VMFL021

VMFL021

Cavitation

Over a Sharp-Edged Orifice Case A: High Inlet Pressure

Overview

| Reference | W.H. Nurick, “Orifice Cavitation and Its Effects on Spray Mixing”. Journal of Fluids Engineering, Vol.98, pp. 681-687, 1976 | ||

| Solver | Ansys Fluent, Ansys CFX | ||

| Physics/Models | Turbulent multiphase flow with cavitation and phase change | ||

| Input File |

| ||

| Project Files | Link to Project Files Download Page |

Test Case

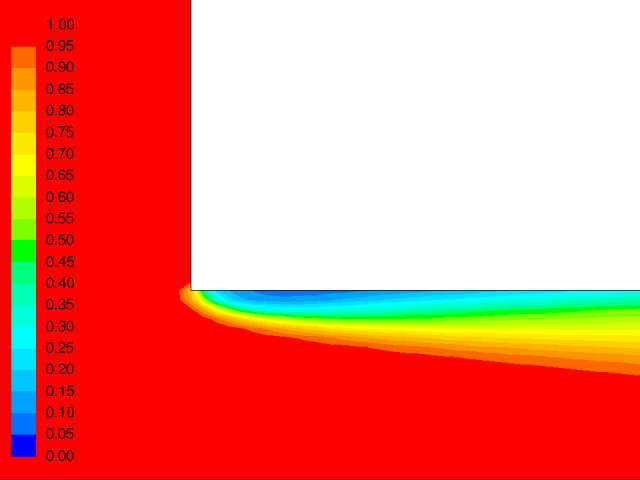

A steady, axisymmetric, multiphase (water/steam) flow, with phase change taking place. Due to sudden contraction a low pressure region occurs near the sharp edge which results in cavitation. Figure 57: Flow Domain depicts the orifice geometry. Flow direction is from left to right.

| Material Properties | Geometry | Boundary Conditions |

|---|---|---|

|

Liquid: Water Density : 1000 kg/m3 Viscosity: 0.001 kg/m-s Gas: Water-Vapor Density: 0.02558 kg/m3 Viscosity: 1.26x10-6 kg/m-s |

L1 = 1.60 cm L2 = 3.20 cm r1 = 1.15 cm r2 = 0.40 cm |

P1 = 250,000,000 Pa P2 = 95,000 Pa T = 300 K Pvapor = 3,540 Pa |

Analysis Assumptions and Modeling Notes

The flow is steady and incompressible. Pressure based solver is used. Fluent uses standard k-ε model with standard wall functions for the turbulence model while CFX uses SST. The Zwart-Gerber-Belamri cavitation model is applied together with mixture multiphase model.

For analysis of results, we calculate and compare the discharge coefficient with the experimental data.

The coefficient of discharge, ,

is the ratio of the mass flow rate through the nozzle to the theoretical

maximum mass flow rate:

In the above equation, is the mass flow rate as calculated

by the CFD solver.