User-programmable features (UPFs) are available with coupled-field elements PLANE222, PLANE223, SOLID225, SOLID226, and SOLID227. Coupled-field UPFs enable you to customize element characteristics, material models, loads, constitutive equations, and output items. The UPFs give you access to all the applicable element results at any location within the element, making it easier to program nonlinearities. The coupled-field UPFs are integrated into the element standard workflow, so you can customize the element property of interest without writing a user element or a user material model from scratch. For your convenience, there are several utility functions available to help you access element results and other element information.

The following topics are available:

User-programmable capabilities are available with coupled-field elements PLANE222, PLANE223, SOLID225, SOLID226, and SOLID227 for the following coupled-diffusion analyses:

Structural-diffusion (KEYOPT(1) = 100001)

Thermal-diffusion (KEYOPT(1) = 100010)

Electric-diffusion (KEYOPT(1) = 100100)

Structural-thermal-diffusion (KEYOPT(1) = 100011)

Structural-electric-diffusion (KEYOPT(1) = 100101)

Structural-thermal-electric-diffusion (KEYOPT(1) = 100111)

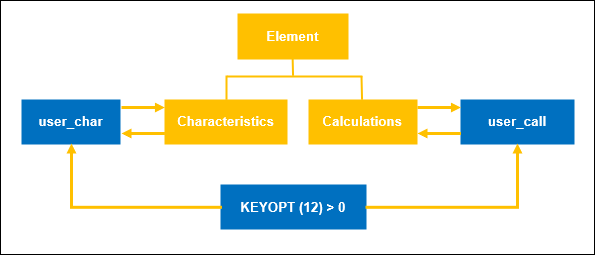

To activate user-programmable features (UPFs), set KEYOPT(12) = 1 on the coupled-field elements used in any of the above analyses. Activating UPFs enables you to define or modify the element material properties, loads, constitutive equations, as well as element results. Multiple functions and subroutines are available to provide you convenient access the element and solution information.

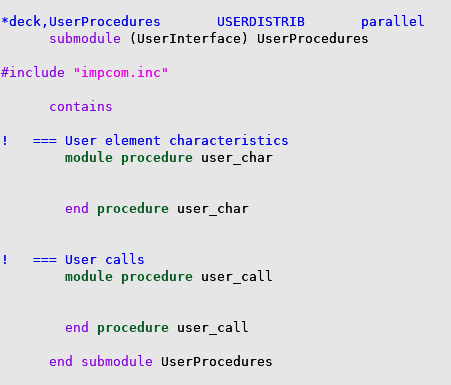

The UserProcedures.F file contains the source code for the routines

that provide an interface to the coupled-field element code and allow you to

customize its behavior. This file can be found on the distribution medium along with

other user routines (see Studying the Mechanical APDL User Routines).

The coupled-field UPF code is implemented as a Fortran submodule programming unit that contains two procedures (Figure 2.1: UserProcedures.F routine ):

user_charTo modify element characteristics, including number of work variables, saved variables, SMISC and NMISC items, element matrix symmetry, and element nonlinearity (see Modifying the Coupled-field Element Characteristics).

user_callTo modify element calculations, such as material properties, loads, element matrices, and load vectors using the utility functions described in Customizing Element Calculations.

Both procedures must be present for UserProcedures.F to be successfully compiled and linked.

You can alter the submodule name (UserProcedures in Figure 2.1: UserProcedures.F routine ) but not the module name (UserInterface).

When compiling UserProcedures.F, the UPF tools will automatically access the ancestor module file userinterface.mod that must be present at the following path:

Linux

/ansys_inc/v251/ansys/customize/include/userinterface.mod

Windows

Program Files\ANSYS Inc\V251\ansys\customize\include\userinterface.mod

The element code makes additional calls to the two subroutines

user_char and user_call when

user-programmable features (UPFs) for a coupled-field analysis are enabled

(KEYOPT(12) = 1). These calls enable you to customize element characteristics and

element calculations by modifying the user_char and

user_call procedures, respectively.

The next sections describe how user_char and

user_call procedures interact with the standard coupled-field

element behavior. The following abbreviations are used in the description of input

and output arguments:

| int – integer |

| dp – double precision |

| log – logical |

| sc – scalar |

| ar – array |

| in – input |

| out – output |

Element characteristics are programmed as an array of integer numbers

(approximately 200) that define the element and control its behavior. The

user_char procedure allows you to reset some of these

characteristics. All other characteristics default automatically.

user_char is called once from the element routine that sets

these default characteristics.

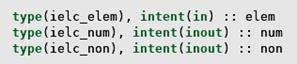

The information about element characteristics is passed to

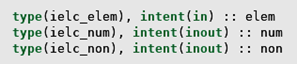

user_char in the form of three data structures: num, non, and elem. The interface information (Figure 2.3: user_char Procedure Interface) resides in the UserInterface module and is not

replicated in the procedure body.

A brief description of user_char arguments is given in

the following table.

Table 2.1: user_char Procedure Arguments

| Name | Type | Content |

|---|---|---|

| num | ielc_num | sizes of element data arrays |

| non | ielc_non | element formulations |

| elem | ielc_elem | element definitions |

Components of the num structure can be used to customize some of the element characteristics as follows:

num%

itemwhere:

item- name of the characteristics.

