Use the Advance tab to access advanced features and define advanced types of forming simulations. For more information about advanced simulation types, refer to Using Advanced Features (Advance Tab).

Use the Advance tab to access advanced features and define advanced types of forming simulations. For more information about advanced simulation types, refer to Using Advanced Features (Advance Tab).

- Trim Line Development

Define an advanced simulation type that enables you to optimize trimming curves through iterative simulations. Click this button to open the Trim Line Development Task Panel and define simulation parameters.

- Runner

When the advanced simulation type has been fully defined, click the button to run the simulation and make results available in the Analysis Tab. This will also open the Runner Task Panel to show job progress and provide job management tools.

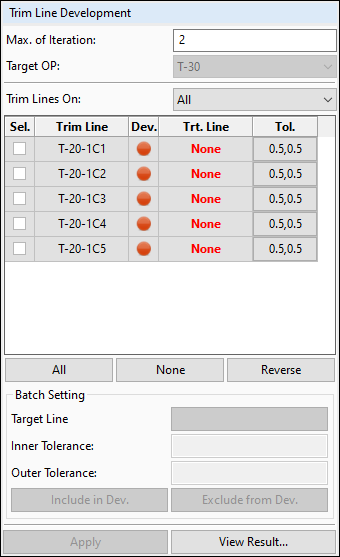

The Trim Line Development feature enables you to run multiple iterations of the simulation and use the results to modify selected trimming curves to create final parts that are within defined tolerances of a target curve. Click the button in the Optimization section of the Advance ribbon to open this task panel and define the parameters of this advanced simulation type.

For more information about defining and running a trim line development simulation, see Trim Line Development.

The Runner task panel on the Advance ribbon enables you to view the progress of the advanced solution type, and perform job management functions. The top line of the panel displays overall status and cumulative run time.

For Trim Line Development, the table shows all iterations of the process, and their completion status. While an iteration is in progress, the Time column displays the approximate time to completion, and once the iteration completes the column displays the total time that iteration took.

Command buttons below the table enable you to the simulation, the simulation or the job to run once other simulations are complete, and existing simulation results from the working directory.

There is no need to wait for all simulation operations to complete before proceeding to the Analysis Tab. As soon as the first operation has completed, the results are available for postprocessing. As more operations complete, more results will be available. This enables you to evaluate the forming process operation by operation, while the simulation progresses, and stop the simulation if any operation produces unsatisfactory results.