For VOF and related techniques, an essential accuracy criteria is the conservation

of volume (or mass). When simulating an injection, for example, it is important that

all of the fluid volume that enters the domain is reflected in the distribution. Volume loss can be an issue when a simulation

involves many time steps, even with a highly accurate integration of Equation 21–1. This is because the small

volume errors associated with each time step can accumulate to yield a significant

loss.

In order to minimize the volume loss, time is handled differently in VOF

simulations than in an ordinary time-dependent scheme. First of all,

Ansys Polyflow attempts to minimize the number of time steps needed by varying the

length of time used for the time steps (). Though you set

for the initial time step of your VOF simulation, it is

automatically determined for all subsequent time steps based on the outcome of the

previous steps (see the section that follows for descriptions of various scenarios).

Another way that VOF simulations minimize volume loss is the manner in which the

elapsed time is calculated. Consider the calculations that are performed at each

time step: the flow field (that is, the values for velocity/pressure and possibly

other variables, such as the temperature or a chemical species concentration) is

computed for a time step, followed by an integration of Equation 21–1. When the new values for the

field are available for the domain, a determination can be made

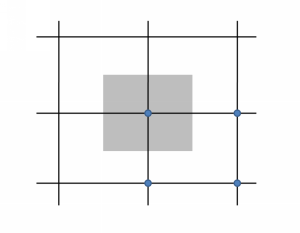

for the subdomains that surround every node (for example, the gray area in Figure 21.2: A Control Volume Surrounding a Node) as to whether

is above the threshold (which represents a "wet" node condition)

or below the threshold (which represents a “dry" node condition). In this

manner, the distribution of wet/dry nodes is known at each time step.

Because it is not possible to numerically integrate discontinuous data without

dissipation, the variation in the size of the wet domain is generally lower than the

net volume of fluid that entered the domain through the inlets during the time step.

To avoid translating this dissipation into a volume loss, Ansys Polyflow calibrates

the elapsed time for a successful time step based on the amount of fluid that

entered the domain, rather than simply equating it with . Note that this calibration is only performed when the flow rate

of fluid entering the domain is nonzero; when no fluid enters (for example, when no inlet

is present), the elapsed time is set equal to the initially defined value of the

time step. For this reason, you should define the initial time step conservatively.