Table 2.2: num Structure Components

Item | Description | Type |

| rcon | number of real constants | int sc |

| smisc | number of summable miscellaneous items | |

| nmisc | number of non-summable miscellaneous items | |

| usvr | number of user saved variables | |

| uwrk | number of user variables |

For example,

num%rcon = 5

sets the number of real constants to 5, and

num%smisc = num%smisc + 2

adds 2 to the default number of summable miscellaneous. Note that you can only increment the number of real constants (num%rcon), the number of summable (num%smisc), or non-summable (num%nmisc) variables. In other words, the custom number of real constants or miscellaneous variables cannot not be less than the number of standard real constants miscellaneous variables listed in element descriptions (Element Reference).

Components of the non structure can be used to set the characteristics that control the element formulation:

non%

itemwhere:

item- name of the element property.

Table 2.3: non Structure Components

Item | Description | Type | Value |

| sym | element matrix | int sc |

0 – symmetric 1 – unsymmetric 2 – symmetric, but may become unsymmetric due to certain material models |

| lin | element linearity |

0 – linear element 1 – nonlinear element |

For example,

non%sym = 1

sets the element matrix to nonsymmetric.

When modifying the above element characteristics, you can access (use in read-only mode) the following components of the elem structure:

elem%

itemwhere:

item- name of the characteristics.

Table 2.4: elem Structure Components

Item | Decription | Type |

|---|---|---|

| type | element type | int sc |

| name | element name | |

| keyop(kyop) | element keyoption (kyop = 1 from 18) |

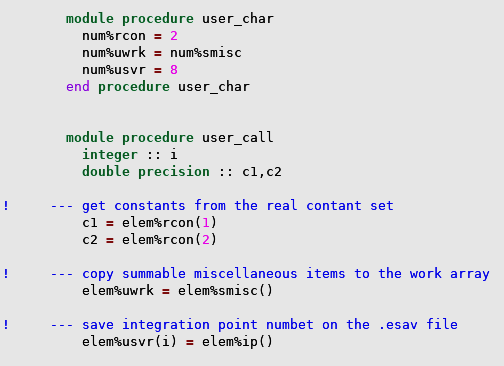

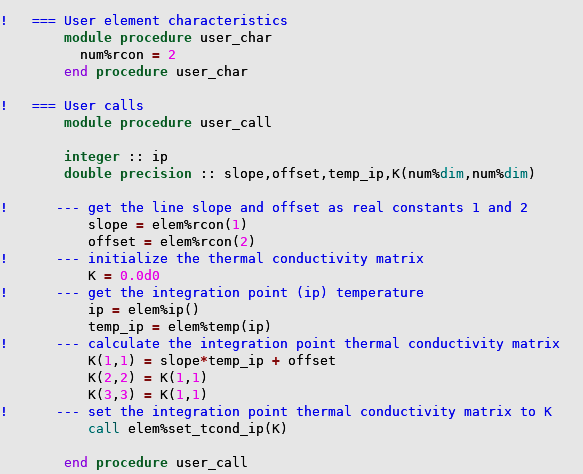

The following example illustrates customization of the element characteristics using the

user_call procedure.

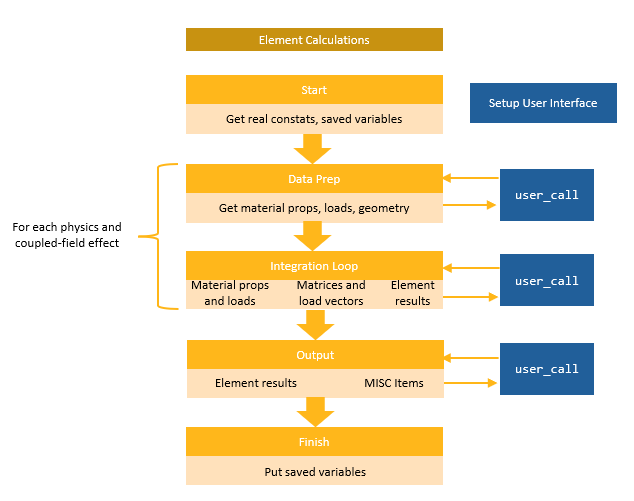

Typical element calculations have three distinct phases: data preparation, integration point calculations, and the output of element results (Figure 2.4: Element Calculation Workflow).

Data preparation — Material properties and element loads are first evaluated during the data preparation stage.

Integration point calculations — Material properties, loads, and element results are then evaluated at each integration point using available solution information, for example, element results from the previous iteration. Element matrices and load vectors are formed in the same integration loop using numerical integration over the element volume. Note that data preparation and numerical integration are performed for each physics and coupled-field effect.

Output of element results — During the output stage, all calculated element quantities are processed, and element results are written to the result file.

The user_call procedure is called multiple times during

the three stages of element calculations. You can use

user_call to customize the evaluation of material

properties and loads at both the data preparation and integration point stage,

modify the constitutive relations at the integration point stage, and modify the

element miscellaneous items in the output phase of element calculations.

The information about the coupled-field element that can be passed to and used in

user_call is in the form of four structures: num, elem, solu, and scope. The

interface information (Figure 2.5: user_call Procedure Interface) resides in the

UserInterface module and is not replicated in the procedure body.

A brief description of user_call arguments is given in

the following table.

