There are currently nine differential viscosity models:

Upper-convected Maxwell and Oldroyd-B models: These are the simplest viscoelastic constitutive equations, although in many situations they are the most numerically cumbersome for Ansys Polyflow. Both models exhibit a constant viscosity and a quadratic first normal-stress difference. They should be selected either when very little information is know about the fluid, or when a qualitative prediction is sufficient. For fluids exhibiting a very high extensional viscosity, the Oldroyd-B model is preferred over the upper-convected Maxwell model.

White-Metzner model: Most fluids are characterized by shear thinning and a non-quadratic first normal-stress difference. With the White-Metzner model, it is possible to reproduce such viscometric features. Several functions for the shear-rate dependence of the viscosity and the relaxation time are available.

When experimental data are available for the shear viscosity and the first normal-stress difference, the material parameters for the White-Metzner model can be obtained easily by curve fitting: first the shear viscosity is defined and fitted, and then the function for the relaxation time can be selected and fitted on the basis of the first normal-stress difference in a simple shear flow.

Despite its interesting features from a viscometric point of view, the White-Metzner model may exhibit strange numerical behavior at high shear rates, leading to spurious oscillations in the Ansys Polyflow solution.

Phan-Thien-Tanner (PTT), Johnson-Segalman, and Giesekus models: These models are the most realistic. In particular, they exhibit shear thinning and a non-quadratic first normal-stress difference at high shear rates. These properties are controlled by their respective material parameters (

,

, and

), as described in the model description below. Also, the selection of nonzero values for

and

will lead to a bounded steady extensional viscosity.

For stability reasons, however, a purely viscous component must be added to the extra-stress tensor in simple shear flow. This is true for the Johnson-Segalman and PTT models when

is nonzero, and for the Giesekus model when

>0.5. The addition of a purely viscous component to the extra-stress tensor affects the viscosity, but not the first normal-stress difference. Shear thinning is still present, but the viscosity curve also shows a plateau zone at high shear rates.

Poor control of the shear viscosity is the usual drawback of the Johnson-Segalman and PTT models used with a single relaxation time, especially toward high shear rates.

Important: Note that you cannot explicitly select the Johnson-Segalman model in the Ansys Polymat interface. It is obtained by selecting the PTT model and setting the value of

to 0.

FENE-P (Finitely Extensible Non-Linear Elastic Dumbbells – Peterlin) model: This model is derived from molecular theories and is based on the assumption that the material behaves as a series of dumbbells linked together by springs. Unlike the Maxwell model, springs can have only a finite extension, so the energy of deformation of the dumbbell becomes infinite for a finite value of the spring elongation.

The FENE-P model requires only four parameters (

,

,

, and the length ratio for the spring), yet it predicts a realistic shear thinning of the fluid and a first normal-stress difference that is quadratic for low shear rates and has a lower slope for high shear rates. It has been observed in practice that viscometric properties of several fluids can often be accurately modeled. The FENE-P model is well suited for simulating the rheological behavior of dilute solutions.

POM-POM model: The pom-pom molecule consists of a backbone to which

arms are connected at both extremities. In a flow, the backbone may orient in a Doi-Edwards reptation tube consisting of the neighboring molecules, while the arms may retract into that tube. The concept of the pom-pom macromolecule makes the model suitable for describing the behavior of branched polymers. The approximate differential form of the model is based on the equations of macromolecular orientation and macromolecular stretching in connection with changes in orientation. In this construction, the pom-pom molecule is allowed only a finite extension, which is controlled by the number of dangling arms. In particular, the strain hardening properties are dictated by the number of arms. Beyond that, the model predicts realistic shear thinning behavior, as well as a first and a possible second normal stress difference.

Leonov model: This model has been developed for the simultaneous prediction of the behavior of trapped and free macromolecular chains for filled elastomers with carbon black and/or silicate. From the point of view of morphology, macromolecules at rest are trapped by particles of carbon black, via electrostatic van der Waals forces. Under a deformation field, electrostatic bonds can break, and macromolecules become free, while a reverse mechanism may develop when the deformation ceases. You can therefore be facing a macromolecular system consisting of trapped and free macromolecules, with a reversible transition from one state to the other one.

This model involves actually two tensor quantities and a scalar one. The tensors focus respectively on the behavior of the free and trapped macromolecular chains of the elastomer, while the scalar quantity quantifies the degree of structural damage (debonding factor). The model exhibits a yielding behavior. It is intrinsically nonlinear, as the nonlinear response develops and is observable at early deformations.

Details about each model are provided below.

The Maxwell model is one of the simplest viscoelastic constitutive equations. It exhibits a constant viscosity and a quadratic first normal-stress difference. Due to its simplicity, it is recommended only when little information about the fluid is available, or when a qualitative prediction is sufficient. Even in this case, the Oldroyd-B model, which can include a purely viscous component, is preferable for numerical reasons.

For the upper-convected Maxwell model, the purely viscous component of the

extra-stress tensor () is equal to zero. The viscoelastic component

(

) is computed from

(6–30) |

where is a model-specific relaxation time,

is the rate-of-deformation tensor, and

is a model-specific viscosity factor for the viscoelastic

component of

. The relaxation time

is defined as the time required for the shear stress to be

reduced to half of its original equilibrium value when the strain rate

vanishes. A high relaxation time indicates that the memory retention of the

flow is high. A low relaxation time indicates significant memory loss,

gradually approaching Newtonian flow (zero relaxation time).

The units for the parameters and their names in the Ansys Polymat interface are as follows:

| Parameter | Name in Ansys Polymat | Mass | Length | Time |

|---|---|---|---|---|

|

| visc | 1 | –1 | –1 |

|

| trelax | – | – | 1 |

|

| – | 1 | –1 | –2 |

|

| – | – | – | –1 |

By default, and

are equal to 1.

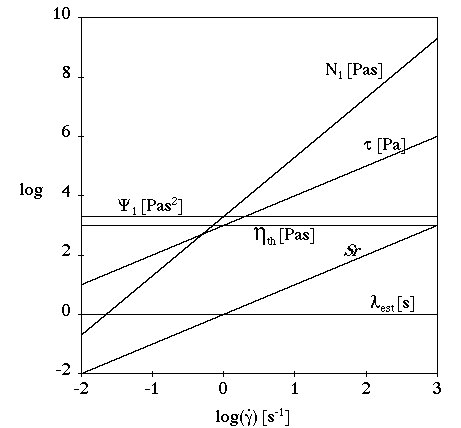

Figure 6.28: Upper-Convected Maxwell Model for a Shear Flow

shows the viscometric functions of the upper-convected Maxwell model in a

simple shear flow. In this example (where =1 s and

=1000 Pa-s),

is constant,

is linear,

is quadratic,

is zero,

is constant,

is zero, and

is linear, showing non-asymptotic behavior.

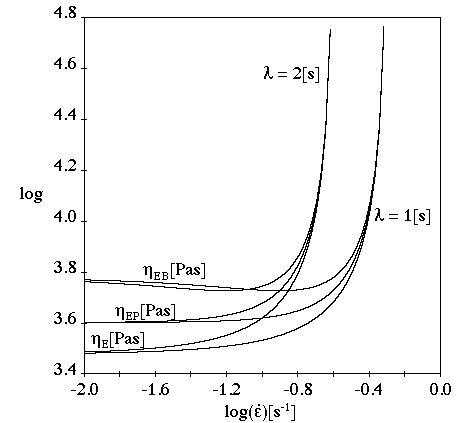

Figure 6.29: Upper-Convected Maxwell Model for an Extensional Flow shows the behavior of the upper-convected Maxwell model in a simple extensional flow.

