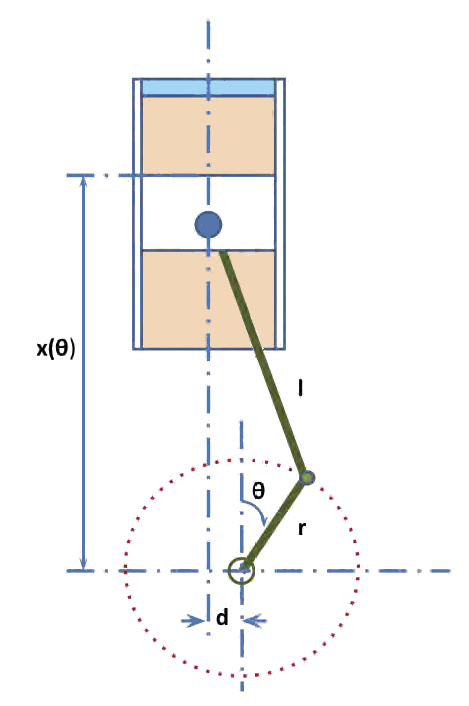

The schematic in Figure 8.7: Schematic of an engine cylinder with a positive piston offset shows the configuration of an engine cylinder with the centerline of the piston pin shifted to the left of the crank shaft by an amount of . A negative

value means the piston pin is located to the right of the crank shaft center. The crank shaft radius is

, the connecting rod length is

, and the bore diameter is

. The nominal values of the clearance volume of the cylinder and the compression ratio are

and

, respectively.

The location of the top piston surface above the crank shaft center x can be expressed as a function of crank angle :

(8–48) |

The crank angle (in radians) is a function of time and engine speed (in rpm) and is given as

, in which the angular velocity of the crank shaft is

.

A positive piston offset will lead to top-dead center (TDC) advance and its effects on piston movement are illustrated by Figure 8.8: Comparison of piston location ( ) versus crank angle (

in degree) between engines with positive piston offset and without piston offset (

and

=0.4) . A "negative" piston offset (that is, the piston pin is to the right of the crank shaft) will result in retarding TDC.

The actual TDC of an engine with a piston offset of can be found as

(8–49) |

And the bottom dead center (BDC) is located at

(8–50) |

The actual stroke can be computed as

(8–51) |

Subsequently, the piston velocity can be derived by taking the time-derivative of the piston location :

(8–52) |

The instantaneous cylinder volume can be found to be:

(8–53) |

and the rate of change of the cylinder volume is the time-derivative of the cylinder volume:

(8–54) |

The internal surface area of the cylinder (for wall heat transfer calculations) is

(8–55) |

or

(8–56) |

is the cylinder-head-to-bore area ratio, and

is the piston-head-to-bore area ratio. The default value of the area ratios is 1.

Figure 8.8: Comparison of piston location ( ) versus crank angle (

in degree) between engines with positive piston offset and without piston offset (

and

=0.4)