Table 2.5: user_call Procedure Arguments

| Name | Type | Content |

|---|---|---|

| num | user_num | Numbers that characterize element entities. |

| elem | user_elem | Components and procedures to access element characteristics,

nodes, coordinates, shape functions, and results.

Procedures to perform operations on element results and print these results. Procedures to define or modify material properties, loads, constitutive equations, and output quantities |

| solu | user_solu | Solution settings and data to control element calculations. |

| scope | user_scope | Parameters to define the scope of element calculations. |

The components and type-bound procedures of these structures are described in detail below.

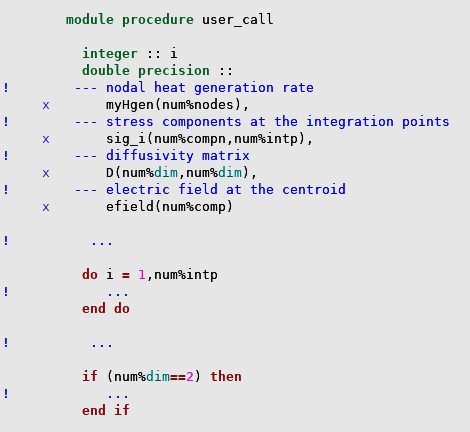

Element numbers (num)

The num structure consists

of frequently used

element

numerical

property

data. All the components of this structure are integer scalar

parameters. You can use these parameters to define the sizes of variables in the

user_call procedure or control do-loop

and if-constructs:

num%

itemwhere:

item– name of element property

Table 2.6: Element Numerical Property Data

Item | Description | Type |

| dim | element dimensionality (2 or 3) | int sc |

| nodes | number of element nodes | |

| cnodes | number of element corner nodes | |

| edges | number of element edges | |

| faces | number of faces | |

| ptsf | number of surface load values per face | |

| fluxes | number of element fluxes (= faces*ptsf) | |

| compn | number of stress or strain vector components | |

| comp | number of field or flux vector components (= dim) | |

| intp | number of integration points | |

| dofs | number of degrees of freedom (DOFs) per node | |

| rcon | number of real constants[a] | |

| uwrk | number of user work variables[a] | |

| usvr | number of user saved variables [a] | |

| smisc | number of SMISC items [a] | |

| nmisc | number of NMISC items [a] |

[a] Default or set in

user_char

Element Data (elem)

The elem structure consists of components and type-bound procedures that let you access the following data and use it to customize element behavior:

Element characteristics and attributes, data arrays.

Nodal coordinates, element shape functions, and shape function derivatives.

Nodal solution results, such as displacements, temperature, electric potential, and concentration.

Element results, such as stress and strains, thermal gradient and flux, electric field and current density, concentration gradient and diffusion flux, as well as miscellaneous output items.

The elem type-bound procedures also allow you to:

Perform some operations on the element nodal data, such as interpolation for missing midside nodes and gradient calculation.

Print nodal and element results in a formatted fashion.

The procedures that allow you to customize material properties, loads, constitutive relations, and element output (the so-called set_ and add_ subroutines) are also implemented as type-bound procedures of the elem structure.

Element data can be accessed as elem components

elem%

item

or type-bound procedures

elem%

item()where:

item- name of the element entity

Table 2.7: Element Characteristics and Attributes

Item | Description | Output Type | ||

|---|---|---|---|---|

| id | element number | int sc | ||

| ip() | current integration point number | |||

| type | element type | |||

| name | element name | |||

| mat | material number | |||

| real | real constant set number | |||

| csys | element coordinate system number | |||

| keyop() | element keyoptions | int array (18) | ||

| nodes() | element nodes | int array (num%nodes) | ||

| shape | element form shape:

| int sc | ||

| ashape | actual element shape:

| |||

| midn | element midside nodes key: .true. if element has midsize nodes | log sc | ||

| vol() | element volume | dp sc |

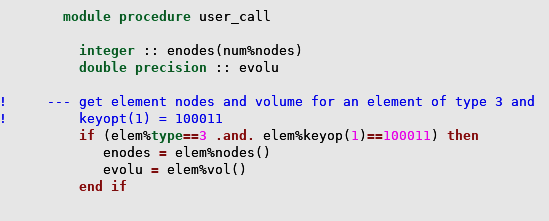

For example,

elem%id

returns the element number, and

elem%ip()

returns the integration

point number for the current call to user_call. The use of

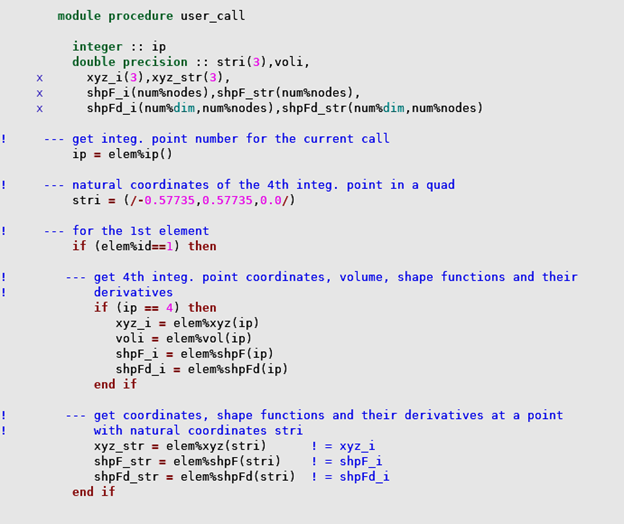

some typical element properties is illustrated in the following example.