In this example (where =1 s and

=1000 Pa-s),

,

, and

are unbounded for

, and

(6–31) |

(6–32) |

(6–33) |

(6–34) |

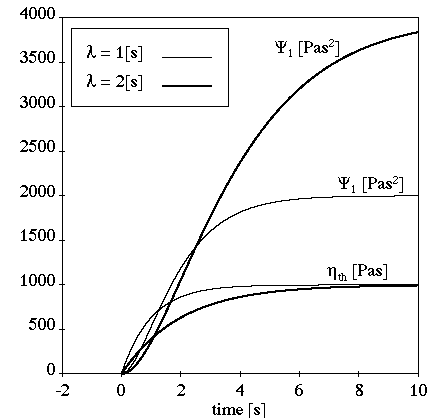

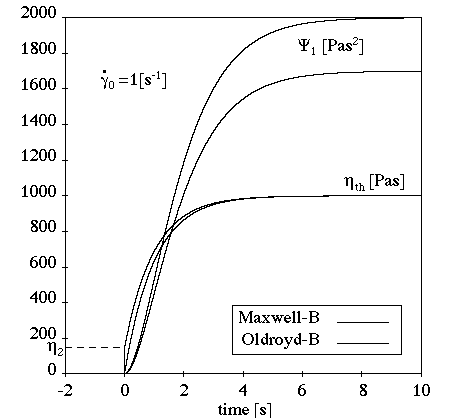

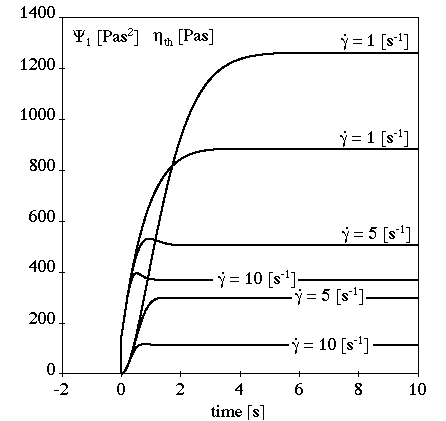

Figure 6.30: Upper-Convected Maxwell Model for a Transient Shear Flow shows the behavior of the upper-convected Maxwell model in a transient shear flow.

In this example (where =1 s,

=1000 Pa-s, and

s-1), there is no stress

overshoot and the transient phase depends upon the relaxation time.

The Oldroyd-B model is, like the Maxwell model, one of the simplest viscoelastic constitutive equations. It is slightly better than the Maxwell model, because it allows for the inclusion of the purely viscous component of the extra stress, which leads to better behavior of the numerical scheme. Oldroyd-B is a good choice for fluids that exhibit a very high extensional viscosity.

For the Oldroyd-B model, is computed from Equation 6–30,

and

is computed (optionally) from Equation 6–27.

in Equation 6–30, and

in Equation 6–27 are partial shear viscosities. Ansys Polymat uses

Equation 6–28

and Equation 6–29

to compute the value of

, based on a specified value for the viscosity ratio,

.

The units for the parameters and their names in the Ansys Polymat interface are as follows:

| Parameter | Name in Ansys Polymat | Mass | Length | Time |

|---|---|---|---|---|

|

| visc | 1 | –1 | –1 |

|

| trelax | – | – | 1 |

|

| ratio | – | – | – |

|

| – | 1 | –1 | –2 |

|

| – | – | – | –1 |

By default, and

are equal to 1, and the viscosity ratio

is equal to 0 (that is,

and

are equal to 0).

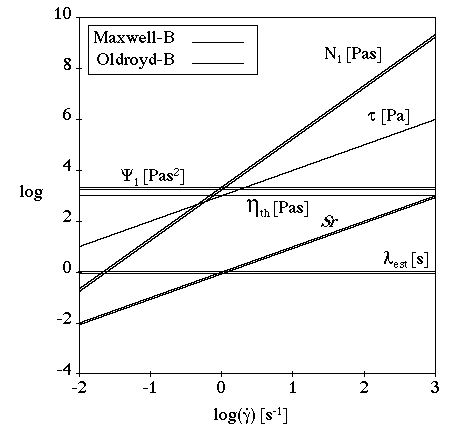

Figure 6.31: Oldroyd-B Model for a Shear Flow shows

the viscometric functions of the Oldroyd-B model in a simple shear flow. In

this example, =1 s and (with the viscosity ratio equal to 0.15)

=850 Pa-s and

=150 Pa-s. In the resulting curves,

is constant,

is linear,

is quadratic,

is zero,

is constant,

is zero, and

is linear, showing non-asymptotic behavior. Notice that

the curves are moved down in comparison to the upper-convected Maxwell

model; this is due to the Newtonian part of the model (nonzero value for

), which reduces the viscoelastic effects (

,

,

, and

).

Figure 6.32: Oldroyd-B Model for a Transient Shear Flow shows

the behavior of the Oldroyd-B model in a transient shear flow. In this

example, =1 s,

=1000 Pa-s, and

s–1. Notice that

there is an instantaneous response of the shear stress to the applied shear

rate; this is due to the Newtonian part of the model. Otherwise, the

Oldroyd-B model exhibits the same behavior as the upper-convected Maxwell

model.

Most fluids are characterized by shear-thinning and non-quadratic first normal-stress difference. With the White-Metzner model, it is possible to reproduce such viscometric features.

The White-Metzner model computes from

(6–35) |

and is computed (optionally) from Equation 6–27.

in Equation 6–35 and

in Equation 6–27 are partial shear viscosities.

The relaxation time () and the viscosity (

) can be constant or represented by the power law or the

Bird-Carreau law for shear-rate dependence.

The power-law representation of the total viscosity is

(6–36) |

where is the consistency factor,

is the power-law index, and

is the natural time (that is, inverse of the shear rate at

which the fluid changes from Newtonian to power-law behavior).

The Bird-Carreau representation of the viscosity is

(6–37) |

where is the natural time and

is the power-law index.

and

are then computed from Equation 6–28 and

Equation 6–29,

based on a specified value for the viscosity ratio,

.

The power-law representation of the relaxation time is

(6–38) |

The Bird-Carreau representation of the relaxation time is

(6–39) |

Important: Note that the power-law representation for the relaxation time should be avoided, since it leads to high relaxation times for low shear rates. The Bird-Carreau representation is better, yielding a constant (and bounded) relaxation time at low shear rates.

If you are fitting experimental curves using the White-Metzner model, you will need to do the fitting in two parts:

Choose the viscosity function and fit its parameters. See Shear-Rate Dependence of Viscosity for information about the parameters for the function you choose (constant, Bird-Carreau, or power law).

Choose the relaxation time function and fit its parameters to the experimental curve for the first normal-stress difference. See Shear-Rate Dependence of Viscosity for information about the parameters for the function you choose (constant, Bird-Carreau, or power law). Note that the relaxation time function has no effect on the steady viscosity curves.

The units for the White-Metzner parameters and their names in the Ansys Polymat interface are as follows:

| Parameter | Name in Ansys Polymat | Mass | Length | Time |

|---|---|---|---|---|

|

| viscosity function | 1 | –1 | –1 |

|

| relaxation time function | – | – | 1 |

|

| ratio | – | – | – |

|

| – | 1 | –1 | –2 |

|

| – | – | – | –1 |

By default, and

are constant values equal to 1, and the viscosity ratio

is equal to 0 (that is,

and

are equal to 0).

