This tutorial includes:

- 28.1. Tutorial Features

- 28.2. Overview of the Problem to Solve

- 28.3. Preparing the Working Directory

- 28.4. Simulating the Coal Combustion without Swirl and without Nitrogen Oxide

- 28.5. Simulating the Coal Combustion with Swirl and without Nitrogen Oxide

- 28.6. Simulating the Coal Combustion with Swirl and with Nitrogen Oxide

In this tutorial you will learn about:

Importing a CCL file in CFX-Pre.

Setting up and using Proximate/Ultimate analysis for hydrocarbon fuels in CFX-Pre.

Viewing the results for nitrogen oxide in CFD-Post.

|

Component |

Feature |

Details |

|---|---|---|

|

CFX-Pre |

User Mode |

General mode |

|

Analysis Type |

Steady State | |

|

Fluid Type |

Reacting Mixture, Hydrocarbon Fuel | |

|

CCL File |

Import | |

|

Domain Type |

Single Domain | |

|

Boundaries |

Coal Inlet | |

|

Air Inlet | ||

|

Outlet | ||

|

No-slip Wall | ||

|

Periodic | ||

|

Symmetry | ||

|

CFD-Post |

Plots |

Particle Tracking |

In this tutorial, you will model coal combustion and radiation in a furnace. Three different coal combustion simulations will be set up:

Coal Combustion with no-swirl burners where there is no release of nitrogen oxide during the burning process.

Coal Combustion with swirl burners where there is no release of nitrogen oxide during the burning process.

Coal Combustion with swirl burners where there is release of nitrogen oxide during the burning process.

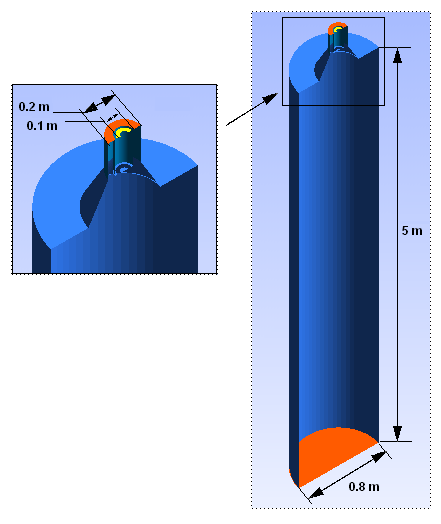

The following figure shows half of the full geometry. The coal

furnace has two inlets: Coal Inlet and Air Inlet, and one outlet. The Coal Inlet (see the inner yellow annulus shown in the figure inset) has air

entering at a mass flow rate of 1.624e-3 kg/s and pulverized coal

particles entering at a mass flow rate of 1.015e-3 kg/s. The Air Inlet (see the outer orange annulus shown in the figure

inset) is where heated air enters the coal furnace at a mass flow

rate of 1.035e-2 kg/s. The outlet is located at the opposite end of

the furnace and is at a pressure of 1 atm.

The provided mesh occupies a 5 degree section of an axisymmetric coal furnace. Each simulation will make use of either symmetric or periodic boundaries to model the effects of the remainder of the furnace. In the case of non-swirling flow, a pair of symmetry boundaries is sufficient; in the case of flow with swirl, a periodic boundary with rotational periodicity is required.

The relevant parameters of this problem are:

Coal Inletstatic temperature = 343 KSize distribution for the drops being created by the

Coal Inlet= 12, 38, 62, 88Air Inletstatic temperature = 573 KOutletaverage static pressure = 0 PaCoal Gunwall fixed temperature = 800 KCoal Inletwall fixed temperature = 343 KAir Inletwall fixed temperature = 573 KFurnace wallfixed temperature = 1400 KO2mass fraction = 0.232Proximate/ultimate analysis data for the coal. Note that proximate/ultimate analysis data is used to characterize the properties of the coal including the content of moisture, volatile, free carbon, and ash, as well as the mass fractions of carbon, hydrogen and oxygen (the major components), sulfur and nitrogen.

The approach for solving this problem is to first import, into CFX-Pre, a CCL file with the proximate/ultimate analysis data for the coal and the required materials and reactions. The first simulation will be without nitrogen oxide or swirl. Only small changes to the boundary conditions will be made to create the second simulation, which has swirl in the flow. After each of the first two simulations, you will use CFD-Post to see the variation of temperature, water mass fraction and radiation intensity. You will examine particle tracks colored by temperature and by ash mass fraction. The last simulation has swirl and also involves the release of nitrogen oxide. Finally, you will use CFD-Post to see the distribution of nitrogen oxide in the third simulation.

