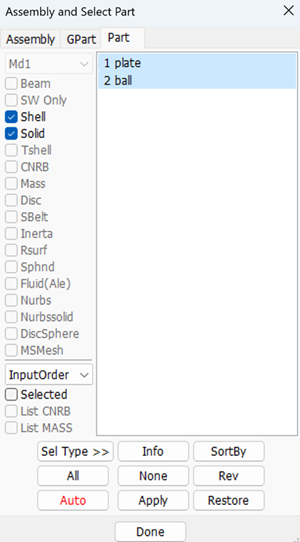

- Part

Select parts to display.

There are total 18 columns on the tree list, such as "Name", "Type", "Id", "Color", etc. Right-click the header or blank area of the tree list can pop a menu to set display or not of each column.

- Displayed

Just show displayed parts on the tree.

-

Show all.

Blank all.

Reverse the display state of all FE parts and Geometry part.

Restore.

List Active Only.

List Inactive Only.

List Finite Element Only.

List Geometry Only.

Search FE parts or Geometry parts.

- Search

Input the object for search.

Search down.

Search up.

Set search conditions.

Menu items

- Expand All

Expand all assembly tree items.

- Collapse All

Collapse all assembly tree items.

- Show All Assemblys

Show all assembly tree items, some assembly tree item may be hidden if it has no children.

- Others

Set tree column shown/hiden.

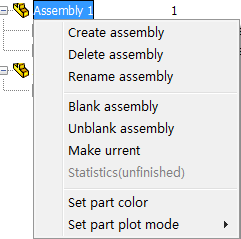

Menu tool for assembly management

- Create Assembly

Create new assembly and make it as the current.

- Delete Assembly

Delete selected assembly.

- Rename Assembly

Rename selected assembly.

- Blank Assembly

Blank selected assembly, blank all parts that belong to this assembly.

- Unblank Assembly

Unblank selected assembly, unblank all parts that belong to this assembly.

- Make Current

Make selected assembly as the current, new created parts will set as children of this assembly automaticly.

- Statistics

Get statistic information for selected assembly.

- Set Part Color

Set the same color for all parts that belong to selected assembly with Set Color Dialog.

- Set Part Plot Mode

Set the same plot mode for all parts that belong to selected assembly.

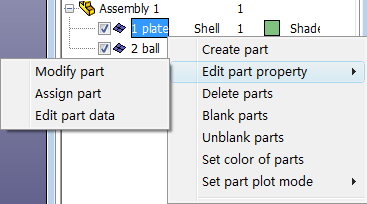

Menu tool for FE part management

- Create part

Create new part.

- Edit part property

Edit part property with Part Property Dialog, include "Modify part", "Assign part" and "Edit part data".

- Delete parts

Delete selected parts.

- Blank parts

Blank selected parts.

- Unblank parts

Unblank selected parts.

- Set color of parts

Set the same color for all selected parts with Set Color Dialog.

- Set part plot mode

Set the same plot mode for all selected parts.

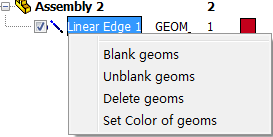

Menu tool for Geometry part management

- Blank Geoms

Blank selected geometry parts.

- Unblank Geoms

Unblank selected geometry parts.

- Delete Geoms

Delete selected geometry parts.

- Set Color of Geoms

Set the same color for selected parts with Set Color Dialog.

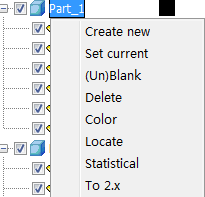

Menu tool for Geometry part group management

- Create new

Create new geometry part group.

- Set current

Set selected geometry part group as the current.

- (Un)Blank

Blank or unblank selected geometry part group.

- Delete

Delete selected geometry part group.

- Color

Set color of selected geometry part group with Set Set Color Dialog.

- Locate

Locate selected geometry part group.

- Statistical

Get statistical information of selected geometry part group.

- To 2.x

Convert selected geometry part group items to version 2.4.

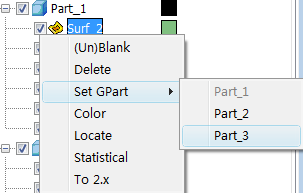

Menu tool for Geometry item management

- (Un)Blank

Blank or Unblank selected geometry items.

- Delete

Delete selected geometry items.

- Set GPart

Set geometry part group of selected geometry items.

- Color

Set color of selected geometry items with Set Color Dialog.

- Locate

Locate selected geometry items.

- Statistical

Get statistical information of selected geometry items.

- To 2.x

Convert selected geometry items to version 2.4.

- Model selection drop-down menu

For use when multiple models are loaded (Md1/Md2/Md3/etc...).

- Beam

Select/deselect Beam elements.

- Shell

Select/deselect Shell elements.

- Solid

Select/deselect Solid elements.

- Tshell

Select/deselect Tshell elements.

- Mass

Select/deselect Mass elements.

- Discrete

Select/deselect Discrete elements.

- Seatbelt

Select/deselect Seatbelt elements.

- Inertia

Select/deselect Inertia elements.

- Rsurf

Select/deselect Rigid-surface elements.

- SPHnd

Select/deselect SPH nodes elements.

- Fluid

Select/deselect Fluid elements.

- NumOrder

Display part list as numerical order, default is user order.

- Selected

List displayed parts only.

- Info

Show PART Info for selected parts.

- SortBy

Sort parts by prop/elform.

- All

Select all parts.

- None

Deselect all parts.

- Rev

Reverse part selection.

- Auto

Update selection automatically (Red=on).

- Apply

Update selected parts (when Auto=off).

- Restore

Restore the last removed part.

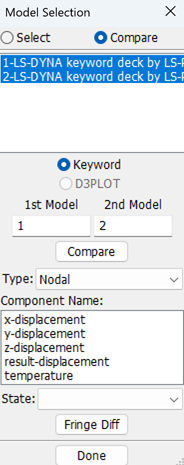

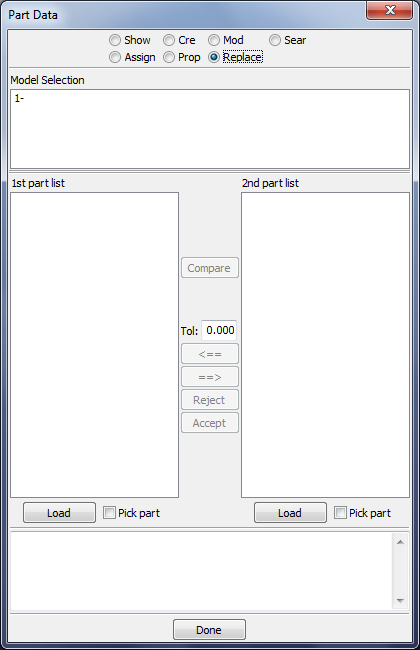

These subdialogs are accessed though several different command interfaces.

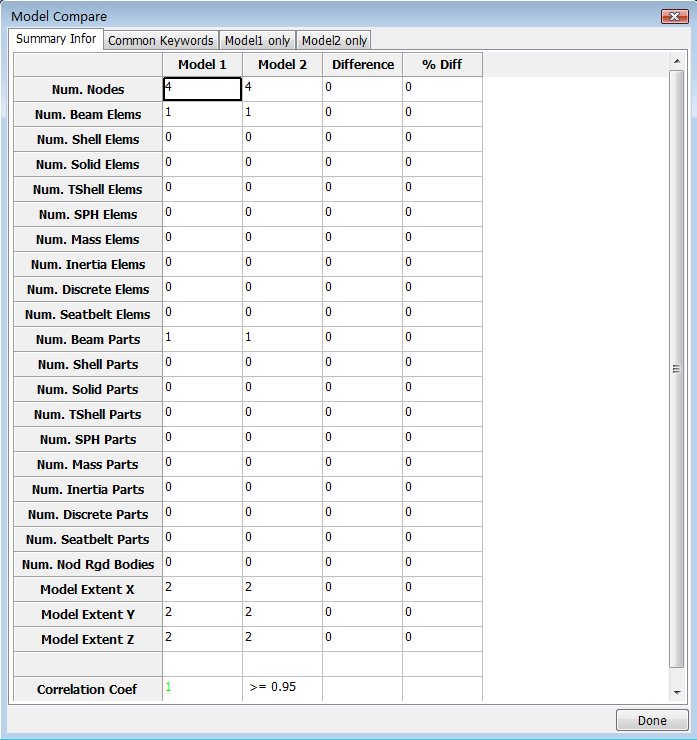

Compare all keywords of selected two models.

Operation Step:

Read in two different models, use ModelCompare_M1.k and ModelCompare_M2.k.

FEM->Model and Part->Model Selection.

Select radio button "Compare", select the two models in the model list.

Click button "Compare".

- 1. Summary Information

Gives the summary information of the selected two models, such as node count, element count, part count and etc.

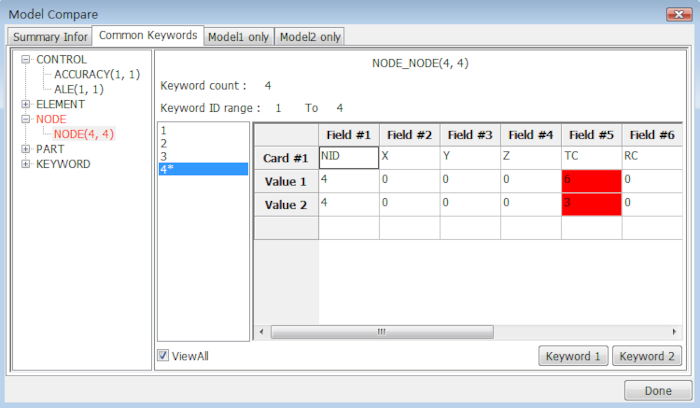

- 2. Common Keywords

List all keywords exist in both model 1 and model 2. If someone is different in these two models, it will be highlighted with red color.

- ViewAll

View all entries for this keyword on two models.

- Keyword 1

Popup original keyword form of model 1.

- Keyword 2

Popup original keyword form of model 2.

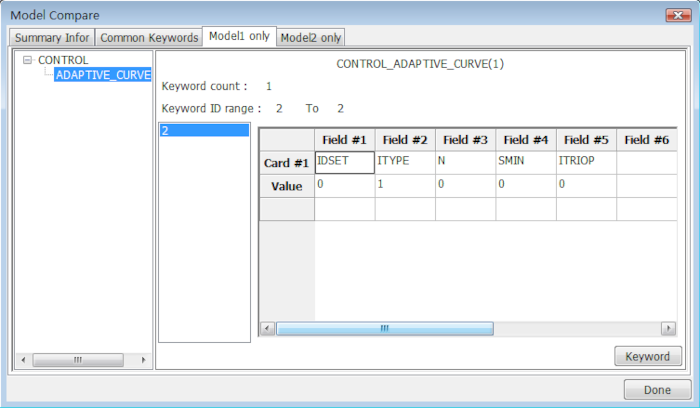

- 3. Model1 Only

List keywords just exist in model 1.

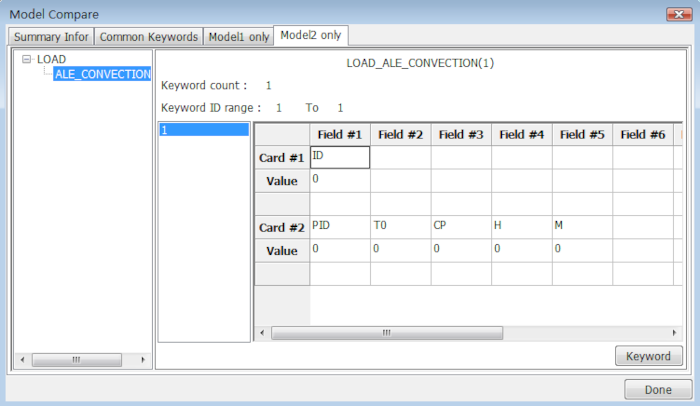

- 4. Model2 Only

List keywords just exist in model 2.

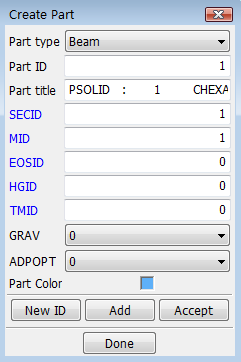

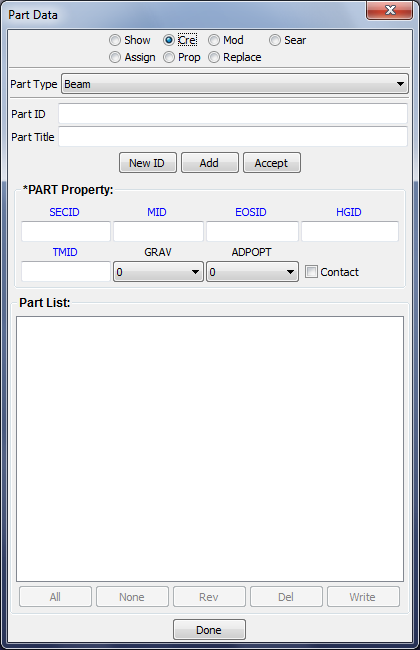

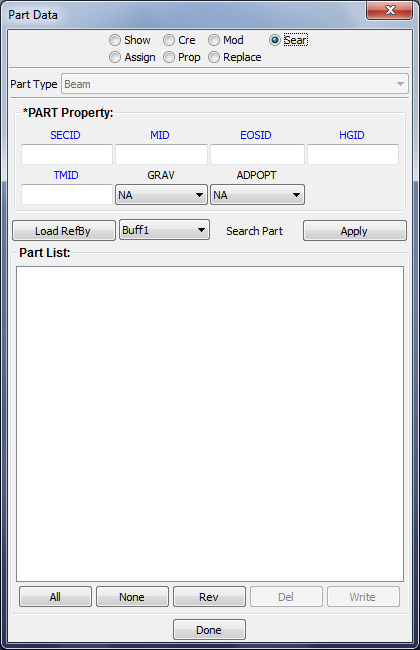

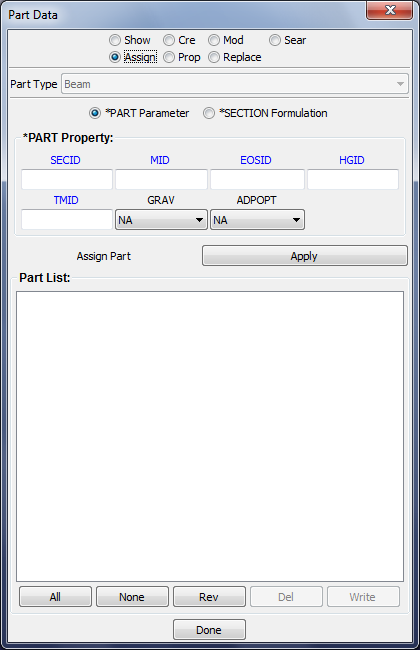

This interface provides functions for create new part, modify part property or assign new data to part.

- Part type

Select part type.

- Part ID

Set part ID.

- Part title

Set part title.

- SECID

Input section ID or select section ID in popuped link dialog.

- MID

Input material ID or select material ID in popuped link dialog.

- EOSID

Input eos ID or select eos ID in popuped link dialog.

- HGID

Input hourglass ID or select hourglass ID in popuped link dialog.

- TMID

Input thermal material ID or select thermal material ID in popuped link dialog.

- GRAV

Select part initialization for gravity loading.

- ADPOPT

Select part adaptivity.

- Part Color

Set part color with Set Color Dialog.

- New ID

Set new part ID.

- Add

Add a new part with default parameters.

- Accept

Accept part data.

- Done

Exit dialog.

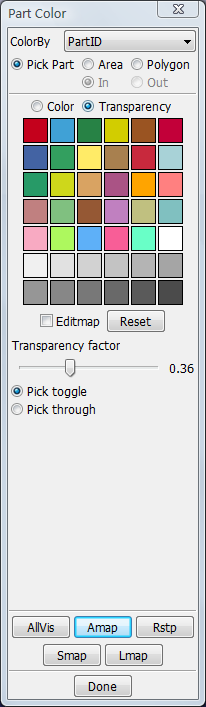

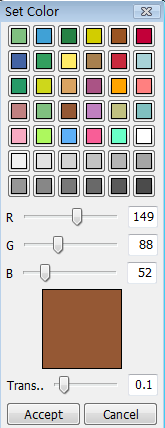

Set color and transparency factor for selected items. Now there are 6*7 colors defined in the color map, also user can set self-defined colors with different R, G, B values.

