- Shape Mesh

Simple shell/solid meshing interface.

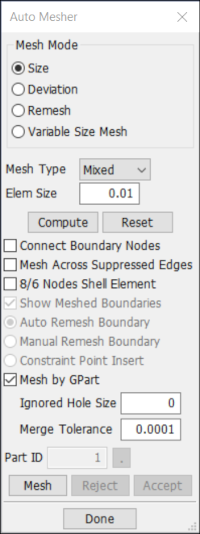

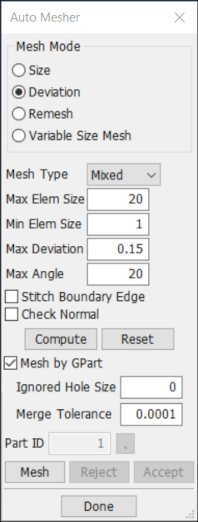

- Auto Mesh

Surface mesh interface.

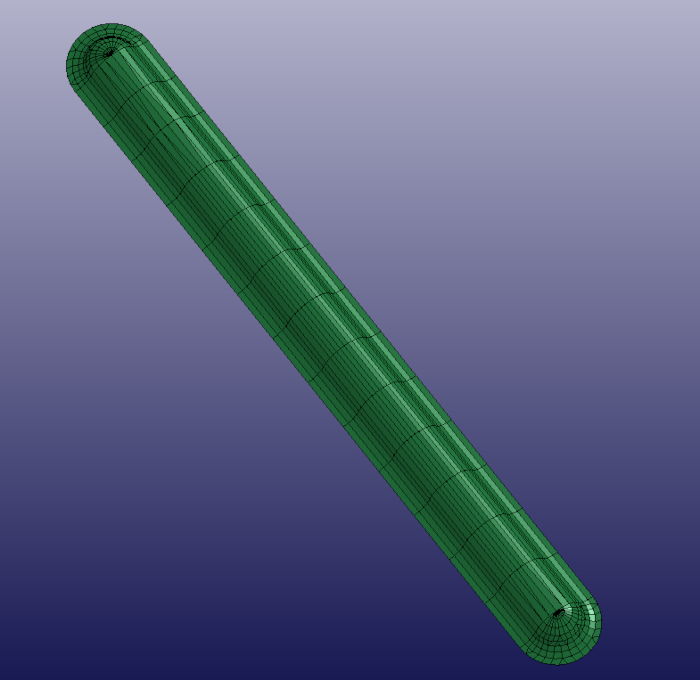

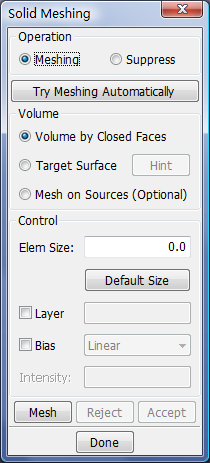

- Solid Mesh

Solid mesh interface.

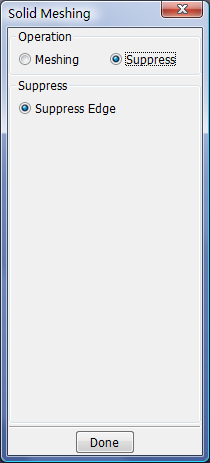

- Block Mesh

2/3 D block mesher interface.

- N-Line Mesh

2, 3, and 4 line mesh interface.

- 2D Mesh

2D mesh sketchboard interface.

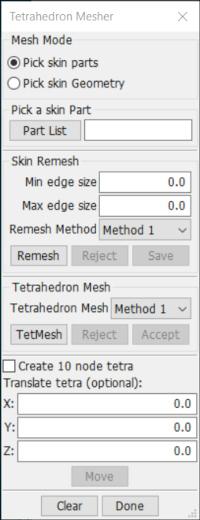

- Tetrahedron Mesh

Tetrahedron mesher interface.

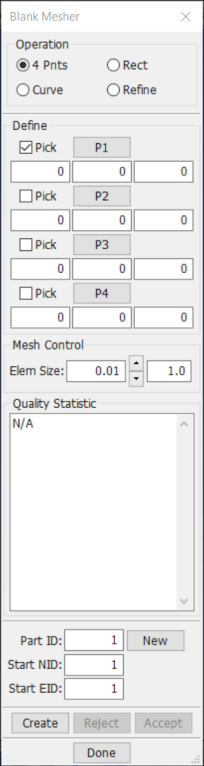

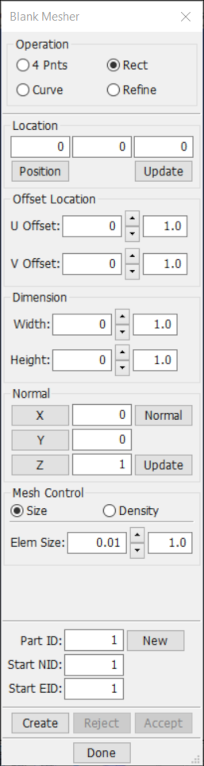

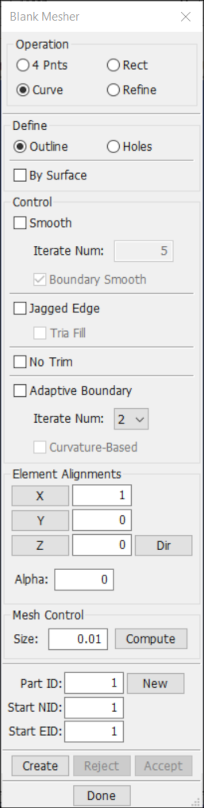

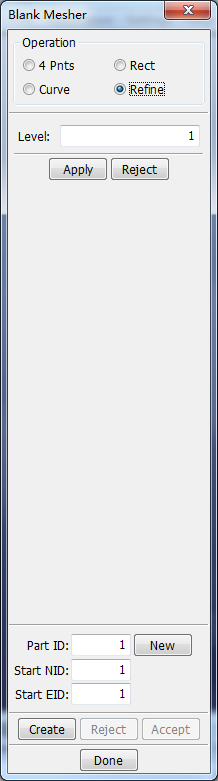

- Blank Mesh

Blank mesher interface.

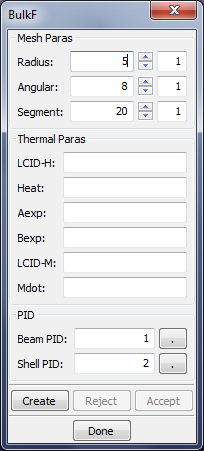

- Bulk Fluid

Bulk fluid pipe meshing interface.

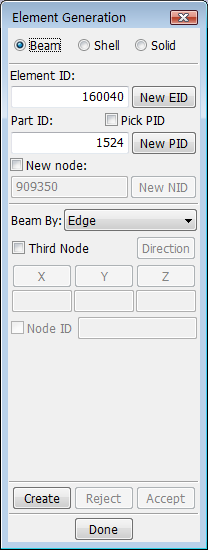

- Element Generation

Create beam, shell, and solid elements.

- Node Edit

Show, create, delete, and modify nodes.

- Element Edit

Show, create, delete, and modify elements.

- 2D NURBS

Show, create, delete, and modify 2D FEM NURBS keyword.

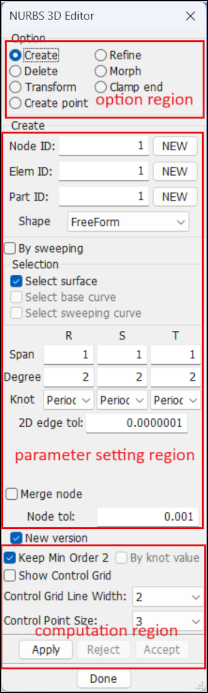

- 3D NURBS

Show, create, delete, and modify 3D FEM NURBS keyword.

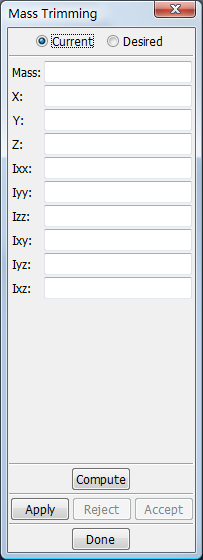

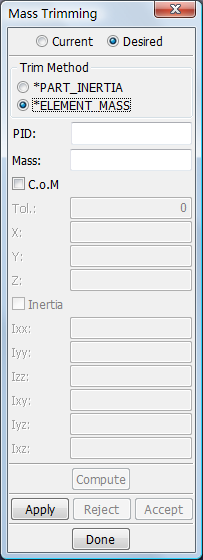

- Mass Trim

Mass trim interface.

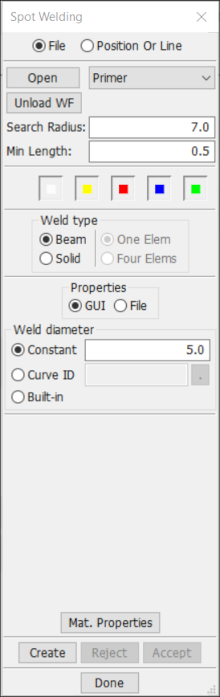

- Spot Welding

Generate spotweld elements from a spotweld file.

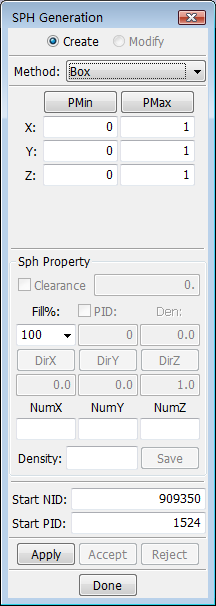

- SPH Generation

Sphere particle generation interface.

- Disc Sphere Generation

Disc Sphere generation interface.

- Multi Solver Mesh

Convert between Multiple Solver mesh and mesh.

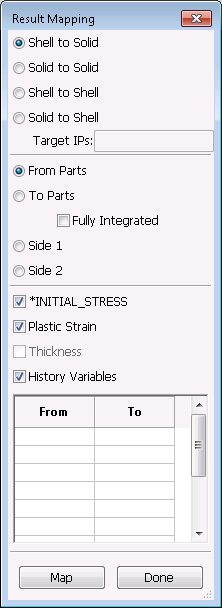

- Result Mapping

Initial stress mapping interface.

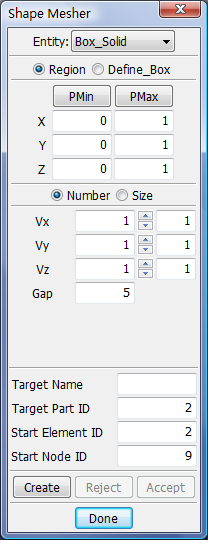

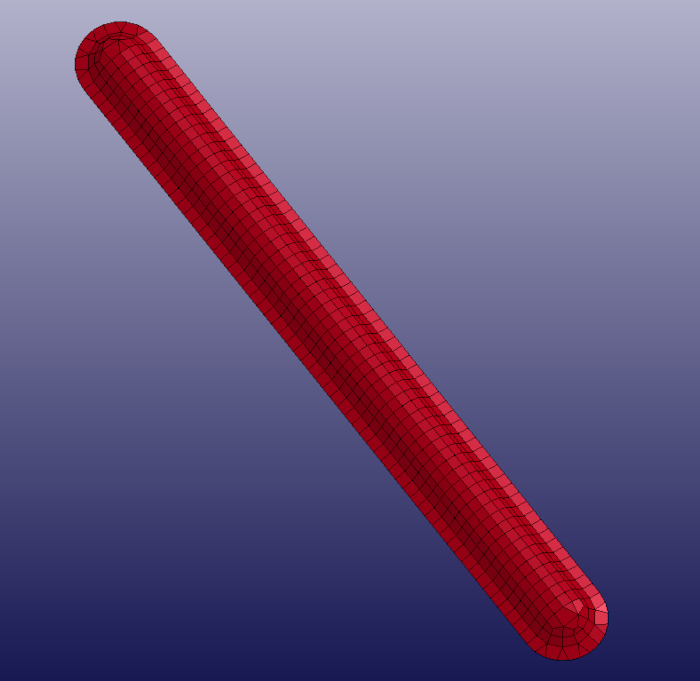

This interface, often used for generating solid meshes for ALE simulations, can be used to generate solid and shell meshes.

- Box Solid

Define a box and generate solid mesh of it.

- Box Shell

Define a box and generate shell mesh of it.

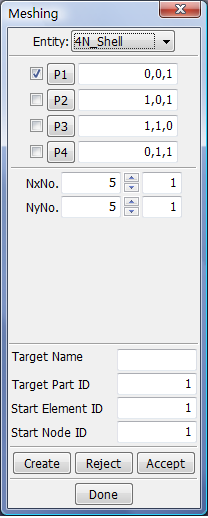

- 4N Shell

Define four node surface and generate shell mesh of it.

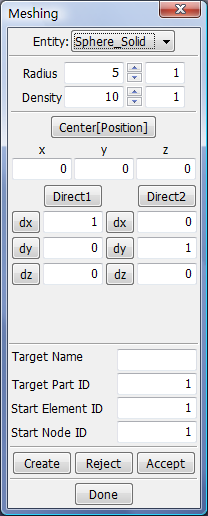

- Sphere Solid

Define a sphere and generate solid mesh of it.

- Sphere Shell

Define a sphere and generate shell mesh of it.

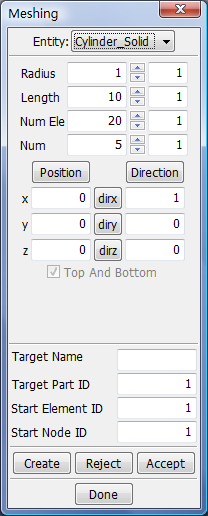

- Cylinder_Solid

Define a cylinder and generate solid mesh of it.

- Cylinder_Shell

Define a cylinder and generate shell mesh of it.

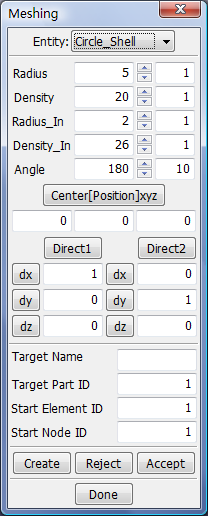

- Circle_Shell

Define a circle and generate shell mesh of it.

- Region

Use General Selection Interface to get region max and min values.

- Define_Box

Use Entity Operation Interface to get box max and min values.

- PMin/PMax

Use Position Dialog to get minimum/maximum point.

- X/Y/Z

Enter x/y/z-coordinates of minimum and maximum point.

- Number

Enter number of elements along x/y/z.

- Size

Enter size along x/y/z.

- Vx/Vy/Vz

Enter Number/Size along x/y/z.

- Gap

Extend min/max of box by this value.

- Target Name

Enter target part name.

- Target Part ID

Enter target part ID.

- Start Element ID

Enter starting element ID.

- Start Node ID

Enter starting node ID.

- Create

Create mesh for the entity.

- Reject

Reject the created mesh.

- Accept

Accept the created mesh.

- Done

Exit meshing interface.

- Checkbox P1/P2/P3/P4

Use General Selection Dialog to Pick node for point 1/2/3/4.

- Button P1/P2/P3/P4

Use Position Dialog to get point 1/2/3/4.

- Text P1/P2/P3/P4

Enter coordinates in format "x, y, z" for point 1/2/3/4.

- NxNo.

Enter number of elements along x.

- NyNo.

Enter number of elements along y.

- Radius

Enter radius of sphere.

- Density

Enter density of sphere.

- Center[Position]

Use Position Dialog to get sphere center.

- x/y/z

Enter x, y, z of the sphere center.

- Direct1

Call Direction Dialog to get direction 1.

- Direct2

Call Direction Dialog to get direction 2.

- dx/dy/dz

Set direction x/y/z for 1/-1 (toggles).

- Radius

Enter cylinder radius.

- Length

Enter cylinder length.

- Num Ele

Enter number of elements in circumferential direction

- Num

Enter number of elements along the length of the cylinder.

- Position

Call Position Dialog to get position.

- Direction

Call Direction Dialog to get direction.

- dirx/diry/dirz

Set direction x/y/z for 1/-1 (toggles).

- Top And Bottom

Extend min/max of box by this value.

- Radius

Radius of circle.

- Density

Density of Circle (Must more than 2).

- Radius_In

Radius of circle inside.

- Density_In

Density of Circle Inside (Must more than 2).

- Angle

Span Angle.

- Center[Position]xyz

Call Position Dialog to get position.

- Direct1

Call Direction Dialog to get direction 1.

- Direct2

Call Direction Dialog to get direction 2.

- dx/dy/dz

Set direction x/y/z for 1/-1 (toggles).

This interface is for surface mesh generation. Two meshing methods are available: By size and By Deviation.

- Auto Mesh

Size mode creates uniformly sized elements.

- Tool Mesh

Specifically for metalforming applications where surfaces may contain very small radii that need to be meshed accurately, and at the same time have flat areas that require a relatively coarse mesh. Tool meshing requirements are very different from those of structural finite element analysis.

- Two kind mesh comparison

Show the difference between size-based and deviation-based.

- Size

Select the size mode.

- Deviation

Select the deviation mode.

- Mesh Type

Generate triangle mesh only or mixed.

- Elem Size

Enter average element size.

- Compute

Compute mesh parameter by model extend.

- Reset

Reset mesh parameter to default.

- Show Meshed Boundaries

Before Accept and After Mesh, will become sensitive. Show the boundary node as blank square.

- Auto remesh boundary

Before Accept and After Mesh, will become sensitive. On the boundary, left-click to increase the node num and right-click to decrease it. Then automesh it according to the new boundary.

- Manual remesh boundary

Before Accept and After Mesh, will become sensitive. On the boundary, left-click to add a new node and right-click to remove a node. Then automesh it according to the new boundary.

- Mesh By GPart

The mesh generated from same GPart will be organized into same part.

- Ignored Hole Size

Holes under specified size will be ignored.

- Part ID

Assign new generated mesh to this part or create a new part if this part id doesn't exist.

- Mesh

Generate shell mesh for selected surfaces.

- Reject

Reject the last operation.

- Accept

Accept the last operation.

- Done

Exit this dialog.

- Max Elem Size

Enter maximum element size.

- Min Elem Size

Enter minimum element size.

- Max Deviation

Enter maximum deviation ratio.

- Max Angle

Enter maximum feature angle.

Generate solid mesh of mappable volumes.

- Meshing

Generate solid mesh manually or automatically.

- Suppress

Suppress geometry edges which resist sweeping.

- Try Meshing Automatically

Once the decomposition is done, click this button try to mesh automatically. all the volumes have to be mappable, otherwise unmappable volume will be omitted.

- Volume by Closed Faces

Pick volume to be sweep on graphic area. For manual purpose only.

- Target Surface

Pick face as sweep target on graphic area. For manual purpose only.

- Hint

Click until found the proper target face.

- Mesh on Sources(Optional)

Pick sources' mesh if needed. For manual purpose only.

- Elem Size

Specify the element size.

- Default Size

Click to get the reference element size.

- Layer

Check to enable layer control. For manual purpose only.

- Bias

Check to enable bias control. For manual purpose only.

- Intensity

Specify the bias intensity. For manual purpose only.

- Mesh

Generate solid mesh. For manual purpose only.

- Reject

Reject the last sweep.

- Accept

Accept all sweep.

- Done

Exit the interface and accept all sweep.

This interface is for index based mesh generation and is similar to mesh generation methods used in LS-INGRID. This capability is under development and eventually will be expanded to be a very powerful addition to LS-PrePost.

- Create

Create blocks.

- Parameter

Parameter and Expression.

- Blank/Del

Blank or delete blocks.

- Rd/Write

Read and write command files.

- Move Pts

Move points.

- Distribute

Distribute blocks' nodes.

- Rotate Pts

Rotate points.

- Project

Project points/lines/surfaces of blocks to geoemtry.

- Info

Show internal node coordinate of given block.

- Multiple Blocks

Create multi blocks.

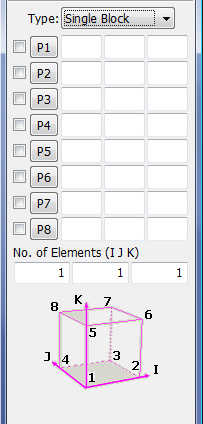

- Single Block

Create single blocks.

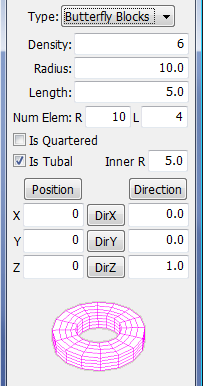

- Butterfly Block

Create a butterfly block.

- Create

Create blocks.

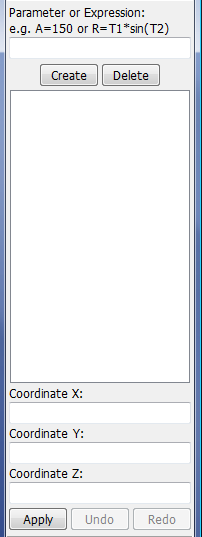

- Parameter

Parameter and Expression.

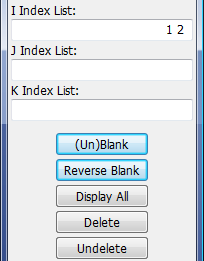

- Bland/Del

Blank or delete blocks.

- Rd/Write

Read and write command files.

- Move Pts.

Move points.

- Distribute

Distribute blocks' nodes.

- Rotate Pts

Rotate points.

- Project

Project points/lines/surfaces of blocks to geoemtry.

- Info

TODO

- Type

Select block type.

- I Index List

I index list for blocks.

- J Index List

J index list for blocks.

- K Index List

K index list for blocks.

- X Position List

X coordinate for blocks

- Y Position List

Y coordinate for blocks.

- Z Position List

Z coordinate for blocks.

- Part ID

The generated mesh will belong to.

- Create

Create the block.

- Reject

Reject the last operation.

- Accept

Accept the last operation.

- Done

Exit interface.

- P1

When check box is checked, pick from graphic. Click button P1 to call Position Dialog to create a Point, or enter x/y/z.

- Px

Same as P1

- No. of Elements(I J K)

Enter number of elements along I, J, K.

- Density

Density of the cylinder perimeter.

- Radius

Radius of the cylinder.

- Length

Length of the cylinder.

- R

Number of elements in Radius direction.

- L

Number of elements in Length direction.

- Is Quartered

- Is Tubal

The cylinder is empty.

- Inner R

Sensitive when Is Tubal is checked. The inner raidus of cylinder.

- Parameter or Expression

Enter parameter or expression. Such as A=150 or R=T1*sin(T2).

- Create

Create a parameter or expression.

- Delete

Delete a parameter or expression.

- Coordinate X

Function to evaluate x coordinate.

- Coordinate Y

Function to evaluate y coordinate.

- Coordinate Z

Function to evaluate z coordinate.

- Apply

Apply eval function to current domain block.

- Undo

Undo the last operation.

- Redo

Redo the last Undoed operation.

- I Index List

I coordinate of blocks to be blank or delete.

- J Index List

J coordinate of blocks to be blank or delete.

- K Index List

K coordinate of blocks to be blank or delete.

- (Un)Blank

Blank blocks.

- Reverse Blank

Reverse blank status of blocks.

- Display All

Display all blocks.

- Delete

Delete blocks.

- Undelete

Undelete blocks.

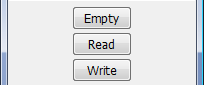

- Empty

Empty current buffer for blockm commmand.

- Read

Read command file.

- Write

Write command file.

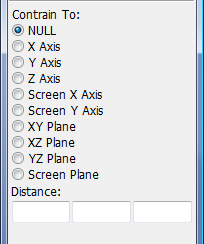

- NULL

No constraint.

- X Aixs

Constraint to X Axis.

- Y Aixs

Constraint to Y Axis.

- Z Aixs

Constraint to Z Axis.

- Screen X Axis

Constraint to screen X Axis.

- Screen Y Axis

Constraint to screen Y Axis.

- XY Plane

Constarint to XY Plane.

- XZ Plane

Constarint to XZ Plane

- YZ Plane

Constarint to YZ Plane.

- Screen Plane

Constraint to screen plane.

- Distance

Sensitive according to former option. the distance on x/y/z direction.

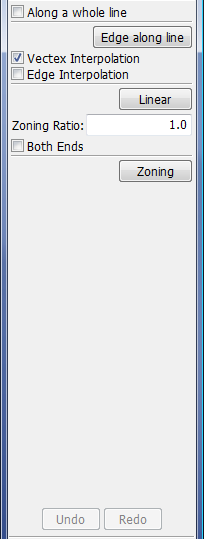

- Along a whole line

Distribute edge along a whole line.

- Edge along line

Distribute edge along line.

- Vectex Interpolation

Vectex Interpolation in Bi-linear and Tri-linear Multiple Faces and Solids Interpolation.

- Edge Interpolation

Edge Interpolation in Bi-linear and Tri-linear Multiple Faces and Solids Interpolation.

- Linear

Apply Linear Interpolation.

- Zoning Ratio

Zoning Ratio (a positive number).

- Both Ends

Relative spacing of nodes of an edge from both ends.

- Zoning

Apply Edge Zoning.

- Undo

Undo last interpolation.

- Redo

Redo last interpolation.

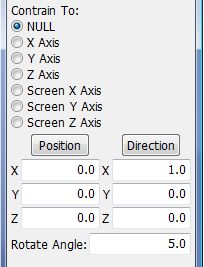

- NULL

No constraint.

- X Aixs

Constraint to X Axis.

- Y Aixs

Constraint to Y Axis.

- Z Aixs

Constraint to Z Axis.

- Screen X Axis

Constraint to screen X Axis.

- Screen Y Axis

Constraint to screen Y Axis.

- Screen Z Axis

Constraint to screen Z Axis.

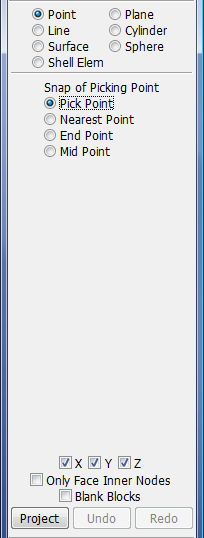

- Project to point.

Project to point.

- Line

Project to line.

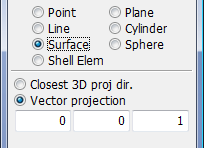

- Surface

Project to surface.

- Shell Element

Project to shell elements.

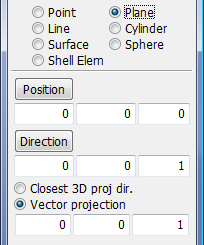

- Plane

Define a plane with an origin and a vector.

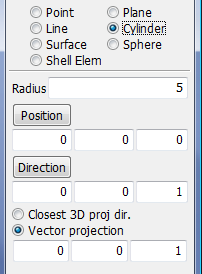

- Cylinder

Define a Cylinder with an origin, a vector and a radius.

