VM-EXD-MECH-003

VM-EXD-MECH-003

2-D Taylor Cylinder Impact

Overview

| Reference: | No theoretical solution. Experimental results and code-comparisons are available:

| ||

| Analysis Type(s): | Explicit Dynamics 2-D | ||

| Elements: | 4-Node Hex | ||

| Boundary Conditions: | Fixed Constraint | ||

| Structural Interactions: | Proximity-Based Contact | ||

| Fluid-Structure Interactions: | No | ||

| Bonds: | No | ||

| Materials: | Copper |

Test Case

The Taylor cylinder impact test uses a right circular cylinder of a test material which impacts a theoretically rigid target. In this test, an OFHC copper cylinder, 0.762 cm in diameter and 2.54 cm in length, impacts a rigid plate at 19000 cm/s.

| Material Properties | Geometric Properties | Loading | ||

|---|---|---|---|---|

| Cylinder material = copper |

| Impact velocity = 190 m/s |

Analysis Assumptions and Modeling Notes

Two parts are created to model the copper cylinder and the rigid plate. 2-D axial symmetry is used to reduce simulation time.

Material data for copper is obtained from the Explicit Materials data source in Engineering Data. This data is the same as the material data used in the code comparison reference.

A ~0.15 mm element size is used to mesh the cylinder. The rigid plate is modeled with a single element.

Proximity-based contact is used to calculate the impact of the cylinder on the plate. The initial velocity of the cylinder is 190 m/s and the simulation is run for 8 x 10-5 s.

Results Comparison

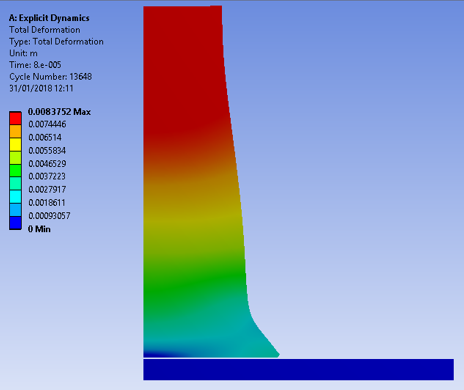

The final cylinder profile is similar to the profile shown for the Autodyn results shown in the code comparison reference.

The cylinder radius in the impact plane agrees well with the experimentally obtained values, as well as with other simulation programs.

The final cylinder length in this simulation is greater than that of the experimental value, but agrees well with the length calculated by the other simulation programs using the same material model for copper.

This plot shows the final share of the deformed copper cylinder (rotated through 360 degrees) at the end of the simulation: