For many extrusion simulations, the goal is to predict the die shape needed to produce a desired extrudate shape. This can be accomplished using the inverse extrusion approach (described in Inverse Extrusion and Die Design), as long as the flow at the die exit is well balanced. When it is not well balanced (that is, has large velocity variations), it is necessary to modify the shape of the die.

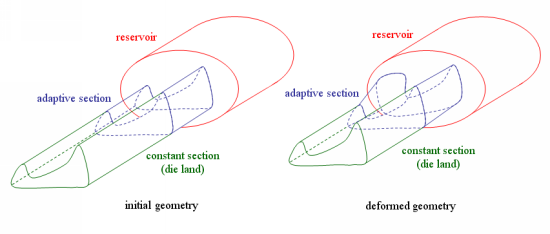

This chapter focuses on mesh parameterization for dies with a simple shape. Figure 35.1: The Main Sections of a Die shows the three main parts of such dies: the constant section (die land), the adaptive section, and the reservoir. This figure also provides an example of the difference between the initial geometry and the deformed geometry that balances the flow in the die.

In order to balance the die, you can make the following modifications:

modify the shape of the inlet for the adaptive section

You can "open" (enlarge) the zones where the velocity is low and thereby bring more fluid in this zone. You can also "close" (reduce) the zones where the velocity is large.

modify the length of the adaptive section

If the length is too short, stagnation zones may result. If it is too long, it is less efficient.

modify the length of the constant section

If the constant section is too long, the effect of adaptive section deformations will be reduced, because the fluid will have a "long" distance to reorganize itself.

In order to make such modifications, you need to prescribe the deformation of volumes, surfaces, lines, and points.