VMFL020

VMFL020

Adiabatic

Compression of Air in Cylinder by a Reciprocating Piston

Overview

| Reference | L.D. Russell, G.A. Adebiyi, Classical Thermodynamics, Saunders College Publishing, Philadelphia, PA, 1993 | ||

| Solver | Ansys Fluent, Ansys CFX | ||

| Physics/Models | Dynamic Mesh, Transient flow with ideal gas effects | ||

| Input File |

| ||

| Project Files | Link to Project Files Download Page |

Test Case

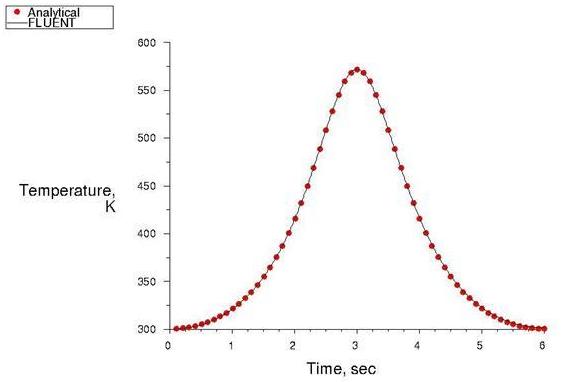

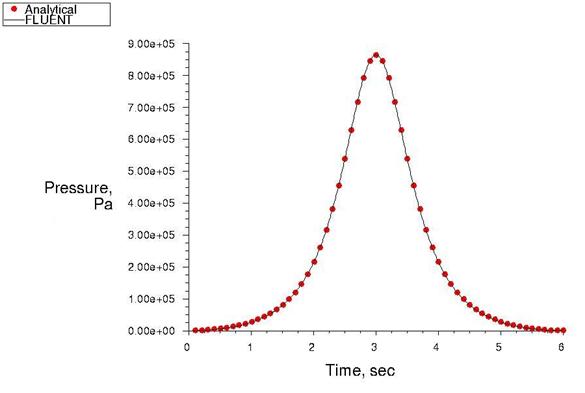

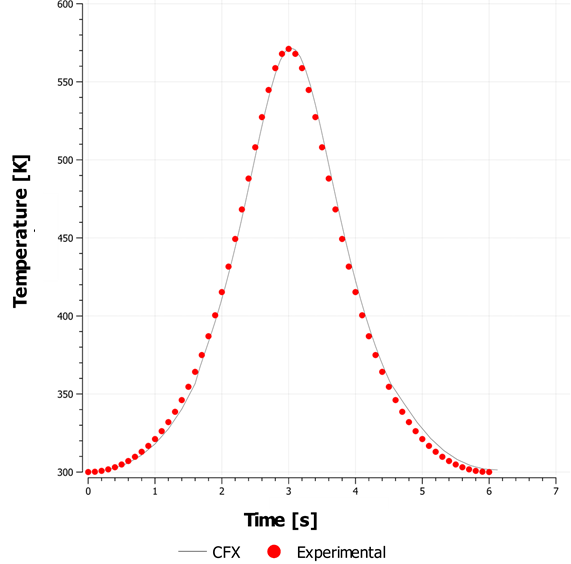

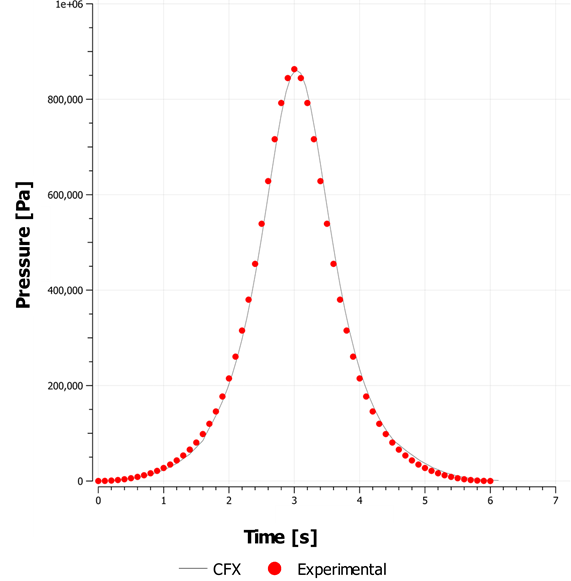

Air undergoes adiabatic compression due to the movement of a piston inside a rectangular box, representing a cylinder geometry in 2–D as shown in Figure 51: In-Cylinder Piston Description. The Top Dead Center (TDC) corresponds to a crank angle of 360°. The piston moves back after reaching TDC.

| Material Properties | Geometry | Boundary Conditions |

|---|---|---|

|

Ideal gas law for density Viscosity = 1.7894 X 10–5 kg/m-s |

Length of the block = 10 m Width of the block = 8 m |

Movement of the piston is modeled using deforming mesh |

Analysis Assumptions and Modeling Notes

The compression within the cylinder is assumed to be adiabatic. The spring-based smoothing method with local remeshing is used for modeling the dynamic mesh motion.