Start Ansys Polymat by typing polymat. Then follow the

procedure below to perform the fitting for the data presented in Experimental Data.

Note that the fitting calculation for this example will take longer than for the generalized Newtonian example in Example 1: Non-Isothermal Generalized Newtonian Model, due to the added complexity of the model.

![]() Select Fluid Model

Select Fluid Model

Choose an Integral non-isothermal viscoelastic model.

Integral non-isothermal viscoelastic model

Integral non-isothermal viscoelastic model

Return to the top-level menu.

![]() Material Data

Material Data

Enter the Integral Viscoelastic models menu.

Integral Viscoelastic models

Integral Viscoelastic models

Specify the temperature dependence.

Temperature dependence

Temperature dependence

Select the Arrhenius approximate law.

Arrhenius approximate law

Arrhenius approximate law

Return to the Integral Viscoelastic models menu.

Specify the number of relaxation modes.

Modify the spectrum

Modify the spectrum

Set the number of relaxation modes to

4. Number of relaxation modes

Number of relaxation modes

Return to the Integral Viscoelastic models menu.

No modification

No modification

Specify the damping function.

Modify the damping function

Modify the damping function

Select the Reversible Papanastasiou-Scriven model.

Reversible Papanastasiou-Scriven model

Reversible Papanastasiou-Scriven model

Select the Modify alfa and Modify beta menu items, and keep the default values for each. (This step is necessary so that Ansys Polymat will not remind you that you need to set or confirm those values by selecting the menu items.)

Return to the Integral Viscoelastic models menu.

Return to the top-level Ansys Polymat menu.

Enter the Automatic Fitting menu.

Automatic fitting

Automatic fitting

Enter the List of Experimental Curves menu.

Add experimental curves

Add experimental curves

Add the first experimental curve (

visco_200.crv). Add a new curve

Add a new curve

Select the curve named visco_200.crv.

Enter the name of the curve file

Enter the name of the curve file

Set the reference temperature to

200. Modify the temperature

Modify the temperature

Specify that the curve is a shear viscosity curve.

Modify the curve type

Modify the curve type

Choose steady shear viscosity (the default).

steady shear viscosity

steady shear viscosity

Return to the List of Experimental Curves menu.

Add the second experimental curve (

visco_220.crv). Add a new curve

Add a new curve

Select the curve named visco_220.crv.

Enter the name of the curve file

Enter the name of the curve file

Set the reference temperature to

220. Modify the temperature

Modify the temperature

Specify that the curve is a shear viscosity curve.

Modify the curve type

Modify the curve type

Choose steady shear viscosity (the default).

steady shear viscosity

steady shear viscosity

Return to the List of Experimental Curves menu.

Repeat to add the third shear viscosity curve (

visco_240.crv) and set the appropriate reference temperature and curve type.Add the storage modulus curve (

gprime.crv). Add a new curve

Add a new curve

Select the curve named gprime.crv.

Enter the name of the curve file

Enter the name of the curve file

Set the reference temperature to

220. Modify the temperature

Modify the temperature

Specify that the curve is a storage modulus curve.

Modify the curve type

Modify the curve type

Choose storage modulus G’.

storage modulus G’

storage modulus G’

Return to the List of Experimental Curves menu.

Add the loss modulus curve (

gsecond.crv). Add a new curve

Add a new curve

Select the curve named gsecond.crv.

Enter the name of the curve file

Enter the name of the curve file

Set the reference temperature to

220. Modify the temperature

Modify the temperature

Specify that the curve is a loss modulus curve.

Modify the curve type

Modify the curve type

Choose loss modulus G".

loss modulus G"

loss modulus G"

Return to the List of Experimental Curves menu.

Return to the Automatic Fitting menu.

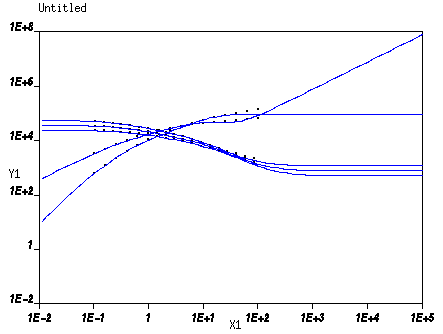

Plot the five experimental data curves.

Draw experimental curves

Draw experimental curves

Set the numerical parameters for the calculation.

Numerical options for fitting

Numerical options for fitting

Limit the range of relaxation times to be from a minimum of

0.1to a maximum of10. Modify the range of relaxation times

Modify the range of relaxation times

Return to the Automatic Fitting menu.

Specify a name for the material data file (for example,

example3.mat). Enter the name of the result file

Enter the name of the result file

Start the fitting calculation.

Run fitting

Run fitting

The results of the fitting calculation are as follows:

RESULTS Integral Viscoelastic models Integral viscoelastic flow Type of model : KBKZ model N2 / N1 = 0.0000000E+00 [auto] ad.visc. = 0.7632522E+03 [auto] Damping function : Reversible Papanastasiou - Scriven alfa = 0.6365238E+01 [auto] beta = 0.0000000E+00 [auto] Number of relaxation modes = 4 Mode - Viscosity - Relaxation Time 1 6.63042E+03 [auto] 1.00000E-01 [auto] 2 7.89786E+03 [auto] 4.64159E-01 [auto] 3 1.51692E+04 [auto] 2.15443E+00 [auto] 4 4.68693E+03 [auto] 1.00000E+01 [auto] Arrhenius approximate law h(t) = exp( -alfa * (t - talfa) ) alfa = 0.2150435E-01 [auto] talfa = 0.2200000E+03 [auto]

The computed and experimental curves are shown in Figure 10.3: Plot of Computed and Experimental Curves.