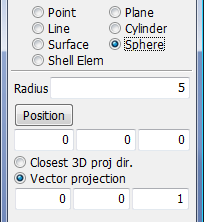

- Sphere

Define a Sphere with an origin and a radius.

- Point

Project to point.

- Line

Project to line.

- Surface

Project to surface.

- Shell Element

Project to shell elements.

- Plane

Project to a plane.

- Cylinder

Project to cylinder.

- Sphere

Project to sphere.

- Pick Point

Get XYZ at pick location on curve.

- Nearest Point

Get XYZ at nearest point on curve.

- End Point

Get XYZ at end of curve.

- Mid Point

Get XYZ at middle of curve.

- X

Project in X Component.

- Y

Project in Y Component.

- Z

Project in Z Component.

- Only Face Inner Nodes

Project the Inner nodes when projecting Face(s).

- Blank Blocks

Blank or unblank Blocks.

- Project

Project the Block.

- Undo

Undo last Projection.

- Redo

Redo last Projection.

- Closest 3D proj dir.

Project Block to mesh in closet 3D direction.

- Vector projection

Project Block in specified vector direction.

- Position

Select a Coordinate as the Orginal Point.

- Direction

Select a Direction as Plane Normal.

- Radius

Enter the radius for cylinder.

- Position

Select a Coordinate as the Orginal Point.

- Direction

Select a Direction as Plane Normal.

- Closest 3D proj dir.

Project Block to mesh in closet 3D direction.

- Vector projection

Project Block in specified vector direction.

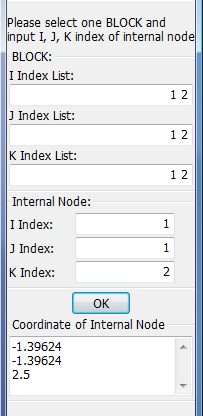

- I Index List

I Coordinate of one block.

- J Index List

J Coordinate of one block.

- K Index List

K Coordinate of one block.

- I Index

I Coordinate of one Internal Node.

- J Index

J Coordinate of one Internal Node.

- K Index

K Coordinate of one Internal Node.

- OK

Get the internal node coordinate.

- Coordinate of Internal Node

Show internal node coordinate in the list.

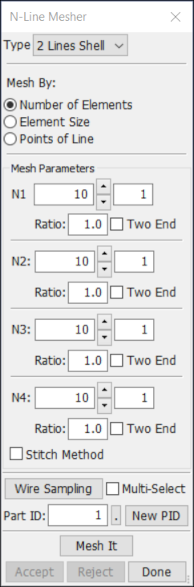

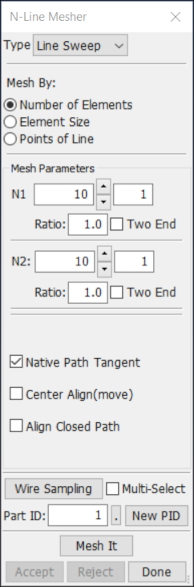

This interface is for shell mesh generation using curves and often useful in cases where a topology mesher leaves holes due to missing CAD surface data.

- 2 Line Shell

Create a mesh between 2 lines

- line sweep

Create a mesh by sweeping one line along another line

- Number of elements

Mesh by number of elements.

- Element size

Mesh by element size.

- Point of Line

Mesh by existing points of line.

- N1

Enter or adjust number of elements along line 1.

- Ratio

Bias radio.

- Two End

Bias from two end.

- N2

Enter or adjust number of elements along line 2.

- N3

Enter or adjust number of elements along line 3.

- N4

Enter or adjust number of elements along line 4.

- Part Id

Enter or select target part ID.

- New PID

Get new default part ID.

- Mesh It

Perform meshing.

- Accept

Accept the created mesh.

- Reject

Reject the created mesh or the selected lines.

- Done

Exit the nLMesh Interface.

- N1

Enter or adjust number of elements along cross section.

- Ratio

Bias ratio.

- Two End

Bias from two end.

- N2

Enter or adjust number of elements along sweep path.

- Native Path Tangent

Use native curve tangent as sweep direction.

- Center Align(move)

Generate the shell mesh with the sweep path center aligned.

This interface is for 2D mesh generation. Firstly, user should create some points, lines, circles or circular arc in sketch board. And use filleting, extending, trimming, deleting and transforming tools to modify curves. Finally, using those curves and mesh tools to generate 2D mesh. You can also create 3d cone and sphere mesh directly in this dialog.

Use this interface to generate a solid mesh of tetrahedron elements.

- Skin Remesh

Remesh a skin surface.

- Tetrahedral Mesh

Generate a tetrahedral mesh of a skin surface.

- Move

Move skin mesh or tetrahedral mesh to a new position.

- Pick a skin Part

pick a part from graphic when entering this dialog.

- Part List

Popup list of current parts for selection.

- Min edge size

Enter or change minimum element edge size for remesher.

- Max edge size

Enter or change maximum element edge size for remesher.

- Remesh

Remesh the skin surface.

- Reject

Reject the remesh operation.

- Save

Save skin or remesher skin as a new part.

- TetMesh

Prepare selected part and send to tetrahedron mesher.

- Reject

Reject tet mesh.

- Accept

Accept tet mesh.

- Create 10 node tetra

Create 10 node tetra elements instead of 4 node. Only take effect with "Accept".

This interface is primarily intended for mesh generation of blanks for metalforming simulations, but it may also have applications in other areas.

- 4 Pnts

Using 4 Corner Nodes (of a blank) and Element Size to generate a mesh.

- Rect

Mesh rectangle of given Length and Width with element size or number of elements.

- Curve

Allows a mesh to be created on an enclosed curve. Element alignment can be along global axis or user defined. Mesh boundary options are as follows: Smoothed, Left Jagged (and optionally filled with trias), or No-Trim (creates a rectangular blank without trimming.

- Refine

Multi-level refine.

- Pick

Pick node on model to define Node 1/2/3/4.

- P1

Call Position Dialog for Points 1.

- P2

Call Position Dialog for Points 2.

- P3

Call Position Dialog for Points 3.

- P4

Call Position Dialog for Points 4.

- Elem Size

Element size for the blank.

- Quality Statistic

Statistic quality of generated elements before accept.

- Part ID

Part ID for the current blank.

- New

Get a new part ID from the current model.

- Start NID

The starting node id of of new created blank mesh.

- Start EID

The starting element id of of new created blank mesh.

- Create

Create the blank mesh.

- Reject

Reject the last operation.

- Accept

Accept the last operation.

- Done

Exit this dialog.

- Location

the left bottom corner of this rectangle.

- Position

Call Position Dialog for location4.

- Update

Update the location.

- U Offset

Enter or adjust plane center in the u direction.

- V Offset

Enter or adjust plane center in the v direction.

- Width

Enter or adjust width of blank.

- Height

Enter or adjust height of blank

- X

Change plane normal to global x.

- Y

Change plane normal to global y.

- Z

Change plane normal to global z.

- Normal

Call Direction Dialog to creat plane normal.

- Update

Update plane normal.

- Size

Give element size for blank.

- Density

Give number of elements for blank.

- Elem Size

Set or adjust element size for the blank (along diagonal).

- U Density

Set or adjust number of elements along u direction.

- V Density

Set or adjust number of elements along v direction.

- Outline

Pick curve(s) to define the outline boundary.

- Holes

Pick curve(s) to define holes.

- By Surface

Define outline and holes by surface

- Smooth

Smooth the interior nodes after trimming (enter number of iterations).

- Iterate Num

number of smoothing iterations.

- Boundary Smooth

Smooth the nodes on the boundary after trimming.

- Jagged Edge

Do a rought trim keeping the quadratic shape of the elements.

- Tria Fill

Fill interior boundary notches with triangular elements.

- No Trim

Create a quadratic mesh that covers the curves but performs no trim.

- X

Set alignment direction along X.

- Y

Set alignment direction along Y.

- Z

Set alignment direction along Z.

- Dir

Call Direction Dialog to create alignment for the elements.

- Alpha

Rotate the above given alignment direction by this angle.

- Size

Element size for the blank.

This interface is used for generating bulk fluid pipe mesh.

- Radius

Radius of the pipe.

- Angular

Angular of the pipe.

- Segment

Segment of the path.

- LCID-H

Load curve ID for H.

- Heat

Heat transfer coefficient.

- Aexp

A exponent.

- Bexp

B exponent.

- LCID-M

Load curve ID for mass flow rate.

- Mdot

Mass flow rate.

- Beam PID

Enter beam part ID.

- Shell PID

Enter shell part ID.

- Create

Preview the mesh.

- Reject

Reject the created mesh.

- Accept

Accept the created mesh.

- Done

Exit the bulk fluid pipe mesh interface.

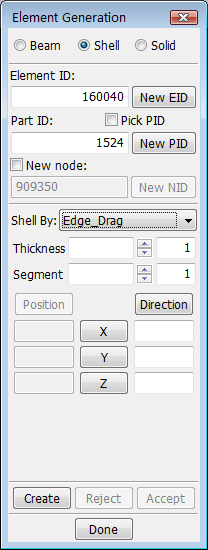

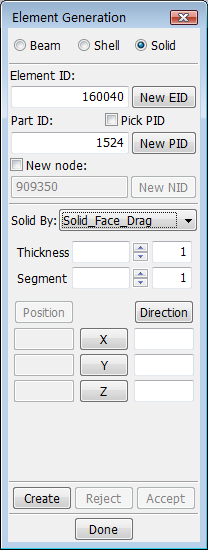

This interface provides a variety of methods for generating beam, shell, and solid elements.

- Beam

Generate beam elements.

- Edge

Create Beam by Edge.

- Curve

Create Beam by Curve.

- Node Drag

Create Beam by Node_Drag.

- Node Spin

Create Beam by Node_Spin.

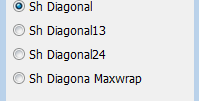

- Shell_Diagonal

Create Beam by Shell_Diagonal.

- Shell

Generate shell elements.

- Solid_Surface, Solid_Face, or Edge_Extend

Create shell by Solid_Surface, Solid_Face or Edge_Extend.

- Edge_Drag

Create shell by Edge_Drag.

- Edge_Spin

Create shell by Edge_Spin.

- Segment_Set

Create shell by Segment_Set.

- Fill_Holes

Create shell by Fill_Holes.

- Cohesive

Create cohesive shell.

- Solid

Generate solid elements.

- Solid_Face_Drag, Solid_Face_Offset or Solid_Face_Spin

Create solid by Solid_Face_Drag, Solid_Face_Offset or Solid_Face_Spin.

- Shell_Drag, Shell_Offset or Shell_Spin

Create solid by Shell_Drag, Shell_Offset or Shell_Spin.

- Shell_Thickness

Create solid by Shell_Thickness.

- Two_Shell_Sets

Create solid by Two_Shell_Sets.

- Shell_Sweep

Create solid by Shell_Sweep.

- Tetra_2_Ten or Hex_2_Tetra

Create solid by Tetra_2_Ten or Hex_2_Tetra.

- Cohesive

Create cohesive solid.

- Sample

- Sample1:

Show how to create element Beam.

- Sample2:

Show how to create element Shell.

- Sample3:

Show how to create element Solid.

- Element ID

Enter new element starting ID.

- New ID

Use default new element ID.

- Part ID

Enter part ID for newly generated elements.

- Pick PID

Pick part ID from graphics, part type must be consistent with the element type to be created.

- New PID

Use default new part ID.

- New node

Check to create new nodes.

- Beam By

Set beam element generation method.

- Create

Create element.

- Reject

Reject last generated element.

- Accept

Accept all new generated elements.

- Done

Exit from element generate interface.

Generate beam elements.

- Third Node

Set third node on/off.

- Direction

Get direction by Direction Dialog.

- X

Set X direction.

- Y

Set Y direction.

- Z

Set Z direction.

- Node ID

ID of the third node.

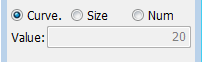

- Curve.

Create beam just be curve without any change.

- Size

Curve mesh by element size.

- Num

Curve mesh by number of element.

- Value

Enter size or number of elements (if zero segment by points).

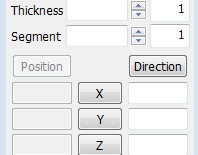

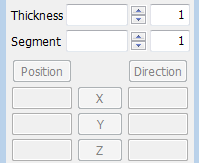

- Thickness

Set total thickness for generation.

- Segment

Set number of segments for generation.

- Direction

Get direction by Direction Dialog.

- X

Set direction 1,0,0 (click 2nd time to reverse).

- Y

Set direction 0,1,0 (click 2nd time to reverse).

- Z

Set direction 0,0,1 (click 2nd time to reverse).

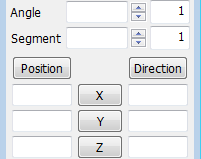

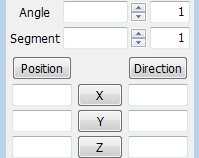

- Angle

Set total angle for generation.

- Segment

Set number of segments for generation.

- Position

Get position with Position Dialog.

- Thickness

Set total thickness for generation.

- Segment

Set number of segments for generation.

- Direction

Get direction by Direction Dialog.

- X

Set direction 1,0,0 (click 2nd time to reverse).

- Y

Set direction 0,1,0 (click 2nd time to reverse).

- Z

Set direction 0,0,1 (click 2nd time to reverse).

- Angle

Set total angle for generation.

- Segment

Set number of segments for generation.

- Position

Get position with Position Dialog.

- SSegId

Popup set segment id list.

