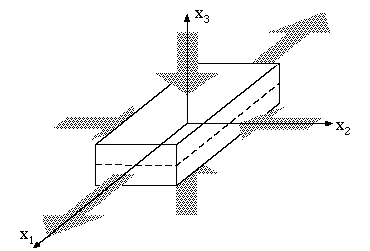

Steady extensional flow can be uniaxial, biaxial, or planar. Uniaxial extensional flow is illustrated in Figure 7.2: Uniaxial Extensional Flow and defined as follows:

(7–10) |

where is a constant elongational strain rate.

The corresponding stress distribution can be written as

(7–11) |

(7–12) |

where is the uniaxial extensional viscosity.

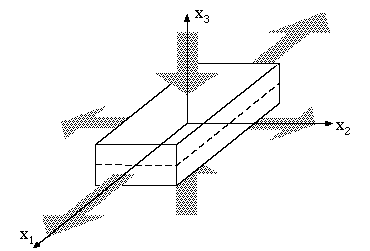

Biaxial extensional flow is illustrated in Figure 7.3: Biaxial Extensional Flow and defined as follows:

(7–13) |

where is a constant elongational strain rate.

The corresponding stress distribution can be written as

(7–14) |

(7–15) |

where is the biaxial extensional viscosity.

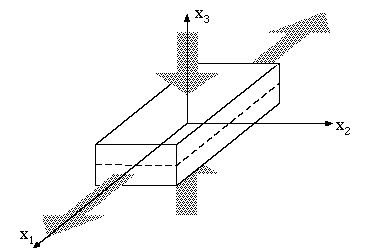

Planar extensional flow is illustrated in Figure 7.4: Planar Extensional Flow and defined as follows:

(7–16) |

where is a constant elongational strain rate.

The corresponding stress distribution can be written as

(7–17) |

where is the planar extensional viscosity.

For extensional flow fields, the uniaxial, biaxial, and planar extensional viscosity

curves (,

, and

) can be computed. Click Uniaxial Extensional

Viscosity, Biaxial Extensional Viscosity, and/or

Planar Extensional Viscosity in the Load Curves (Part

I) menu if you want Ansys Polymat to compute one (or more) of these

curves.

To compute each of these curves, you will need to specify a minimum and maximum

extensional strain rate ( and

), and the number of sampling points. See Defining Numerical Parameters and Defining Numerical Parameters for information about

specifying numerical parameters for viscometric property curves. See Specifying the Curves to be Calculated for information about

specifying which curves you want to compute and plot. (Note that, if you use the

automatic fitting method, Ansys Polymat will automatically compute and plot the curves

for all properties for which experimental data curves have been defined.)