The elem structure gives you access

to several arrays of element data, listed in the following table. You can access

the whole array as

elem%

item()

or a single element of this array as

elem%

item(n)where:

item– name of the data array

n– array entry number

The arrays are read-only, except for the usvr and uwrk arrays that you can

both read from and write into. Arrays usvr and uwrk can be used for data

storage. Data will be saved between multiple calls made to

user_call between the Start and Finish stages of the

element calculations (Figure 2.4: Element Calculation Workflow). Data stored in

the usvr array is also written to the .esav file.

The following element properties (Table 2.9: Element Coordinates and Shape Data) require you to specify the location where the property is calculated:

elem%

item(loc)where:

item- name of the element property

loc- location within the element:none = nodes

0 = centroid

ip = integration point number

(s,t,r) = natural coordinates of a point within the element

Table 2.9: Element Coordinates and Shape Data

Item | Description | Location | Output Type |

|---|---|---|---|

| xyz[a] | X, Y, Z coordinates | nodes | dp ar(3,num%nodes) |

| centroid |

dp ar(3) | ||

| integration point |

dp ar(3) | ||

| (s,t,r) |

dp ar(3) | ||

| shpF | shape functions |

centroid integration point (s,t,r) | dp ar (num%nodes) |

| shpFd[a] | shape function derivatives | dp ar (num%dim,num%nodes) | |

| vol[a] | volume | integration point | dp sc |

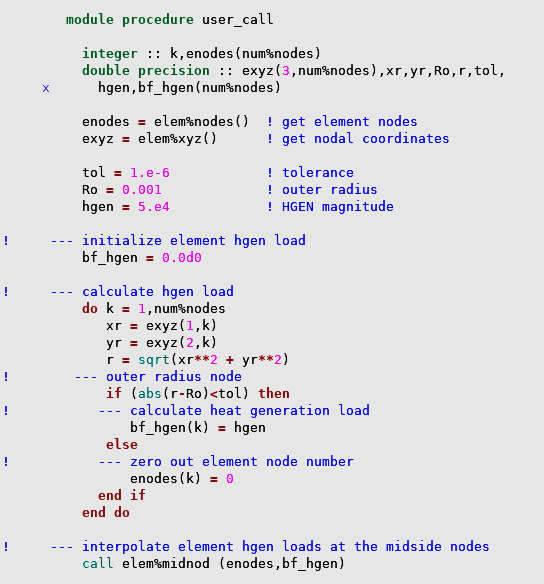

You can also perform the following operations on a set of scalar nodal values.

Midside node interpolation

call elem%midnod(

nodes,var)where:

nodes– list of element nodes with missing midside nodes (in)var– array of nodal variables to be interpolated (in/out)This subroutine modifies the array of nodal variables (

var) by filling up the missing midside node entries with interpolated values.Table 2.10: Element Midside Node Interpolation

Name Description Input Type Input / Output Type midnod midside node interpolation int ar(num%nodes) dp ar(num%nodes) The following example mimics a heat generation body load defined on the outer radius of a circular 2-D model.

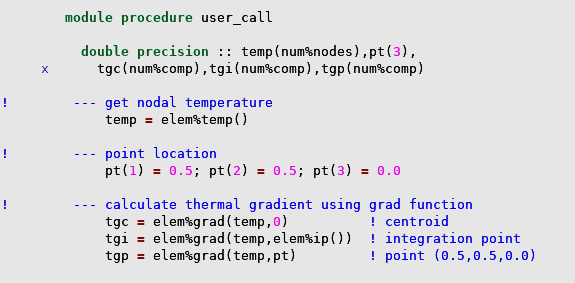

Gradient calculation

elem%grad(

var,loc)where:

var– array of nodal variables,loc– location within the element:0 = centroid

ip = integration point number

(s,t,r) = natural coordinates of a point within the element

The resulting array contains the derivatives of the nodal variable

varwith respect to X, Y, and Z in the element coordinate system.Table 2.11: Element Gradient Operation

Name Description Input Type Location Output Type grad gradient dp ar(num%nodes) centroid dp ar(num%nodes) integration point (s,t,r)

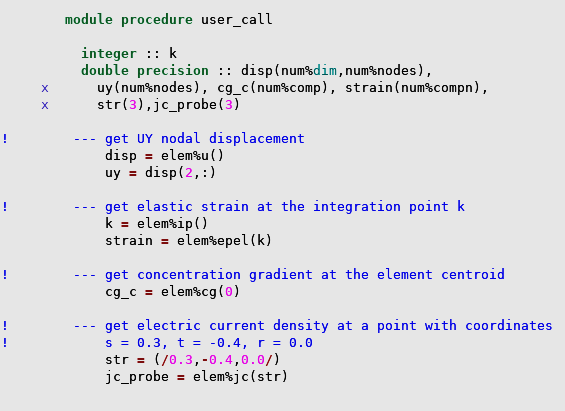

You can access nodal and element results using the elem type-bound procedures (see Table 2.12: Element Results).