- R

Red factor value for user-defined color.

- G

Green factor value for user-defined color.

- B

Blue factor value for user-defined color.

- Trans..

User-defined transparency level.

- Accept

Apply selected color and transparency level to selected items.

- Cancel

Cancel color setting operation and exit set color dialog.

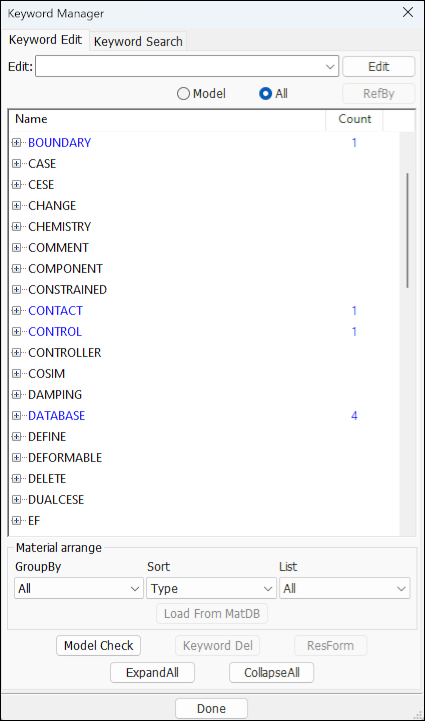

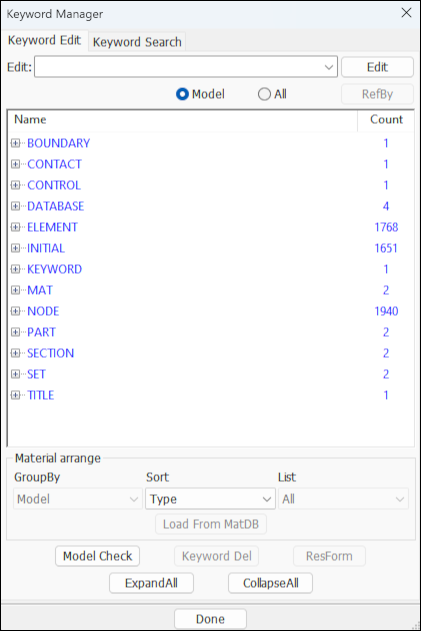

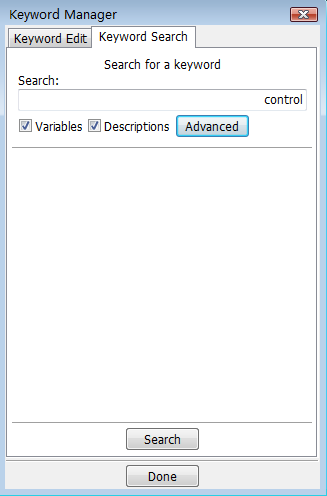

This interface supplied a general tool for keywords management.

- Keyword Edit

Include edit keyword data, keyword delete and keyword transfer.

- Keyword Search

Search keyword in current model.

- Edit

Edit the input keyword.

- Model

Show keywords of current model.

- All

Show all keywords.

- RefBy

Show keywords which refer to selected keyword, in Keyword RefBy Dialog.

- Model Check

Model Check.

- Keyword Del

Delete selected keyword by IDs use Keyword Delete Dialog.

- ResForm

Restore all keywords using the Restore All Keyword Form dialog.

Note: Double click subitem of each kgroup will popup Keyword Form to edit keyword data.

Special control for material keywords arrange

- GroupBy

Group material by element type.

- Sort

Sort material list by name or type no.

- List

List material by first character of name.

- Load From DataBase

Load from MatDB.

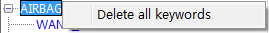

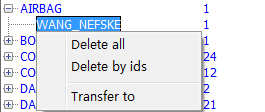

Menu tool for keyword management

- Delete all keywords

Delete all keywords of selected keyword group use Keyword Group Delete Dialog.

- Delete all

Delete all selected keyword use Keyword Group Delete Dialog.

- Delete by ids

Delete selected keyword by ids use Keyword Delete Dialog.

- Transfer to

Transfer selected keyword to other similiar keyword use Keyword Transfer Dialog.

- Search

Input object for search.

- Variables

Search in variable fields.

- Descriptions

Search in Description fields.

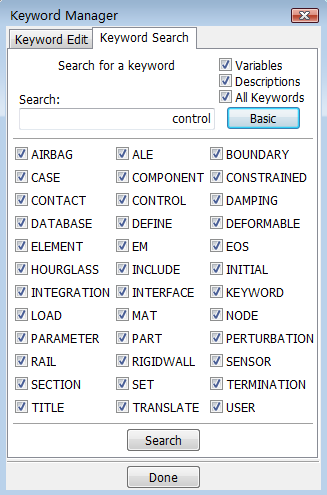

- Advanced

More options for search.

- All Keywords

Select all keywords for search.

- Basic

Basic search.

- Check box for KGroup

Checked to search in this keyword group, otherwise skip this keyword group when running search.

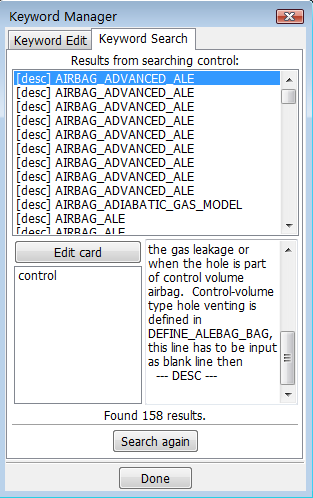

- Edit card

Read keyword data.

- Search again

Search again.

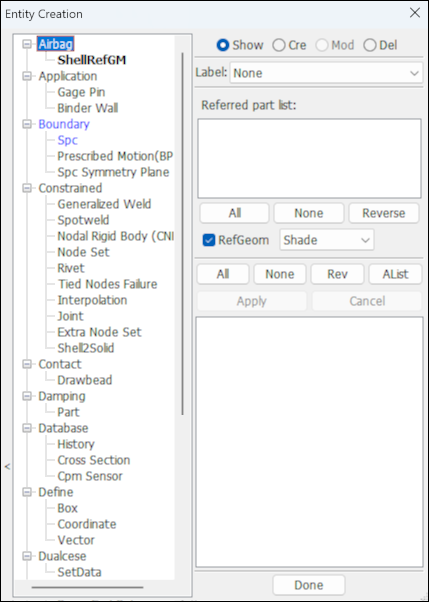

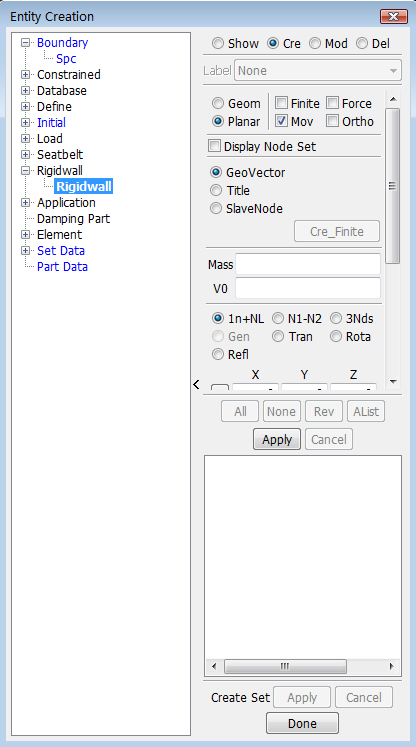

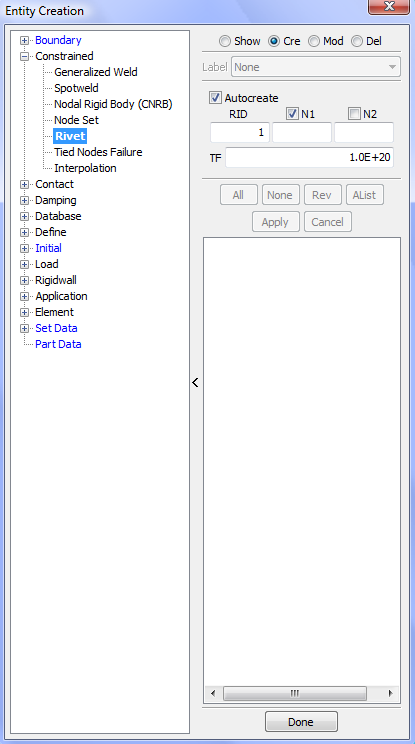

This interface used for entity data management, include display setting, creation, modification and delete.

- Spc

*BOUNDARY_SPC_NODE.

- Generalized Weld

*CONSTRAINED_GENERALIZED_WELD_SPOT.

- Spotweld

*CONSTRAINED_SPOTWELD.

- Nodal Rigid Body (CNRB)

*CONSTRAINED_NODAL_RIGID_BODY,*CONSTRAINED_NODAL_RIGID_BODY_SPC.

- Node Set

*CONSTRAINED_NODE_SET.

- Rivet

*CONSTRAINED_ RIVET.

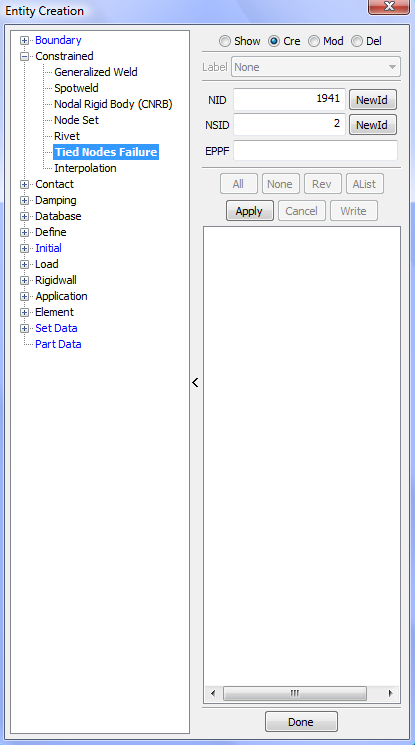

- Tied Nodes Failure

*CONSTRAINED_TIED_NODES_FAILURE.

- Interpolation

*CONSTRAINED_INTERPOLATION and *CONSTRAINED_INTERPOLATION_LOCAL.

- Drawbead

*CONTACT_DRAWBEAD.

- Part

*DAMPING_PART_MASS and *DAMPING_PART_STIFFNESS.

- History

*DATABASE_HISTORY kind data.

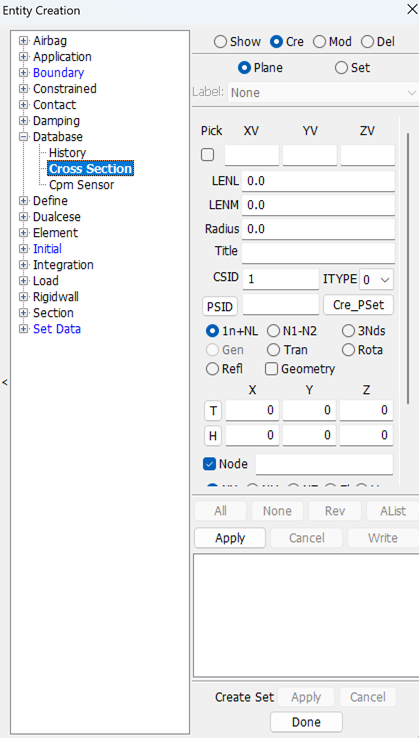

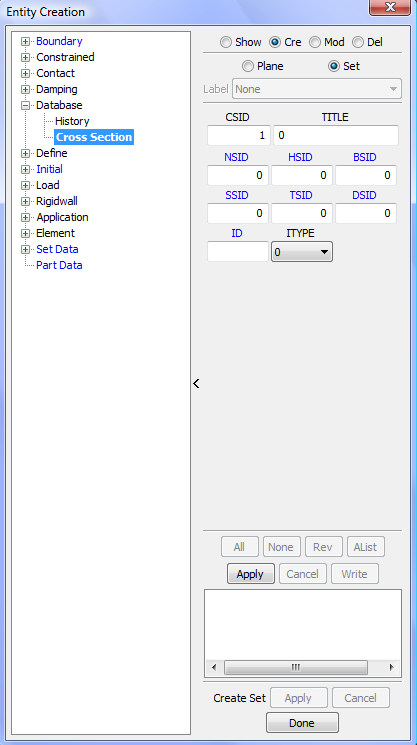

- Cross Section

*DATABASE_CROSS_SECTION_SET and *DATABASE_CROSS_SECTION_PLANE.

- Box

*DEFINE_BOX,*DEFINE_BOX_ADAPTIVE and *DEFINE_BOX_COARSEN.

- Coordinate

*DEFINE_COORDINATE_NODES,*DEFINE_COORDINATE_SYSTEM and *DEFINE_COORDINATE_VECTOR.

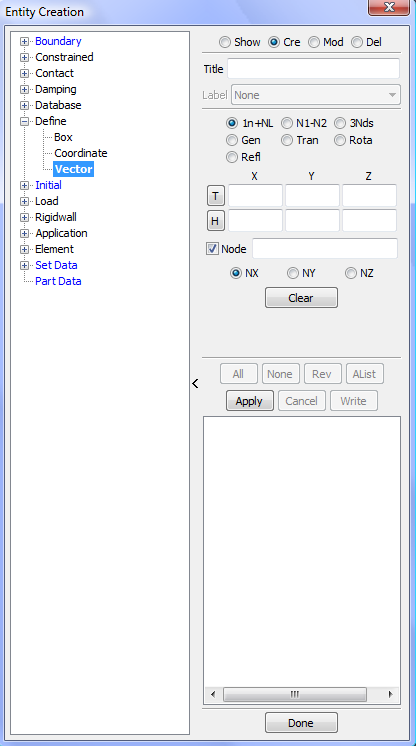

- Vector

*DEFINE_VECTOR.

- Mass

*ELEMENT_MASS.

- Seatbelt Accelerometer

*ELEMENT_SEATBELT_ACCELEROMETER.

- Velocity

*INITIAL_VELOCITY.

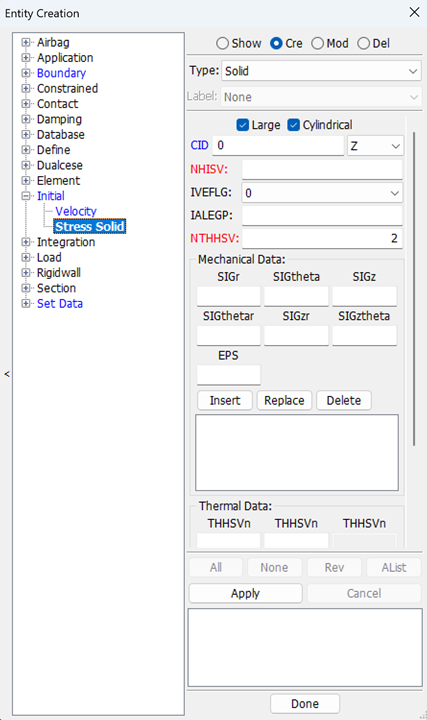

- Stress Solid

*INITIAL_STRESS_SOLID

- Node

*LOAD_NODE_POINT,*LOAD_NODE_SET and *LOAD_RIGID_BODY.

- Segment

*LOAD_SEGMENT and *LOAD_SEGMENT_SET.

- Rigid Body

*LOAD_RIGID_BODY.

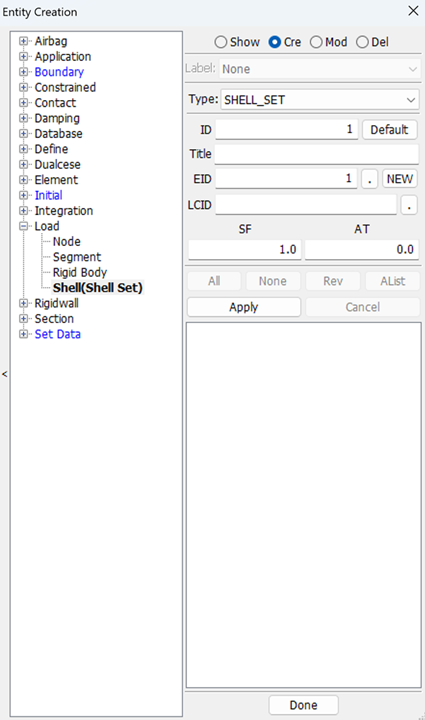

- Shell(Shell Set)

*.