If this is the first tutorial you are working with, it is important to review the following topics before beginning:

Create a working directory.

Ansys CFX uses a working directory as the default location for loading and saving files for a particular session or project.

Download the

coal_combustion.zipfile here .Unzip

coal_combustion.zipto your working directory.Ensure that the following tutorial input files are in your working directory:

CoalCombustion.gtmCoalCombustion_Reactions_Materials.ccl

Set the working directory and start CFX-Pre.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

You will first create a simulation where there is no release of nitrogen oxide, a hazardous chemical, during the process. Swirl burners will not be used in this simulation.

In CFX-Pre, select File > New Case.

Select General and click .

Select File > Save Case As.

Set File name to

CoalCombustion_nonox.cfx.Click .

Right-click

Meshand select Import Mesh > CFX Mesh.The Import Mesh dialog box appears.

Configure the following setting(s):

Setting

Value

File name

CoalCombustion.gtm

Click Open.

Right-click a blank area in the viewer and select Predefined Camera > Isometric View (Z up) from the shortcut menu.

CFX Command Language (CCL) consists of commands used to carry

out actions in CFX-Pre, CFX-Solver Manager, and CFD-Post. The proximate/ultimate

analysis data for the coal as well as the materials and reactions

required for the combustion simulation will be imported from the CCL

file. You will review, then import, the contents of the CoalCombustion_Reactions_Materials.ccl file.

Note: The physics for a simulation can be saved to a CCL (CFX Command Language) file at any time by selecting File > Export > CCL.

Open

CoalCombustion_Reactions_Materials.cclwith a text editor and take the time to look at the information it contains.The CCL sets up the following reactions:

Fuel Gas OxygenHC Fuel Char FieldHC Fuel DevolatPrompt NO Fuel Gas PDFThermal NO PDF.

The CCL also sets up the following materials:

AshCharFuel GasGas mixtureHC FuelHC Fuel Gas Binary MixtureRaw Combustible

The reactions

Prompt NO Fuel Gas PDFandThermal NO PDFare used only in the third simulation. Other pure substances required for the simulation will be loaded from the standard CFX-Pre materials library.In CFX-Pre, select File > Import > CCL.

The Import CCL dialog box appears.

Under Import Method, select Replace.

This will replace the materials list in the current simulation with the ones in the newly imported CCL.

Under Import Method, select Auto-load materials.

This will load pure materials such as

CO2,H2O,N2,O2, andNO— the materials referenced by the imported mixtures and reactions — from the CFX-Pre materials library.Select

CoalCombustion_Reactions_Materials.ccl(the file you reviewed earlier).Click Open.

Expand the

MaterialsandReactionsbranches underSimulationto make sure that all the materials and reactions described above are present.

Create a new domain named Furnace as

follows:

Right-click

Simulation>Flow Analysis 1in the Outline tree view and click Insert > Domain.Set Name to

Furnace.Click

On the Basic Settings, tab under Fluid and Particle Definitions, delete

Fluid 1and create a new fluid definition namedGas Mixture.Click Add new item

and create a new fluid definition

named

and create a new fluid definition

named HC Fuel.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Location and Type

> Location

B40

Fluid and Particle Definitions

Gas Mixture

Fluid and Particle Definitions

> Gas Mixture

> Material

Gas Mixture [ a ]

Fluid and Particle Definitions

> Gas Mixture

> Morphology

> Option

Continuous Fluid

Fluid and Particle Definitions

HC Fuel

Fluid and Particle Definitions

> HC Fuel

> Material

HC Fuel [ b ]

Fluid and Particle Definitions

> HC Fuel

> Morphology

> Option

Particle Transport Solid

Fluid and Particle Definitions

> HC Fuel

> Morphology

> Particle Diameter Change

(Selected)

Fluid and Particle Definitions

> HC Fuel

> Morphology

> Particle Diameter Change

> Option

Mass Equivalent[ c ]

Fluid Models

Multiphase

> Multiphase Reactions

(Selected)