elem%

item(loc)where:

item- name of the element result

loc- location within the element:none = nodes

0 = centroid

ip = integration point number

(s,t,r) = natural coordinates of a point

Table 2.12: Element Results

| Location | Output |

|---|---|---|

| nodes | dp ar(num%dim,num%nodes) |

| centroid | dp ar(num,%dim) | |

| integration point | dp ar(num,%dim) | |

| (s,t,r) | dp ar(num,%dim) | |

| nodes | dp ar(num%nodes) |

| centroid | dp sc | |

| integration point | dp sc | |

| (s,t,r) | dp sc | |

| nodes | dp ar(num%compn,num%nodes) |

| centroid | dp ar(num%compn) | |

| integration point | dp ar(num%compn) | |

| (s,t,r) | dp ar(num%compn) | |

| nodes |

dp ar(num%comp,num%nodes) |

| centroid | dp ar(num%comp) | |

| integration point | dp ar(num%comp) | |

| (s,t,r) | dp ar(num%comp) | |

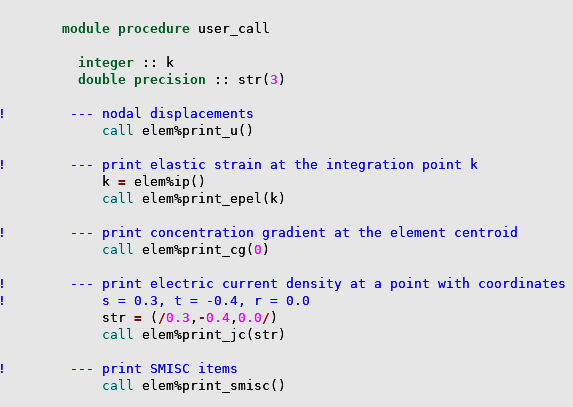

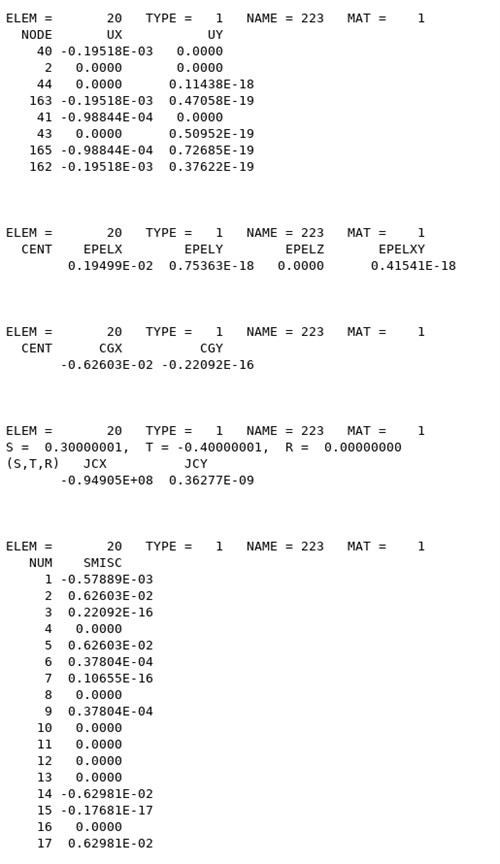

You can print element results in a formatted way using the elem type-bound print_ procedures (see Table 2.13: Print Element Results).

call elem%print_

item(loc)where:

item- name of the element result

loc- location within the element:none = nodes

0 = centroid

ip = integration point number

(s,t,r) = natural coordinates of a point

Note: elem%print_ routines are not supported for simulations using distributed-memoy parallel (DMP) processing.

Table 2.13: Print Element Results

Item | Description | Location |

|---|---|---|

| u | displacement |

nodes centroid integration point (s,t,r) |

|

temp volt conc |

temperature electric potential concentration | |

|

eptt epel epth epdi eppl s |

total strain elastic strain thermal strain diffusion strain plastic strain stress | |

|

tg tf ef jc cg df |

thermal gradient thermal flux electric field electric current concentration gradient diffusion flux | |

| smisc | summable miscellaneous | - |

| nmisc | non-summable miscellaneous |

To define or modify materials, loads, constitutive equations, and output quantities, use the set_ and add_ elem type-bound procedures, respectively.

To assign a value

varto the element propertyitem, use:

call elem%set_ item_level(var)To modify the element property

itemby adding the valuevarto it, use:

call elem%add_ item_level(var)where:

item- name of the user-programmable element quantitylevel- level of customization:

p = data prep ip = integration point o = output

var- variable that overwrites (set_) or is being added (add_) to the element quantityitem

User-programmable element quantities that can be defined or modified by the set_ and add_ elem type-bound procedures are listed in the following table.

Table 2.14: User-programmable Element Quantities

Item | Description | Level | Variable Type |

|---|---|---|---|

| tcond | thermal conductivity matrix | p | dp ar(num%comp,num%comp) |

| ip | |||

| hgen | heat generation rate | p | dp ar(num%nodes) |

| ip | dp sc | ||

| hflux | heat flux surface load | p | dp ar(num%fluxes) |

| tf | thermal flux | ip | dp ar(num%comp) |

| econd | electric conductivity matrix | p | dp ar(num%comp,num%comp) |

| ip | |||

| jc | integration point current density | ip | dp ar(num%comp) |

| diffu | diffusivity matrix | p | dp ar(num%comp,num%comp) |

| ip | |||

| csat | saturated concentration | p | dp sc |

| ip | |||

| dgen | heat generation rate | p | dp ar(num%nodes) |

| ip | dp sc | ||

| dflux | diffusion flux surface load | p | dp ar(num%fluxes) |

| df | diffusion flux | ip | dp ar(num%comp) |

| smisc[a] | summable miscellaneous | o | dp ar(num%smisc) |

| nmisc[a] | non-summable miscellaneous | o | dp ar(num%nmisc) |

[a] Only the set_ procedure can be used with the smisc and nmisc items.