- Rigidwall

*RIGIDWALL.

The following entities can be created using the Create Entity interface.

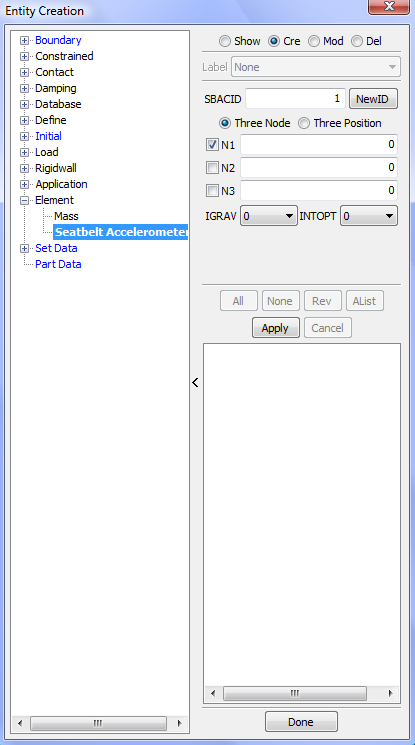

This interface is used to create accelerometers which in LS_DYNA are defined using the *ELEMENT_SEATBELT_ACCELEROMETER keyword card. An accelerometer is a tria element and all 3 nodes must be rigid. Rigid nodes are those belonging to a rigid body, a *CONSTRAINED_NODAL_RIGID_BODY, or extra nodes to a rigid body. Node1 of the accelerometer is defined in *DATABASE_HISTORY_NODE for outputting time histories to NODOUT and other binary time history databases. The accelerations are output in the accelerometer local coordinate system.

There are two methods for define seatbelt accelerometer data.

- Three Nodes

Create accelerometer by three nodes.

- Three Position

Create accelerometer by three position.

- Show

Show existing *ELEMENT_SEATBELT_ACCELEROMETER entities.

- Cre

Create new *ELEMENT_SEATBELT_ACCELEROMETER entities.

- Mod

Modify existing *ELEMENT_SEATBELT_ACCELEROMETER entities.

- Del

Delete existing *ELEMENT_SEATBELT_ACCELEROMETER entities.

- Label

Select label type.

- SBACID

Enter *ELEMENT_SEATBELT_ACCELEROMETER ID (unique number)..

- NewID

Generate new ID.

- IGRAV

Set value for gravitational accelerations parameter.

- INTOPT

Set value for integration option parameter.

- All

Select all *ELEMENT_SEATBELT_ACCELEROMETER entities.

- None

Deselect all *ELEMENT_SEATBELT_ACCELEROMETER entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range.

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

Define Seatbelt Accels data by 3Nodes:

- N1/N2/N3

Pick node or enter node ID.

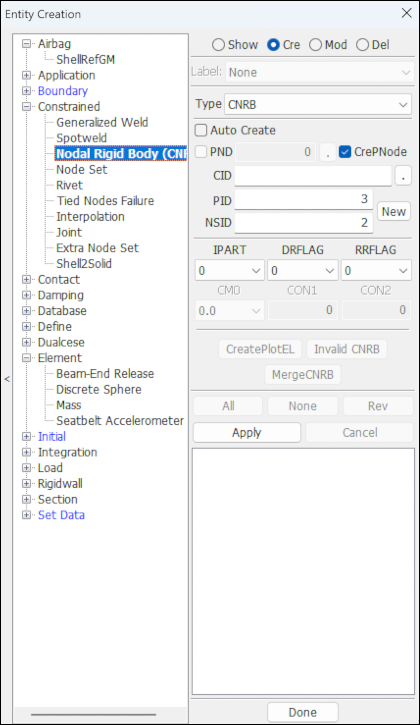

Define Seatbelt Accels data by 3Position:

- X

Enter Origin Position X Value / X Direction / xy Plane X.

- Y

Enter Origin Position Y Value / Y Direction / xy Plane Y.

- Z

Enter Origin Position Z Value / Z Direction / xy Plane Z.

- Vector

Call Direction Dialog.

- Modify

Modify coordinates useing Coordinate Creating dialog.

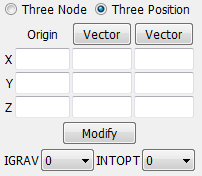

This interface is for metal forming applications. It provides a facility to create binder walls for the tooling parts.

- Pick

Pick part for Binder Wall.

- PartId

Select PartID.

- NewPid

Use default new PartID.

- NewEid

Set default element starting ID.

- El_normal

Select element normal to build Binder Wall .

- Direction

Input direction to build Binder Wall.

- Direction

Call Direction Dialog to get direction.

- dirx

Set direction x for 1/-1.

- diry

Set direction y for 1/-1.

- dirz

Set direction z for 1/-1.

- Reverse Direction

Reverse direction.

- Angle

Click to reverse angle.

- Length

Input length value.

- Segment

Set total segment for generation element.

- Clear Sel

Clear current selection when building wall.

- Build

Build Binder Wall.

- Reject

Reject Binder Wall.

- Accept

Accept Binder Wall.

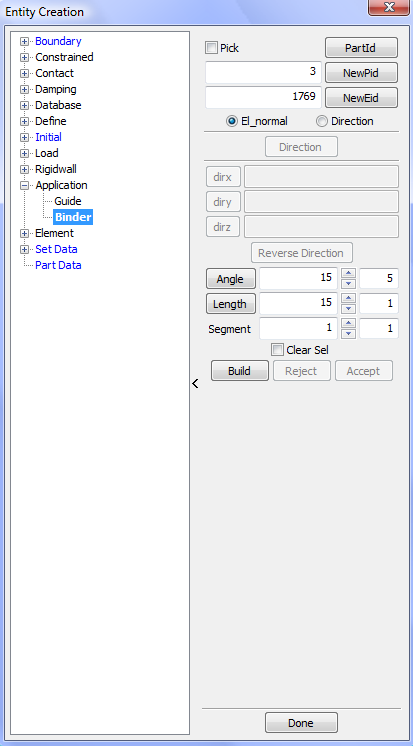

This interface is used for showing, creating, modifying, and deleting the following LS_DYNA keyword cards:

*CONSTRAINED_NODAL_RIGID_BODY

*CONSTRAINED_NODAL_RIGID_BODY_INERTIA

*CONSTRAINED_NODAL_RIGID_BODY_SPC

*CONSTRAINED_NODAL_RIGID_BODY_SPC_INERTIA

- Show

Show existing *CONSTRAINED_NODAL_RIGID_BODY entities.

- Cre

Create new *CONSTRAINED_NODAL_RIGID_BODY entities.

- Mod

Modify existing *CONSTRAINED_NODAL_RIGID_BODY entities.

- Del

Delete existing *CONSTRAINED_NODAL_RIGID_BODY entities.

- CDel

Check and delete invalid *CONSTRAINED_NODAL_RIGID_BODY.

- Label

Select label type.

- Type

Set current entity type (CNRB, CNRB_INERTIA, CNRB_SPC_INERTIA).

- Auto Create

Create CNRB when the right mouse is clicked after finish picking.

- PND

Check to pick node from model to be PNODE.

- CrePNode

Check to create PNODE at the mass center of selected nodes.

- PID

Enter Part ID of the nodal rigid body.

- CID

Enter Coordinate ID/Open link dialog by clicking on the label.

- NSID

Enter Node Set ID .

- New ID

Set PID and NSID to next highest available ID.

- PNODE

Enter PNODE/Open link dialog by clicking on the label.

- IPART

Set print flag.

- DRFLAG

Set displacement release flag.

- RRFLAG

Set rotation release flag.

- CMO

Set center of mass constraint option.

- CON1

Set first constraint parameter.

- CON2

Set second constraint parameter.

- CreatePlotEL

Create plot element with selected CNRB.

- InvalidCNRB

Select all invalid CNRB.

- MergeCNRB

Merge two or more CNRB into one CNRB.

- Apply

Apply create, delete, and modify.

- Cancel

Cancel current modification or selection.

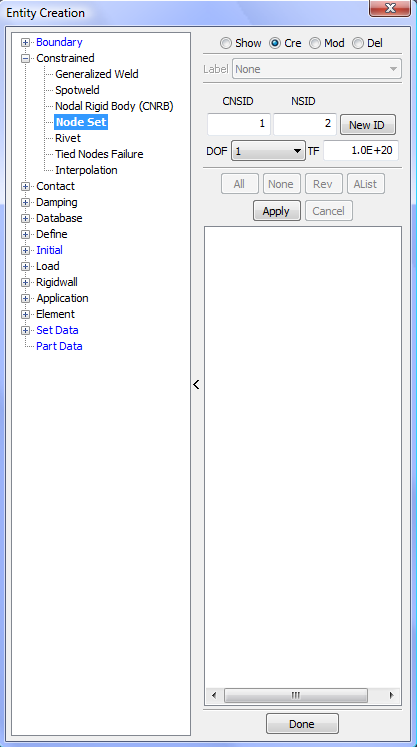

This interface is used for showing, creating, modifying, and deleting *CONSTRAINED_NODE_SET cards in LS_DYNA.

- Show

Show existing *CONSTRAINED_NODE_SET entities.

- Cre

Create new *CONSTRAINED_NODE_SET entities.

- Mod

Modify existing *CONSTRAINED_NODE_SET entities.

- Del

Delete existing *CONSTRAINED_NODE_SET entities.

- Label

Select label type.

- CNSID

Enter constrained node set ID.

- NSID

Enter Node Set ID.

- New ID

Set default new ID.

- DOF

Select degree of freedom.

- TF

Enter failure time for nodal constraint set.

- All

Select all CONSTRAINED_ NODE_SET entities.

- None

Deselect all CONSTRAINED_ NODE_SET entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities).

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

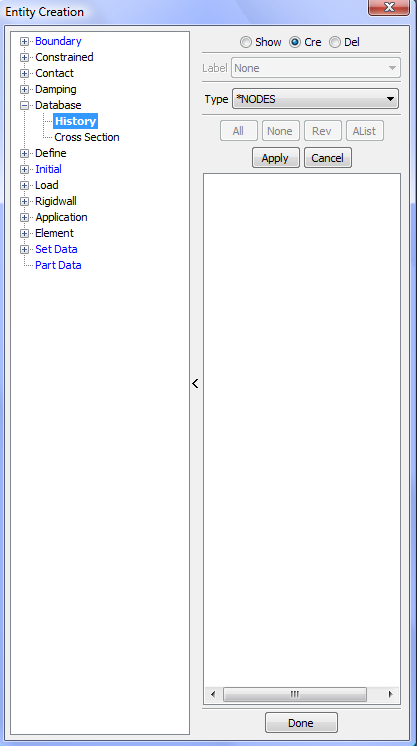

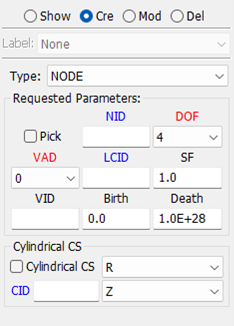

Time history output requests in LS_DYNA for nodes and elements are done using the following keyword cards:

*NODES:*DATABASE_HISTORY_NODE

*BEAM:*DATABASE_HISTORY_BEAM

*SHELL:*DATABASE_HISTORY_SHELL

*SOLID:*DATABASE_HISTORY_SOLID

*TSHELL:*DATABASE_HISTORY_TSHELL

*SPH:*DATABASE_HISTORY_SPH

- Show

Show existing *DATABASE_HISTORY entities.

- Cre

Create new *DATABASE_HISTORY entities.

- Del

Delete existing *DATABASE_HISTORY entities.

- Label

Select label type.

- Type

Select database history data type, include NODE, BEAM, SHELL, SOLID, SPH, TSHELL.

- All

Select all *DATABASE_HISTORY entities.

- None

Deselect all *DATABASE_HISTORY entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities).

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- Write

Write selected data to file.

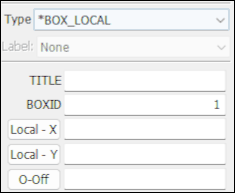

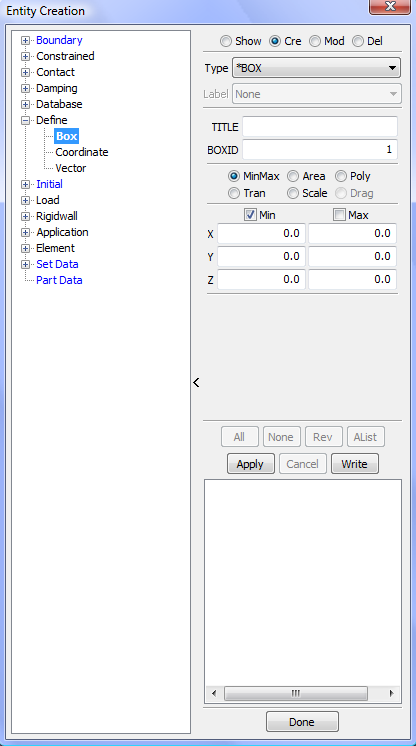

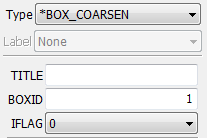

This interface is used for showing, creating, modifying, and deleting the following LS_DYNA keyword cards:

*DEFINE_BOX

*DEFINE_BOX_ADAPTIVE

*DEFINE_BOX_COARSEN

*DEFINE_BOX_LOCAL

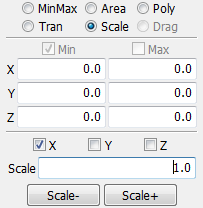

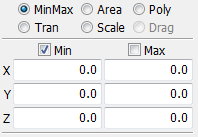

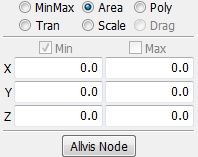

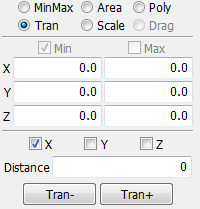

The creation and modification can be carried out by various method such as selecting nodes by area, by polygon, and all visible. There are also facilities for translation and scaling.

Types of define_box data:

*Box:Define *DEFINE_BOX data. *BOX_ADAPTIVE:Define *DEFINE_BOX_ADAPTIVE data. *BOX_COARSEN:Define *DEFINE_BOX_COARSEN data. *BOX_LOCAL:Define *DEFINE_BOX_LOCAL data. Methods of define define_box data:

MinMax:Select two nodes as minimum and maximum for box. Area:Select nodes inside a user defined area for the box. Poly:Select nodes inside a user defined region for the box. Tran:Translate box. Scale:Scale box. Drag:Drag box(This option is currently unavailable).

- Show

Show existing *DEFINE_BOX entities.

- Cre

Create new *DEFINE_BOX entities.

- Mod

Modify existing *DEFINE_BOX entities.

- Del

Delete existing *DEFINE_BOX entities.

- Type

Select entity type.

- Label

Set current entity label type.

- All

Select all *DEFINE_BOX entities.

- None

Deselect all *DEFINE_BOX entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities).

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- Write

Write box to file.

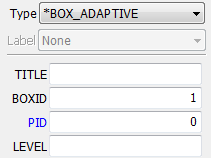

- PID

Enter PartID - If zero, all active elements are considered (only available for type: *BOX_ADAPTIVE).

- LEVEL

Maximum number of refinement levels for elements in box (only available for type: *BOX_ADAPTIVE).

- IFLAG

Enter 0/1 (only available for type: *BOX_COARSEN).

- Min

Pick node as minimum extreme of box.

- Max

Pick node as maximum extreme of box.

- X

X coordinate of min/max.

- Y

Y coordinate of min/max.

- Z

Z coordinate of min/max.

- Allvis Node

Select all visable nodes as maximum and minimum of box.

- X

Translate box in x direction.

- Y

Translate box in y direction.

- Z

Translate box in z direction.

- Distance

Enter distance to translate box.

- Tran-

Translate in negative direction.

- Tran+

Translate in positive direction.