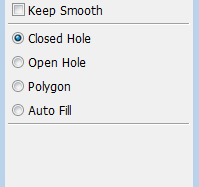

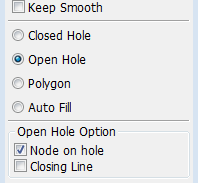

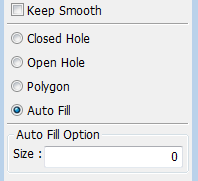

- Keep Smooth

Keep the new element smooth with the neighbors.

- Closed Hole

Pick a node on the edge of hole.

- Open Hole

Pick a node on the edge and a closing line.

- Polygon

Pick nodes to define a polygon to fill.

- Auto Fill

Fill all holes smaller than size specified.

Open Hole Option

- Node on hole

Pick a node on the hole.

- Closing Line

Pick a closing line.

Auto Fill Option

- Size

Hole size.

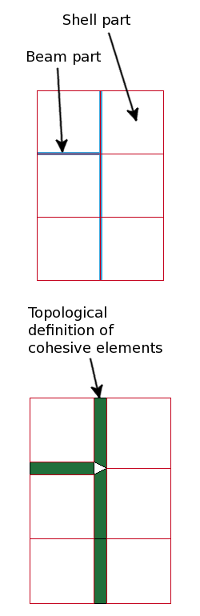

Cohesive elements are used to model an adhesive connection between elements which may lose its bond. Initially, the cohesive elements have zero volume.

Cohesive shell elements can be created at element edges shared by two shell elements. You must specify a (temporary) beam part which defines the cohesive interface. That is, the shell edges where the cohesive elements will be inserted.

- Shell part

Select the shell part(s) to be connected by cohesive elements.

- Beam part

Select the beam part(s) which defines where cohesive elements will be created.

The image to the left shows a shell part where all elements are connected and the beam part shows where to insert cohesive elements. The image beneath shows the topological connection after the cohesive elements have been created.

The elements in the shell part have been disconnected at locations for the selected beam part. Cohesive shell elements with zero volume have been inserted at these locations.

Create a solid from another type of object.

- Thickness/Angle

Set total thickness or angle for generation.

- Segment

Set number of segments for generation.

- Direction

Get direction by Direction Dialog.

- X

Set direction 1,0,0 (click 2nd time to reverse).

- Y

Set direction 0,1,0 (click 2nd time to reverse).

- Z

Set direction 0,0,1 (click 2nd time to reverse).

- Position

Get position with Position Dialog.

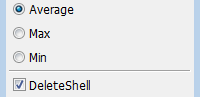

- Average

Set thickness for average.

- Max

Set thickness for max.

- Min

Set thickness for min.

- DeleteShell

Delete shell after create solid.

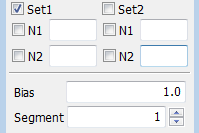

- Set1

Select shell elements for set 1.

- N1

Pick or enter reference node 1 on set 1.

- N2

Pick or enter reference node 2 on set 1.

- Set2

Select shell elements for set 2.

- N1

Pick or enter reference node 1 on set 2.

- N2

Pick or enter reference node 2 on set 2.

- Bias

Set bias value at shell set 1.

- Segment

Set number of segments for generation.

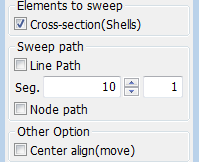

- Cross-section(Shells)

Select shell elements as cross-section.

- Line Path

Select a line as sweep path.

- Seg.

Set num. of segments along the line.

- Node path

Select a node as sweep path.

- Center align(move)

Align selected elements center with the path.

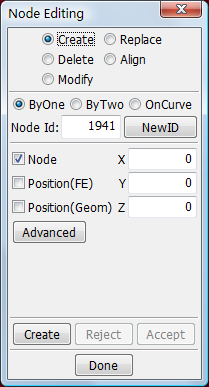

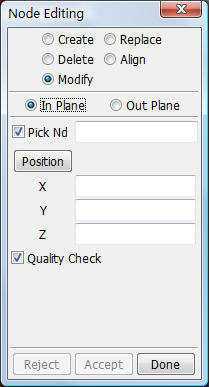

The main purpose of this interface is to create new nodes in various ways, and there are several methods of replacing, aligning, and modifying nodal locations to assist in mesh clean-up.

- Create

Create nodes interface.

- Replace

Replace or merge nodes interface.

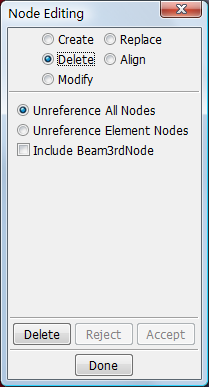

- Delete

Delete nodes interface.

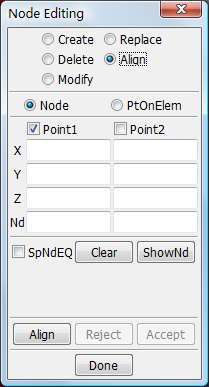

- Align

Align nodes interface.

- Modify

Modify nodes interface.

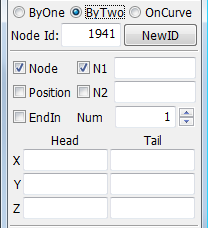

- ByOne

Create one node.

- ByTwo

Creation will include both head and tail nodes.

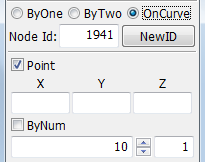

- OnCurve

Create nodes on a curve.

- Node Id

Input node id.

- NewID

Get new default ID.

- Node

Pick node on model to define new node coordinates.

- Position(FE)

Pick a position(FE) to define new node coordinate.

- Position(Geom)

Pick a position(Geom) to define new node coordinate.

- X

Enter X coordinate of new node.

- Y

Enter Y coordinate of new node.

- Z

Enter Z coordinate of new node.

- Advance

Advanced pick position dialog.

- Create

Create nodes and put to temp buffer.

- Reject

Reject last created nodes.

- Accept

Commit created nodes and clear all of them from screen.

- Done

Exit this interface.

- Node

Pick node on model to define new node coordinate.

- Position

Pick a position to define new node coordinate.

- EndIn

Create new nodes at N1 and N2 also.

- N1

Pick node 1 or point to define first point.

- N2

Pick node 2 or point to define second point.

- Num

Set create node number.

- HeadX

Head x coordinate.

- HeadY

Head y coordinate.

- HeadZ

Head z coordinate.

- TailX

Tail x coordinate.

- TailY

Tail y coordinate.

- TailZ

Tail z coordinate.

- Point

Pick a point on a line.

- X

Enter X coordinate of new node.

- Y

Enter Y coordinate of new node.

- Z

Enter Y coordinate of new node.

- ByNum

The number of nodes will create on a line.

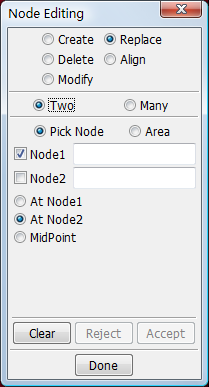

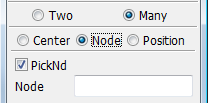

- Two

Replace node by two.

- Many

Replace many nodes.

- Pick Node

Pick node.

- Area

By area select nodes.

- Node1

Pick node on model to define node 1.

- Node2

Pick node on model to define node 2.

- At Node1

Move node2 to node1.

- At Node2

Move node1 to node2.

- MidPoint

Move node1 and node2 to midpoint.

- Clear

Clear node 1 and 2.

- Reject

Reject last replacement node.

- Accept

Accept replacement node.

- Done

Exit this interface.

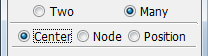

- Center

Take center for replace target position.

- Node

Pick node for replace target node.

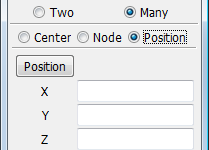

- Position

Call Position Dialog and get target position.

- PickNd

Pick node for replace target position.

- Node

Node id for replace target node.

- Position

Call Position Dialog and get position.

- X

Enter X coordinate of new point 2.

- Y

Enter Y coordinate of new point 2.

- Z

Enter Z coordinate of new point 2.

- Unreference All Nodes

Delete Unreference All Nodes.

- Unreference Element Nodes

Delete Unreference Element Nodes.

- Include Beam3rdNode

Ixclude beam third node in selection.

- Delete

Delete selected nodes.

- Reject

Cancel last deletion.

- Accept

Commit deleted node.

- Done

Exit this interface.

- Node

Define points by node and pick nodes to align.

- PtOnElem

Define points on elements and pick nodes to align.

- Point1

Pick or define point1.

- Point2

Pick or define point2.

- Point1-X

Enter X coordinate of new point 1.

- Point1-Y

Enter Y coordinate of new point 1.

- Point1-Z

Enter Z coordinate of new point 1.

- Point2-X

Enter X coordinate of new point 2.

- Point2-Y

Enter Y coordinate of new point 2.

- Point2-Z

Enter Z coordinate of new point 2.

- ND

Enter id for Node.

- SpNdEQ

Special equal space node alignment.

- Clear

Clear position 1 and 2, and picked nodes.

- ShowNd

Show nodes between the 2 nodes.

- Align

Align nodes on line between points 1 and 2.

- Reject

Reject last aligned node.

- Accept

Accept alignment.

- Done

Exit this interface.

- In Plane

In plane.

- Out Plane

Out plane.

- Pick Nd

Pick node to modify.

- Position

Popup dialog get position.

- X

Enter X coordinate of new position.

- Y

Enter Y coordinate of new position.

- Z

Enter Z coordinate of new position.

- Quality Check

Check element quality when modifying node.

- Reject

Reject last modify node.

- Accept

Accept modified nodes.

- Done

Exit this interface.

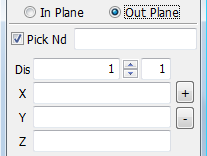

- Pick Nd

Define points by node and pick nodes to align.

- Dis

Input distance.

- X

Enter X coordinate of new position.

- Y

Enter Y coordinate of new position.

- Z

Enter Z coordinate of new position.

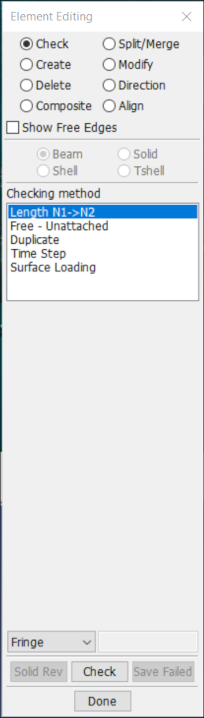

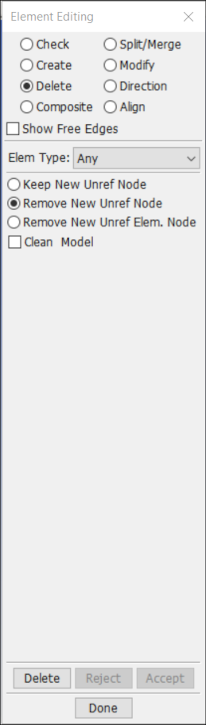

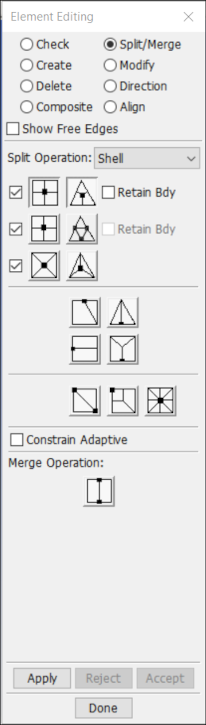

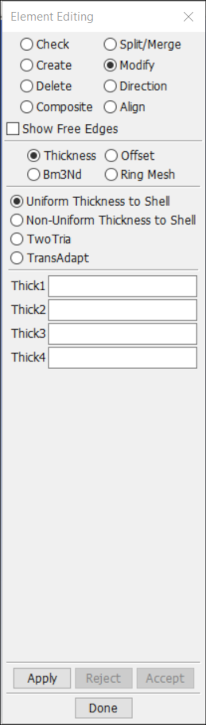

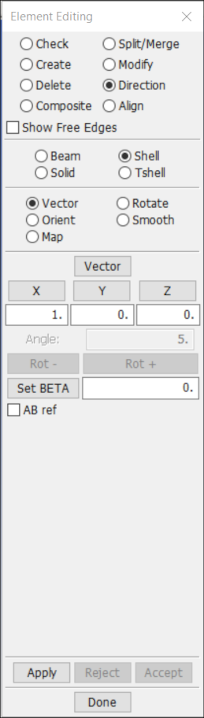

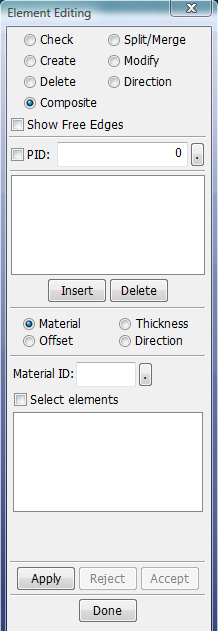

The main purpose of this interface is to provide various mesh quality check and repair functions in one central area. Single element creation for various element types is available, and splitting of shells using various schemes is available for quick repair of an existing mesh.

- Check

Check elements interface.

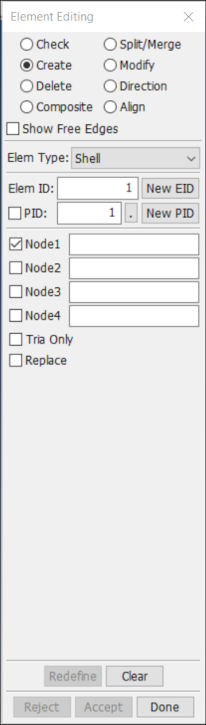

- Create

Create elements interface.

- Delete

Delete elements interface.

- Split/Merge

Split/merge shell elements interface.

- Modify

Modify elements interface.

- Direction

Element orientation (default material direction, AOPT=0) interface.

- Composite

Create/modify *ELEMENT_SHELL_COMPOSITE elements.

- Show Free Edges

Find and show free edges.

- Beam

Check beam elements.

- Shell

Check shell elements.

- Solid

Check solid elements.

- Tshell

Check tshell elements.

- Fringe

Display results option.

- Solid Rev

Change node order in solids.

- Check

Press to perform checking.

- Save Failed

Save elements to general selection buffer.

- Done

Exit this interface.

- Elem Type

Selete element type(Beam/Shell/Solid/Tetra/Hexa/Discrete) to create.

- Elem Id

Input element id.

- New EID

Get new default element ID.

- PID

Pick part id.

- New PID

Get new default part id.

- NODE1

Pick node on model to define node 1.

- NODE2

Pick node on model to define node 2.

- NODE3

Pick node on model to define node 3.

- NODE4

Pick node on model to define node 4.

- Tria Only

Create triangle elements only.

- Replace

Replace an existing shell element.

- Redefine

Create nodes and put into temporary buffer.

- Clear

Clear all fields and set default new node id.

- Reject

Commit created nodes and clear them from screen.

- Accept

Commit created nodes and clear all of them from screen.

- Done

Exit this interface.

- Elem Type

Selete element type to delete.

- Remove Unref Node

Remove unreferenced nodes.

- Delete

Delete elements.

- Reject

Reject deletion(reset).

- Accept

Make deletion permanant.

- Done

Exit this interface.

Pick element at dot to define split location.

Pick element at dot to define split location.

Pick element at dot to define split location.

Pick element at dot to define split location.

Pick element at dot to define split location.

Pick element at dot to define split location.

Pick element at dot to define split location.

Pick element at dot to define split location.

Pick element at dot to define split location.

Pick element at dot to define split location.

Pick element at dot to define split location.

- Apply

Apply split elements.

- Reject

Reject last split elements.

- Accept

Accept all split elements.

- Done

Exit this interface.

- Add Thickness to Shell

Change two triangle.

- Two Tria

Change two triangle.

- Quality Check

Check element quality when modifying element.

- Thick1

Input first thickness value.

- Thick2

Input second thickness value.

- Thick3

Input third thickness value.

- Thick4

Input fourth thickness value.

- Apply

Apply modified elements.

- Reject

Reject last modified elements.

- Accept

Accept all modified elements.

- Done

Exit this interface.

- Shell

Set default material directon for shell elements.

- Vector

Orientate elements by vector.

- Solid

Set default material directon for solid elements.

- Rotate

Incrementally totate element orientation.

- Vector

Rotate orientation by increment in positive direction.

- X

X component of vector.

- Y

Y component of vector.

- Z

Z component of vector.

- Angle

Increment angle for psi(degrees).

- Rot-

Increment psi in negative direction.

- Rot+

Increment psi in positive direction.

- Set PSI

Explicitly set psi angle value for selected elements.

- AB ref

Use Airbag Reference Geometry as base geometry.

- Apply

Apply orientation by vector.

- Reject

Reject the modified element orientations.

- Accept

Accept the modified element orientations.

- Done

Exit this interface.

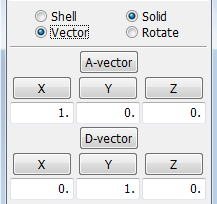

Direction -> Solid and Vector

- A-vector

A-vector for solid _ortho.

- X

X component of A-vector.

- Y

Y component of A-vector.

- Z

Z component of A-vector.

- D-vector

D-vector for solid _ortho.

- X

X component of D-vector.

- Y

Y component of D-vector.

- Z

Z component of D-vector.

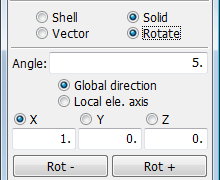

Direction -> Solid and Rotate

- Angle

Increment angle for psi(degrees).

- Global direction

Rotate about element global axis.

- Local ele. axis

Rotate about element local axis.

- X

X component of rotation vector.

- Y

Y component of rotation vector.

- Z

Z component of rotation vector.

- Rot-

Rotate orientation by increment in negative direction.

- Rot+

Rotate orientation by increment in positive direction.

*ELEMENT_SHELL_(OFFSET_)COMPOSITE is created/modified within this interface. Each ply represent an integration point. Tapered layups (when a ply is not covering the whole part) can be created by setting a very small thickness and a *MAT_NULL material at locations where a certain ply does not exist. In this way a whole physical ply can be evaluated over the complete part by selecting the desired integration point.

- PID

Active part to operate on. Pick, type in or select part from list. Only one part is active at any singe time.

- Insert

Insert a new ply below the currently selected. Select none to insert at first position.

- Delete

Delete selected plies for selected elements.

Composite -> Material

- Material ID

Type in material ID or select it from list.

- Select Elements

Put elements that match selected plies and materials in to selection buffer.

- Apply

Apply the material ID to selected plies and elements.

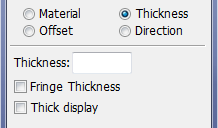

Composite -> Thickness

- Thickness

Enter the thickness to be applied to selected plies.

- Fringe Thickness

Fringe plot the total thickness for selected layers.

- Thick display

Display the layup for each element as blocks.

- Apply

Apply the thickness to selected plies and elements.

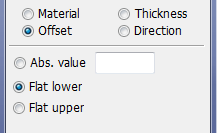

Composite -> Offset

- Abs. value

Enter the absolute value for the offset.

- Flat lower

Let LSPP compute the currently total thickness and apply an offset that locate the nodes at the bottom surface of the stack.

- Flat upper

Let LSPP compute the currently total thickness and apply an offset that locate the nodes at the upper surface of the stack.

- Apply

Apply the offset based on the above selection to the currenly selected plies and elements.

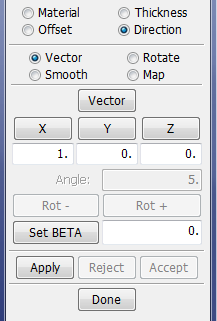

Composite -> Direction -> Vector

Unmodified ply direction: The vector N1->N2 is drawn with a red arrow

Modified ply direction: The vector N1->N2 rotated Bi degrees is drawn with a green arrow

Modified ply direction: The vector N1->N2 rotated Bi + BETA degrees is drawn as a blue arrow. BETA is the angle from the _BETA keyword option.

- Vector

Brings up the vector selection interface.

- X,Y,Z

Set the direction to {1,0,0}, {0,1,0} and {0,0,1} respectively in the direction fields below.

- Set BETA

Set the material angle to a specified value.

- Apply

Apply the direction from the text fields above to selected plies and elements. The vector will be projected on to each element in the element normal direction and the material angle will be computed and applied to the keyword.

- Accept/Reject

Accept or reject the smoothed ply directions.

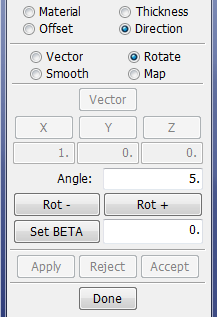

Composite -> Direction -> Rotate

- Angle

Angle increment to rotate.

- Rot +/-

Rotate the direction for selected plies and elements "Angle" degrees about positive or negative element normal direction.

- Accept/Reject

Accept or reject the rotated ply directions.

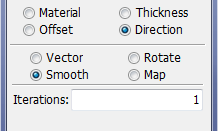

Composite -> Direction -> Smooth

- Iterations

Number of smooth iterations to be performed.

- Apply

Perform smoothing of directions on selected plies and elements by applying the average direction of all attached elements.

- Accept/Reject

Accept or reject the smoothed ply directions.

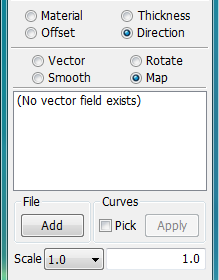

Composite -> Direction -> Map

- File Add

Create a direction vector by adding from (.dvm) file defined as vectors at discrete points.

The format of the file is simply a text file with one line for each coordinate (xc, yc, zc) and the vector (xd, yd, zd) at this point:

x1c y1c z1c x1d y1d z1d x2c y2c z2c x2d y2d z2d . . .

- Curves

Create a vector field from geometric curves.

- Pick

Activate picking of curves.

- Apply

Create the vector field from selected curves.

- Scale

Scale factor for the displayed vectors from the file.

- Apply

Apply the selected discrete vector field map to the selected plies and elements as the directions of those items. This uses the vector that is closest to each element. The vector is then projected onto the element in the element's normal direction, and the corresponding ply angle is computed and applied to the shell.

- Accept/Reject

Accept or reject the smoothed ply directions.

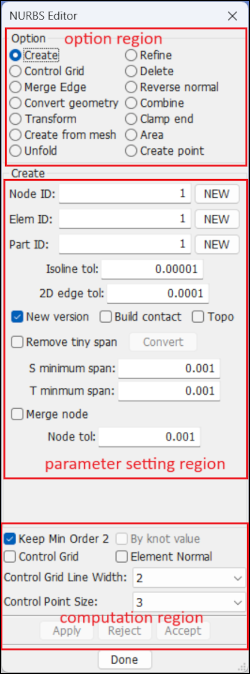

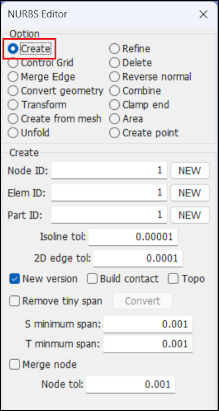

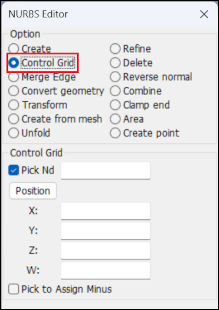

This interface is used to create and modify FEM NURBS element.

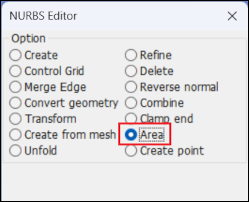

Option region: Option for NURBS 2D element creation or editing.

Create: Create NURBS 2D element by selecting NURBS surface geometry.

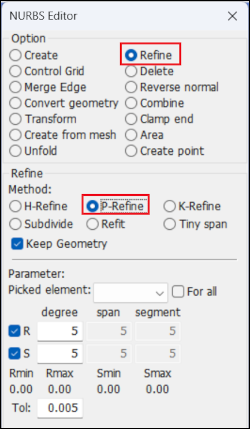

Refine: Select NURBS 2D element to refine.

Control Grid: view coordinates of NURBS 2D patch control points.

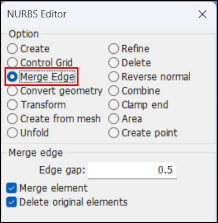

Merge Edge: Merge the common edge between two adjcent NURBS elements.

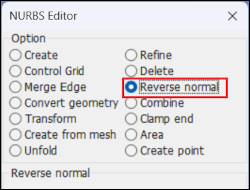

Reverse normal: Select NURBS 2D elements and reverse their normal.

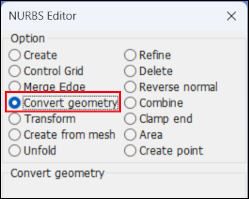

Convert geometry: Convert NURBS 2D element into geometry.

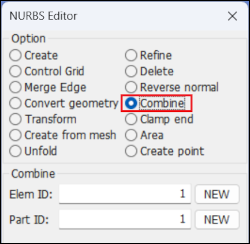

Combine: Combine multiple elements into one element.

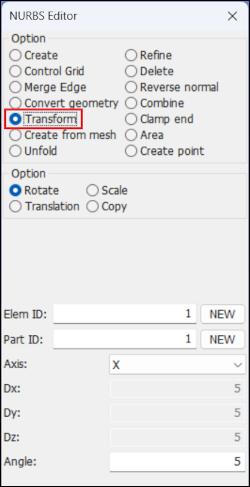

Transform: There are 4 methods to transform NURBS 2D patch: rotate, scale, translate and copy.

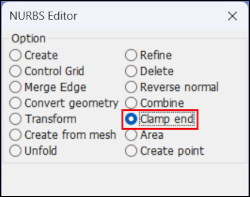

Clamp end: Clamp the knot vector of NURBS 2D patch.

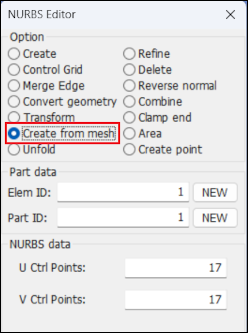

Create from mesh: Create NURBS 2D patch from mesh.

Area: Calculate area of NURBS 2D element.

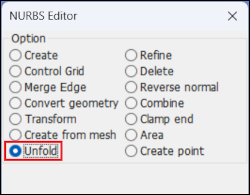

Unfold: Unfold NURBS 2D patch from 3D to 2D plane.

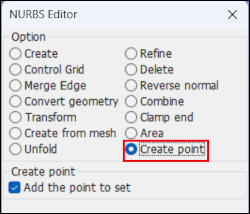

Create point: Pick a point on NURBS 2D patch and calculate the parameter coordinate (u,v) of the point.

Parameter setting region: Setting parameter values in the case of every option.

Computation region: This region is share for all options.

Keep Min Order 2: if this button is checked, the element degree will be checked, in case that the degree in S-direction or t-direction is smaller than 2, the degree will be raised to be 2.