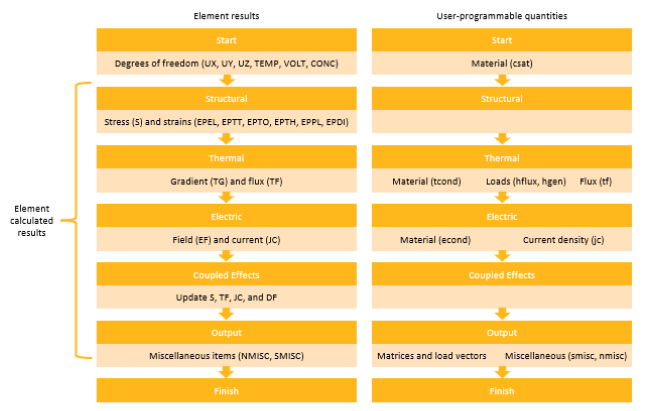

When modifying the user-programmable element quantities using the set_ and add_ subroutines (Table 2.14: User-programmable Element Quantities), you may need to access the nodal DOF and element calculated results. While the nodal DOF results are always available at the start of the element calculation, the element calculated results such as strains, fields, fluxes, and miscellaneous items are calculated in a sequence shown on the left of Figure 2.6: Element Results Calculation vs. User-Programmable Quantities Workflow. Therefore, element calculated results may or may not be ready at the time when a set_ or add_ subroutine is called to update a user-programmable quantity as shown on the right of Figure 2.6: Element Results Calculation vs. User-Programmable Quantities Workflow.

For example, when customizing thermal quantities such as thermal conductivity (tcond) or heat generation rate (hgen) in a structural-thermal-diffusion analysis, you can access structural results such as stress and elastic strain using elem%s(loc) and elem%epel(loc) functions, respectively, because the standard structural results are calculated before the thermal quantities are customized. On the other hand, standard diffusion results such as concentration gradient and diffusion flux are calculated after the customization of thermal properties, and results reported by elem%cg(loc) and elem%df(loc) during thermal calculations may not be up to date.

When a needed standard element result has not yet been calculated, you can independently derive it from the DOF solution using the element shape functions (Table 2.9: Element Coordinates and Shape Data) or the gradient operation (Table 2.11: Element Gradient Operation).

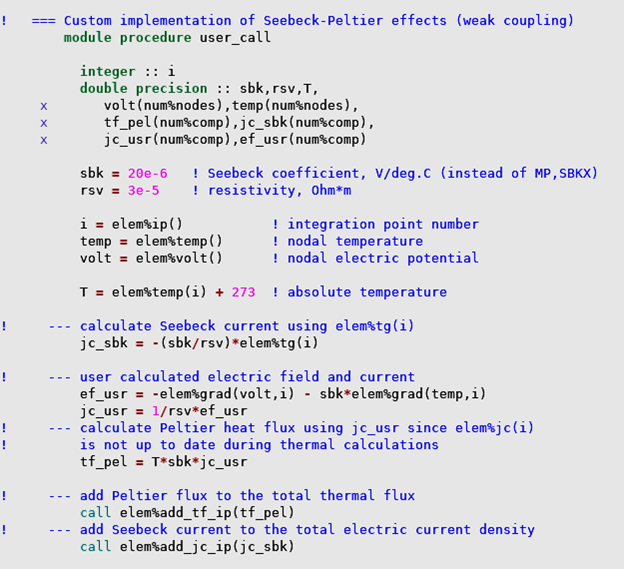

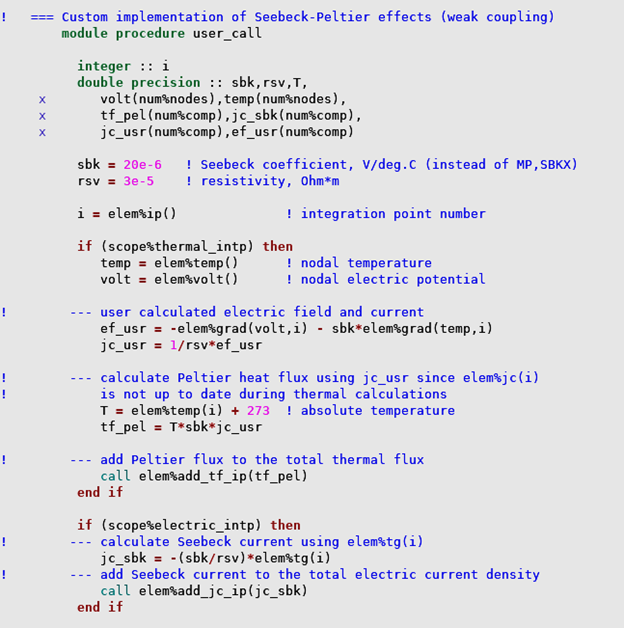

In the following example, both the thermal flux (tf) and the electric current density (jc) are customized at the integration point level to mimic the Seebeck-Peltier effects without specifying MP,SBKX that would invoke the standard coupled-field effect (Thermoelectrics in the Theory Reference). The integration point (i) thermal gradient needed for the calculation of the Seebeck electric current density (jc_usr) is already available as elem%tg(i) when elem%add_jc_ip(jc_usr) is called and does not need to be recalculated. On the other hand, the Peltier thermal flux calculation needs the total electric current density that will become available only in the next (electric) stage of the element workflow (Figure 2.6: Element Results Calculation vs. User-Programmable Quantities Workflow). To overcome this limitation, you can independently calculate the total current density (jc_usr) needed for the Peltier heat contribution to thermal flux as shown in the example below.

