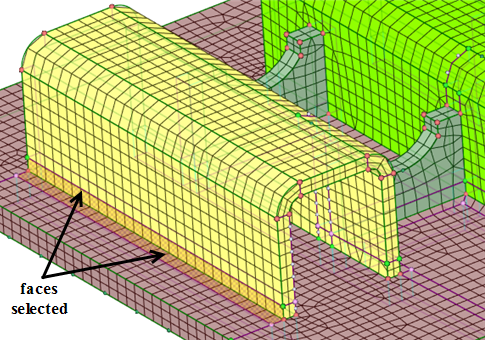

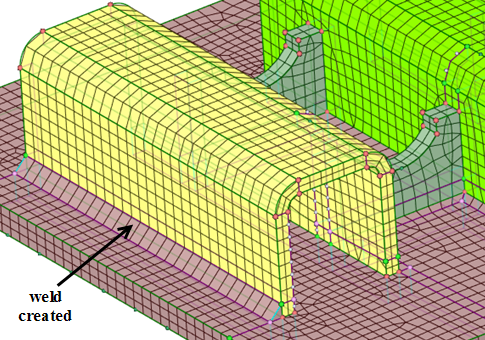

Creating a Blend (Weld) Between Faces

The plates being welded should be in the same component so that only one blocking exists. Faces cannot be shared between two separate blocking components.

If the weld geometry exists either as a surface or as a solid, you may prefer to use the Snap Associated option so that the new block faces that are created are associated to the geometry. Also note that the weld geometry should be in the same component as the plates for the same reason.

Plates can be meshed as separate components with separate component blocking, but in this situation the edges and faces may be duplicate. Use Merge Blocking to merge the blocking components together prior to generating the welds. After merging blockings you can check the edge/face connectivity to ensure the edges/faces are properly connected.

The weld created will have the same material (family) as the face which was selected first.

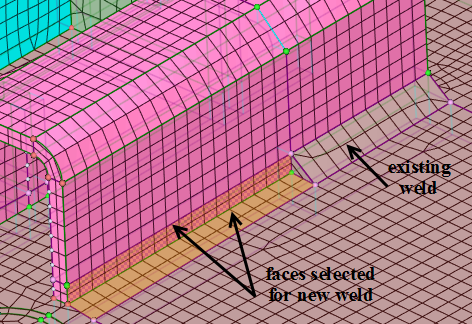

If another weld exists connected to the current (new) weld, the material (family) from the neighboring weld will be used.

If there are welds on both sides which have different materials (families), the material (family) from the first selected face is used.