By knot value: this button is use for 'Refine' option only. If this button is checked, all refinement operation is done in 2D domain. Otherwise, all refinement operation is done in 3D physical position.

Control grid: checked this button to show the control point grid.

Element normal: check this button to show the element normal.

Control grid line width: this is for controlling the width of control grid line displaying.

Control point size: this is for controlling the size of control point dsiplaying.

Apply: click this button for computation and preview the result.

Reject: reject the previewed result.

Accept: accept the result and add it into database.

- Create

To create the NURBS element, do the following:

Select radio button 'Create' in 'Option' group.

Select NURB Surface geometry.

Set parameter vlaue for NURBS element creation.

Click 'Apply' to preview the NURBS element.

Click 'Accept' to add the element into database.

Parameter settings:

'Isoline tol': tolerance threshold for detecting if the 2d trimming curve is an isoline in S-direciton or T-direction '2D edge tol': tolerance threshold for 2d edge line 'Build contact': this button is used for he case of multiple nurbs elements creation. If this button is checked, the contact topology data will be created and added into keyword card. 'Remove tiny span': if this button is checked, the tiny span in knot vector will be detected and removed. 'S minimum span': the threshold value for removing tiny span in S knot vector. If the span length is smaller than the specified value, the span will be removed. 'T minimum span': the threshold value for removing tiny span in T knot vector. If the span length is smaller than the specified value, the span wil be removed in T knot vector. 'Merge node': if this button is checked, the overlapped nodes will be detected and merged. 'Node tol': the threshold for overlapped node dectection. - Control Grid

Pick a control point to view its coordinates (x, y, z, w).

- Merge Edge

Merge common edge shared by 2 NURBS elements.

Edge gap: tolerance threshold for detecting if the common edge can be merged.

- Convert geometry

Convert NURBS element into geometry.

- Transform

Rotate, scale, translate, or copy the NURBS element.

Rotate: Rotate NURBS 2D patch around a specified axis. User can select X-axis, Y-axis, Z-axis and vector as axis for rotation.

Scale: Scale NURBS 2D patch by the specified number.

Translation: Translate NURBS 2D patch to a new place.

Copy: Copy NURBS 2D patch.

- Create from mesh

Create NURBS 2D patch from mesh. Picks a mesh and create a new NURBS 2D patch approximating the mesh.

U Ctrl Points: number of control point in u-direction

V Ctrl Points: number of control point in v-direction

- Unfold

Unfold NURBS 2D patch from 3D to 2D plane.

- H-Refine

Refine NURBS element by using the 'H-refinement' method. Select the radio button 'Refine' in option region and select radio button 'H-Refinement' in parameter setting region.

Keep geometry: if this button is checked, the element is refined by symbol operation, otherwise, the element is refined by numerical operation.

Parameter: parameter value setting for H-refinement.

R: parameter values are applied in R-direction.

S: parameter values are applied in S-direction.

Degree: this is disabled in 'H-Refinement'.

span: average length of span for H-refinement.

segment: this is disabled in 'H-Refinement'.

- P-Refine

Refine NURBS element by using he method of 'P-refinement'. User selects radio button 'Refine' in option region and select radio button 'P-Refinement' in parameter setting region.

Keep geometry: if this button is checked, the element is refined by symbol operation, otherwise, the element is refined by numerical operation.

Parameter: parameter value setting for h-refinement.

R: parameter values are applied in R-direction.

S: parameter values are applied in S-direction.

Degree: element degree number.

span: this is disabled.

segment: this is disabled.

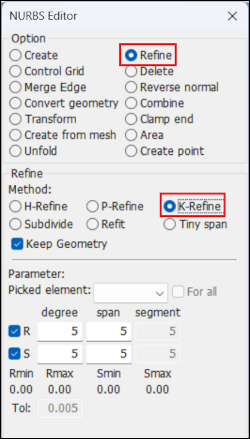

- K-Refine

Refine NURBS element by using he method of 'K-refinement'. Select the radio button 'Refine' in the option region and select radio button 'K-Refinement' in parameter setting region.

Keep geometry: if this button is checked, the element is refined by symbol operation, otherwise, the element is refined by numerical operation.

Parameter: parameter value setting for h-refinement.

R: parameter values are applied in R-direction.

S: parameter values are applied in S-direction.

Degree: element degree number.

span: average length of span for h-refinement.

Segment : this is disabled for 'K-Refinement'.

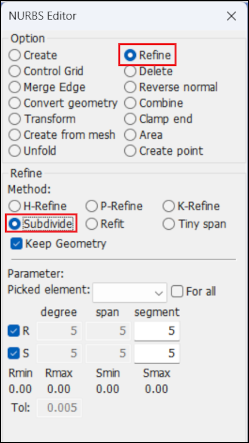

- Refine-Subdivide

Refine NURBS element by using he method of 'Subdivide'. User selects radio button 'Refine' in option region and select radio button 'Subdivide' in parameter setting region.

Keep geometry: if this button is checked, the element is refined by symbol operation, otherwise, the element is refined by numerical operation.

Parameter: parameter value setting for h-refinement.

R: parameter values are applied in R-direction.

S: parameter values are applied in S-direction.

Degree: this is disabled. 'span': this is disabled.

Segment : an integer number for how many equivalent span will be created in element.

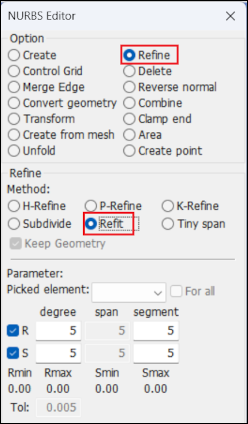

- Refine-Refit

Refine NURBS element by using he method of 'Refit'. User selects radio button 'Refine' in option region and select radio button 'Refit' in parameter setting region.

Keep geometry: this button is disable, the element is refitted by numerical operation.

Parameter: parameter value setting for h-refinement.

R: parameter values are applied in R-direction.

S: parameter values are applied in S-direction.

Degree: element degree number.

span: this is disable.

segment: an integer number for how many equivalent span will be created in element.

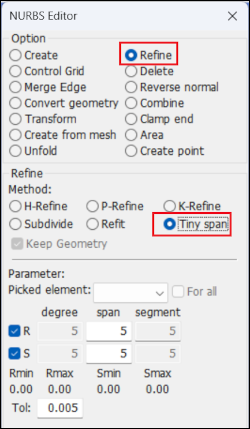

- Refine-Tiny span

Refine NURBS element by using he method of 'Tiny span '. User selects radio button 'Refine' in option region and select radio button 'Tiny span ' in parameter setting region.

Keep geometry: this button is disabled.

Parameter: parameter value setting for h-refinement.

R: parameter values are applied in R-direction.

S: parameter values are applied in S-direction.

Degree: this is disabled.

span: average length of span for h-refinement.

segment: this is disabled.

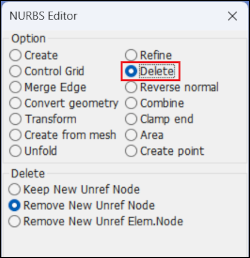

- Delete

Remove the NURBS element.

- Reverse normal

Reverse NURBS element normal.

- Combine

Combine multiple NURBS elements into a single element.

- Clamp End

Clamp the knot vector of NURBS 2D patch. For example, if a NURBS 2D patch has knot vector {-2, -1, 0, 1, 2, 3, 4} on u-direction and the degree is 2, after clamped, the knot vector is {0,0,0, 1, 2, 2, 2}.

- Area

Calculate and display the NURBS 2D element area.

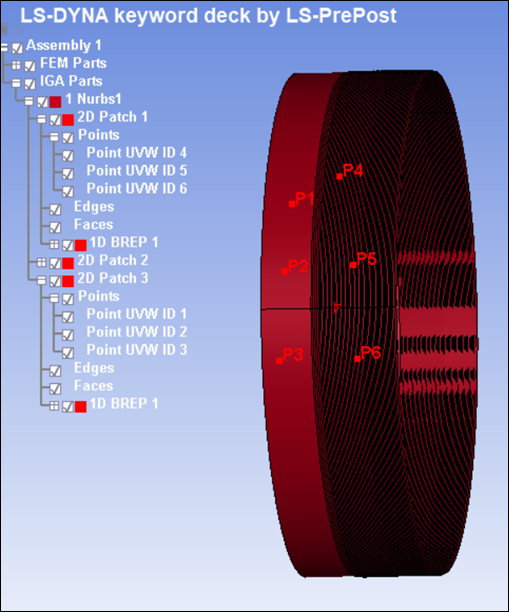

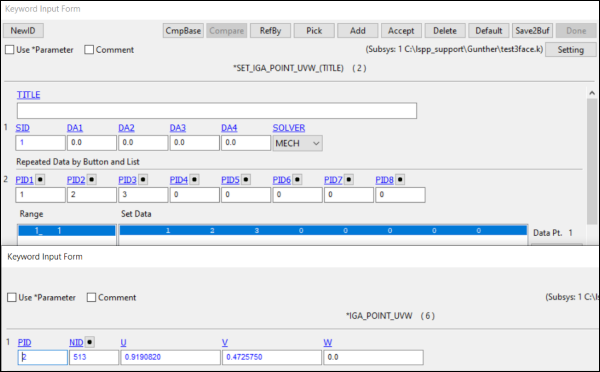

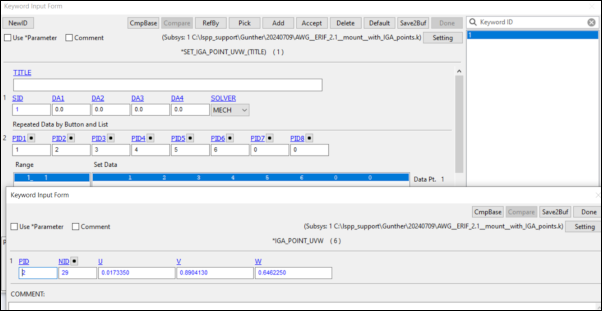

- Create point

Create entity *IGA_POINT_UVW on NURBS 2D element. If the button ‘Add the point to set’ is checked, the new created *IGA_POINT_UVW will be added to the entity *SET_IGA_POINT_UVW. If the button ‘Add the point to set’ is unchecked, the new *IGA_POINT_UVW will be unreferenced.

To create *IGA_POINT_UVW on a NURBS 2D patch, user click one location on a patch and click , the *IGA_POINT_UVW shows, click to save the point into database. The point label will be added in the GUI tree.

The (U, V, W) coordinates of the point are viewable in the keyword card.