Figure 6.33: White-Metzner Model for a Shear Flow compares the White-Metzner model to the

upper-convected Maxwell model for a simple shear flow. In this example, the

Bird-Carreau viscosity law is used, with =1000 Pa-s,

=10 s, and

=0.5. The relaxation time

is 1 s. Notice that

and

are non-constant for large shear rates,

is nonlinear,

is non-quadratic for large shear rates, and

and

are equal to 0.

In transient shear flow, the White-Metzner model is similar in behavior to the upper-convected Maxwell model. The shape of the curves is the same, but the duration of the transient phase depends on the relaxation time function. If this function is constant, the duration to reach the regime situation is the same; if it is not constant, the duration of the transient phase depends upon the relaxation time function. Usually, the relaxation time is a decreasing function of the shear rate, so the duration of the transient phase is reduced for high shear rate.

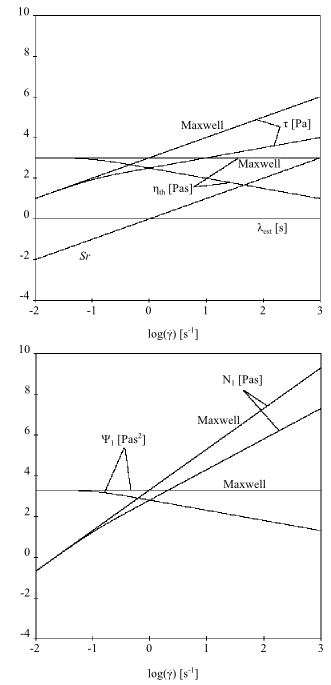

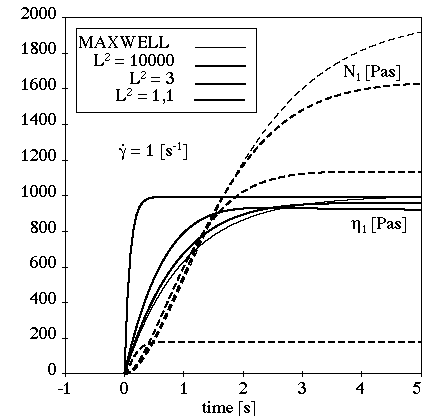

Figure 6.34: White-Metzner Model for a Transient Shear Flow with Constant Relaxation Time shows the viscometric curves for a constant relaxation time and Figure 6.35: White-Metzner Model for a Transient Shear Flow with a Bird-Carreau Relaxation Time shows the curves for a shear-rate-dependent relaxation time. In Figure 6.34: White-Metzner Model for a Transient Shear Flow with Constant Relaxation Time, the shear thinning affects the final value of the viscosity and the first normal-stress coefficient. The transient phase is not affected by the shear rate. In Figure 6.35: White-Metzner Model for a Transient Shear Flow with a Bird-Carreau Relaxation Time, there is no shear thinning, so there is no effect on the final value of the viscosity. The first normal stress coefficient is affected by the variation of relaxation time with shear rate. The transient phase is affected by the shear rate.

The Phan-Thien-Tanner (PTT) model is one of the most realistic differential viscoelastic models. It exhibits shear thinning and a non-quadratic first normal-stress difference at high shear rates.

The PTT model computes from

(6–40) |

and is computed (optionally) from Equation 6–27.

in Equation 6–40 and

in Equation 6–27 are partial shear viscosities. Ansys Polymat uses

Equation 6–28

and Equation 6–29

to compute the value of

, based on a specified value for the viscosity ratio,

.

and

are material properties that control, respectively, the

shear viscosity and elongational behavior. A nonzero value for

leads to a bounded steady extensional viscosity.

The units for the parameters and their names in the Ansys Polymat interface are as follows:

| Parameter | Name in Ansys Polymat | Mass | Length | Time |

|---|---|---|---|---|

|

| visc | 1 | –1 | –1 |

|

| trelax | – | – | 1 |

|

| ratio | – | – | – |

|

| eps | – | – | – |

|

| xi | – | – | – |

|

| – | 1 | –1 | –2 |

|

| – | – | – | –1 |

By default, and

are equal to 1, the viscosity ratio

is equal to 0 (that is,

and

are equal to 0), and

and

are also equal to 0. Note that when

=0, the PTT model is reduced to the Johnson-Segalman model.

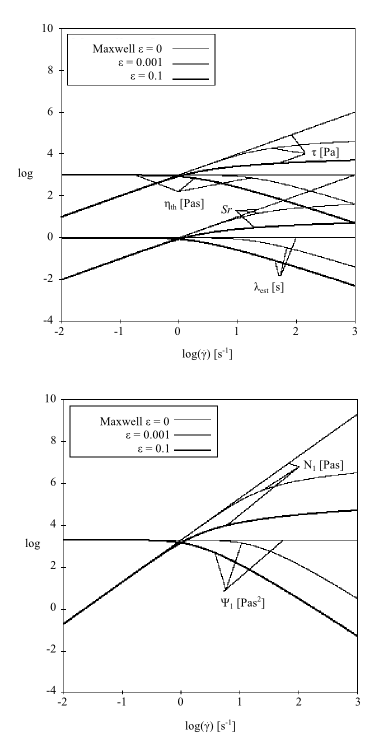

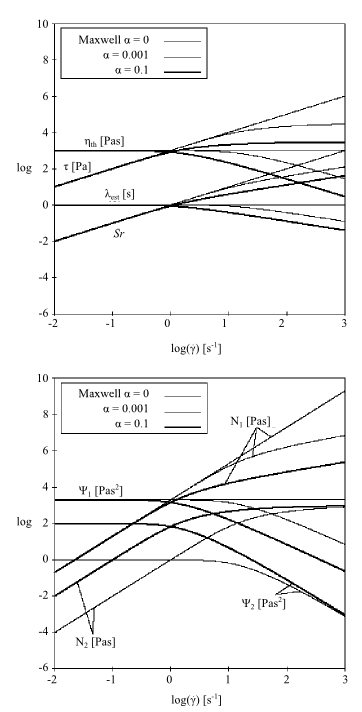

In a simple shear flow (Figure 6.36: PTT Model for a Shear Flow), for >0, you can see a shear-thinning effect and a

non-quadratic behavior for the first normal-stress difference

. Notice also that, for

>0, the elasticity level

remains finite for increasing shear rate (asymptotic

behavior).

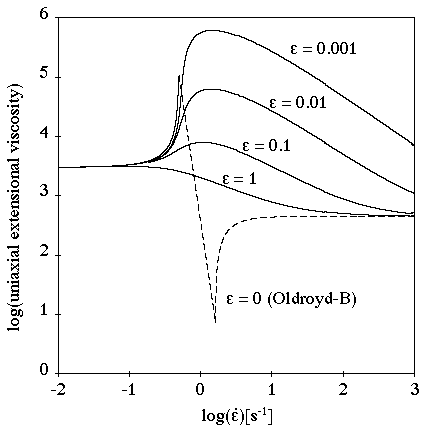

The parameter also affects the extensional viscosities, as shown in

Figure 6.37: PTT Model for a Steady Extensional Flow.

The steady extensional viscosities are finite, and tend toward the Newtonian

component of the extensional viscosity (that is, they are uniaxial) for

large extension rates. For small values of

, there is extension thickening and thinning; for large

values, there is only extension thinning.