Note that the set_ and add_ procedures are designed so that the respective element

variable is updated only when the program is ready to accept it. Therefore, the

sequence in which these subroutines are called within

user_call is irrelevant.

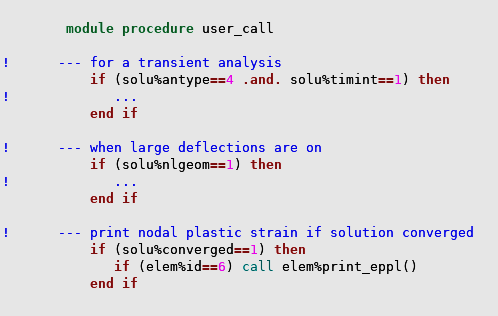

Solution Settings and Controls (solu)

The structure solu contains frequently used

solution settings that you can use to control the calculations in

user_call. They can be accessed as:

solu%

itemwhere:

item– name of the solution parameter

Table 2.15: Solution Settings

Item | Description | Output Type | Output Value | ||||

|---|---|---|---|---|---|---|---|

| antype | analysis type | int sc | ANTYPE command | ||||

| nlgeom | geometric nonlinearities | int sc | 0 – off 1 – on | ||||

| nropt | Newton-Raphson option | int sc | NROPT command:

| ||||

| nrunsym | Newton-Raphson option set to UNSYM | int sc | 0 – default 1 – if NROPT,UNSYM | ||||

| xtrap | extrapolation of integration point results to element corner nodes (ERESX command) | int sc | 0 – copy 1 – extrapolate except in elements with active plasticity 2 – extrapolate | ||||

| timint | transient effects (TIMINT command) | int sc | 0 – off 1 – on | ||||

| ldstep | current load step number | int sc | |||||

| isubst | current substep number | int sc | |||||

| nsubst | maximum number of substeps | int sc | NSUBST command setting | ||||

| ieqitr | current iteration number | int sc | |||||

| neqitr | maximum number of iterations | int sc | NEQIT command setting | ||||

| output | element output pass (result calculation) | int sc | 0 – off 1 – on | ||||

| svrupd | history (state) variables update | int sc | 0 – not updated 1 – updated | ||||

| converged | converged solution | int sc | 0 – non converged 1 – converged | ||||

| time%beg | time at the beginning of the current step | dp sc | |||||

| time%end | time at the end of the current load step | dp sc | TIME command setting | ||||

| time%cur | current time value | dp sc | |||||

| time%inc | current time increment | dp sc | |||||

| time%prv | previous time value | dp sc | |||||

| time%ino | previous time increment | dp sc | |||||

| toffst | temperature offset from absolute zero to zero | dp sc | TOFFST command setting |

Scope of calculations (scope)

The user_call procedure is called multiple times from

different parts of the element code, including every integration point of each

physics (Figure 2.4: Element Calculation Workflow). It may be inefficient to

repeat the same calculations every time the user_call

procedure is called. The components of the scope data structure allow you to narrow down the calculations to a

specific location in the element workflow.

Using the scope variables, you can limit your code to the physics, data preparation or integration loop of that physics, to a specific element quantity, or to the element output calculations:

scope%

calcscope%

calc_levelscope%

calc_level_itemwhere:

calc- area of element calculations

level- level of customization

prep = data prep intp = integration point

item- name of the user-programmable element quantity

All variables in the scope data structure are of logical type.

Table 2.16: Parameters to Define the Scope of User Calculations

| Name | Description | Type |

| thermal | thermal calculations | log sc |

| thermal_prep | thermal data prep | |

|

thermal_prep_tcond thermal_prep_hgen thermal_prep_hflux | input tcond, hgen, hflux calculation | |

| thermal_intp | thermal integration loop | |

|

thermal_intp_hgen thermal_intp_tcond thermal_intp_tf | integration point tcond, hgen, tf calculation | |

| electric | electric calculations | log sc |

| electric_prep | electric data prep | |

| electric_prep_econd | input econd calculation | |

| electric_intp | electric integration loop | |

|

electric_intp_econd electric_intp_jc | integration point tcond, jc | |

| diffusion | diffusion calculations | log sc |

| diffusion_prep | diffusion data prep | |

|

diffusion_prep_diffu diffusion_prep_csat diffusion_prep_dgen diffusion_prep_dflux | input diffu, csat, dgen, dflux calculation | |

| diffusion_intp | diffusion integration loop | |

|

diffusion_intp_diffu diffusion_intp_csat diffusion_intp_dgen diffusion_intp_df | integration point diffu, csat, dgen, df calculation | |

| output | output calculations | log sc |

|

output_smisc output_nmisc | smisc and nmisc calculation | |

A more efficient version of the user_call Example 2.11: Customizing Thermoelectric Constitutive Equations is shown in the following example.

