The Coulomb friction model shown in Figure 13.28: Friction Model has two states: sticking and sliding. The friction model is not continuously differentiable at the transition point between sticking and sliding. This can lead to convergence difficulties in some cases. Arctangent friction is designed to help in such cases by providing a smoothly varying frictional stress with respect to the sliding velocity. As opposed to the Coulomb friction model, the Arctangent friction model is a viscous one, where the frictional stress depends upon the sliding velocity. The frictional stress is related to the sliding velocity in the following way:

(7–1) |

Where is a reference slip rate. This is controlled by the real contact 23 of

the contact element.

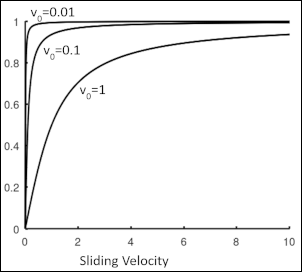

Figure 7.1: Arctangent Friction shows how the frictional stress approaches

the sliding frictional stress from the coulomb friction asymptotically as the sliding velocity

increases. The figure also shows the effect of the reference slip rate,

on the frictional stress. For the same slip rate, as the reference

slip rate is decreased, the frictional stress equals

at a faster and steeper rate. Thus, a small value of

compared to typical slip rate in the problem will make the frictional

stress variation closer to classic coulomb friction but may make problem harder to

converge, while a large value of

might be easier to converge but the frictional stress may not reach

the coulomb friction dictated value of

. The recommended value of

is around 1/10th to 1/100th of the typical sliding rate. By default,

it is set to be elastic slip tolerance (which in turn, is a function of average mesh

length) per unit time.