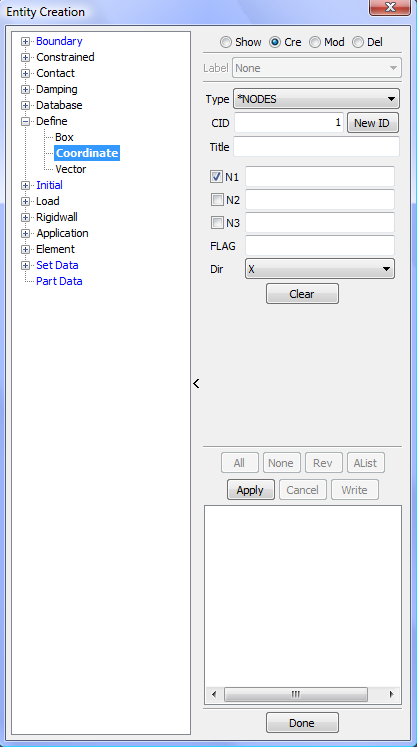

This interface is used for showing, creating, modifying, and deleting the following LS_DYNA keyword cards:

*DEFINE_COORDINATE_NODES

*DEFINE_COORDINATE_SYSTEM

*DEFINE_COORDINATE_VECTOR

- *NODES

Entity data of *DEFINE_COORDINATE_NODES.

- *SYSTEM

Entity data of *DEFINE_COORDINATE_SYSTEM.

- *VECTOR

Entity data of *DEFINE_COORDINATE_VECTOR.

- Show

Show existing *DEFINE_COORDINATE entities.

- Cre

Create new *DEFINE_COORDINATE entities.

- Mod

Modify existing *DEFINE_COORDINATE entities.

- Del

Delete existing *DEFINE_COORDINATE entities.

- Label

Set current entity label type.

- Type

Select coordinate type.

- Clear

Clear current data.

- All

Select all *DEFINE_COORDINATE entities.

- None

Deselect all *DEFINE_COORDINATE entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities).

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- Write

Write selected coord data to file.

- CID

Coordinate ID. A unique number has to be defined.

- Title

Enter box title.

- N1

Enter node ID for node at local origin.

- N2

Enter node ID for node on loacal x-axis.

- N3

Enter node ID for node on local x-y plane.

- FLAG

Set to unity, 1, if the local system is to be updated each time step for the BOUNDARY_SPC nodal constraints and ELEMENT_BEAM type 6, the discrete beam element. Generally, this option when used with nodal SPC's is not recommended since it can cause excursions in the energy balance because the constraint forces at the node may go through a displacement if the node is partially constrained.

- Dir

Axis defined by node N2 moving from the origin node N1. The default direction is the x-axis.

Use imbedded Vector Operation Interface to create system and vector data

Note: For Show, Modify, and Delete, the Entity Operation Interface will show. For Create:*SYSTEM and Create:*VECTOR, the Vector Operation Interface is embedded in the middle controls area.

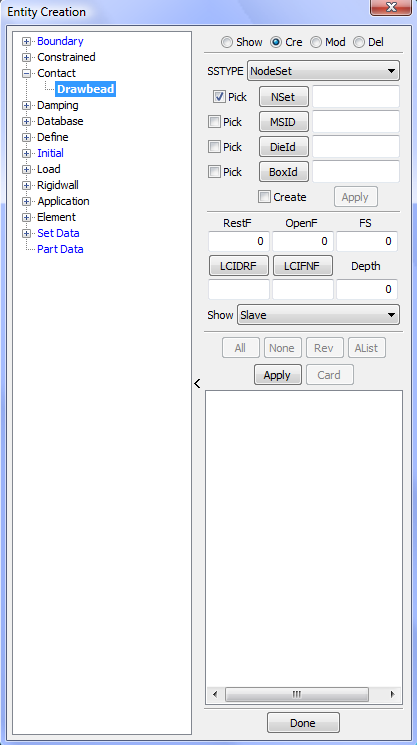

This interface is for metal forming. It allows display, creation, modification, and deletion of draw beads. Drawbeads are generally created on dies to control the draw of the work piece. The inputs for creating drawbeads are generally curves from a die design group. Alternately the input can be a node set or a beam part. These node sets and beam parts are generally created using other facilities in LS-PrePost. Given the geometry of the drawbead, die part, and the blank information, this interface creates a contact definition for the drawbead in the form of a *CONTACT_DRAWBEAD keyword card.

- Show

Show existing *CONTACT_DRAWBEAD entities.

- Cre

Create new *CONTACT_DRAWBEAD entities.

- Mod

Modify existing *CONTACT_DRAWBEAD entities.

- Del

Delete existing *CONTACT_DRAWBEAD entities.

- SSTYPE

Set current slave set ID type.

- NSet/Curve/PBeam

Select Slave Set .

- MSID

Select Master Set.

- DieId

Select Die.

- BoxId

Select Box.

- Create

Create box by picking nodes.

- Apply

Create new box and put ID to next field.

- RestF

Enter restraining force.

- OpenF

Enter opening force.

- FS

Enter friction force.

- LCIDRF

Enter LCIDRF value.

- LCIFNF

Enter LCIDNF value.

- Depth

Enter drawbead depth value.

- All

Select all *CONTACT_DRAWBEAD entities.

- None

Deselect all *CONTACT_DRAWBEAD entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities)..

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

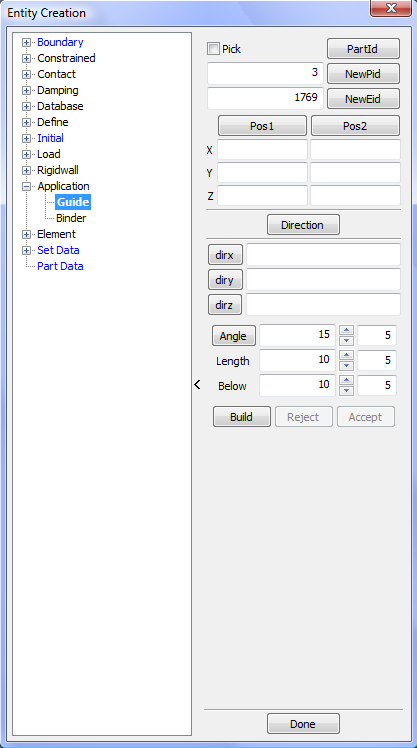

This interface is primarily intended for creation of guides used in metal forming analysis. Typically the mesh for a guide is built using this interface and a contact definition between the blank edge and the guide is prepared using other facilities in LS-PrePost.

- Pick

Pick part for Guide.

- PartId

Select PartID.

- NewPid

Use default new PartID.

- NewEid

Set default element starting ID.

- Pos1

Call Position Dialog to get the first position.

- Pos2

Call Position Dialog to get the second position.

- X

Input position x value.

- Y

Input position y value.

- Z

Input position z value.

- Direction

Call Direction Dialog to get direction.

- dirx

Set direction x for 1/-1.

- diry

Set direction y for 1/-1.

- dirz

Set direction z for 1/-1.

- Angle

Reverse angle.

- Length

Input length.

- Below

Set below persent in the length.

- Build

Build guide.

- Reject

Reject guide building.

- Accept

Accept guide building.

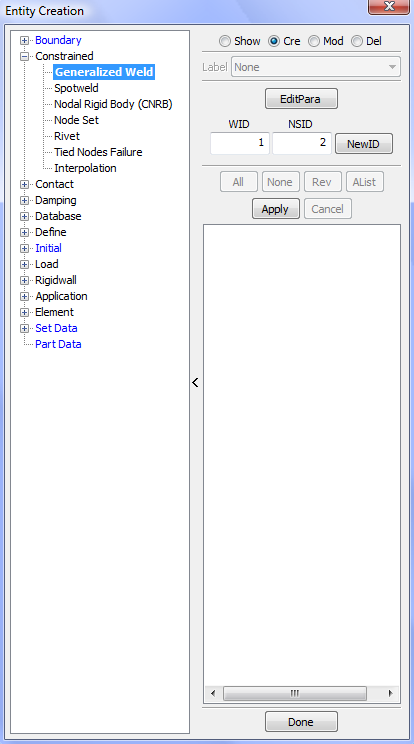

*CONSTRAINED_GENERALIZED_WELD has many variants in LS_DYNA, but this interface is specifically for showing, creating, modifying, and deleting *CONSTRAINED_GENERALIZED_WELD_SPOT cards. Failure parameters can be set as desired and used for the welds being created. Also these parameters can be modified as necessary for each weld.

- Show

Show existing *CONSTRAINED_GENERALIZED_WELD_SPOT entities.

- Cre

Create new *CONSTRAINED_GENERALIZED_WELD_SPOT entities.

- Mod

Modify existing *CONSTRAINED_GENERALIZED_WELD_SPOT entities.

- Del

Delete existing *CONSTRAINED_GENERALIZED_WELD_SPOT entities.

- Label

Select label type.

- EditPara

Click to view and edit weld parameters.

- WID

Enter genweld optional ID.

- NSID

Enter Node Set ID.

- NewId

Set NSID to next highest, avaialble ID.

- All

Select all Constrained GWeld entities.

- None

Deselect all Constrained GWeld entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities).

- Apply

Apply entries for creation/modification or selections for deletion.

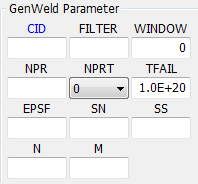

Click button "EditPara" to view and edit parameter of *CONSTRAINED_GENERALIZED_WELD_SPOT:

- CID

Enter coordinate system ID.

- FILTER

Enter number of force vectors saved for filtering.

- WINDOW

Enter time window for filtering.

- NPR

Enter number of individual nodal pairs.

- NPRT

Print option for RBDOUT (see LS_DYNA keyword manual for details).

- TFAIL

Enter failure time for constraint set.

- EPSF

Enter effective plastic strain at failure.

- SN

Enter normal force at failure, only for brittle failures.

- SS

Enter shear force at failure, only for brittle failures.

- N

Enter exponent for normal force, only for brittle failures.

- M

Enter exponent for shear force, only for brittle failures.

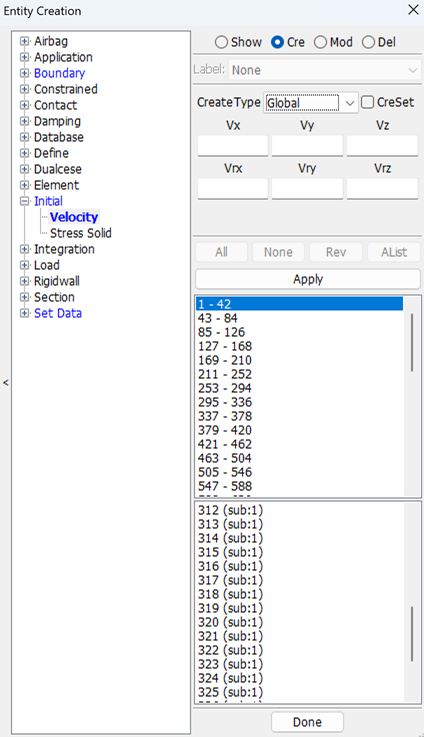

One of the most common initial conditions for crash simulations is some type initial velocity. There are some basic methods of defining initial velocity states in LS_DYNA using *INITIAL_VELOCITY and *INITIAL_VELOCITY_GENERATION, and these methods are effective for simple situations like assigning velocities to all nodes.

In contrast creating initial velocity definitions for directions other than Global XYZ can be more complex and requires additional facilities. This interface allows the flexibility to define velocities in global or local systems, along a vector, in polar coordinates, and even using a combination of angular plus translational. This interface is often used to generate initial velocity conditions for door slam, head impact, and full vehicle crash analysis.

- Show

Show existing *INITIAL_VELOCITY entities.

- Cre

Create new *INITIAL_VELOCITY entities.

- CreSet

Create node set for initial velocity

- Mod

Modify existing *INITIAL_VELOCITY entities.

- Del

Delete existing *INITIAL_VELOCITY entities.

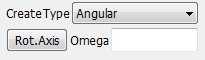

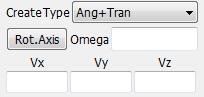

- Create Type

Set current inivel create type.

- All

Select all *INITIAL_VELOCITY entities.

- None

Deselect all *INITIAL_VELOCITY entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities).

- Apply

Apply entries for creation/modification or selections for deletion.

Create Type as Global:

- Vx

Enter initial velocity in x direction.

- Vy

Enter initial velocity in y direction.

- Vz

Enter initial velocity in z direction.

- Vrx

Enter initial rotational velocity in x direction.

- Vry

Enter initial rotational velocity in y direction.

- Vrz

Enter initial rotational velocity in z direction.

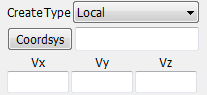

Create Type as Local:

- Coordsys

Popup lind dialog to get coordsys ID.

- Vx

Enter initial velocity in x direction.

- Vy

Enter initial velocity in y direction.

- Vz

Enter initial velocity in z direction.

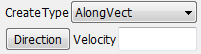

Create Type as AlongVect:

- Direction

Get Direction.

- Velocity

Enter velocity.

Create Type as Angular:

- Rot.Axis

Get position and direction.

- Omega

Enter omega.

Create Type as Ang+Tran:

- Rot.Axis

Get position and direction.

- Omega

Enter omega .

- Vx

Enter initial velocity in x direction.

- Vy

Enter initial velocity in y direction.

- Vz

Enter initial velocity in z direction.

Create Type as Cylindrical:

- CID

Open *Define_Coordinate_kind link dialog

- Direction X/Y/Z

Which axis of CID is parallel with the z axis of coordiate system that will be created internally.

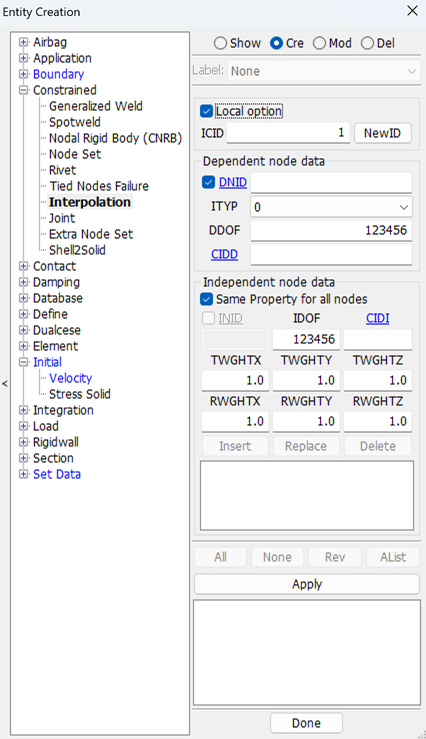

This interface is used for showing, creating, modifying, and deleting *CONSTRAINED_INTERPOLATION and *CONSTRAINED_INTERPOLATION_LOCAL cards in LS_DYNA.

INTERPOLATION:*CONSTRAINED_INTERPOLATION data edit.

INTERPOLATION_LOCAL:*CONSTRAINED_INTERPOLATION_LOCAL data edit.

- Show

Show existing *CONSTRAINED_INTERPOLATION entities.

- Cre

Create new *CONSTRAINED_INTERPOLATION entities.

- Mod

Modify existing *CONSTRAINED_INTERPOLATION entities.

- Del

Delete existing *CONSTRAINED_INTERPOLATION entities.

- Label

Select label type.

- Local option

Check to create with _LOCAL option.

- ICID

Input interpolation constraint ID.

- NewID

Set default new interpolation id.

- DNID

Input or pick dependent node ID.

- DDOF

Input dependent degrees-of-freedom.

- ITYP

Set type of INID,0 for node id,1 for node set id.

- CIDD

Input local coordinate system ID.

- Same Property for all nodes

Check to create as all independent nodes have the same property.

- INID

Pick or input independent node ID.

- IDOF

Independent degrees-of-freedom using the same form as DDOF above.

- CIDI

Local coordinate system ID.

- TWGHTX

This weight scales the x-translational component.

- TWGHTY

This weight scales the y-translational component.

- TWGHTZ

This weight scales the z-translational component.

- RWGHTX

This weight scales the x-rotational component.

- RWGHTY

This weight scales the y-rotational component.

- RWGHTZ

This weight scales the z-rotational component.

- Insert

Insert current data group.

- Replace

Replace current data group.

- Delete

Delete current data group.

- All

Select all *CONSTRAINED_INTERPOLATION entities.

- None

Deselect all *CONSTRAINED_INTERPOLATION entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities).

- Apply

Apply entries for creation/modification or selections for deletion.