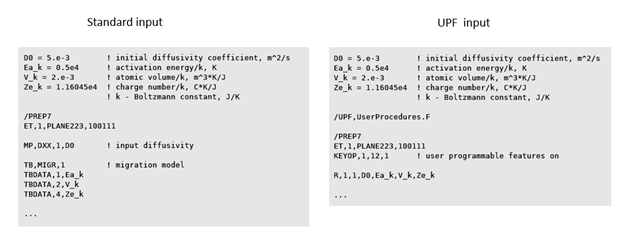

This example demonstrates the coupled-field user-programmable features (UPFs) by reproducing the standard element calculations performed when the migration model (TB,MIGR) is specified The coupled-field UPFs are activated by setting KEYOPT(12) to 1 on a coupled-field element with diffusion degrees-of-freedom. The diffusion and migration parameters (D0, Ea/k, V/k, and Ze/k) are input as real constants instead of TB,MIGR that triggers the standard calculations (Figure 2.7: Standard vs. User-programmable APDL Input).

The following calculations are performed in UserProcedures.F:

the integration point diffusivity matrix D is customized using the elem%set_diffu_ip procedure

the diffusion flux constitutive equation is customized to include stress-migration flux (df_s) and electro-migration flux (df_e), and added to the total diffusion flux using the elem%add_df_ip procedure

The summable miscellaneous items corresponding to the pure diffusion flux (DFCX, DFCY, DFCZ,DFCSUM ), stress-migration flux (DFSX, DFSY, DFSZ, DFSSUM), and electro-migration flux (DFEX, DFEY, DFEZ,DFESUM), respectively, are calculated at the element centroid and output using the elem%set_smisc_o procedure

*deck,UserProcedures USERDISTRIB parallel

submodule (UserInterface) UserMigr

#include "impcom.inc"

contains

module procedure user_char

num%rcon = 5 ! number of real constants

non%lin = 1 ! nonlinear analyses

end procedure user_char

module procedure user_call

integer :: i

double precision :: D0,Ea_k,V_k,Z_k,C,T,Dt,

x D(num%dim,num%dim),

x stress(num%compn,num%nodes),sigH(num%nodes),

x df_c(num%comp),df_s(num%comp),df_e(num%comp),

x df_s_m,df_e_m,df_c_m,smisc(num%smisc)

! --- get migration parameters as real constants

D0 = elem%rcon(2) ! initial diffusivity coefficient

Ea_k = elem%rcon(3) ! activation energy/k

V_k = elem%rcon(4) ! atomic volume/k

Z_k = elem%rcon(5) ! charge number/k

! --- nodal stress

stress = elem%s()

! --- hydrostatic stress

sigH = (stress(1,:) + stress(2,:) + stress(3,:))/3.

! --- integration point:

if (scope%diffusion_intp) then

i = elem%ip() ! number

C = elem%conc(i) ! concentration

T = elem%temp(i) + solu%toffst ! temperature

Dt = D0*exp(-Ea_k/T) ! diffusivity

D = 0.0d0 ! diffusivity matrix

D(1,1) = Dt; D(2,2) = Dt; D(3,3) = Dt

! --- set integration point diffusivity

call elem%set_diffu_ip(D)

! --- hydrostatic stress gradient driven migration

df_s = (V_k*C/T)*matmul(D,elem%grad(sigH,i))

! --- electric field driven migration

df_e = (Z_k*C/T)*matmul(D,elem%ef(i))

! --- add df_s to the total diffusion flux

call elem%add_df_ip(df_s)

! --- add df_e to the total diffusion flux

call elem%add_df_ip(df_e)

end if

! --- centroidal calculations

if (scope%output) then

C = elem%conc(0) ! concentration

T = elem%temp(0) + solu%toffst ! temperature

Dt = D0*exp(-Ea_k/T) ! diffusivity

df_c = -Dt*elem%grad(elem%conc(),0)

df_s = Dt*V_k*C*elem%grad(sigH,0)/T

df_e = Dt*Z_k*C*elem%ef(0)/T

df_c_m = sqrt(df_c(1)**2 + df_c(2)**2 + df_c(3)**2)

df_s_m = sqrt(df_s(1)**2 + df_s(2)**2 + df_s(3)**2)

df_e_m = sqrt(df_e(1)**2 + df_e(2)**2 + df_e(3)**2)

! --- save magnitudes of diffusion fluxes as nmiscs

smisc = elem%smisc() ! copy standard smisc

! --- store diffusion flux

smisc(2) = df_c(1)

smisc(3) = df_c(2)

if (num%comp==3) smisc(4) = df_c(3)

smisc(5) = df_c_m

! --- store stress migration flux

smisc(6) = df_s(1)

smisc(7) = df_s(2)

if (num%comp==3) smisc(8) = df_s(3)

smisc(9) = df_s_m

! --- store electric migration flux

smisc(14) = df_e(1)

smisc(15) = df_e(2)

if (num%comp==3) smisc(16) = df_e(3)

smisc(17) = df_e_m

call elem%set_smisc_o(smisc)

if (solu%isubst==10) call elem%print_smisc()

end if

end procedure user_call

end submodule UserMigr