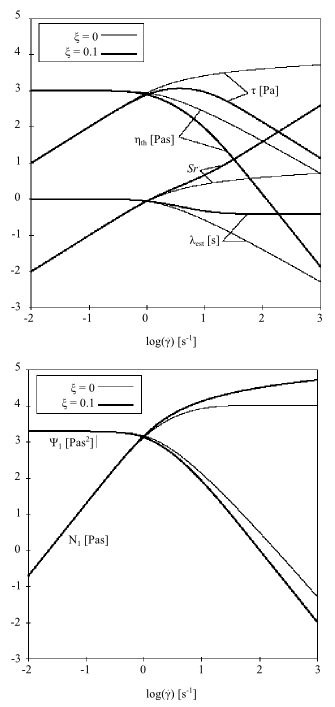

Important: If the parameter is not zero, then the viscosity ratio

must be at least 1/9, in order to ensure the stability

of the shear flow. However, this value may decrease when

does not vanish. The slope of the shear stress

vs. shear rate curve must be positive everywhere, contrary to what

is shown on the left in Figure 6.38: Effect of ξ on the PTT Model for a Shear Flow with

=0.1.

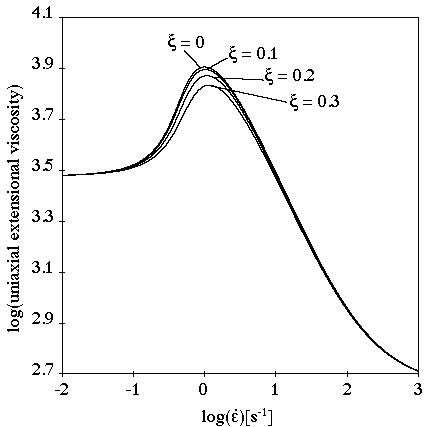

The parameter has almost no effect on extensional viscosity, as shown in

Figure 6.39: Effect of ξ on the PTT Model for a Steady Extensional

Flow. The maximum of the extensional viscosities decreases when

increases.

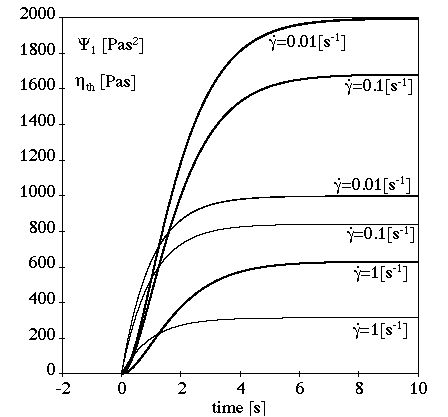

In a transient shear flow (Figure 6.40: PTT Model in a Transient Shear Flow), a moderate stress overshoot is observed. The stress overshoot increases as shear rate increases. Shear thinning is observed, and the normal stress is non-quadratic. The transient phase is reduced as the shear rate increases.

Like the PTT model, the Giesekus model is one of the most realistic differential viscoelastic models. It exhibits shear thinning and a non-quadratic first normal-stress difference at high shear rates.

The Giesekus model computes from

(6–41) |

and is computed (optionally) from Equation 6–27.

in Equation 6–41 and

in Equation 6–27 are partial shear viscosities. Ansys Polymat uses

Equation 6–28

and Equation 6–29

to compute the value of

, based on a specified value for the viscosity ratio,

.

is the unit tensor and

is a material constant that controls the extensional

viscosity and the ratio of the second normal-stress difference to the first.

For low values of shear rate,

(6–42) |

For the majority of fluids, this ratio is between 0.1 and 0.2.

The units for the parameters and their names in the Ansys Polymat interface are as follows:

| Parameter | Name in Ansys Polymat | Mass | Length | Time |

|---|---|---|---|---|

|

| visc | 1 | –1 | –1 |

|

| trelax | – | – | 1 |

|

| ratio | – | – | – |

|

| alfa | – | – | – |

|

| – | 1 | –1 | –2 |

|

| – | – | – | –1 |

By default, and

are equal to 1, the viscosity ratio

is equal to 0 (that is,

and

are equal to 0), and

is also equal to 0.

In a simple shear flow (Figure 6.41: Giesekus Model for a Shear Flow),

controls the shear-thinning effect. The first

normal-stress difference is non-quadratic, and the cut-off appears earlier

if

increases. If

>0.5, you must add a Newtonian component

(

) to the total viscosity in order to avoid instabilities.

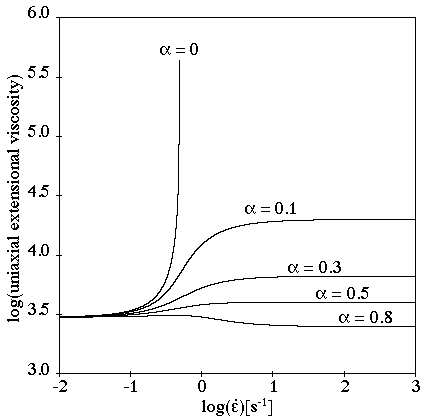

Figure 6.42: Effect of α on the Giesekus Model for an Extensional Flow shows the behavior of the Giesekus fluid in an extensional flow.

Here, the steady extensional viscosities are finite. For small values of

extension thickening occurs, and for large values

extension thinning occurs.

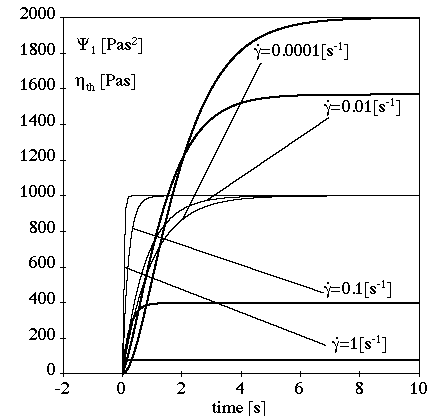

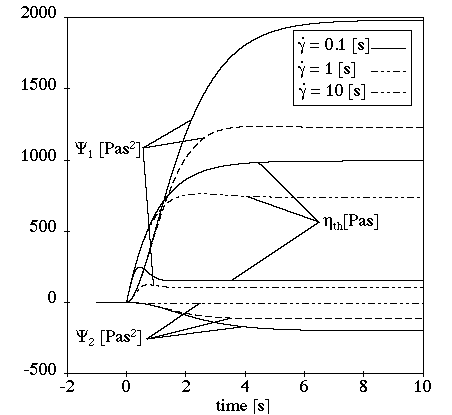

In a transient shear flow (Figure 6.43: Giesekus Model for a Transient Shear Flow), the stress overshoot is less severe than for the PTT model; there are fewer oscillations.

The duration of the transient phase depends on the imposed shear rate (the same behavior as for the PTT model). For a high shear rate, the stress overshoots during the transient phase. As the shear rate increases, the final value decreases as the overshoot increases. The duration of the transient phases decreases as the shear rate increases.

The FENE-P model is derived from molecular theories and is based on the

assumption that the polymer macromolecules are idealized as dumbbells linked

with an elastic connector or spring and suspended in a Newtonian solvent of

viscosity . Unlike in the Maxwell model, however, the springs are allowed

only a finite extension, so that the energy of deformation of the dumbbell

becomes infinite for a finite value of the spring elongation. This model

predicts a realistic shear thinning of the fluid and a first normal-stress

difference that is quadratic for low shear rates and has a lower slope for high

shear rates.