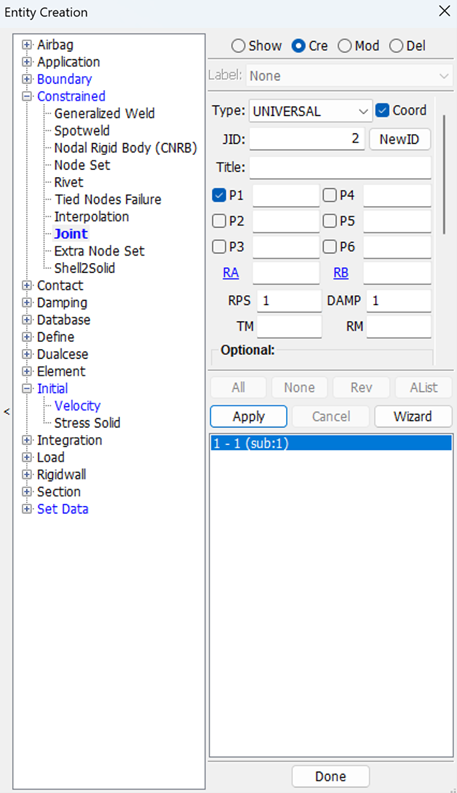

This interface is used for showing, creating, modifying, and deleting *CONSTRAINED_JOINT_option cards in LS-DYNA.

- Type

Type of joint to be created.

- Coord

The connection coordinates are given instead of the nodal point IDs required.

- JID

Joint ID.

- NewID

Get default new joint ID.

- Title

Joint title.

- Ni

Pick node I.

- RA

Select rigid body A.

- RB

Select rigid body B.

- RPS

Relative penalty stiffness.

- DAMP

Damping scale factor on default damping value.

- TM

Lumped translational mass.

- RM

Lumped rotational inertia.

- PARM

Parameter which a function of joint type. Leave blank for MOTORS. Gears: define R2/R1. Rack and Pinion: define h. Pulley: define R2/R1. Screw: define x/w.

- LCID

Define load curve ID for MOTOR joints.

- TYPE

Define integer flag for MOTOR joints.

- R1

Radius, R1, for the gear and pulley joint type. If left undefined, nodal points 5 and 6 are assumed to be on the outer radius.

- Local

The force output data is to be transformed into a local coordinate.

- Failure

Define failure for penalty-based joints.

- RAID

Rigid body or accelerometer ID.

- LST

Flag for local system type: EQ.0: rigid body. EQ.1: accelerometer.

- CID

Coordinate ID for resultants in the failure criteria. If zero, the global coordinate system is used.

- TFAIL

Time for joint failure. If zero, joint never fails.

- COUPL

Coupling between the force and moment failure criteria.

- NXX

Axial force resultant Nxx F at failure.

- NYY

Force resultant Nyy F at failure.

- NZZ

Force resultant Nzz F at failure.

- MXX

Torsional moment resultant Mxx F at failure.

- MYY

Moment resultant Myy F at failure.

- MZZ

Moment resultant Mzz F at failure.

- Show

Show existing joint.

- Cre

Create new joint.

- Mod

Modify joint value.

- Del

Delete joint.

- Label

Set current entity label type.

- All

Select all joint entity.

- None

Select none joint.

- Rev

Reverse selection joint.

- Alist

Select all entities within the selected range.

- Done

Close dialog.

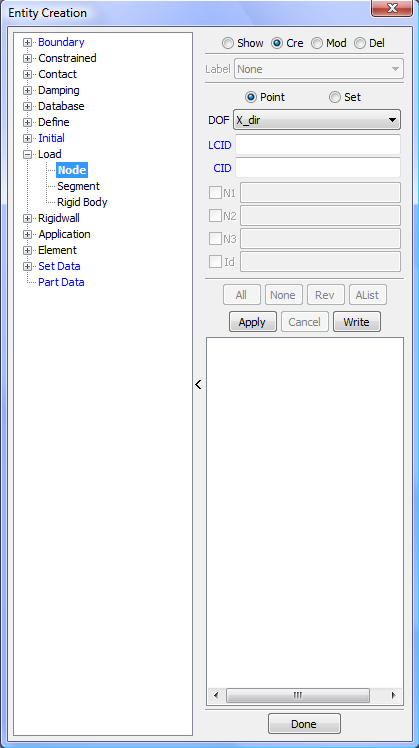

This interface enables you to interactively show, create, modify, and delete load points and sets. It is an alternative to creating loads using Page 3 keyword cards, in that load points can be directly picked from the graphics viewport.

Node:*LOAD_NODE_POINT data edit

Set:*LOAD_NODE_SET data edit

- Show

Show existing load node entities.

- Cre

Create new load node entities.

- Mod

Modify existing load node entities .

- Del

Delete existing load node entities.

- Label

Select label type.

- Node

Set current entity type as LOAD_NODE_POINT.

- Set

Set current entity type as LOAD_NODE_SET.

- DOF

Set current DOF type .

- LCID

Load Curve ID.

- CID

Coordinate System ID.

- N1

Node ID 1.

- N2

Node ID 2.

- N3

Node ID 3.

- Id

Node, Part, Node Set ID (Modify Only).

- All

Select all load node entities.

- None

Deselect all load node entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities).

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- Write

Write selected load data to file.

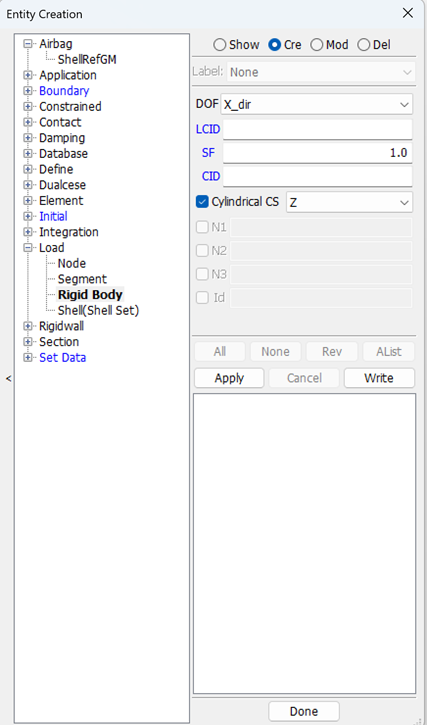

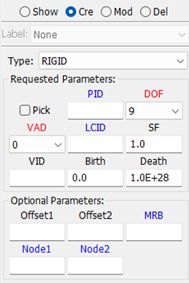

This interface enables you to interactively show, create, modify, and delete a load rigid body. It is an alternative to creating loads using Page 3 keyword cards in that load points can be directly picked from the graphics viewport.

*LOAD_RIGID_BODY data edit.

- Show

Show existing load node entities.

- Cre

Create new load node entities.

- Mod

Modify existing load node entities.

- Del

Delete existing load node entities.

- Label

Select label type.

- Rigid

Set current entity type as LOAD_RIGID_BODY.

- DOF

Set current DOF type .

- LCID

Load Curve ID.

- CID

Coordinate System ID.

- Cylindrical CS

Create point load based on cylindrical coordinate system.

- N1

Node ID 1.

- N2

Node ID 2.

- N3

Node ID 3.

- Id

Node, Part, Node Set ID (Modify Only).

- All

Select all load node entities.

- None

Deselect all load node entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities)..

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- Write

Write selected load data to file.

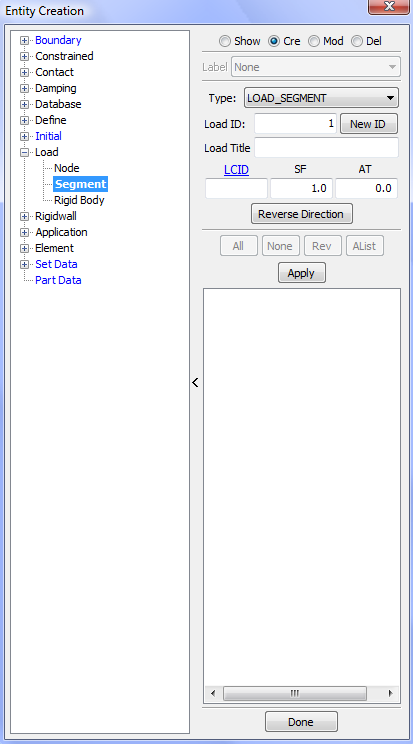

This interface is used for showing, creating, modifying, and deleting *LOAD_SEGMENT and *LOAD_SEGMENT_SET cards in LS_DYNA.

Load_segment : *LOAD_SEGMENT data edit.

Load_segment_set : *LOAD_SEGMENT_SET data edit.

- Show

Show existing load segment entities.

- Cre

Create new load segment entities.

- Mod

Modify existing load segment entities.

- Del

Delete existing load segment entities.

- Label

Select label type.

- Type

Select load segment data type.

- Load ID

Input load data ID.

- New ID

Set defualt new ID for load data.

- Load Title

Input load data title.

- LCID

Load Curve ID.

- SF

Load curve scale factor.

- AT

Arrival time for pressure or birth time of pressure.

- SSID

Segment set ID.

- Reverse Direction

Reverse direction of load_segment.

- All

Select all load segment entities.

- None

Deselect all load segment entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range.

- Apply

Apply entries for creation/modification or selections for deletion.

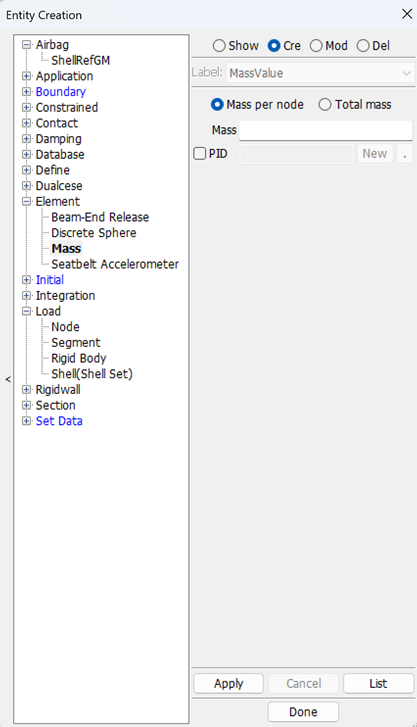

This interface allows for the display, creation, modification, and deletion of *ELEMENT_MASS entities in LS_DYNA.

Edit *ELEMENT_MASS data

- Show

Show existing mass data.

- Cre

Create new mass data.

- Mod

Modify existing mass data .

- Del

Delete existing mass data.

- Label

Select label type.

- Mass

Enter mass value.

- Mass per node

Input mass value is assigned to each selected node.

- Total mass

Input total mass value is divided by total number of selected nodes and assigned to each one.

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel the operation.

- List

List mass elements.

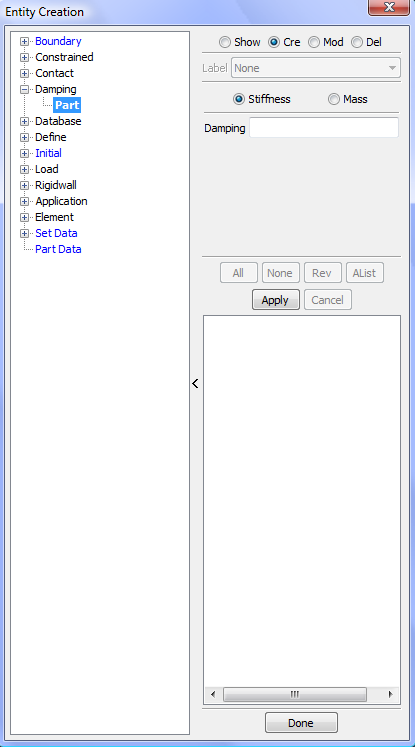

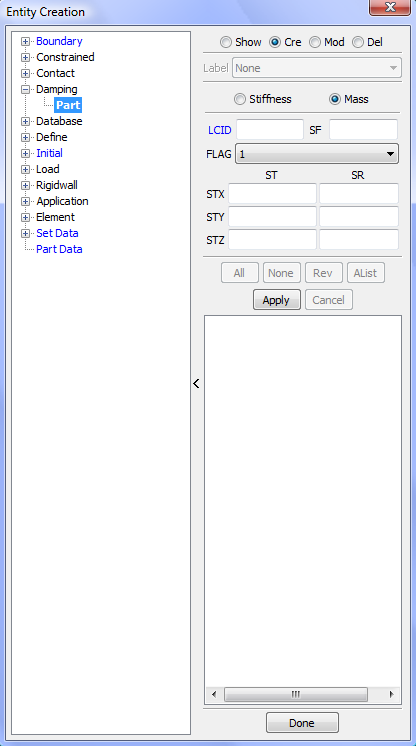

This interface is for showing, creating, modifying, and deleting the following damping definitions:

| *DAMPING_PART_MASS |

| *DAMPING_PART_STIFFNESS |

This is an alternative method to using Page 3 keyword card forms in that there is direct interaction with the model via the graphics viewport.

- Stiffness

Damping part stiffness.

- Mass

Damping part mass.

- Show

Show existing damping part nodes.

- Cre

Create new damping part nodes.

- Mod

Modify damping part value.

- Del

Delete damping part.

- Label

Select label type.

- Stiffness

Damping part stiffness.

- Mass

Damping part mass.

- Damping

Input damping value.

- All

Select all damping part entities.

- None

Deselect all damping part entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range.

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- LCID

Load curve ID which specifies system damping for parts.

- SF

Scale factor for load curve.

- FLAG

Set to unity if global components of damping forces require separate scale factors.

- ST

Scale factor on translational damping forces.

- SR

Scale factor on rotational damping moments.

- STX/Y/Z

Set X/Y/Z direction.

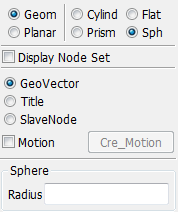

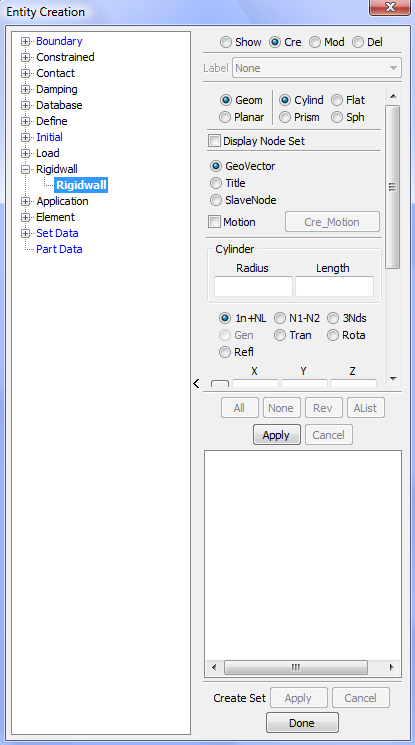

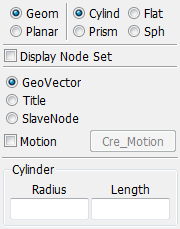

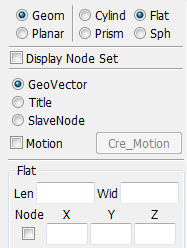

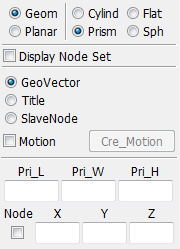

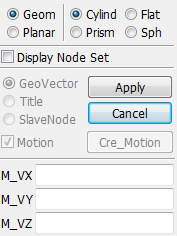

This interface is used for showing, creating, modifying, and deleting *RIGIDWALL cards in LS_DYNA. The main advantage of this interface is the ability to graphically view the various rigidwall definitions with the flexibility of positioning them using translate, rotate, and reflect functions.

- Geom:Set geometry option.

- Cylind:

Create geometyr cylinder.

- Flat:

Create geometyr Flat.

- Prism:

Create geometyr Prism.

- Sph:

Create geometyr Sph.

- Motion:

Create slave and motion.

- Planar:

Set planar option.

- Show

Show existing *RIGIDWALL entities.

- Cre

Create new *RIGIDWALL entities.

- Mod

Modify existing *RIGIDWALL entities.

- Del

Delete existing *RIGIDWALL entities.

- Label

Select label type.

- Geom

Set geometry option (bottom panel options shown below).

- Planar

Set planar option (bottom panel options shown below).

- Display Node Set

Display Node Set.

- GeomVector

Creat geometry.

- Title

Input para.