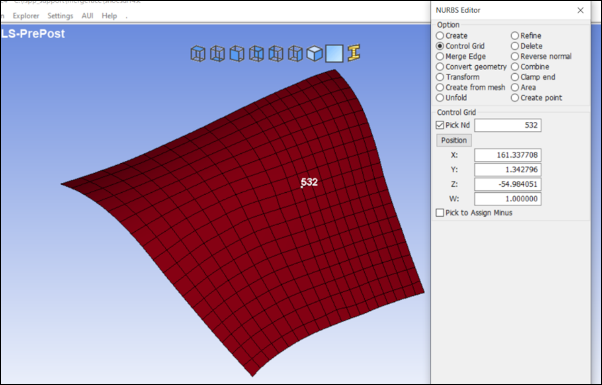

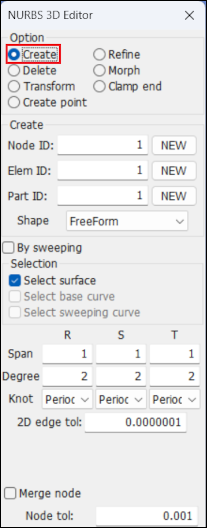

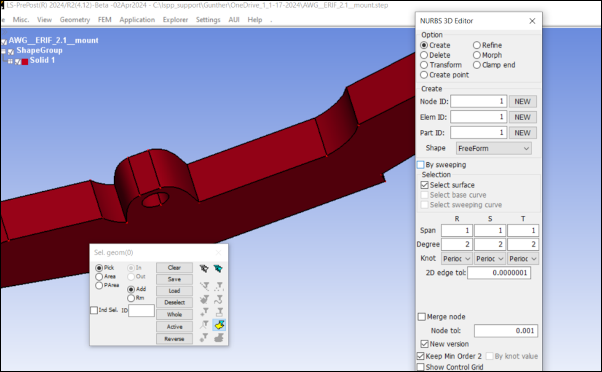

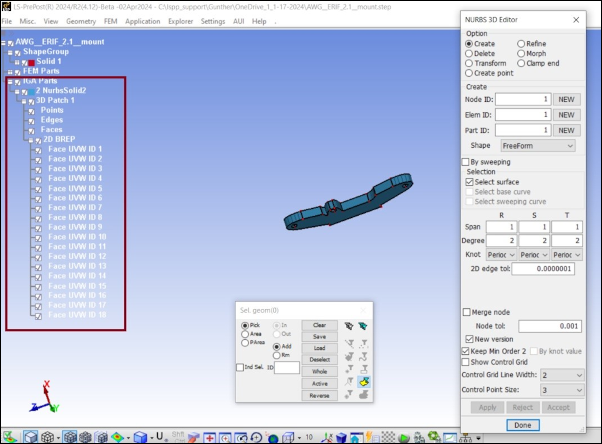

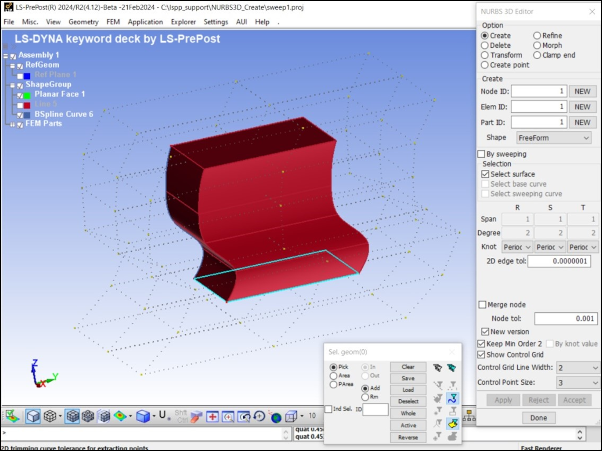

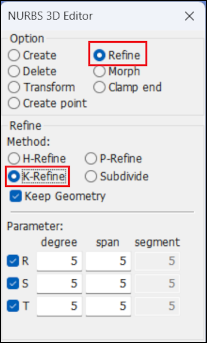

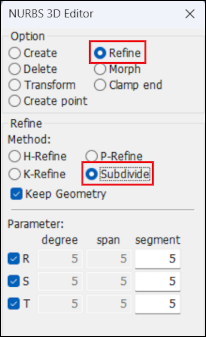

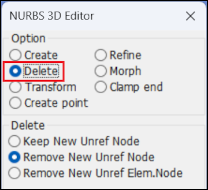

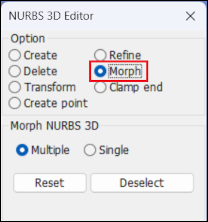

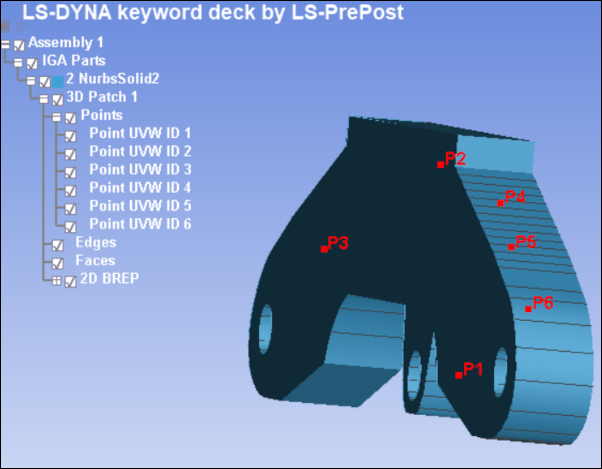

This interface is used to create and modify FEM NURBS 3D entity.

Option region: Option for NURBS 3D element creation or editing.

Create: Create NURBS 3D element by selecting NURBS surface geometry.

Refine: Select NURBS 3D element to refine.

Morph: Select NURBS 3D element, select control point to morph it.

Transform: Transform the selected NURBS 3D element.

Delete: Delete the selected NURBS 3D element.

Clamp end: Change the selected NURBS 3D element to be clamped on the end of knot vector.

Parameter setting region: Setting parameter values in the case of every option.

Computation region: This region is shared for all options.

Keep Min Order 2: If this button is checked, the element degree will be checked, in case that the degree in S-direction or t-direction is smaller than 2, the degree will be raised to be 2. 'By knot value': this button is use for 'Refine' option only. If this button is checked, all refinement operation is done in 2D domain. Otherwise, all refinement operation is doen in 3D physical position.

Show Control Grid: Check this button to show the control point grid.

Element normal: Check this button to show the element normal.

Control grid line width: This controls the display width of the control grid lines.

Control point size: This controls the display size of control points.

Apply: Click this button for computation and preview the result.

Reject: Reject the previewed result.

Accept: Accept the result and add it into database.

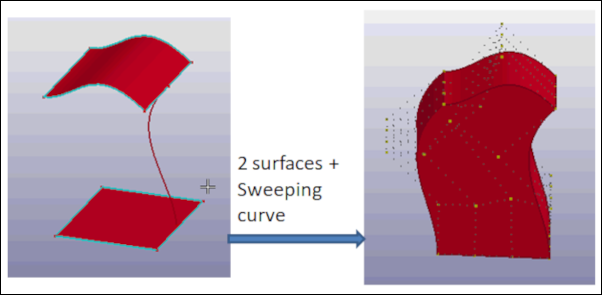

- Create

Create a 3D NURBS element.

To Create NURBS 3D element:

Select radio button 'Create' in 'Option' group.

Check the box for 'By sweeping', check the button 'Select surface' and select 1 or 2 NURB Surface geometry.

Check the box for 'Select sweeping curve', select a curve for the ridge.

Click button 'Apply' to preview the NURBS element and click button' Accept' to add the element into database.

- Parameter setting

- 2D edge tol

Tolerance threshold for 2d edge line.

- Merge node

If this button is checked, overlapped nodes will be detected and merged.

- Node tol

The threshold for overlapped node dectection.

- NURBS 3D element creation.

'Create' selected

Property value can be set by using ‘Span’, ‘Degree’, ‘Knot’ property during element creation.

IGA entity can be displayed in the GUI tree after .k file was imported or 3D element was created.

Activate Periodic property for ‘free-form’ and ‘sweeping’ NURBS 3D creation.

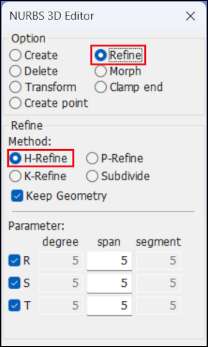

- H-Refine

Refine NURBS element by using he method of 'H-refinement'. User selects radio button 'Refine' in option region and select radio button 'H-Refinement' in parameter setting region.

Keep geometry: if this button is checked, the element is refined by symbol operation, otherwise, the element is refined by numerical operation.

Parameter: parameter value setting for h-refinement.

R: parameter values are applied in R-direction.

S: parameter values are applied in S-direction.

Degree: this is disabled in 'H-Refinement'.

span: average length of span for h-refinement.

segment: this is disabled in 'H-Refinement'.

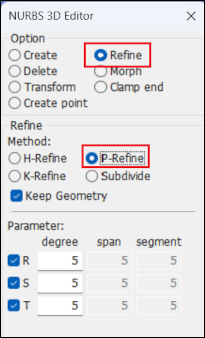

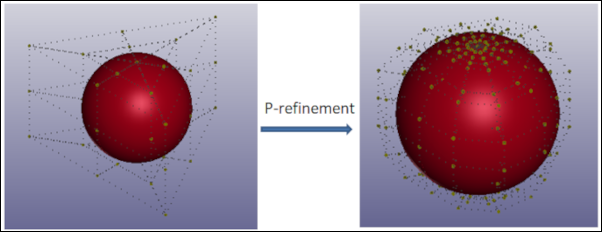

- P-Refine

Refine NURBS element by using he method of 'P-refinement'. User selects radio button 'Refine' in option region and select radio button 'P-Refinement' in parameter setting region.

Keep geometry: if this button is checked, the element is refined by symbol operation, otherwise, the element is refined by numerical operation.

Parameter: parameter value setting for h-refinement.

R: parameter values are applied in R-direction.

S: parameter values are applied in S-direction.

Degree: element degree number.

span: this is disabled.

segment: this is disable.

- K-Refine

Refine NURBS element by using he method of 'K-refinement'. Select the 'Refine' radio button in the option region and select radio button 'P-Refinement' in parameter setting region.

Keep geometry: if this button is checked, the element is refined by symbol operation, otherwise, the element is refined by numerical operation.

Parameter: parameter value setting for h-refinement.

R: parameter values are applied in R-direction.

S: parameter values are applied in S-direction.

Degree: element degree number.

Span: average length of span for h-refinement.

Segment: this is disabled for 'K-Refinement'.

- Refine-Subdivide

Refine NURBS element by using he method of 'Subdivide'. User selects radio button 'Refine' in option region and select radio button 'Subdivide' in parameter setting region.

Keep geometry: if this button is checked, the element is refined by symbol operation, otherwise, the element is refined by numerical operation.

Parameter: parameter value setting for h-refinement.

R: parameter values are applied in R-direction.

S: parameter values are applied in S-direction.

Degree: this is disable.

span: this is disable.

segment: an integer number for how many equivalent span will be created in element.

- Delete

Remove the 3D NURBS element.

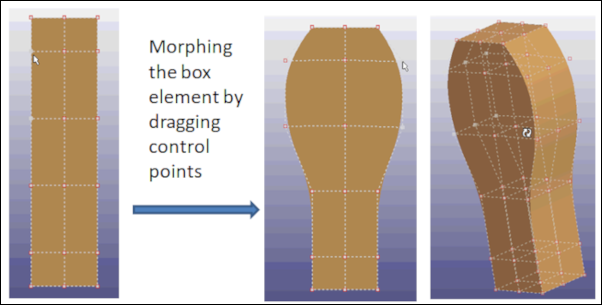

- Morph

Morph NURBS 3D patch by dragging control points.

Multiple: pick multiple control points and drag them at same time for morphing;

Single: pick a single control point and drag it for morphing;

Reset: set the morphed NURBS 3D patch to the original position;

Deselect: set the picked control points to be un-selected.

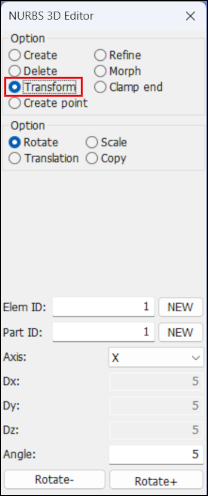

- Transform

Refine NURBS element by using he method of 'Tiny span '. User selects radio button 'Refine' in option region and select radio button 'Tiny span ' in parameter setting region.

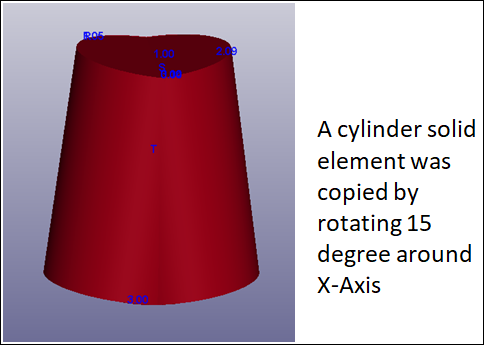

Rotate: create a new NURBS 3D patch by rotating the original one around an axis. The axis can be defined as ‘X-Axis’, ‘Y-Axis’, ‘Z-Axis’ or other vector.

Scale: create a new NURBS 3D patch by scaling the original one.

Translate: create a new NURBS 3D patch by translating the original one.

Copy: create a new NURBS 3D patch by copying the original one.

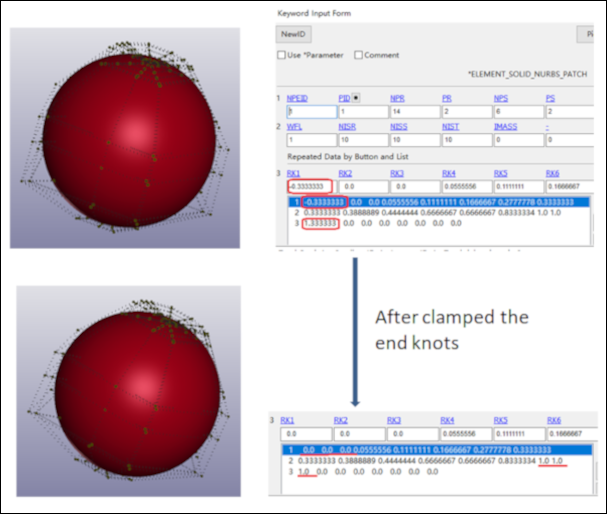

- Clamp end

Clamp the knot vector of NURBS 3D patch. For example, if a NURBS 3D patch has knot vector {-2, -1, 0, 1, 2, 3, 4} on u-direction and the degree is 2, after clamped, the knot vector is {0,0,0, 1, 2, 2, 2}.

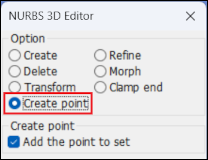

- Create point

Create entity *IGA_POINT_UVW on NURBS 3D element. If the button ‘Add the point to set’ is checked, the new created *IGA_POINT_UVW will be added to the entity *SET_IGA_POINT_UVW. If the button ‘Add the point to set’ is unchecked, the new *IGA_POINT_UVW will be unreferenced.

To create *IGA_POINT_UVW on a NURBS 3D patch, user click one location on a patch and click ‘Apply’ button, the *IGA_POINT_UVW shows, user click ‘Accept’ button to save the point into database. The point label will be added in the GUI tree.

The (U, V, W) coordinates of the point can be seen in keyword card.

This interface is for modifying model or part mass properties to obtain desired mass, center of mass, and inertia.

- Current

Measure the current mass, center of mass, and inertia properties (which serve as starting reference values).

- Desired

Assign desired mass properties using one of two methods: (1) add *ELEMENT_MASS to selected nodes or (2) convert *PART to *PART_INERTIA (if necessary) and assign specified properties.

- Mass

Desired mass.

- X

X-coordinate for current center of gravity.

- Y

Y-coordinate for current center of gravity.

- Z

Z-coordinate for current center of gravity.

- Ixx

Current Ixx component for mass moment of inertia.

- Iyy

Current Iyy component for mass moment of inertia.

- Izz

Current Izz component for mass moment of inertia.

- Ixy

Current Ixy component for mass moment of inertia.

- Iyz

Current Iyz component for mass moment of inertia.

- Ixz

Current Ixz component for mass moment of inertia.

- Compute

Automatically fill in mass properties for VISIBLE entities.

- Apply

Apply mass trim.

- Reject

Reject mass trim.

- Accept

Accept mass trim.

- Done

Exit mass trim interface.

- *PART_INERITA

Select ONE rigid body part to use as *PART_INERTIA to obtain desired properties.

