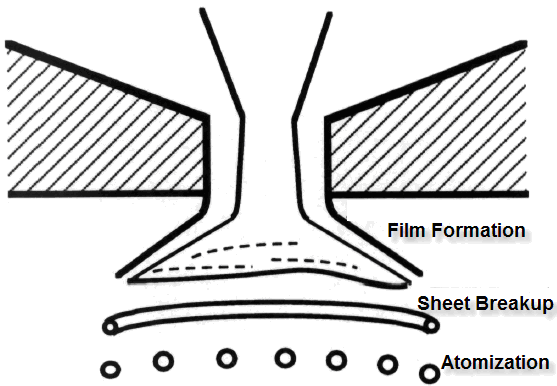

Hollow-cone sprays are typically created by pressure-swirl injectors. The injector contains internal swirl vanes that produce rotational motion in the liquid. The liquid forms a film along the inside walls of the injector with an air core in the center. The liquid film becomes a free sheet when exiting the injector, and the tangential velocity of the liquid becomes radial. As the radial distance from the centerline to the sheet increases, the rotation decreases due to conservation of angular momentum. Additionally, because of the conservation of mass, the sheet thins as it progresses, and subsequently disintegrates into droplets, forming a hollow cone spray. Once droplets are formed, their behavior is governed by secondary breakup, drag, collision, coalescence and vaporization.

The modeled processes in Ansys Forte are sketched in Figure 6.6: Modeled processes in a hollow-cone spray . Both inwardly-opening (with an air core but no pintle) and outwardly opening (with a pintle but no air core) are considered. These two sub-models governing the behavior of these sprays are described in the following sub-sections.