The FENE-P model computes from

(6–43) |

where is computed from

(6–44) |

and is the ratio of the maximum length of the spring to its

length at rest:

(6–45) |

is an equilibrium length that corresponds to rigid motion

(in this case,

=0 and the tension in the connector equals the Brownian

forces).

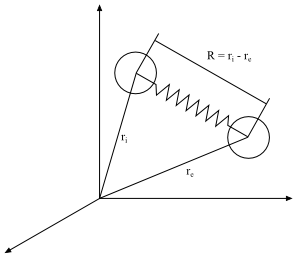

is the maximum allowable dumbbell length. Figure 6.44: Dumbbell Definitions for the FENE-P Model shows how

the distance between dumbbells is based on the relative position of both

ends.

is always greater than 1. As

becomes infinite, the FENE-P model reduces to the

upper-convected Maxwell model.

is computed (optionally) from Equation 6–27.

in Equation 6–43 and

in Equation 6–27 are partial shear viscosities. Ansys Polymat uses

Equation 6–28 and Equation 6–29 to compute the value of

, based on a specified value for the viscosity ratio,

.

The motion of the dumbbells is the result of hydrodynamic, Brownian, and

spring forces. represents the tension in the spring (spring forces) and

the Brownian motion.

represents the Newtonian (hydrodynamic) forces.

See [1] for additional information about the FENE-P model. Note that the FENE-P model is not available for non-isothermal flows.

The units for the parameters and their names in the Ansys Polymat interface are as follows:

| Parameter | Name in Ansys Polymat | Mass | Length | Time |

|---|---|---|---|---|

|

| visc | 1 | –1 | –1 |

|

| trelax | – | – | 1 |

|

| ratio | – | – | – |

|

| Lsqrd | – | 2 | – |

|

| – | 1 | –1 | –2 |

|

| – | – | – | –1 |

By default, ,

, and

are equal to 1, and the viscosity ratio

is equal to 0 (that is,

and

are equal to 0).

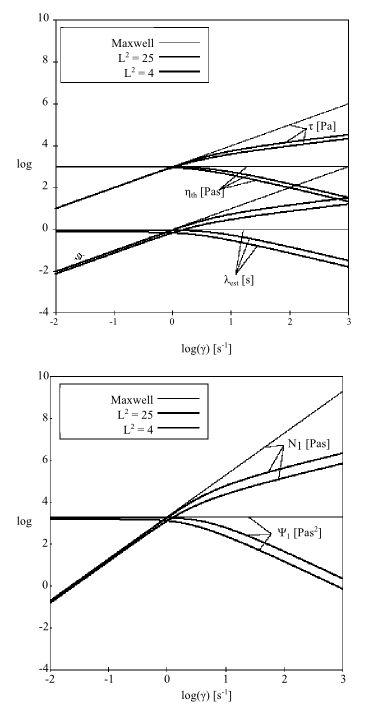

The behavior of the FENE-P model with small values of for a simple shear flow is illustrated in Figure 6.45: Effect of Small Values of L^2 on the FENE-P Model for Shear

Flow.

Shear thinning occurs with this model, and for large values of shear rate,

the slope is –2/3. Therefore the addition of a Newtonian viscosity

component is not required for stability. The first normal-stress difference

is non-quadratic, and the second normal-stress difference is 0. The cut-off

appears sooner when

decreases, down to a value of 3. No asymptotic behavior is

observed. For low values of shear rate,

decreases as

decreases.

The behavior of the FENE-P model with large values of for a simple shear flow is illustrated in Figure 6.46: Effect of Large Values of L^2 on the FENE-P Model for Shear

Flow.

For large values of , the FENE-P model is observed to exhibit Maxwellian

behavior: quadratic first normal-stress difference and

close to

. For

close to 1, Newtonian behavior is observed: quadratic but

small first normal-stress difference,

tends toward 0, cut-off occurs at high shear rates. For

low shear rates,

(6–46) |

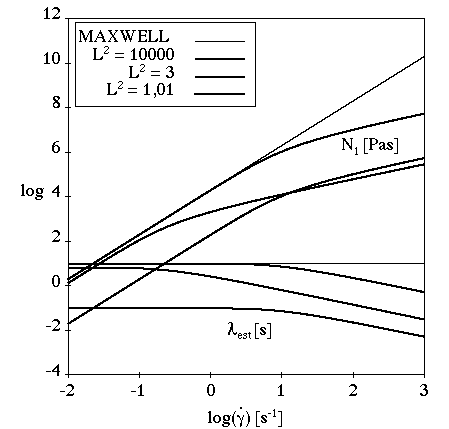

For extensional flows, controls the extensional viscosity. As shown in Figure 6.47: Effect of L^2 on the FENE-P Model for Extensional Flow, the

extensional viscosities are finite. For large values of

, the FENE-P model is observed to exhibit Maxwellian

behavior: the extensional viscosities are very high for

. For

close to 1, Newtonian behavior is observed: the

extensional viscosities are constant.

The behavior of the FENE-P model for a transient shear flow is shown in

Figure 6.48: Effect of Large Values of L^2 on the FENE-P Model for Transient Shear

Flow

and Figure 6.49: Effect of Mid-Range Values of L^2 on the FENE-P Model for Transient

Shear Flow.

For high shear rates, the stress overshoots in the transient phase. When the

shear rate increases, the final value and the transient phase decrease while

the overshoot increases. For large values of , the FENE-P model is observed to exhibit Maxwellian

behavior: no stress overshoots. For mid-range values of

, the stress overshoots increase and the transient phase

decreases as

decreases. For

close to 1, Newtonian behavior is observed: no stress

overshoots and a short transient phase even for high values of shear rate.

In the POM-POM model, the pom-pom molecule consists of a backbone to which

arms are connected at both extremities. In a flow, the

backbone may orient in a Doi-Edwards reptation tube consisting of the

neighboring molecules, while the arms may retract into that tube. The concept of

the pom-pom macromolecule makes the model suitable for describing the behavior

of branched polymers. The approximate differential form of the model is based on

equations of macromolecular orientation, and macromolecular stretching in

relation to changes in orientation.

The model, referred to as DCPP ([2],

[8]), allows for a nonzero second normal

stress difference. The DCPP model computes from an orientation tensor,

and a stretching scalar

(states variables), on the basis of the following algebraic

equation:

(6–47) |

where is the shear modulus and

is a nonlinear material parameter (the nonlinear material

parameter will be introduced later on). The state variables

and

are computed from the following differential equations:

(6–48) |

(6–49) |

In these equations, and

are the relaxation times associated with the orientation and

stretching mechanisms respectively. In the last equation,

characterizes the number of dangling arms (or priority) at the

extremities of the pom-pom molecule or segment. It is an indication of the

maximum stretching that the molecule can undergo, and therefore of a possible

strain hardening behavior.

can be obtained from the elongational behavior.

is a nonlinear parameter that has enabled the introduction of

a non-vanishing second normal stress difference in the DCPP model.

A multi-mode DCPP model can also be defined. Each contribution will involve an orientation tensor

and a stretching variable

. A few guidelines are required for the determination of the

several linear and nonlinear parameters.

Consider a multi-mode DCPP model characterized by modes sorted with increasing values of relaxation times

(increasing seniority). The linear parameters

and

characterizing the linear viscoelastic behavior of the model

can be determined with the usual procedure.