Multiphase

> Multiphase Reactions

> Reactions List

HC Fuel Char Field, HC Fuel Devolat

Heat Transfer

> Option

Fluid Dependent

Turbulence

> Option

k-Epsilon

Combustion

> Option

Fluid Dependent

Thermal Radiation

> Option

Fluid Dependent

Fluid Specific Models

Fluid

Gas Mixture

Fluid

> Gas Mixture

> Heat Transfer

> Heat Transfer

> Option

Thermal Energy

Fluid

> Gas Mixture

> Thermal Radiation

> Option

Discrete Transfer

Fluid

> Gas Mixture

> Thermal Radiation

> Number of Rays

(Selected)

Fluid

> Gas Mixture

> Thermal Radiation

> Number of Rays

> Number of Rays

32 [ d ]

Fluid

HC Fuel

Fluid

> HC Fuel

> Heat Transfer

> Heat Transfer

> Option

Particle Temperature

Fluid Pair Models

Fluid Pair

Gas Mixture | HC Fuel

Fluid Pair

> Gas Mixture | HC Fuel

> Particle Coupling

Fully Coupled

Fluid Pair

> Gas Mixture | HC Fuel

> Momentum Transfer

> Drag Force

> Option

Schiller Naumann

Fluid Pair

> Gas Mixture | HC Fuel

> Heat Transfer

> Option

Ranz Marshall

Fluid Pair

> Gas Mixture | HC Fuel

> Thermal Radiation Transfer

> Option

Opaque

Fluid Pair

> Gas Mixture | HC Fuel

> Thermal Radiation Transfer

> Emissivity

1 [ e ]

Fluid Pair

> Gas Mixture | HC Fuel

> Thermal Radiation Transfer

> Particle Coupling

(Selected)

Fluid Pair

> Gas Mixture | HC Fuel

> Thermal Radiation Transfer

> Particle Coupling

> Particle Coupling

Fully Coupled

Click the Ellipsis

icon to open the Material dialog box, then

select

icon to open the Material dialog box, then

select Gas Mixtureunder theGas Phase Combustionbranch. Click .Click the Ellipsis

icon to open the Material dialog box, then

select

icon to open the Material dialog box, then

select HC Fuelunder theParticle Solidsbranch. Click .The use of the

Mass Equivalentoption for the particle diameter is used here for demonstration only. A physically more sensible setting for coal particles, which often stay the same size or get bigger during combustion, would be the use of theSwelling Modeloption with a Swelling Factor of0.0(the default) or larger.Increasing the number of rays to 32 from the default 8, increases the number of rays leaving the bounding surfaces and increases the accuracy of the thermal radiation calculation.

With this setting, the particles are modeled as black bodies.

Click .

In this section you will create boundary conditions for the coal inlet, the air inlet, the outlet, and multiple no-slip walls. You will also create two symmetry-plane boundary conditions for this no-swirl case.

You will create the coal inlet boundary with mass flow rate

and static temperature set consistently with the problem description.

The particle diameter distribution will be set to Discrete

Diameter Distribution to model particles of more than one

specified diameter. Diameter values will be listed as specified in

the problem description. A mass fraction as well as a number fraction

will be specified for each of the diameter entries. The total of mass

fractions and the total of number fractions will sum to unity.

Create a boundary named

Coal Inlet.Configure the following setting(s) of

Coal Inlet:Tab

Setting

Value

Basic Settings

Boundary Type

Inlet

Location

CoalInlet

Boundary Details

Mass and Momentum

> Option

Mass Flow Rate

Mass and Momentum

> Mass Flow Rate

0.001624 [kg s^-1]

Flow Direction

> Option

Normal to Boundary Condition

Heat Transfer

> Option

Static Temperature

Heat Transfer

> Static Temperature

343 [K]

Component Details

O2

Component Details

> O2

> Option

Mass Fraction

Component Details

> O2

> Mass Fraction

0.232

Fluid Values

Boundary Conditions

> HC Fuel

> Particle Behavior

> Define Particle Behavior

(Selected)

Boundary Conditions

> HC Fuel

> Mass and Momentum

> Option

Zero Slip Velocity

Boundary Conditions

> HC Fuel

> Particle Position

> Option

Uniform Injection

Boundary Conditions

> HC Fuel

> Particle Position

> Particle Locations

(Selected)

Boundary Conditions

> HC Fuel

> Particle Position

> Particle Locations

> Particle Locations

Equally Spaced

Boundary Conditions

> HC Fuel

> Particle Position

> Number of Positions

> Option

Direct Specification

Boundary Conditions

> HC Fuel

> Particle Position

> Number of Positions

> Number

200

Boundary Conditions

> HC Fuel

> Particle Mass Flow

> Mass Flow Rate

0.001015 [kg s^-1]

