Coextrusion is a process that is widely used to take advantage of the different mechanical, chemical, electrical, thermal-insulation, and possibly optical properties of different materials. Combining different grades of the same material into an extruded product also allows the use of cheaper materials or recycled resin where it is possible.

Coextrusion of two or more materials can be simulated with Ansys Polyflow in 2D and in 3D. For 2D cases, there are very few limitations on the complexity of the deformation of the moving interface. With advanced 2D remeshing techniques such as the Thompson transformation and Optimesh 2D methods, there is no constraint on the displacement of the nodes, so they can move anywhere in the plane of the flow.

For full 3D coextrusion problems, however, difficulties may arise in some circumstances. The limitation of the Optimesh and streamwise remeshing techniques that the nodes can be relocated only in the plane orthogonal to the extrusion direction may be too constraining. In some cases, the nodes should be allowed to move in all three dimensions. The Thompson 3D remeshing technique allows for full 3D motion of the nodes, but it also requires longer CPU time (due to the 3D relocation of the points) and may be less robust in some cases. Other techniques are currently under consideration.

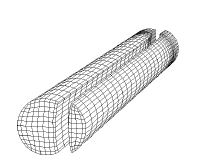

Depending upon the complexity of the geometry and/or the shape of the die itself, the intersection line between the die wall and the moving boundary may move along a curved line (as shown in Figure 15.11: 3D Coextrusion Example). Along this line, the normal component of the velocity is 0, whereas the tangential component is nonzero.

You will need to specify a nonzero slip coefficient along the wall in order to allow the intersection line to slide along the die border. Then the intersection line can move in a way that keeps it inside the geometrical entity defined by the wall. The slip coefficient should be specified such that the slip velocity remains small with respect to the mean flow velocity.

Using multiple materials in Ansys Polydata can also be considered an alternative approach to coextrusion. For more information, see Using Multiple Materials in Polymer Flows.