Then the relaxation times () for stretching should be determined. Depending on the average

number of entanglements of backbone section, the ratio

should be within the range of 2 to 10. For a completely

unentangled polymer segment, you may accept the physical limit of

=

.

should also satisfy the constraint

, since

sets the fundamental diffusion time for the branch point

controlling the relaxation of polymer segment (

).

The parameter indicating the number of dangling arms (or priority) at the

extremities of a pom-pom segment

, also indicates the maximum stretching that can be undergone

by that segment, and therefore its possible strain hardening behavior. For a

multi-mode DCPP model, both seniority and priority are assumed to increase

together towards the inner segments; hence

should also increase with

. The parameter

can be obtained from the elongational behavior.

is a fifth set of nonlinear parameters that control the ratio

of second to first normal stress differences. The value of parameter

should range between 0 and 1. For moderate values,

corresponds to twice the ratio of the second to the first

normal stress difference, and may decrease with increasing seniority.

As for other viscoelastic models, a purely viscous component can be added to the viscoelastic component

, in order to get the total extra-stress tensor:

(6–50) |

where

(6–51) |

where is the rate-of-deformation tensor and

is the viscosity.

The units for the parameters and their names in the Ansys Polymat interface are as follows:

| Parameter | Name in Ansys Polymat | Mass | Length | Time |

|---|---|---|---|---|

|

| visc2 | 1 | –1 | –1 |

|

| trelax | - | - | 1 |

|

| G0 | 1 | –1 | –2 |

|

| tlambda | - | - | 1 |

|

| nbarms | - | - | - |

|

| xi | - | - | - |

|

| - | 1 | –1 | –2 |

|

| - | - | - | –1 |

|

| - | - | - | - |

|

| - | - | - | - |

By default, and

are set to 1, the number of arms

to 2 and the other parameters to 0.

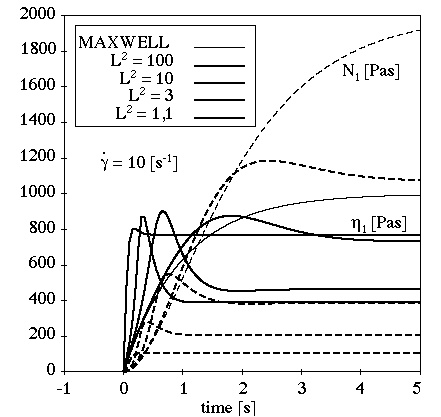

Figure 6.50: Effect of Parameter ξ for Steady Shear Flow shows the

steady viscometric behavior of a single mode DCPP fluid model for various

values of the parameter . For the present illustration, the shear modulus equals

1000, while the relaxation times for orientation and stretching have been

assigned the values 1 and 0.5, respectively. As can be seen, constant

viscosity and quadratic first normal stress difference are obtained at low

shear rates. Nonlinear behavior is found beyond

. We also find that an increasing value of

enforces the nonlinear behavior, while it also generates a

non-vanishing second normal stress difference. The other nonlinear

parameters

and

have actually a negligible influence on the viscometric

properties.

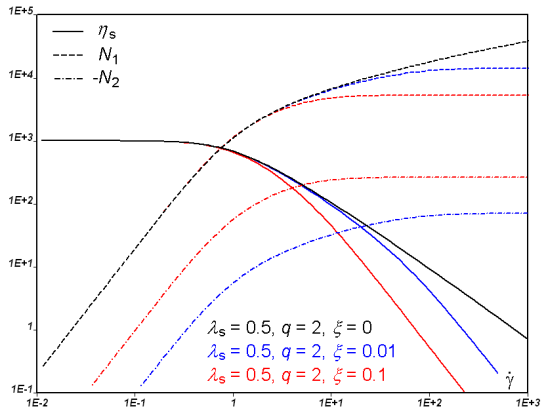

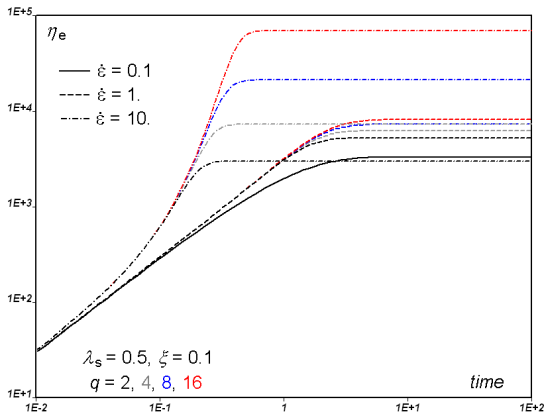

In Figure 6.51: Effect of Parameter q on Steady Elongation Viscosity, we

display the steady elongation viscosity of a single mode DCPP fluid model

for increasing values of . For the continuous curves, the shear modulus equals 1000,

while the relaxation times for orientation and stretching have been assigned

the values 1 and 0.5, respectively. Also, the nonlinear parameter

is equal to 0.1. As is known for the DCPP model, and more

generally for pom-pom models, the parameter

is an indication of branching, and therefore of strain

hardening in elongation. As can be seen from Figure 6.51: Effect of Parameter q on Steady Elongation Viscosity, the

elongation viscosity increases when the strain

rate is larger than

, and the strain hardening is enhanced for increasing

values of

. The figure also shows the steady elongation viscosity

obtained for

as well as for

. As can be seen, the influence of these parameters on the

steady elongation viscosity remains moderate as compared to that of

parameter

.

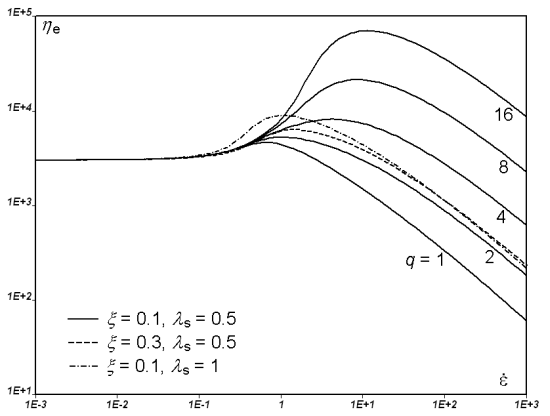

Finally, Figure 6.52: Effect of Parameter q on Transient Elongation Viscosity for Different

Values of the Elongation Rate shows the transient elongation viscosity of various

single-mode DCPP fluid model characterized by different branching levels

(), at elongation rates

successively equal to 0.1, 1 and 10. We find that all

curves collapse at low strain rate (0.1), while they markedly differ at high

strain rate (10).

Figure 6.52: Effect of Parameter q on Transient Elongation Viscosity for Different Values of the Elongation Rate

Elastomers are usually filled with carbon black and/or silicate. From the point of view of morphology, macromolecules at rest are trapped by particles of carbon black, via electrostatic van der Waals forces. Under a deformation field, electrostatic bonds can break, and macromolecules become free, while a reverse mechanism may develop when the deformation ceases. You can therefore be facing a macromolecular system consisting of trapped and free macromolecules, with a reversible transition from one state to the other one.

Leonov and Simhambhatla have developed a rheological model ([9], [10], [3]) for the simultaneous prediction of the behavior for trapped and free macromolecular chains. This model for filled elastomers involves actually two tensor quantities and a scalar one. These tensor quantities focus respectively on the behavior of the free and trapped macromolecular chains of the elastomer, while the scalar quantity quantifies the degree of structural damage (debonding factor). The model exhibits a yielding behavior. It is intrinsically nonlinear, as the nonlinear response develops and is observable at early deformations.

