VM-LSDYNA-SOLVE-030

VM-LSDYNA-SOLVE-030

Bending of Long Plate Subjected to Moment - Plane Strain Model

Overview

| Reference: | Any standard strength-of-materials book |

| Analysis Type(s): | Plane Strain Analysis |

| Element Type(s): | 2D Structural Solid |

| Input Files: | Link to Input Files Download Page |

Test Case

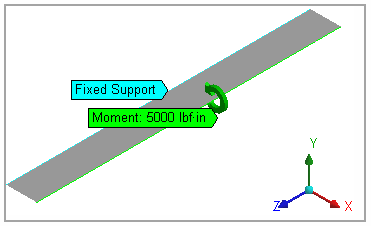

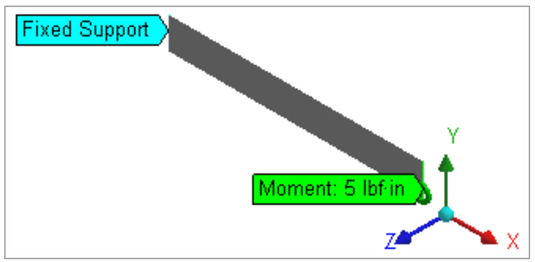

A long, rectangular plate is fixed along the longitudinal face, and the opposite face is subjected to a moment of 5000 lbf-in about the Z axis. To get accurate results, the advanced mesh control element size is set to 0.5 inches. The goal is to find the X normal stress at a distance of 0.5 inches from the fixed support as well as the total deformation and reaction moment.

This test case also appears in the Workbench Verification Manual. See VM-WB-MECH-030.

| Material Properties | Geometric Properties | Loading |

|---|---|---|

|

E = 2.9e7 psi ν = 0 ρ = 0.0007345 lbf·s2/in |

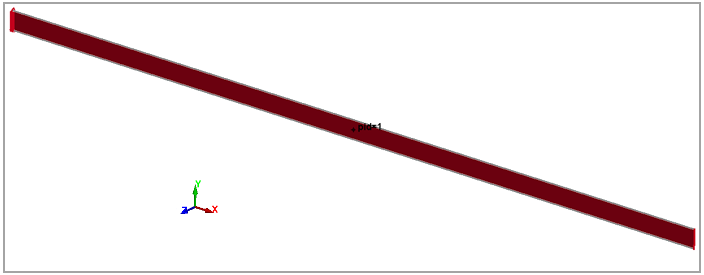

Length L = 1000 in Width W = 40 in Thickness T = 1 in |

M = 9000 lbf-in (Z direction) |

Analysis Assumptions and Modeling Notes

Since the loading is uniform and in one plane (the X-Y plane), the test case can be analyzed as a plane strain problem. Therefore, the moment applied will be per unit length (5000/1000 = 5 lbf-in). The analysis takes into account the unit length in the Z-direction.

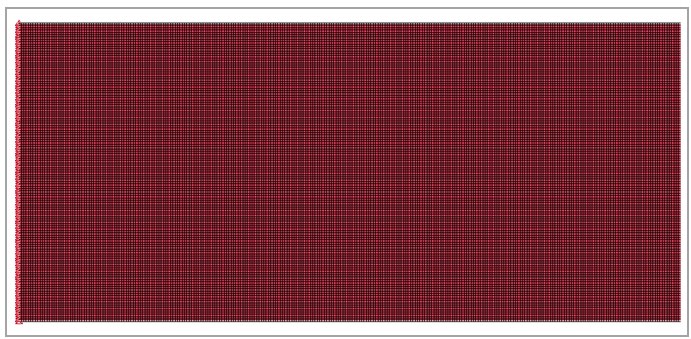

In LS-DYNA, a shell-type model (using the SECTION_SHELL keyword) has been used by selecting the section type, with a value for ELFORM of 13 (using Plane strain) and a value for NIP of 4 (2 x 2 Gauss quadrature with fully integrated two-dimensional elements). To achieve good results, the problem requires a very fine mesh, as shown in Figure 111.

Results Comparison

The LS-DYNA results are nearly identical to the theoretical results.

| Results | Target | LS-DYNA Solver | Error (%) |

|---|---|---|---|

| Normal Stress (psi) | 30 | 29,77 | 0.077% |

| Maximum Normal Stress in the X-Direction (psi) | 30 | 29,77 | 0.077% |

| Maximum Total Deformation (in) | 0.1655e-2 | 0.1655e-2 | 0% |

| Total Reaction Moment (lbf-in) | -5 | -5 | 0% |