Boundary Conditions

> HC Fuel

> Particle Diameter Distribution

(Selected)

Boundary Conditions

> HC Fuel

> Particle Diameter Distribution

> Option

Discrete Diameter Distribution

Boundary Conditions

> HC Fuel

> Particle Diameter Distribution

> Diameter List

12, 38, 62, 88 [micron]

Boundary Conditions

> HC Fuel

> Particle Diameter Distribution

> Mass Fraction List

0.18, 0.25, 0.21, 0.36

Boundary Conditions

> HC Fuel

> Particle Diameter Distribution

> Number Fraction List

0.25, 0.25, 0.25, 0.25

Boundary Conditions

> HC Fuel

> Heat Transfer

> Option

Static Temperature

Boundary Conditions

> HC Fuel

> Heat Transfer

> Static Temperature

343 [K]

Click .

Create the air inlet boundary with mass flow rate and static temperature set consistently with the problem description, as follows:

Create a new boundary named

Air Inlet.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Inlet

Location

AirInlet

Boundary Details

Mass and Momentum

> Option

Mass Flow Rate

Mass and Momentum

> Mass Flow Rate

0.01035 [kg s^-1]

Flow Direction

> Option

Normal to Boundary Condition

Heat Transfer

> Option

Static Temperature

Heat Transfer

> Static Temperature

573 [K]

Component Details

O2

Component Details

> O2

> Option

Mass Fraction

Component Details

> O2

> Mass Fraction

0.232

Click .

Create the outlet boundary with pressure specified, as follows:

Create a new boundary named

Outlet.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Outlet

Location

Outlet

Boundary Details

Mass and Momentum

> Option

Average Static Pressure

Mass and Momentum

> Relative Pressure

0[Pa]

Mass and Momentum

> Pres. Profile Blend

0.05

Click .

Create the Coal Gun Wall boundary with

a fixed temperature as specified in the problem description, as follows:

Create a new boundary named

Coal Gun Wall.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Wall

Location

CoalGunWall

Boundary Details

Heat Transfer

> Option

Temperature

Heat Transfer

> Fixed Temperature

800 [K]

Thermal Radiation

> Option

Opaque

Thermal Radiation

> Emissivity

0.6 [ a ]

Thermal Radiation

> Diffuse Fraction

1

Click .

Create the Coal Inlet Wall boundary with

fixed temperature as specified in the problem description, as follows:

Create a new boundary named

Coal Inlet Wall.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Wall

Location

CoalInletInnerWall, CoalInletOuterWall [ a ]

Boundary Details

Heat Transfer

> Option

Temperature

Heat Transfer

> Fixed Temperature

343 [K]

Thermal Radiation

> Option

Opaque

Thermal Radiation

> Emissivity

0.6

Thermal Radiation

> Diffuse Fraction

1

Click .

Create the Air Inlet Wall boundary with

fixed temperature as specified in the problem description, as follows:

Create a new boundary named

Air Inlet Wall.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Wall

Location

AirInletInnerWall, AirInletOuterWall

Boundary Details

Heat Transfer

> Option

Temperature

Heat Transfer

> Fixed Temperature

573 [K]

Thermal Radiation

> Option

Opaque

Thermal Radiation

> Emissivity

0.6

Thermal Radiation

> Diffuse Fraction

1

Click .

Create the Furnace Wall boundary with a

fixed temperature as specified in the problem description, as follows:

Create a new boundary named

Furnace Wall.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Wall

Location

FurnaceFrontWall, FurnaceOuterWall

Boundary Details

Heat Transfer

> Option

Temperature

Heat Transfer

> Fixed Temperature

1400 [K]

Thermal Radiation

> Option

Opaque

Thermal Radiation

> Emissivity

0.6

Thermal Radiation

> Diffuse Fraction

1

Click .

Create a new boundary named

Quarl Wall.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Wall

Location

QuarlWall

Boundary Details

Heat Transfer

> Option

Temperature

Heat Transfer

> Fixed Temperature

1200 [K]

Thermal Radiation

> Option

Opaque

Thermal Radiation

> Emissivity

0.6

Thermal Radiation

> Diffuse Fraction

1

Click .

You will use symmetry plane boundaries on the front and back regions of the cavity.

Create a new boundary named

Symmetry Plane 1.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Symmetry

Location

PeriodicSide1

Click .

