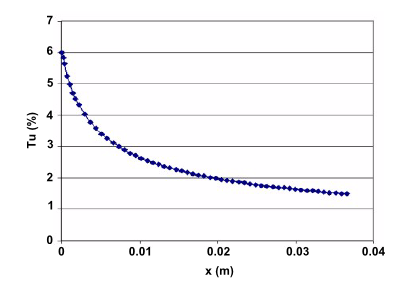

It has been observed that the turbulence intensity specified at an inlet can decay quite

rapidly depending on the inlet viscosity ratio () (and hence turbulence eddy frequency). As a result, the local turbulence

intensity downstream of the inlet can be much smaller than the inlet value (see Figure 4.5: Exemplary Decay of Turbulence Intensity (Tu) as a Function of Streamwise Distance

(x)). Typically, the larger the inlet viscosity ratio, the smaller

the turbulent decay rate. However, if too large a viscosity ratio is specified (that is, >

100), the skin friction can deviate significantly from the laminar value. There is experimental

evidence that suggests that this effect occurs physically; however, at this point it is not clear

how accurately the transition model reproduces this behavior. For this reason, if possible, it is

desirable to have a relatively low (that is,

1 – 10) inlet viscosity ratio and to estimate the inlet value of

turbulence intensity such that at the leading edge of the blade/airfoil, the turbulence intensity

has decayed to the desired value. The decay of turbulent kinetic energy can be calculated with

the following analytical solution:

(4–191) |

For the SST turbulence model in the freestream the constants are:

(4–192) |

The time scale can be determined as follows:

(4–193) |

where is the streamwise distance downstream of the inlet and

is the mean convective velocity. The eddy viscosity is defined as:

(4–194) |

The decay of turbulent kinetic energy equation can be rewritten in terms of inlet turbulence

intensity () and inlet eddy viscosity ratio (

) as follows:

(4–195) |

You should ensure that the values around the body of interest roughly satisfy

>0.1%. For smaller values of

, the reaction of the SST model production terms to the transition onset becomes

too slow, and transition can be delayed past the physically correct location.