VM-WB-MECH-100

VM-WB-MECH-100

3-D Acoustic Modal Analysis with Temperature Change

Overview

| Reference: | Oberg, C. L., Ryan, N. W., & Baer, A. D. (1968). A study of T-burner behavior. AIAA Journal, 6(6), 1131-1137. |

| Solver(s): |

Ansys Mechanical |

| Analysis Type(s): | Modal Analysis |

| Element Type(s): | Solid |

Test Case

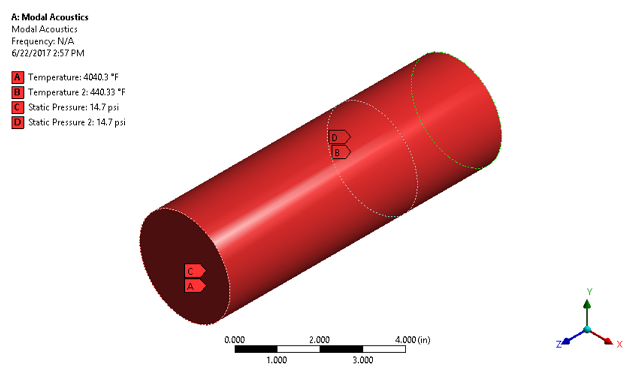

A cylindrical region (single-ended T-burner) is filled with propellant. The temperature distribution in the propellant is discontinuous, where 31% of the length is occupied by "cool" gas, with the remaining volume filled with "hot" gas. Determine the ratio of the amplitudes of pressure at the two ends of the T-burner.

This problem is also presented in VM157 in the Mechanical APDL Verification Manual.

| Material Properties | Geometric Properties | Loading | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

Analysis Assumptions and Modeling Notes

The T-burner is represented as a cylindrical volume. The cool gas occupies 31% of the length at 440.3 °F, while the hot gas of 4040.3 °F occupies the remaining volume. The first non-zero mode is of interest, and the mode is essentially 1-D in nature. Using the ideal gas relationship, the ratio of the temperatures can be used to determine the ratio of the speed of sound and density:

The temperature is applied in the cool and hot regions with a discontinuity at 31% of the length. Based on the reference, the relative amplitude at the hot end should be 0.45.