Create a new boundary named

Symmetry Plane 2.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Symmetry

Location

PeriodicSide2

Click .

Click Solver Control

.

.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Convergence Control

> Max. Iterations

600

Convergence Control

> Fluid Timescale Control

> Timescale Control

Physical Timescale

Convergence Control

> Fluid Timescale Control

> Physical Timescale

0.005 [s] [ a ]

Particle Control

Particle Coupling Control

> First Iteration for Particle Calculation

(Selected)

Particle Coupling Control

> First Iteration for Particle Calculation

> First Iteration

25 [ b ]

Particle Coupling Control

> Iteration Frequency

(Selected)

Particle Coupling Control

> Iteration Frequency

> Iteration Frequency

10 [ c ]

Particle Under Relaxation Factors

(Selected)

Particle Under Relaxation Factors

> Vel. Under Relaxation

0.75

Particle Under Relaxation Factors

> Energy

0.75

Particle Under Relaxation Factors

> Mass

0.75

Particle Ignition

(Selected)

Particle Ignition

> Ignition Temperature

1000 [K]

Particle Source Smoothing

(Selected)

Particle Source Smoothing

> Option

Smooth

Advanced Options

Thermal Radiation Control

(Selected)

Thermal Radiation Control

> Coarsening Control

(Selected)

Thermal Radiation Control

> Coarsening Control

> Target Coarsening Rate

(Selected)

Thermal Radiation Control

> Coarsening Control

> Target Coarsening Rate

> Rate

16 [ d ]

The First Iteration parameter sets the coefficient-loop iteration number at which particles are first tracked; it allows the continuous-phase flow to develop before tracking droplets through the flow. Experience has shown that the value usually has to be increased to 25 from the default of 10.

The Iteration Frequency parameter is the frequency at which particles are injected into the flow after the First Iteration for Particle Calculation iteration number. The iteration frequency allows the continuous phase to settle down between injections because it is affected by sources of momentum, heat, and mass from the droplet phase. Experience has shown that the value usually has to be increased to 10 from the default of 5.

The Target Coarsening Rate parameter controls the size of the radiation element required for calculating Thermal Radiation. Decreasing the size of the element to 16, from the default 64, increases the accuracy of the solution obtained, while increasing the computing time required for the calculations.

Click .

Click Define Run

.

.Configure the following setting(s):

Setting

Value

File name

CoalCombustion_nonox.def

Click .

CFX-Solver Manager automatically starts and, on the Define Run dialog box, Solver Input File is set.

Quit CFX-Pre, saving the simulation (

.cfx) file.

When CFX-Pre has shut down and the CFX-Solver Manager has started, obtain a solution to the CFD problem by following the instructions below:

Ensure that the Define Run dialog box is displayed.

Solver Input File should be set to

CoalCombustion_nonox.def.Click Start Run.

CFX-Solver runs and attempts to obtain a solution. At the end of the run, a dialog box is displayed stating that the simulation has ended.

Select Post-Process Results.

If using stand-alone mode, select Shut down CFX-Solver Manager.

Click .

In this section, you will make plots showing the variation of

temperature, water mass fraction, and radiation intensity on the Symmetry Plane 1 boundary. You will also color the particle

tracks, which were produced by the solver and included in the results

file, by temperature and by ash mass fraction. The particle tracks

help to illustrate the mean flow behavior in the coal furnace.

Right-click a blank area in the viewer and select Predefined Camera > Isometric View (Z up).

This orients the geometry with the inlets at the top, as shown at the beginning of this tutorial.

Edit

Cases>CoalCombustion_nonox_001>Furnace>Symmetry Plane 1.Configure the following setting(s):

Tab

Setting

Value

Color

Mode

Variable

Variable

Temperature

Render

Show Faces

(Selected)

Lighting

(Cleared) [ a ]

Click .

As expected for a non-swirling case, the flame appears a significant distance away from the burner. The flame is likely unstable, as evidenced by the rate of solver convergence; the next simulation in this tutorial involves swirl, which tends to stabilize the flame, and has much faster solver convergence.

Change the variable used for coloring the plot to H2O.Mass Fraction and click Apply.

From the plot it can be seen that water is produced a significant distance away from the burner, as was the flame in the previous plot. As expected, the mass fraction of water is high where the temperature is high.

