In addition to the fluid properties described in Initialization of the Fluid Properties, initial momentum resulting from swirl flow may be important for some types of simulations. Internal combustion engines in particular are designed to impart a significant amount of swirl motion into the incoming air. This aids in turbulent mixing and enhances combustion efficiency. From experimental observation, modelers have determined that a Bessel function profile for the swirl component of the flow more accurately represents the flow under IC engine conditions.

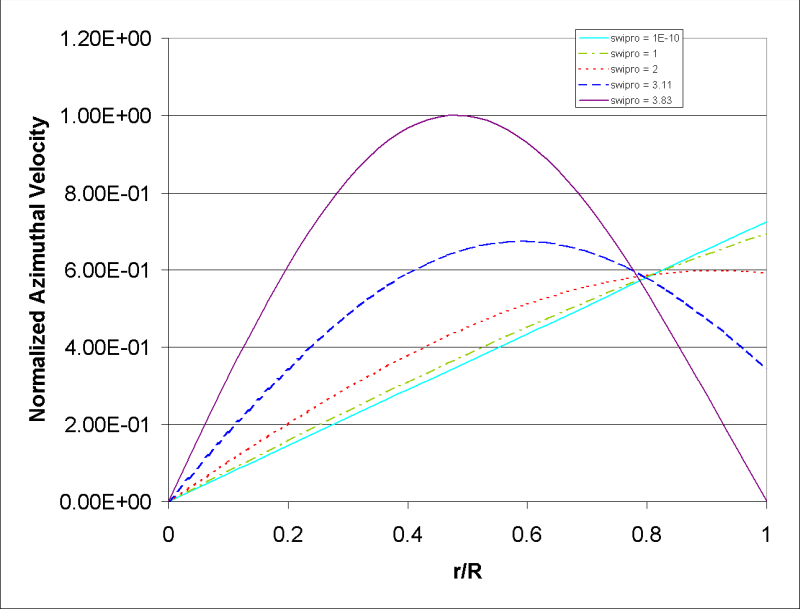

Figure 4.1: Bessel-function swirl velocity profile illustrates the Bessel function velocity profile provided in Ansys Forte and compares it with a simpler "wheel flow" model that is commonly used in other CFD representations. The comparison is shown for the same swirl number. The quantity α is a dimensionless constant that defines the initial azimuthal velocity profile and lies between 0.0 (the wheel flow limit) and 3.83 (zero velocity at the wall). In Figure 4.1: Bessel-function swirl velocity profile, the Bessel profile is illustrated for different values of α . The Bessel function profile is defined to give the same angular momentum as wheel flow with the same swirl number. Thus, higher values of α correspond to the higher initial slope of the Bessel curve. A value suggested by Wahiduzzaman and Ferguson [101] for typical engine applications is about 3.11. The Bessel function profile in Ansys Forte is defined such that it gives the same angular momentum as a wheel-flow profile that has the same swirl number. Thus the initial slope of the α = 3.11 curve is necessarily higher than the corresponding slope for wheel flow.

A second input quantity is the initial swirl ratio of the air rotation rate to crankshaft rotation rate (that is, rpm). When viewed from the positive z direction (the top of the engine cylinder), the swirl is clockwise if SWIRL < 0 and counterclockwise if SWIRL > 0.