- *ELEMENT_MASS

Select nodes to generate *ELEMENT_MASS on, trying to obtain desired properties.

- Include

Are mass and inertia for the selected part included in Current properties.

- PID

Optionally enter part ID for generated mass elements.

- MASS

Desired mass.

- C.o.M

Optionally modify Center of Mass.

- Tol.

Acceptable deviation to the desired center of mass.

- X

X-coordinate for desired center of gravity.

- Y

Y-coordinate for desired center of gravity.

- Z

Z-coordinate for desired center of gravity.

- Inertia

Optionally modify mass moment of inertia.

- Ixx

Desired Ixx component for mass moment of inertia.

- Iyy

Desired Iyy component for mass moment of inertia.

- Izz

Desired Izz component for mass moment of inertia.

- Ixy

Desired Ixy component for mass moment of inertia.

- Iyz

Desired Iyz component for mass moment of inertia.

- Ixz

Desired Ixz component for mass moment of inertia.

This interface is used for generating spotweld elements from a file containing hundreds or thousands of weld locations, and can generate both solid and beam type 9 spotweld elements, in doing so automatically creates the following keywords: *PART, *SECTION, *SET_NODE, *SET_PART, *MAT_SPOTWELD, *HOURGLASS, and *CONTACT_SPOTWELD.

- Sample

Click here to find more regarding Spotweld.

- Open

Load spotweld file.

- Primer

Select spotweld file format(Primer, Master Weld File, XML, Custom).

- Unload WF

Delete weld info. Weld elements will NOT be deleted.

- Search radius

Radius to search for elements to connect with weld element.

- Min Length

Min length for weld elements.

Display weld data.

Display welds which will be smaller than Min Length.

Display welds which will fail being created.

Display welds which will be sucessfully created.

Display welds which have been successfully created.

- Beam

Create Beam element for the welds.

- Solid

Create Solid element for the welds.

- One Elem

Enter x/y/z-coordinates of minimum and maximum point.

- Four Elems

Enter number of elements along x/y/z.

- GUI

Set properties from GUI.

- File

Set properties from file.

- Constant

Constant diameter for weld.

- Curve ID

Diameter as function of min sheet thickness (DEFINE_CURVE ID).

- Built-in

Diameter = 5.*sqrt(min_thickness).

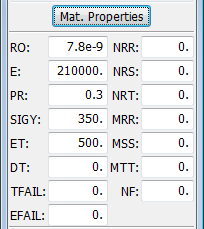

- Mat. Properties

Set material properties.

- Create

Create spotweld.

- Reject

Reject the previewed spotwelds.

- Accept

Accept the previewed spotwelds.

- Done

Exit spotweld generation interface.

- RO

Density.

- E

Young's modulus.

- PR

Poisson's ratio.

- SIGY

Initial yield stress.

- ET

Hardening modulus.

- DT

Time step size for mass scaling.

- TFAIL

Failure time if nonzero.

- EFAIL

Effective plastic strain at failure.

- NRR

Axial force resultant at failure, rr direction.

- NRS

Axial force resultant at failure, rs direction.

- NRT

Axial force resultant at failure, rt direction.

- MRR

Torsional moment resultant at failure, rr direction.

- MSS

Moment resultant at failure, ss direction.

- MTT

Moment resultant at failure, tt direction.

- NF

Number of force vectors stored for filtering.

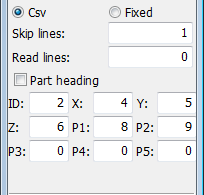

- Csv

Read comma separated file.

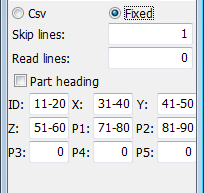

- Fixed

Read file with fixed field width.

- Skip lines

Skip this number of lines in the beginning of file.

- Raad lines

Read this number of lines after \"Skip lines\". 0 = End Of File.

- Part heading

Use part HEADING instead of part ID for PIDx fields.

- ID

Field index for weld ID (not mandatory). Zero is permitted.

- Z

Field index for Z coordinate.

- P3

Field index for LS_DYNA part ID to connect with this weld.

- X

Field index for X coordinate.

- P1

Field index for LS_DYNA part ID to connect with this weld.

- P4

Field index for LS_DYNA part ID to connect with this weld.

- Y

Field index for Y coordinate.

- P2

Field index for LS_DYNA part ID to connect with this weld.

- P5

Field index for LS_DYNA part ID to connect with this weld.

- ID

Columns for weld ID (not mandatory). Single zero is permitted.

- Z

Columns for Z coordinate.

- P3

Columns for LS_DYNA part ID to connect with this weld.

- X

Columns for X coordinate.

- P1

Columns for LS_DYNA part ID to connect with this weld.

- P4

Columns for LS_DYNA part ID to connect with this weld.

- Y

Columns for Y coordinate.

- P2

Columns for LS_DYNA part ID to connect with this weld.

- P5

Columns for LS_DYNA part ID to connect with this weld.

This interface is used to generate particles for SPH modeling. Box, Sphere, Cylinder, Cone, and ShellVolume: SPH Mass = Den*Pitch^3 (where Den = User Specified Density).

NOTE: The Fill% option creates a "partial fill" which means filling up the body with MASS (not filling up to a specified volume percentage). So for the SolidNodes method, if the solid mesh is not of constant element size, it may look odd, and the density of the SPH part will not be what has been specified. For all other methods, it will fill up to the given percentage of both mass and volume.

- Box

Generate SPH in user defined box.

- Sphere

Generate SPH in user defined Sphere.

- Cylinder

Generate SPH in user defined Cylinder.

- Cone

Generate SPH in user defined Cone.

- SolidCenter

SPH particles are created in the center of each solid element, and the mass for each SPH element will be EleVol*Den (where EleVol = Volume of Each Solid Element and Den = User Specified Density).

- SolidNodes

SPH particles are created at existing solid element nodes. The mass for every SPH element will be constant and equal to Vol*Den/N (where Vol = Total Volume of Solid Elements, Den = User Specified Density, N = Number of Solid Element Nodes).

- ShellVolume

The body to be filled must consist of a "water tight" volume of shell element (with no free edges). However, shells normals do not need to be consistent.

- Sample1

Show how to create Sph with Box method.

- Sample2

Show how to create Sph with ShellVolume method.

- Method

Select method to create SPH elements.

- Clearance

Leave gap between SPH nodes and elements.

- Fill%

Fill volume level(%).

- PID

Enter part Id for the unfilled particles (if needed).

- Den

Enter density of the unfilled portion (if needed).

- DirX

Set fill direction in X.

- DirY

Set fill direction in Y.

- DirZ

Set fill direction in Z.

- NumX

No. of particles in X direction or radial direction).

- NumY

No. of particles in Y direction or radial direction).

- NumZ

No. of particles in Z direction or radial direction).

- Density

Enter density of the unfilled portion (if needed).

- Save

Save or replace sph property for each selected part.

- Start Nd ID

Enter starting node Id for the SPH nodes.

- Start Part ID

Enter part Id for the SPH part.

- PMin

Click to activate Position Dialog for min. coordinates.

- PMax

Click to activate Position Dialog for max. coordinates.

- X

Enter X coordintate for min. or max. coordinate point.

- Y

Enter Y coordintate for min. or max. coordinate point.

- Z

Enter Z coordintate for min. or max. coordinate point.

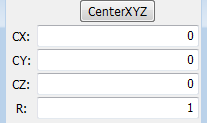

- CenterXYZ

Click to activate Position Interface for center coordinates.

- CX

Enter X coordintate for center of the sphere.

- CY

Enter Y coordintate for center of the sphere.

- CZ

Enter Z coordintate for center of the sphere.

- R

Enter Radius of the sphere.

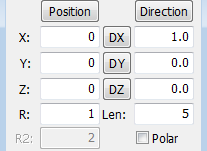

- Position

Activate Position Interface for base point center of cylinder or cone.

- X

Enter X coordintate for base point of the cylinder or cone.

- Y

Enter Y coordintate for base point of the cylinder or cone.

- Z

Enter Z coordintate for base point of the cylinder or cone.

- Direction

Activate Direction Dialog for direction of cylinder.

- DX

Set direction X with 1 or -1.

- DY

Set direction Y with 1 or -1.

- DZ

Set direction Z with 1 or -1.

- R

Enter radius of cylinder or cone.

- Len

Enter length of cylinder or cone.

- R2

Enter end point radius of cone.

- Polar

Generate particals in polar coord. system.

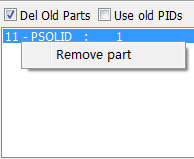

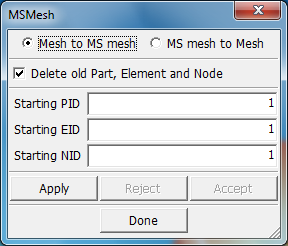

Use this interface to convert between Multiple Solver mesh and mesh.

- Mesh to MSMesh

Convert mesh to MSMesh.

- MS mesh to Mesh

Convert MSMesh to Mesh.

- Delete old Part,Element and Node

decide whether or not to delete old part ,element and node.

- Starting PID

Enter starting part ID.

- Starting EID

Enter starting element ID.

- Starting NID

Enter starting node ID.

- Apply

Apply selected conversion.

- Reject

Reject the convert operation.

- Accept

Accept the conversation.

- Done

Exit MSMesh interface.

This interface is used for mapping *INITIAL_STRESS, including plastic strain, shell thickness and history variables, from one part to another geometrically overlapping part. Here is a detailed description for each map option:

- Shell to Solid mapping

The coordinate for each solid element integration point will be projected on to the closest shell element. This will be the shell element from which the results will be mapped from.

In order to map from a shell to solid element part, you must specify the two topological sides on the solid part(s) that correspond to the upper and lower surface of the shell elements. These are called "Side 1" and "Side 2" in the interface below.

A parametric position beween "Side 1" and "Side 2" will then be computed for each integration point in the solid elements. Data from the through-thickness shell integration point which best matches this parametric position will be selected for mapping of the results.

If the shell has four in-plane result values, an inter- or extrapolated value will be computed at the point on the shell which is closest to the solid element integration point. This inter/extrapolated value will be assigned to the solid element integration point. Meaning that it can actually become larger than the largest of the four shell in-plane values, or smaller than the smallest. Plastic strain will however never be extrapolated to a negative value. Only stress and plastic strain are interpolated, not history variables. History variable values will be assigned from the closest integration point.

- Solid to Solid mapping

The integration point to map to can either be inside or outside the solid elements with results. If it's outside, the closest point on the closest element will be found. The stresses and plastic strain will be inter/extra-polated to this location and the value will be assigned to the integration point. History variable values will be assigned from the closest integration point, they will not be interpolated or extrapolated.

- Shell to Shell mapping

The number of integration points specified on SECTION_SHELL will be used when deciding how many through-thickness integration points will be used for the generated *INITIAL_STRESS keyword. Much like Shell to Solid mapping, the closest parametric coordinate for the through-thickness integration point will be used for assigning the values. In-plane inter/extra-polation is done for the stress and plastic strain. Plastic strain will however never be extrapolated to a negative value. History variable values will be assigned from the closest integration point.

- Solid to Shell mapping

"Side 1" and "Side 2" must be defined for the solid part(s). The *INITIAL_STRESS and thickness can be mapped in two different ways, A and B:

A: If leaving "Target IPs" field empty, the initial_stress results will be mapped to the integration points specified by the *SECTION_SHELL of the shell part and thickness will be applied to *ELEMENT_SHELL_THICKNESS. For each integration point in the shell, the closest points on "Side 1" and "Side 2" will be found. The thickness of the shell will be set to the distance between these two points. The stress will be extracted from the parametric position between "Side 1" and "Side 2" corresponding to the parametric coordinate of the through-thickness shell integration point.

B: Mapping results from a multi-part layered (composite) solid to ELEMENT_SHELL_COMPOSITE can be activated by specifying a list of through-thickness integration point number(s) in the "Target IPs" text field. The thickness between "Side 1" and "Side 2" will be evenly distributed to the specified integration points. The stress results will be extracted from the parametric position between "Side 1" and "Side 2" corresponding to an even distributed of the specified integration points.

In-plane inter/extra-polation is done for the stress and plastic strain. Plastic strain will however not be extrapolated to a negative value. History variable values will be assigned from the closest integration point.

For example, if the solid structure is composed of three parts with two stiff outer skins and a softer core, the mapping to the *ELEMENT_SHELL_COMPOSITE must be made in three steps. The option "Fully integrated" must remain the same for all three mappings as the number of in-plane integration points must remain the same in a *INITIAL_STRESS_SHELL keyword. "Target IPs" must be specified for the three mappings as well to get a mapping to *ELEMENT_SHELL_COMPOSITE. The target integration points are numbered 1 as the first integration point at the bottom and in sequential order to the integration point at the top.

- Shell to Solid

Mesh by number of elements.

- Solid to Shell

Mesh by element size.

- Shell to Shell

Mesh by existing points of line.

- Solid to Shell

Enter or adjust number of elements along line 1.

- Target IPs

Bias radio.

- From Parts

Bias from two end.

- To Parts

Enter or adjust number of elements along line 2.

- Fully Integrated

Enter or adjust number of elements along line 3.

- Side 1

Enter or adjust number of elements along line 4.

- Side 2

Enter or select target part ID.

- *INITIAL_STRESS

Get new default part ID.

- Plastic Strain

Perform meshing.

- Thickness

Accept the created mesh.

- History Variables

Reject the created mesh or the selected lines.

- The "From - To"-table

Exit the nLMesh Interface.

- Map

Perform the map operation.

- Done

Exit result mapping interface.