Change the variable used for coloring the plot to

Radiation Intensityand click Apply.This plot is directly related to the temperature plot. This result is consistent with radiation being proportional to temperature to the fourth power.

When you are finished, right-click

Symmetry Plane 1in the Outline tree view and select Hide.

Color the existing particle tracks for the solid particles by temperature:

Edit

Cases>CoalCombustion_nonox_001>Res PT for HC Fuel.Configure the following setting(s):

Tab

Setting

Value

Color

Mode

Variable

Variable

HC Fuel.Temperature

Click .

Observing the particle tracks, you can see that coal enters the chamber at a temperature of around 343 K. The temperature of the coal, as it moves away from the inlet, rises as it reacts with the air entering from the inlet. The general location where the temperature of the coal increases rapidly is close to the location where the flame appears to be according to the plots created earlier. Downstream of this location, the temperature of the coal particles begins to drop.

You will now create a simulation where swirl burners are used and where there is no release of nitrogen oxide during the process. Swirl burners inject a fuel axially into the combustion chamber surrounded by an annular flow of oxidant (normally air) that has, upon injection, some tangential momentum. This rotational component, together with the usually divergent geometry of the burner mouth, cause two important effects:

They promote intense mixing between fuel and air, which is important for an efficient and stable combustion, and low emissions.

They originate a recirculation region, just at the burner mouth, which traps hot combustion products and acts as a permanent ignition source, hence promoting the stability of the flame.

Ensure that the following tutorial input file is in your working directory:

CoalCombustion_nonox.cfx

Set the working directory and start CFX-Pre if it is not already running.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

Select File > Open Case.

From your working directory, select

CoalCombustion_nonox.cfxand click Open.Select File > Save Case As.

Set File name to

CoalCombustion_nonox_swirl.cfx.Click .

To add swirl to the flow, you will edit the Air

Inlet boundary to change the flow direction specification

from Normal to Boundary Condition to Cylindrical Components. You will also edit the Outlet boundary to change the Pressure Profile

Blend setting from 0.05 to 0; the reason for this change

is explained later. You will also delete the two symmetry plane boundary

conditions and replace them with a periodic domain interface.

Edit

Simulation>Flow Analysis 1>Furnace>Air Inlet.Configure the following setting(s):

Tab

Setting

Value

Boundary Details Flow Direction

> Option

Cylindrical Components

Flow Direction

> Axial Component

0.88

Flow Direction

> Radial Component

0

Flow Direction

> Theta Component

1

Axis Definition

> Rotational Axis

Global Z

Click .

The average pressure boundary condition leaves the pressure profile unspecified while constraining the average pressure to the specified value. In some situations, leaving the profile fully unspecified is too weak and convergence difficulties may result. The 'Pressure Profile Blend' feature works around this by blending between an unspecified pressure profile and a fully specified pressure profile. By default, the pressure profile blend is 5%. For swirling flow, however, imposing any amount of a uniform pressure profile is inconsistent with the radial pressure profile which should naturally develop in response to the fluid rotation, and the pressure profile blend must be set to 0.

Edit

Simulation>Flow Analysis 1>Furnace>Outlet.Configure the following setting(s):

Tab

Setting

Value

Boundary Details

Mass and Momentum

> Option

Average Static Pressure

Mass and Momentum

> Pres. Profile Blend

0

Click .

You will insert a domain interface to connect the Periodic Side 1 and Periodic Side 2 regions.

Create a domain interface named

Periodic.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Interface Type

Fluid Fluid

Interface Side 1

> Region List

PeriodicSide1

Interface Side 2

> Region List

PeriodicSide2

Interface Models

> Option

Rotational Periodicity

Click .

Click Define Run

.

.Configure the following setting(s):

Setting

Value

File name

CoalCombustion_nonox_swirl.def

Click .

CFX-Solver Manager automatically starts and, on the Define Run dialog box, Solver Input File is set.

Quit CFX-Pre, saving the simulation (

.cfx) file.

When CFX-Pre has shut down and the CFX-Solver Manager has started, obtain a solution to the CFD problem by following the instructions below.

Ensure that the Define Run dialog box is displayed.

Solver Input File should be set to

CoalCombustion_nonox_swirl.def.Click Start Run.

CFX-Solver runs and attempts to obtain a solution. At the end of the run, a dialog box is displayed stating that the simulation has ended.

Select Post-Process Results.

If using stand-alone mode, select Shut down CFX-Solver Manager.

Click .