- SlaveNode

Create slave node.

- Motion

Set motion.

- Cre_Motion

Create motion.

- All

Select all *RIGIDWALL entities.

- None

Deselect all *RIGIDWALL entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range.

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- Len

Flat length.

- Wid

Flat width.

- Node

The node for pick coordinate(flat).

- X/Y/Z

X/Y/Z-coordinate of head of edge vector l (flat).

- Pri_L

Enter prism length.

- Pri_W

Enter prism width.

- Pri_H

Enter prism height.

- Node

The node for pick coordinate(prism).

- X/Y/Z

X/Y/Z-coordinate of head of edge vector l (Prism).

Check "Motion" and click button "Cre_Motion" to define motion data.

- Apply

Apply slave and motion.

- Cancel

Cancel create slave and motion.

- M_VX

x-direction cosine of velocity/displacement vector.

- M_VY

y-direction cosine of velocity/displacement vector.

- M_VZ

z-direction cosine of velocity/displacement vector.

This interface is used for showing, creating, modifying, and deleting *CONSTRAINED_RIVET cards in LS_DYNA.

- Show

Show existing *CONSTRAINED_ RIVET entities.

- Cre

Create new *CONSTRAINED_ RIVET entities.

- Mod

Modify existing *CONSTRAINED_ RIVET entities .

- Del

Delete existing *CONSTRAINED_ RIVET entities.

- Label

Select label type.

- Autocreate

Auto create rivet.

- RID

Enter Rivet ID (Optional).

- N1

Pick/Enter node ID 1.

- N2

Pick/Enter node ID 2.

- TF

Enter failure time for nodal constraint set.

- All

Select all *CONSTRAINED_ RIVET entities.

- None

Deselect all *CONSTRAINED_ RIVET entities.

- Rev

Reverse selection.

- AList

all entities within the selected range (Only applies when there are 20+ entities).

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

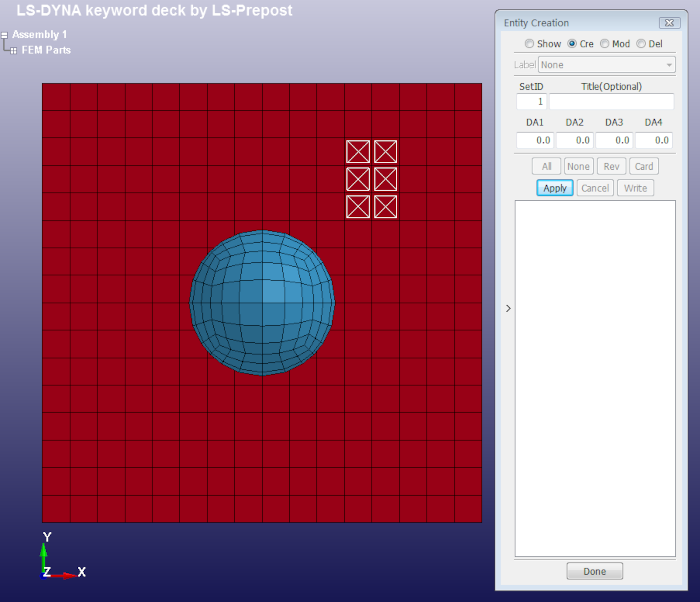

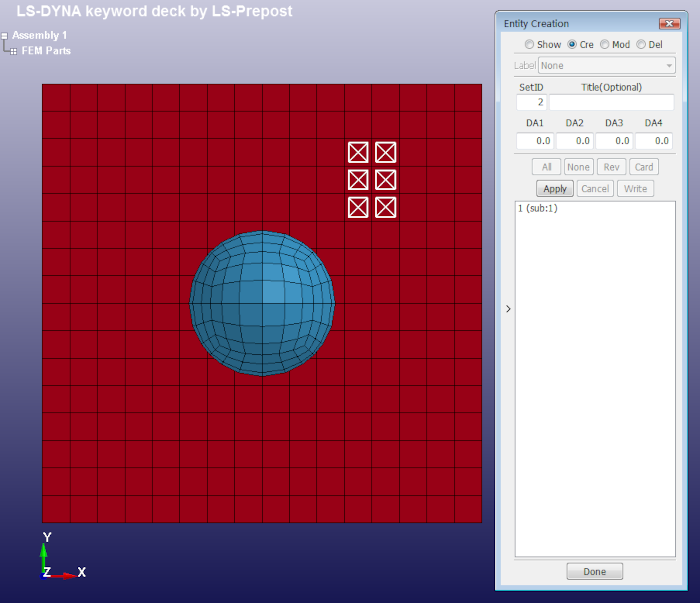

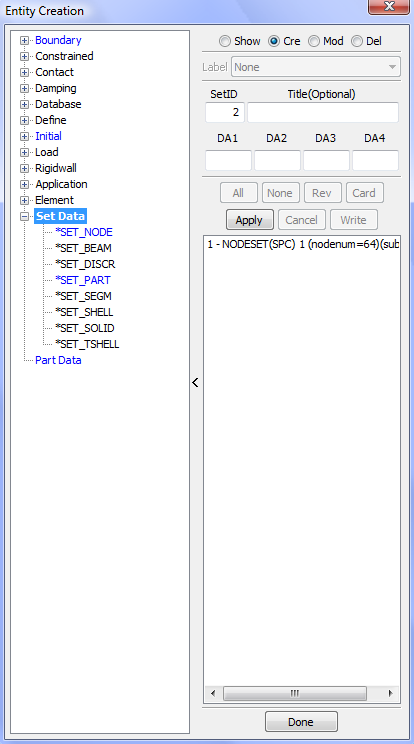

LS_DYNA uses the concept of referring to various entities through sets. There are over 60 different set types, and some of these have additional sub-types. This interface is specifically for showing, creating, modifying, and deleting some of the most common set types:

| *SET_NODE |

| *SET_BEAM |

| *SET_DISCRETE |

| *SET_PART |

| *SET_SEGMENT |

| *SET_SHELL |

| *SET_SOLID |

| *SET_TSHELL |

| *SET_SPH |

- Sample:

Show how to create SET_SEGMENT data, define other types of *SET data are all similiar to *SET_SEGMENT..

- Show

Show existing Set data.

- Cre

Create new Set data.

- Mod

Modify existing Set data.

- Del

Delete existing Set data.

- Label

Select label type.

- SetID

Enter Set ID. All node sets should have a unique set ID.

- Title

Enter title for new/current set (optional).

- DA1

Fist nodal attribute (default value is 0.0).

- DA2

Second nodal attribute (default value is 0.0).

- DA3

Third nodal attribute (default value is 0.0).

- DA4

Fourth nodal attribute (default value is 0.0).

- All

Select all sets.

- None

Deselect all sets.

- Rev

Reverse selection.

- Card

Open keyword input dialog for this set.

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- Write

Write selected sets to a file.

Show how to create SET_SEGMENT data.

Step 1:

Run lspp, load any .k model file that has segment elements and open data creation dialog, goto Constrained Interpolation.

Step 2:

Select Cre method.

Pick segments from the graphic view.

Step 3:

Click Apply to accept data create.

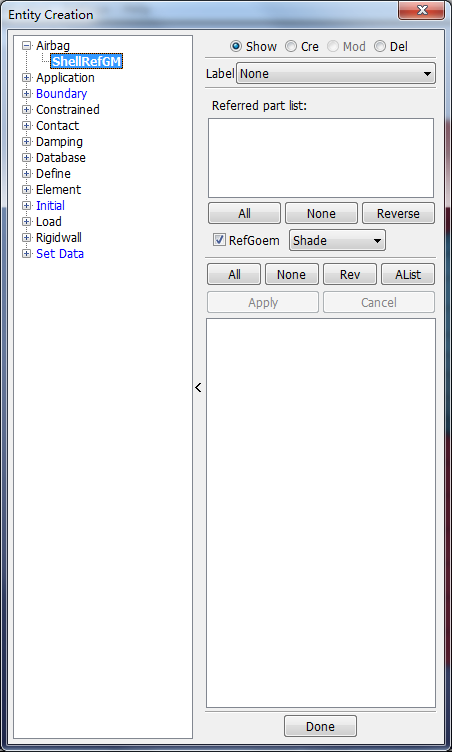

This interface is used for showing, creating, modifying, and deleting the following LS_DYNA keyword cards.

- Show

Show existing airbag shell reference geometry.

- Cre

Create new shell reference geometry.

- Mod

Modify existing shell reference geometry.

- Del

Delete shell reference geometry.

- Label

Set current entity label type.

- Referred part list

Referred parts of shell reference geometry.

- RefGoem

Display airbag reference geometry.

- Shade

Select airbag reference geometry drawing mode.

- All

Select all shell reference geometry entity.

- None

Select none shell reference geometry.

- Rev

Reverse selection shell reference goemetry.

- Alist

Select all entities within the selected range.

- Done

Close dialog.

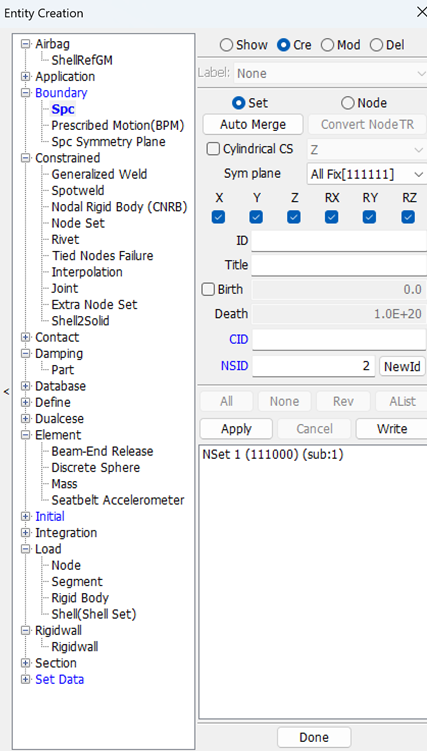

This interface is used for showing, creating, modifying, and deleting *BOUNDARY_SPC_NODE cards in LS_DYNA.

- Show

Show existing SPC nodes.

- Cre

Create new SPC nodes.

- Mod

Modify SPC value .

- Del

Delete SPC.

- Label

Select label type.

- Set

Set current for SPC set.

- Node

Set current for SPC nodes.

- AutoMerge

Merge spc conditions defined separately at same node.

- Convert NodeTR

Convert TC and RC of nodes to boundary spc and set TC and RC to 0.

- Cylindrical CS

Create SPC command based on the cylindrical coordinate system.

- Sym plane

Select symmetry plane.

- ID

ID of boundary spc keyword.

- Title

Title of boundary spc keyword.

- Birth

Check to set birth and death time for SPC.

- Death

Deactivation time for constraint.

- X

Toggle translational constraint in local X direction.

- Y

Toggle translational constraint in local Y direction.

- Z

Toggle translational constraint in local Z direction.

- RX

Toggle rotational constraint about the local X axis.

- RY

Toggle rotational constraint about the local Y axis.

- RZ

Toggle rotational constraint about the local Z axis.

- CID

Enter *DEFINE_COORDINATE_kind ID.

- NSID

Enter *DEFINE_COORDINATE_kind NSID.

- Match

Set filter to exact match.

- NewId

Set default new NSID.

- All

Select all SPC nodes.

- None

Deselect all SPC nodes.

- Rev

Reverse selection.

- AList

Select all entities within the selected range.

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- Write

Write selected data to file.

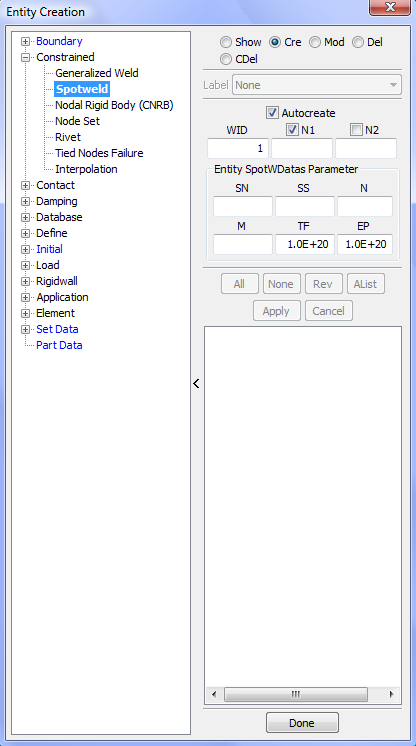

This interface is used for showing, creating, modifying, and deleting *CONSTRAINED_SPOTWELD cards in LS_DYNA.

- Show

Show existing *CONSTRAINED_SPOTWELD entities.

- Cre

Create new *CONSTRAINED_SPOTWELD entities.

- Mod

Modify existing *CONSTRAINED_SPOTWELD entities.

- Del

Delete existing *CONSTRAINED_SPOTWELD entities.

- CDel

Check and delete invalid *CONSTRAINED_SPOTWELD.

- Label

Select label type.

- AutoCreate

Auto creaete spot weld.

- WID

Enter spot weld optional ID .

- N1

Enter Node ID 1.

- N2

Enter Node ID 2.

- SN

Normal force at spotweld failure (optional).

- SS

Shear force at spotweld failure (optional).

- N

Exponent for normal spotweld force (optional).

- M

Exponent for shear spotweld force (optional).

- TF

Failure time for nodal constraint set.

- EP

Effective plastic strain at failure.

- All

Select all Constrained Spotweld.

- None

Deselect all Constrained Spotweld.

- Rev

Reverse selection Constrained Spotweld.

- AList

All selected list Constrained Spotweld.

- Apply

Apply create, delete, and modify.

- Cancel

Cancel modify.

This interface is used to generate *CONSTRAINED_TIED_NODES_FAILURE definitions. These definitions are typically used for shell parts. Given a shell part or other group of shells, each shell is disjointed at all its nodes, and constraint cards are generated with user defined EPPF values.

- Show

Show existing *CONSTRAINED_TIED_NODES_FAILURE entities.

- Cre

Create new *CONSTRAINED_TIED_NODES_FAILURE entities.

- Mod

Modify existing *CONSTRAINED_TIED_NODES_FAILURE entities .

- Del

Delete existing *CONSTRAINED_TIED_NODES_FAILURE entities.

- Label

Select label type.

- NID

Enter starting node ID.

- NewId

Use default starting node ID.

- NSID

Enter starting set_node ID.

- NewId

Use default starting set_node ID.

- EPPF

Enter plastic strain at failure.

- All

Select all *CONSTRAINED_TIED_NODES_FAILURE entities.

- None

Deselect all *CONSTRAINED_TIED_NODES_FAILURE entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities).

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- Write

Write selected data to file.

This interface provides a way of generating *DEFINE_VECTOR keyword cards. The definition of a vector requires xyz coordinates for both the tail and head. Various method are made available for creating a vector with options to translate, rotate, and reflect. Vectors can be shown, created, modified, and deleted through graphical interaction.

There are various methods to define vector, as the following:

- Show

Show existing *VECTOR entities.

- Cre

Create new *VECTOR entities.

- Mod

Modify existing *VECTOR entities.

- Sear

Search for parts using user defined parameters.

- Del

Delete existing *VECTOR entities.

- Title

Set vector title (available for Create and Modify).

- All

Select all *VECTOR.

- None

Deselect all *VECTOR.

- Rev

Reverse selection *VECTOR.

- AList

Select all entities within the selected range.

- Apply

Apply entries for creation/modification.

- Cancel

Cancel this modification or selection.

- Write

Write selected vector data to file.

Note: For Show, Modify, and Delete, the Entity Operation Interface will show. For Create, the Vector Operation Interface is embedded in the middle controls area.

This interface is use to create the following cross section definitions:

*DATABASE_CROSS_SECTION_SET

*DATABASE_CROSS_SECTION_PLANE

This is an alternate method to using Page 3 keyword cards. The definition of a plane is specified through direct interaction with the model in the graphics viewport.

- Plane

Cross section data type for plane.

- Set

Cross section data type for set.

- Show

Show existing *DATABASE_CROSS_SECTION entities.

- Cre

Create new *DATABASE_CROSS_SECTION entities.

- Mod

Modify existing *DATABASE_CROSS_SECTION entities .

- Del

Delete existing *DATABASE_CROSS_SECTION entities.

- Plane

Set current section type for plane.

- Set

Set current section type for set.

- Label

Set current entity label type.

- All

Select all *DATABASE_CROSS_SECTION entities.