In a single-mode approach, the total stress tensor can be decomposed as the sum of free and trapped

contributions, as follows:

(6–52) |

As for other viscoelastic models, a purely viscous component is added to the viscoelastic components in order to get the

total extra-stress tensor:

(6–53) |

where is the rate-of-deformation tensor and

is the viscosity.

In Equation 6–52, subscripts

and

respectively refer to the free and trapped parts. Each of

these contributions obeys its own equation. In particular, they invoke their own

deformation field described by means of Finger tensors.

An elastic Finger tensor is defined for the free chains, which obeys the following

equation:

(6–54) |

where is the relaxation time,

is the unit tensor, while

and

are the first invariant of

and

, respectively, defined as

(6–55) |

(6–56) |

The implemented material function that appears in Equation 6–54 is written as follows:

(6–57) |

The parameter must be

; and increases slightly the amount of shear thinning.

Similarly, an elastic Finger tensor is defined for the trapped chains, which obeys the following

equation:

(6–58) |

where and

are the first invariant of

and

, respectively, defined as

(6–59) |

(6–60) |

In the equation for the trapped chains, the variable quantifies the degree of structural damage (debonding factor),

and is the fraction of the initially trapped chains that are debonded from the

filler particles during flow. The function

is a structural damage dependent scaling factor for the

relaxation time

and is referred to as the “mobility function".

A phenomenological kinetic equation is suggested for :

(6–61) |

In Equation 6–61, is the local shear rate while

is the yielding strain. Also,

is a dimensionless time factor, which may delay or accelerate

debonding.

For the mobility function appearing in Equation 6–58, the following form has been implemented:

(6–62) |

The above selection for the mobility function endows the rheological

properties with a yielding behavior. When is large (or unbounded), the algebraic term dominates the

constitutive equation for

(Equation 6–58), and the solution is expected to be

=1. When

is vanishing,

becomes governed by a purely transport equation; this may lead

to numerical troubles when solving a complex steady flow with secondary motions

(vortices). This situation can occur if parameter

is set to zero and under no-debonding situation

(

). Therefore, we suggest imposing a small (but nonzero) value

for parameter

(by default, we suggest the value 0.05, which is a reasonable

compromise between rheological properties and solver stability). Based on this,

parameter

can be understood as the value of the mobility function under

no-debonding.

Finally, in order to relate the Finger tensors to the corresponding stress

tensor, potential functions are required. For and

, the following expressions are suggested:

(6–63) |

(6–64) |

with and

. It is interesting to note that

has no effect on the shear viscosity, while it contributes to

a decrease of the elongational viscosity. On the other hand, the parameter

increases both shear and elongational viscosities. From there,

stress contributions from free and trapped chains in Equation 6–52 are respectively

given by:

(6–65) |

(6–66) |

where parameter is the initial ratio of free to trapped chains in the system.

A vanishing value of

indicates that all chains are trapped at rest, while a large

value of

indicates a system that essentially consists of free chains.

The units for the parameters and their names in the Ansys Polymat interface are as follows:

| Parameter | Name in Ansys Polymat | Mass | Length | Time |

|---|---|---|---|---|

|

| visc, additional viscosity | 1 | –1 | –1 |

|

| trelax, relaxation time | - | - | 1 |

|

| G, shear modulus | 1 | –1 | –2 |

|

| alpha, initial ratio of free to trapped chains | - | - | - |

|

|

beta, coefficient in

potential function

| - | - | - |

|

|

n, index in potential

function

| - | - | - |

|

| m, deformation history-dependence | - | - | - |

|

|

nu, power index

| - | - | - |

|

| k, mobility under no-debonding | - | - | - |

|

| q, dimensionless time factor | - | - | - |

|

| gamma*, yielding strain | - | - | - |

|

| - | 1 | –1 | –2 |

|

| - | - | - | –1 |

|

| - | - | - | - |

By default, ,

,

,

, and

are set to 1,

and

are set to 2,

is set to 0.05 and the other parameters to 0.

Important: In the current version of Ansys Polymat, you cannot fit the Leonov model and/or draw the corresponding rheometric curves in the chart.

From the point of view of rheology and numerical simulation, for single- and multi-mode fluid models, a purely viscous contribution must be added to the total extra-stress tensor. Actually, this is largely motivated by the fact that the matrix of the discretized system can be singular when all fields are initialized to values that correspond to the solution at rest. Hence, the first or only mode will always be accompanied by a Newtonian contribution, whose corresponding viscosity value received a unit default value. This value can be modified by the user.

Also, as suggested above, a non-vanishing value should be selected for the mobility function under

no-debonding.

As can be seen, next to parameters and

controlling the linear properties, the model involves two

functions and several nonlinear parameters. In a single mode approach, the

influence of these parameters on the viscometric and elongational properties

can be easily identified, and appropriate values can be selected

accordingly. By default, the nonlinear parameters are assigned values that

are relevant from the point of view of rheology. In a multi-mode approach,

in order to facilitate the definition of a flow case, corresponding

nonlinear parameters should preferably be identical for each mode.

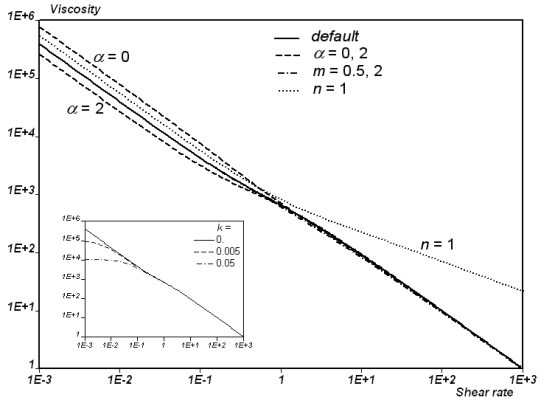

In simple shear flow, the Leonov model exhibits shear thinning, which is

slightly affected by some parameters. Figure 6.53: Shear Viscosity of the Leonov Model with Parameters G=1000, λ=1,

q=1, β=0, ν=2, γ*=2, and a=1, k=n=m=0 (continuous

lines). shows

that an increase of the parameter (initial ratio of free to trapped chains) slightly

decreases the shear viscosity at low shear rates. This can be easily

understood if you consider, for example, that when

=0, the material consists only of trapped chains at rest.

The figure also shows that parameter

increases the shear viscosity at high shear rates, while

parameter

has a very limited influence. Finally, as can be seen in

Figure 6.53: Shear Viscosity of the Leonov Model with Parameters G=1000, λ=1,

q=1, β=0, ν=2, γ*=2, and a=1, k=n=m=0 (continuous

lines).,

shear viscosity curves do not show a plateau at low shear rates. This is the

fingerprint of the yielding behavior of the fluid model, which is controlled

by the value of the mobility function under no-debonding (parameter

). Actually, if

increases, the viscosity curves exhibit a plateau at low

shear rates; however, as can be seen in the insert, this does not affect the

behavior at high shear rates, while it may improve the stability of the

solver.

Figure 6.53: Shear Viscosity of the Leonov Model with Parameters G=1000, λ=1, q=1, β=0, ν=2, γ*=2, and a=1, k=n=m=0 (continuous lines).

Dashed and dashed-dotted lines show the viscosity for the value of the parameters as indicated. The insert shows the viscosity curves obtained for various values of the mobility function under no-debonding (parameter k). Note that these curves are not obtained from Ansys Polymat; they result from semi-analytical calculations.