- None

Deselect all *DATABASE_CROSS_SECTION entities.

- Rev

Reverse selection.

- AList

Select all entities within the selected range (Only applies when there are 20+ entities)..

- Apply

Apply entries for creation/modification or selections for deletion.

- Cancel

Cancel this modification or selection.

- Write

Write selected section data to file.

Cross Plane section data:

- Pick

Pick node to set edge vector.

- XV

X-direction of head of edge vector.

- YV

Y-direction of head of edge vector.

- ZV

Z-direction of head of edge vector.

- LENL

Length of L edge .

- LENM

Length of M edge.

- Radius

Radius for circle plane.

- Title

Enter title.

- CSID

Rigid body or accelerometer ID.

- ITYPE

Flag for local system type.

- PSID

Part set ID link button.

- Cre_PSet

Create part set by genselect.

Embedded in middle portion of this panel is the Vector Operation Interface. Follow the link for a detailed description.

- CSID

Optional ID for cross section. If not specified cross section ID is taken to be the cross section order in the input deck.

- TITLE

Crowss section descriptor. It is suggested that unique descriptions be used.

- NSID

Nodal set ID, see *SET_NODE_option.

- HSID

Solid element set ID, see *SET_SOLID.

- BSID

Beam element set ID, see *SET_BEAM.

- SSID

Shell element set ID, see *SET_SHELL_option.

- TSID

Thick shell element set ID, see *SET_TSHELL.

- DSID

Discrete element set ID, see *SET_DISCRETE.

- ID

Rigid body or accelerometer ID.

- ITYPE

Flag for local system type.

- Type

Select entity type, SOLID or SOLID_SET.

- Large

Format size, if unchecked, NHISV must also set to zero, and, if checked, a larger format is used and NHISV is used.

- Cylindrical

Check to define stress components in cylindrical coordinate system.

- CID

Reference cartesian coordinate system for the cylindrical coordinate system, 0 for global coordinate system.

- NHISV

Number of additional history variables, which is typically equal to the number of history variables stored at the integration point + IVEFLG.

- IVEFLG

Initial Volume/energy flag.

- IALEGP

The ALE multi-material group (AMMG) ID.

- NTHHSV

Number of thermal history variables per thermal integration point.

- SIGij

Define the ijth stress component.

- EPS

Effective plastic strain.

- THHSVn

nth thermal time history variable.

This interface is used for showing, creating, modifying, and deleting *LOAD_SHELL and *LOAD_SHELL_SET cards in LS_DYNA.

| SHELL_ELEMENT: *LOAD_ SHELL data edit. |

| SHELL_SET: *LOAD_ SHELL _SET data edit. |

- ID

Loading ID.

- Default

Set loading id as default.

- Title

A description of the loading.

- EID

Shell element (set) ID.

- NEW

Create new shell element set.

- LCID

Load curve ID.

- SF

Load curve scale factor.

- AT

Arrival time for pressure or birth time of pressure.

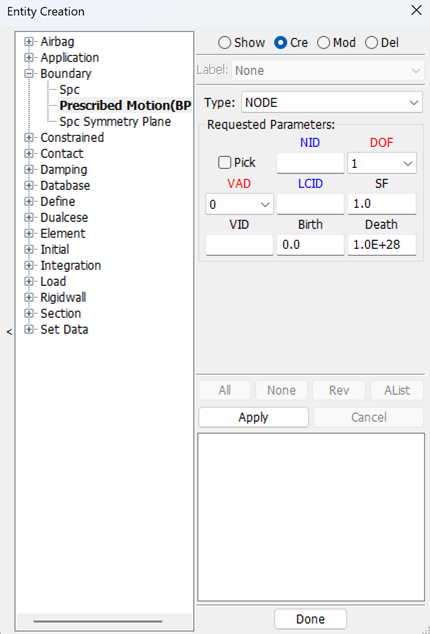

This interface is used for showing, creating, modifying, and deleting keywords of:

| *BOUNDARY_PRESCRIBED_MOTION_NODE |

| *BOUNDARY_PRESCRIBED_MOTION_SET |

| *BOUNDARY_PRESCRIBED_MOTION_RIGID |

| *BOUNDARY_PRESCRIBED_MOTION_RIGID_LOCAL |

- Type

Select type of BPM.

- Pick

Check to pick nodes.

- NID

Node ID.

- DOF

Applicable degrees-of-freedom, see *BOUNDARY_PRESCRIBED_MOTION_option.

- VAD

Velocity/Acceleration/Displacement flag, see *BOUNDARY_PRESCRIBED_MOTION_option.

- LCID

Load curve ID to describe motion value versus time.

- SF

Load curve scale factor (default=1.0).

- VID

Vector ID for DOF values of 4 or 8.

- Birth

Time imposed motion/constraint is activated (default=0.0).

- Death

Time imposed motion/constraint is removed (default=1.0E+28).

- Offset1

Offset for DOF types 9-11 (y, z, x direction).

- Offset2

Offset for DOF types 9-11 (z, x, y direction).

- MRB

Master rigid body for measuring the relative displacement.

- Node1

Optional orientation node, n1, for relative displacement.

- Node2

Optional orientation node, n2, for relative displacement.

- Cylindrical CS

Create BPM command based on the cylindrical coordinate system.

- R/T

The vector direction to be created.

- CID

Id of *DEFINE_COORDINATE.

- X/Y/Z

Which axis of CID is parallel with the z axis of coordiate system that will be created internally.

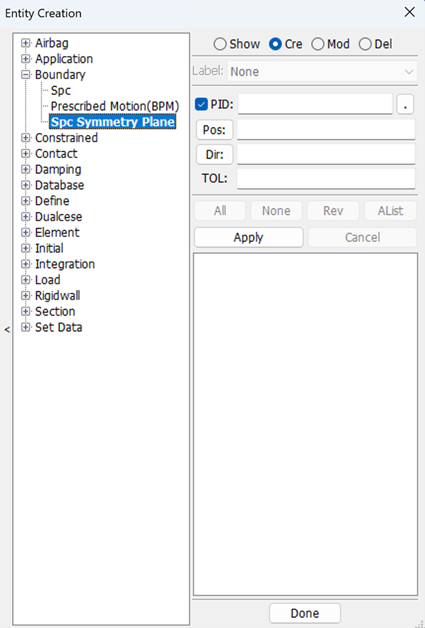

This interface is used for showing, creating, modifying, and deleting keywords of *BOUNDARY_ SPC_SYMMETRY_PLANE.

- PID

Input deformable part on which the constraints will be imposed.

- Pos

Input position of the plane.

- Dir

Input normal vector of the plane.

- TOL

Input the distance tolerance value within which the nodes on the deformable part will be constrained.

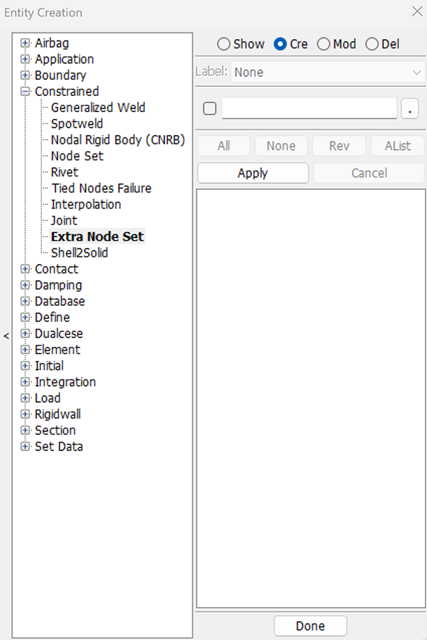

This interface is used for showing, creating, modifying, and deleting keywords of *CONSTRAINED_EXTRA_NODES_SET.

- PID

Part ID of rigid body to which the nodes are added.

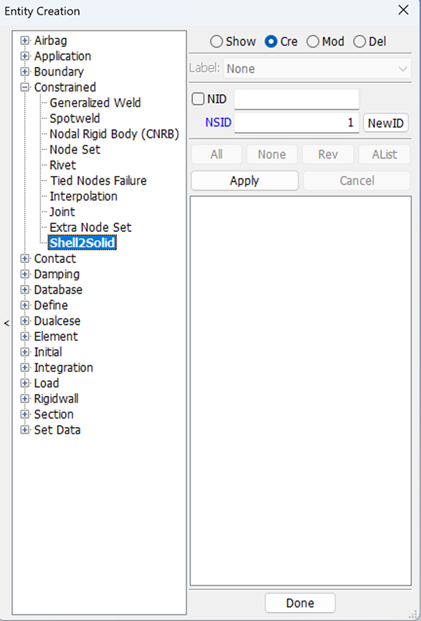

This interface is used for showing, creating, modifying, and deleting keywords of *CONSTRAINED_SHELL_TO_SOLID.

- NID

Node id on shell element.

- NSID

ID of node set.

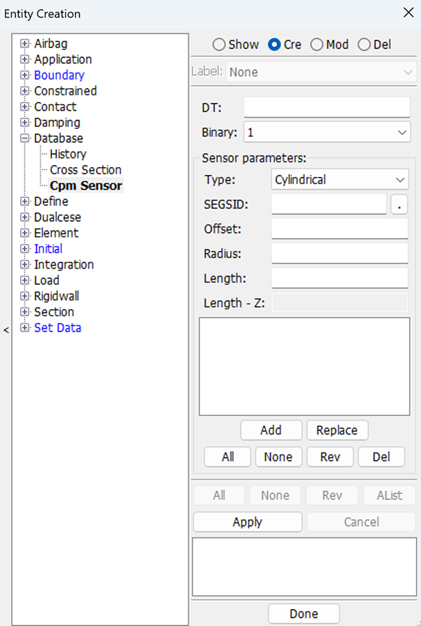

This interface is used for showing, creating, modifying, and deleting keywords of *DATABASE_CPM_SENSOR.

- DT

Input output interval.

- Binary

Flag for the binary file.

- Type

Select type of sensor.

- SEGSID

Input id of *SET_SEGMENT.

- Offset

Input offset distance between sensor and segment.

- Radius

Input radius of cylindrical sensor.

- Length

Input length of cylindrical sensor.

- Length – Z

Input length on z-direction of the rectangle sensor.

- Add

Add sensor data.

- Replace

Replace sensor data.

- All

Select all of the list.

- None

Deselect all of the list.

- Rev

Reverse selection of the list.

- Del

Delete selected items of the list.

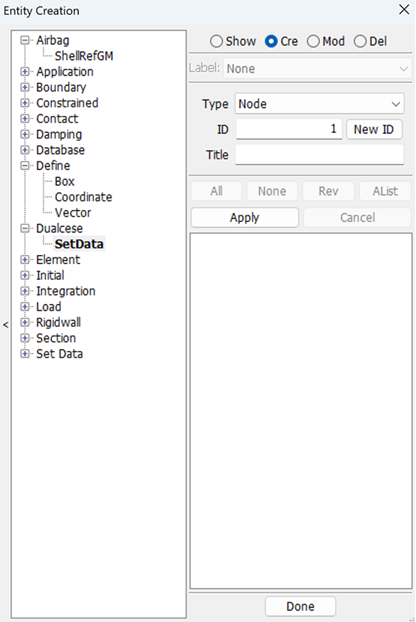

This interface is used for showing, creating, modifying, and deleting keywords of *DUALCESE_NODESET, *DUALCESE_ELEMENTSET, *DUALCESE_SEGMENTSET.

- Type

Set type of DualCESE set data.

- ID

Set ID of DualCESE set data.

- New ID

Get default ID of DualCESE set data.

- Title

Set title of DualCESE set data.

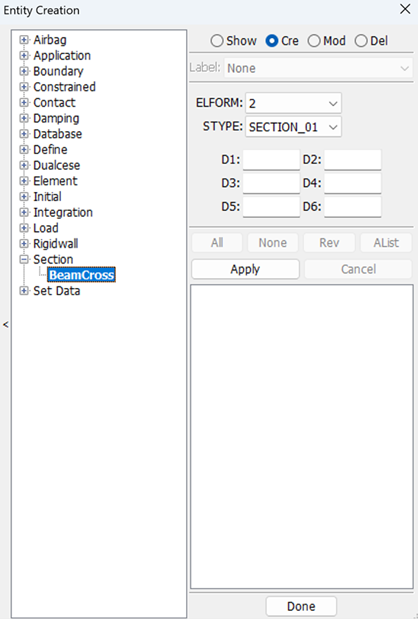

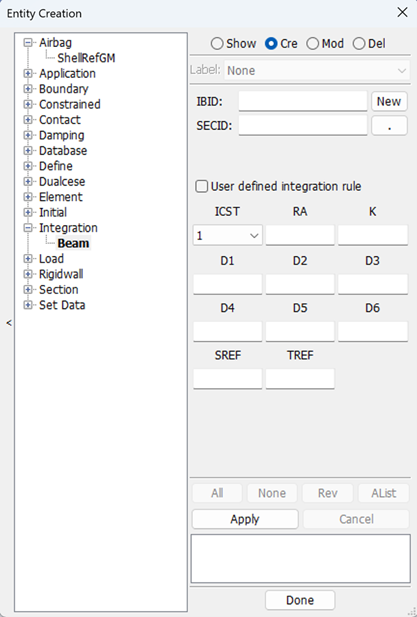

This interface is used for showing, creating, modifying, and deleting keywords of *INTEGRATION_BEAM.

- IBID

Set id of *INTEGRATION_BEAM.

- New

Generate new id for *INTEGRATION_BEAM.

- SECID

Target *SECTION_BEAM which the *INTEGREATION_BEAM will be referred by.

- ICST

Standard cross section type.

- RA

Relative area of cross section.

- K

Integration refinement parameter for standard cross section types.

- D1 – D6

Cross-section dimensions.

- SREF

Location of reference surface normal to s, for the Hughes-Liu beam only.

- TREF

location of reference surface normal to t, for the Hughes-Liu beam only.

- S

Normalized s-coordinate of integration point, -1 <= s <= 1.

- T

Normalized t-coordinate of integration point, -1 <= t <= 1.

- WF

Weighting factor.

- PID

Optional PID, used to identify material properties for this integration point.

- Insert

Insert user defined integration rule to data array.

- Replace

Replace user defined integration rule of data array.

- Delete

Delete user defined integration rule of data array.

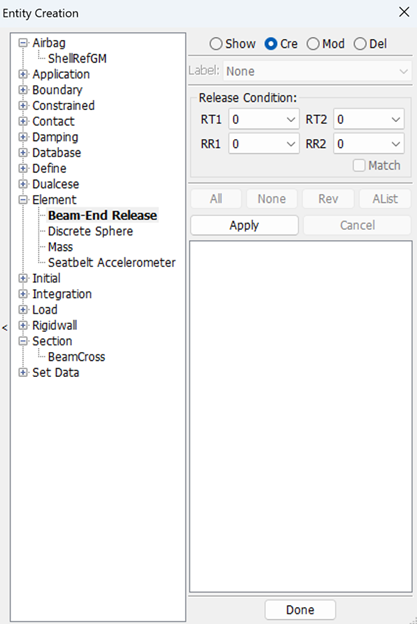

This interface is used for showing, creating, modifying, and deleting release conditions of exist *ELEMENT_BEAM.

- RT1

Release conditions for translations at node N1.

- RT2

Release conditions for translations at node N2.

- RR1

Release conditions for rotations at node N1.

- RR2

Release conditions for rotations at node N2.

- Match

Match case, show all if all zero.

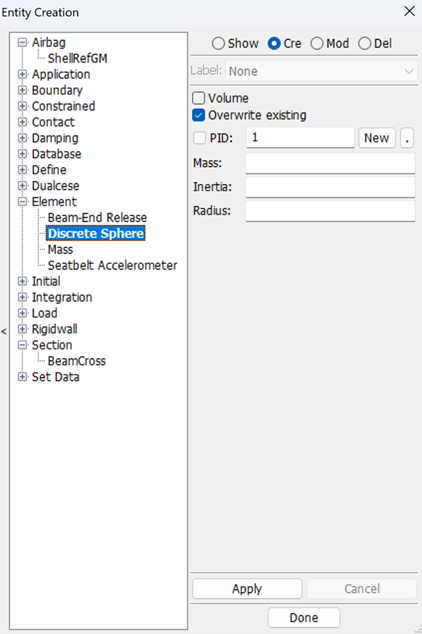

This interface is used for showing, creating, modifying, and deleting keywords of *ELEMENT_DISCRETE_SPHERE or *ELEMENT_DISCRETE_SPHERE_VOLUME.