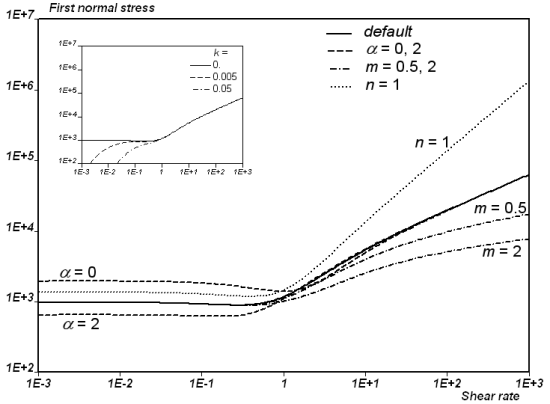

Figure 6.54: First Normal Stress Difference of the Leonov Model with Parameters

G=1000, λ=1, q=1, β=0, ν=2, γ*=2, and a=1, k=n=m=0

(continuous lines). shows

that similar trends are found for the first normal stress difference. Figure 6.54: First Normal Stress Difference of the Leonov Model with Parameters

G=1000, λ=1, q=1, β=0, ν=2, γ*=2, and a=1, k=n=m=0

(continuous lines). shows

that an increase of the parameter slightly decreases the first normal stress difference at

all shear rates. The figure also shows that parameter

increases the first normal stress difference at all shear

rates, while parameter

decreases it at high shear rates. Finally, as can be seen,

the first normal stress difference shows a plateau at low shear rates; this

is a counterpart of the yielding behavior of the fluid model, which is also

controlled by the value of the mobility function under no-debonding

(parameter

). Actually, if

increases, the first normal stress difference exhibit a

quadratic behavior at low shear rates; however, as can be seen in the

insert, this does not affect the behavior at high shear rates, while it may

improve the stability of the solver.

Figure 6.54: First Normal Stress Difference of the Leonov Model with Parameters G=1000, λ=1, q=1, β=0, ν=2, γ*=2, and a=1, k=n=m=0 (continuous lines).

Dashed, dashed-dotted and dotted lines show the first normal stress

difference for the value of the parameters as indicated. The insert shows

the curves of first normal stress difference obtained for various values of

the mobility function under no-debonding (parameter ). Note that these curves are not obtained from Ansys Polymat;

they result from semi-analytical calculations.

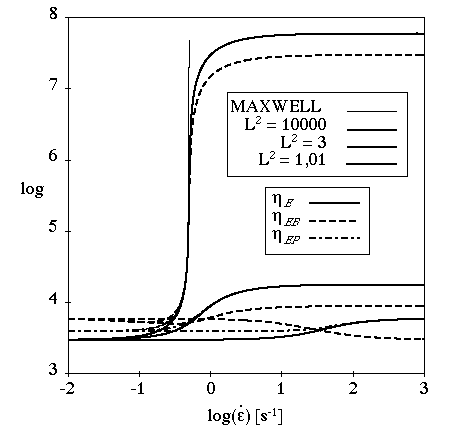

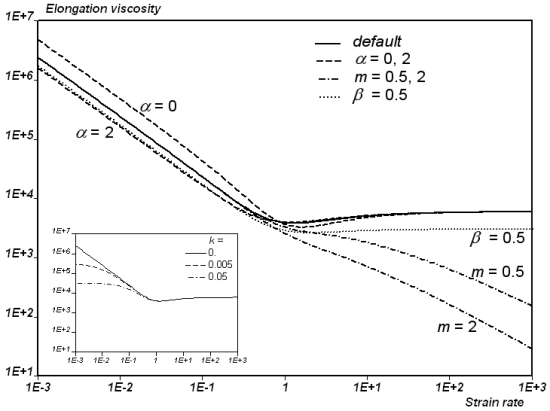

In simple elongation flow, the Leonov model exhibits marked strain

thinning at low strain rates; it is slightly affected by some parameters.

Figure 6.55: Elongation Viscosity of the Leonov Model with Parameters G=1000,

λ=1, q=1, n=1, ν=2, γ*=2, and a=1, β=k=m=0 (continuous

lines). shows that an increase of the parameter (initial ratio of free to trapped chains) slightly

decreases the elongation viscosity at low strain rates. This can be easily

understood if you consider, for example, that when

=0, the material consists only of trapped chains at rest.

The figure also shows that parameter

increases the elongation viscosity at high strain rates,

while parameters

and

decrease the elongation viscosity. Finally, as can be seen

in Figure 6.55: Elongation Viscosity of the Leonov Model with Parameters G=1000,

λ=1, q=1, n=1, ν=2, γ*=2, and a=1, β=k=m=0 (continuous

lines)., elongation viscosity curves do not show a plateau. This is the

fingerprint of the yielding behavior of the fluid model, which is controlled

by the value of the mobility function under no-debonding (parameter

). Actually, if

increases, the elongation viscosity curves exhibit a

plateau at low strain rates; however, as can be seen in the insert of Figure 6.55: Elongation Viscosity of the Leonov Model with Parameters G=1000,

λ=1, q=1, n=1, ν=2, γ*=2, and a=1, β=k=m=0 (continuous

lines).,

this does not really affect the behavior at high strain rates while it may

improve the stability of the solver.

Figure 6.55: Elongation Viscosity of the Leonov Model with Parameters G=1000, λ=1, q=1, n=1, ν=2, γ*=2, and a=1, β=k=m=0 (continuous lines).

Dashed, dashed-dotted and dotted lines show the elongation viscosity for

the value of the parameters as indicated. The insert shows the curves of the

steady elongation viscosity obtained for various values of the mobility

function under no-debonding (parameter ). Note that these curves are not obtained from Ansys Polymat;

they result from semi-analytical calculations.

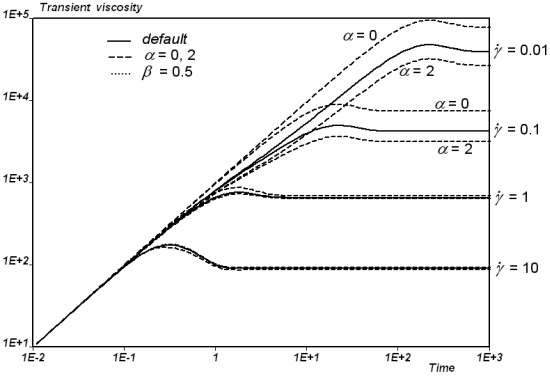

Figure 6.56: Transient Shear Viscosity of the Leonov Model Versus Time, at Shear

Rates Ranging from 10^-2 to 10, With Parameters G=1000, λ=1, q=1,

n=1, β=0, ν=2, γ*=2, and a=1, k=m=n=0, (continuous

lines).

shows the transient shear viscosity versus time at shear rates ranging from

10-2 to 10, for various values of parameters

and

. At first, as can be seen, the transient shear viscosity

exhibits an overshoot before reaching the steady value. It is also

interesting to note that the response time decreases when the shear rate

increases. This actually results from the increasing mobility function under

increasing shear rates. Eventually, we find that parameter

decreases the elongation viscosity, while the other

parameters have a somewhat less marked influence.

Figure 6.56: Transient Shear Viscosity of the Leonov Model Versus Time, at Shear Rates Ranging from 10^-2 to 10, With Parameters G=1000, λ=1, q=1, n=1, β=0, ν=2, γ*=2, and a=1, k=m=n=0, (continuous lines).

Dashed and dotted lines show the viscosity for the value of the parameters as indicated. Note that these curves are not obtained from Ansys Polymat; they result from semi-analytical calculations.