- Volume

Check to create *ELEMENT_DISCRETE_SPHERE_VOLUME.

- Overwrite existing

Check to overwrite existing discrete sphere with the same node.

- PID

Input part id of the discrete sphere element.

- New

Create new part id of the discrete sphere element.

- Mass( or Volume)

Input mass (or volume) of the discrete sphere element.

- Inertia

Input inertia of the discrete sphere element.

- Radius

Input radius of the discrete sphere element.

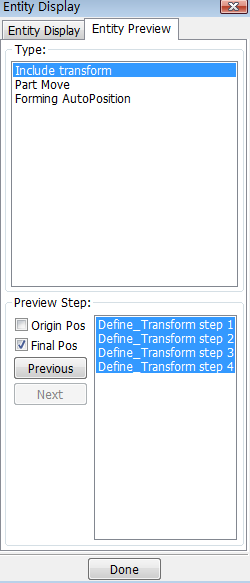

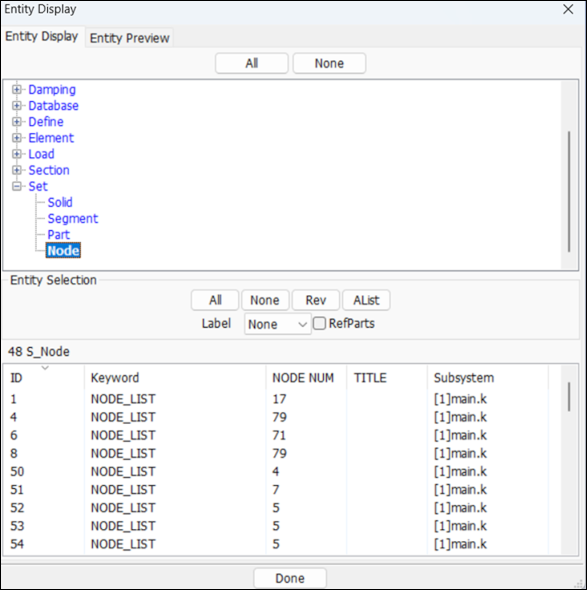

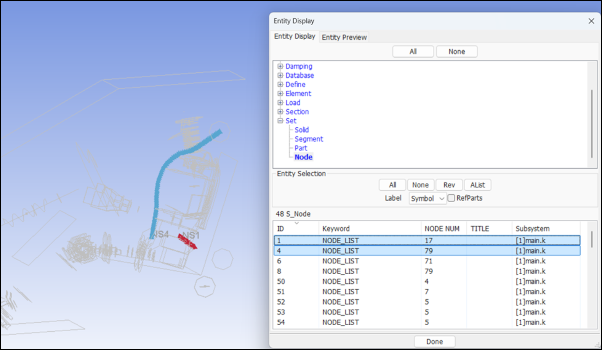

This interface is primarily a tool for entity management.

- Entity Display

Manager of entity display.

- Entity Preview

Preview of entity if it has been transformed.

- All

Turn on all entities.

- None

Turn off all entities.

- All

Turn on all entities in the current list.

- None

Turn off all entities in the current list.

- Rev

Reverse selection.

- AList

Turn on all entities in the selected range only.

- Label

Select label type.

The software draws selected entities in different colors, so that the image is more clear.

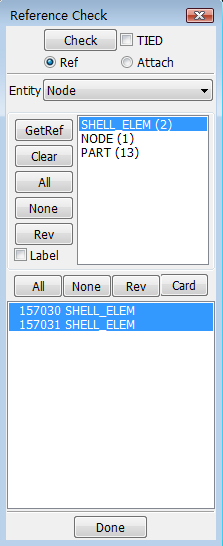

This interface provides a means of determining how different entities within a model are related and referenced.

- Reference

Determining how entities are referenced by other entities in the model.

- Attach

Determining how parts of a complex model are physically connected to each other.

- Check

Check all referenced again.

- TIED

Set check with inipene.

- Entity

Set current refcheck entity type.

- GetRef

Get selected nodes referenced data.

- Clear

Clear selected referenced data.

- All

Select all referenced.

- None

Select none referenced.

- Rev

Reverse selection referenced.

- Label

Set entity display label.

- All

Select all referenced.

- None

Select none referenced.

- Rev

Reverse selection referenced.

- Card

Read selection referenced data by card.

- Part

Attach by part.

- Element

Attach by element.

- AllVis

Attach by all visiable.

- Selected

Attach by selected nodes.

- Attach

Get attached nodes referenced data.

- AttachAll

Get all attach nodes referenced data.

- Clear

Clear attach.

- All

Select all referenced.

- None

Select none referenced.

- Rev

Reverse selection referenced.

- Write

Write out refdata.

- MSubsys

Move attach to new subsystem.

This interface can be used for renumbering and offsetting of entities within a model. This is only available during the pre-processing phase. An entire model can be renumbered or individual data types like nodes, materials, etc... can be renumbered and offset. For each entity type, either all or a specified range can be renumbered/offset. Upon renumbering or offsetting all referenced data will get updated by LS-PrePost.

- Renumber

Renumber keyword file by user ID.

- Offset

Renumber keyword file by offset user ID.

- Fit-in-Range

Renumber keywords into target range.

- Renumber

Renumber keyword file by user ID.

- Offset

Renumber keyword file by offset user ID.

- Fit-in-Range

Renumber keywords into target range.

- Keyword

Renumber or offset keywords by selected keywords or all.

- Part

Renumber or offset nodes, elements and parts by selected.

- Selected

Renumber or offset selected nodes, shells or parts.

- Save renumbering log file

Save renumbering information to a log file.

- Reset part color

Rest part color if renumber part.

Select keywords in the tree list control, set start ids for selected keywords and range of keywords, then renumber or offset them.

- Set range for renumber/offset

Set range id in column 'from' and 'to' of the tree for renumber/offset.

- Start ID

Renumber start id/offset value ,or click the Column "StartID" of each item to edit the start id.

- SetAll

Set all the start id as the same.

- SetSel

Set start id of current selected item.

- Clear

clear current select.

- Renumber

Renumber or offset current data.

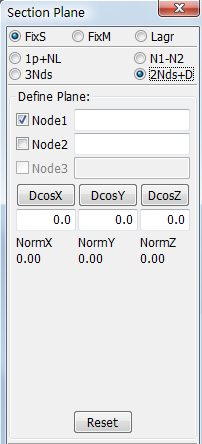

The SPlane interface is used to create section planes that can be used to perform section cuts of the model for further analysis. Various methods of cutting model cross sections are available, and the model can be animated in section cut mode.

The cross section plane can be fixed to space, fixed to the model and a lagrangian type section cutting is also available. If the model is fringed with plastic strains prior to cutting section, then the section cut will be fringed also. Model can be clipped on either side of the section plane by Off/Clip-/Clip+.

- FixS

Fixed in space means that the section plane will not move once defined.

- FixM

Fixed to Model means that the section plane can move if the nodes used to define it move.

- Lagr

Lagrangian means that a group of elements is cut initially, and then those same elements are tracked throughout the animation (and are not confined to a flat plane as the model deforms). This option is most similar to *DATABASE_CROSS_SECTION.

- 1p+NL

Define plane with 1 point and a normal. See 1p+NL sub function description.

- N1-N2

Define plane with 2 nodes (node 1 on plane, node 2 indicates normal vector). See N1-N2 sub fuction description.

- 3Nds

Define plane with 3 nodes. See 3Nds sub fuction description.

- 2Nds+D

Define plane by picking 2 nodes and a direction cosine. See 2Nds+D sub function description.

- Base Pt. Location

Dynamic display of base point coordinate(Xpos/Ypos/Zpos).

- No.of Cuts

Enter number of cuts to make/distance to move plane along the normal.

- Upd Bspt

Update base point with the current position.

- Left Arrow

Step 1 increment back.

- MP Anim

Animate moving plane along the normal.

- Right Arrow

Setp 1 increment forward.

- Clr Kpsc

Clear kept section cuts in memory.

- Project View

View section cut normal to section plane.

- Clipping Mode

Choose clipping mode (Off/Clip+/Clip-).

- Kp Cuts

Keep and display all section cuts.

- Clr

Clear all section cuts.

- Cut

Cut the section.

- Options

Other options for section plane. See Options sub function description.

- Crush

Plot intrusions relative to a plane. See Crush sub function description.

- Model

Draw normal model.

- Meas

Active section cut measure interface. See Meas sub function description.

- Line

Active section cut line plot interface. See Line sub function description.

- Force

Open section force plot interface. See Force sub function description.

- Save

Activesave plane and cut interface. See Save sub function description.

- Done

Exit section plane interface.

- BasePt

Define base point by entering x, y, z coordinates.

- BaseNd

Define base point by picking/entering a node ID.

- X/Y/Z

Enter base point x/y/z-coordinate.

- Node

Enter node number for base point.

- NormX/NormY/NormZ

Set x/y/z-component of normal vector to 1. (User also has the option to manually enter the x,y and z-components in the fields provided).

- Centroid

Use centroid of model as base point.

- CG

Use center of gravity of model as base point.

- Reset

Clear base point and normal settings.

- Node1/Node2/Node3

Enter or pick Node1/Node2/Node3.

- DcosX/DcosY/DcosZ

Enter X/Y/Z directional cosine component.

- Reset

Clear base point and normal settings.

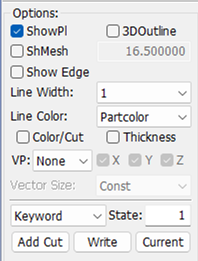

This sub-panel allows changing color and with of section cut lines, projecting the section cut to true view and turning part thickness and vector plotting of element quantities at section level. Section cuts can be exported in various formats.

- ShowPI

Show section plane with model.

- 3DOutline

Show 3D model outline with section.

- ShMesh

Show section plane as mesh.

- Show Edge

Show edge of section.

- Line Width

Set section cut line width.

- Line Color

Set section cut line color.

- Color/Cut

Use different color for each section cut.

- Thickness

Draw section cut with thickness.

- VP

Draw vector n section cut.

- X/Y/Z

The X/Y/Z component of vector on/off.

- Vector Size

Set vector size for vector point.

- Format

Choose desired output format(Keyword/VDA/IGES/Coord+V).

- State

Enter state number for the section data to be written.

- Add Cut

Add cut to current geometry database.

- Write

Start writing section data to file.

- Curr State

Write section data for current state.

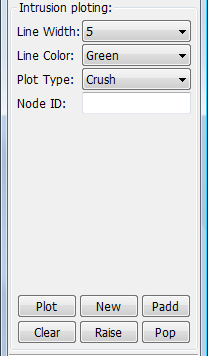

Allows plotting crush of a point in the model with respect to a plane. This plane can be fixed to space or moving with the model.

- Line Width

Select intrusion plotting line width.

- Line Color

Select intrusion plotting line color.

- Plot Type

Select histroy plot type.

- Node ID

Enter or pick a node ID to compute intrusion.

- Plot

Plot intrusion line data in current XY-Plot window.

- New

Plot intrusion line data in a new XY-Plot window.

- Padd

Add intrusion line data to current XY-Plot window.

- Clear

Clear picked/entered node IDs.

- Raise

Raise all open XY-Plot windows.

- Pop

Open and raise all closed XY-Plot windows.

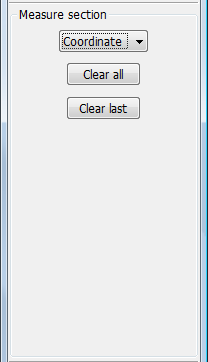

Various measurements methods are available on section cuts: coordinate, distance, 3pt-angle, 3pt-radius and 2ln-angle. Although the main application for this is for metal forming simulations, it has wide range of applications in other fields.

- Coordinate

Choose quantity to be measured.

- Clear all

Clear all measured highlight.

- Clear last

Clear last picked position.

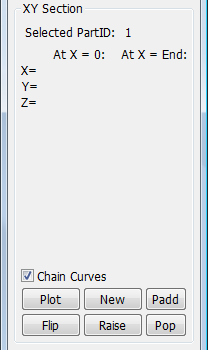

Section cut line plotting allows for plotting section properties (like shell thickness) on xy-plots. x-axis on the xy-plot is the length of the section cut line developed to a straight line. The main application of this is in metal forming simulations.

- Chain Curves

Chain broken curves into 1 single curve.

- Plot

Plot section distance vs fringe component in current XY-Plot window.

- New

Plot section distance vs fringe component in a new XY-Plot window.

- Padd

Add section distance vs fringe component data to current XY-Plot window.

- Raise

Raise all open XY-Plot windows.

- Pop

Open and Raise all closed XY-Plot windows.

- Flip

Flip the XY curve in the x-axis.

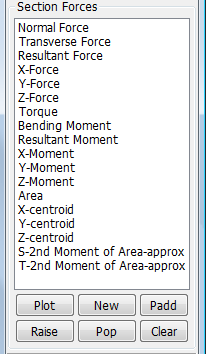

LS_DYNA has a facility to calculate and output section forces by user defining *DATABASE_CROSS_SECTION. This interface allows sections to be defined interactively and LS-PrePost computes the section quantities if shell resultants are available in d3plot files. Generally this data is available in d3plot files unless it is turned off by the use of *DATABASE_EXTENT_BINARY options.

- Menu List

Select items for plotting.

- Plot

Plot section variable vs time in current XY-Plot window.

- New

Plot section variable vs time in a new XY-Plot window.

- Padd

Add selected data to current XY-Plot window.

- Raise

Raise all open XY-Plot windows.

- Pop

Open and Raise all closed XY-Plot windows.

- Clear

Clear selected items in the list.

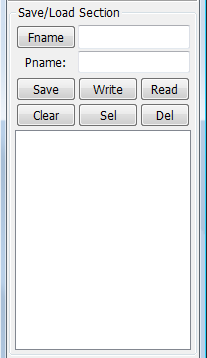

Section plane definitions can be saved and loaded. This allows users define sections once and save them for future model revision use. Often users want to cut a cross section on various model iterations at the same specific location.

- Fname

Click to browse directory or enter filename.

- Pname

Enter name for this section definition.

- Save

Save current plane definition to buffer.

- Write

Write plane definitions from buffer to file.

- Read

Read plane definitions from file to buffer.

- Clear

Clear all plane definitions in buffer.

- Sel

Select plane definition from list as current plane.

- Del

Delete elected plane definition from buffer.

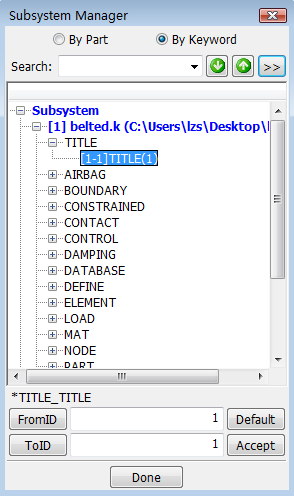

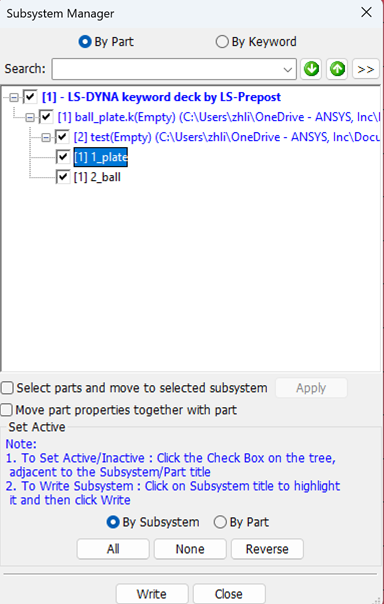

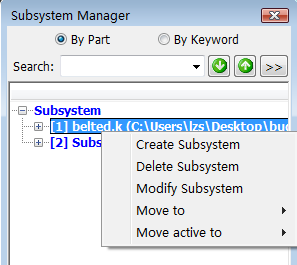

This interface allows grouping of parts of a full model to sub-systems. LS-PrePost stores the contents of each include file in sub-systems. The Create option allows for the creation of a new sub-system. Part of the model can then be moved from one sub-system to another.

- By Part

Show subsystem by part.

- By Keyword

Show subsystem by keyword.

- Search

Input the object for search.

Search down.

Search down.

Search down.