In this section, you will make plots showing the variation of

temperature, water mass fraction, and radiation intensity on the Periodic Side 1 boundary. You will also color the existing

particle tracks by temperature and by ash mass fraction.

Right-click a blank area in the viewer and select Predefined Camera > Isometric View (Z up).

Edit

Cases>CoalCombustion_nonox_swirl_001>Furnace>Periodic Side 1.Configure the following setting(s):

Tab

Setting

Value

Color

Mode

Variable

Variable

Temperature

Render

Show Faces

(Selected)

Lighting

(Cleared)

Click .

As expected, the flame appears much closer to the burner than in the previous simulation, which had no swirl. This is due to the fact that the swirl component applied to the air from

Air Inlettends to entrain coal particles and keep them near the burner for longer, therefore helping them to burn.

Change the variable used for coloring the plot to H2O.Mass Fraction and click Apply.

Similar to the no-swirl case, the mass fraction of water with swirl is directly proportional to the temperature of the furnace.

Change the variable used for coloring the plot to

Radiation Intensityand click Apply.When you are finished, right-click

Periodic Side 1in the Outline tree view and select Hide.

Edit

Cases>CoalCombustion_nonox_swirl_001>Res PT for HC Fuel.Configure the following setting(s):

Tab

Setting

Value

Color

Mode

Variable

Variable

HC Fuel.Temperature

Click .

You will now create a simulation that involves both swirl and

the release of nitrogen oxide. The CCL file that was previously imported

contains the nitrogen oxide material, NO, and

reactions, Prompt NO Fuel Gas PDF and Thermal NO PDF, required for this combustion simulation.

Nitrogen oxide is calculated as a postprocessing step in the solver.

Ensure that the following tutorial input files are in your working directory:

CoalCombustion_nonox_swirl.cfxCoalCombustion_nonox_swirl_001.res

Set the working directory and start CFX-Pre if it is not already running.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

Select File > Open Case.

From your working directory, select

CoalCombustion_nonox_swirl.cfxand click Open.Select File > Save Case As.

Set File name to

CoalCombustion_noxcpp_swirl.cfx.Click .

In this section, you will edit the Furnace domain by adding the new material NO to the

materials list. CFX-Solver requires that you specify enough information

for the mass fraction of NO at each of the system

inlets. In this case, set the NO mass fraction

at the air and coal inlets to zero.

Edit

Simulation>Flow Analysis 1>Furnace.Configure the following setting(s):

Tab

Setting

Value

Fluid Specific Models

Fluid

Gas Mixture

Fluid

> Gas Mixture

> Combustion

> Chemistry Post Processing

(Selected)

Fluid

> Gas Mixture

> Combustion

> Chemistry Post Processing

> Materials List

NO

Fluid

> Gas Mixture

> Combustion

> Chemistry Post Processing

> Reactions List

Prompt NO Fuel Gas PDF,Thermal NO PDF

These settings enable the combustion simulation with nitrogen oxide (NO) as a postprocessing step in the solver. The NO reactions are defined in the same way as any participating reaction but the simulation of the NO reactions is performed after the combustion simulation of the air and coal. With this one-way simulation, the NO will have no effect on the combustion simulation of the air and coal.

Click .

Edit

Simulation>Flow Analysis 1>Furnace>Air Inlet.Configure the following setting(s):

Tab

Setting

Value

Boundary Details

Component Details

NO

Component Details

> NO

> Mass Fraction

0.0

Click .

Edit

Simulation>Flow Analysis 1>Furnace>Coal Inlet.Configure the following setting(s):

Tab

Setting

Value

Boundary Details

Component Details

NO

Component Details

> NO

> Mass Fraction

0.0

Click .

When CFX-Pre has shut down and the CFX-Solver Manager has started, obtain a solution to the CFD problem by following the instructions below.

Ensure that the Define Run dialog box is displayed.

Solver Input File should be set to

CoalCombustion_noxcpp_swirl.def.Under the Initial Values tab, select Initial Values Specification.

Select

CoalCombustion_nonox_swirl_001.resfor the initial values file using the Browse tool.

tool.The fluid solution from the previous case has not changed for this simulation. Loading the results from the previous case as an initial guess eliminates the need for the solver to solve for the fluids solutions again.

Click Start Run.

CFX-Solver runs and attempts to obtain a solution. At the end of the run, a dialog box is displayed stating that the simulation has ended.

Select Post-Process Results.

If using stand-alone mode, select Shut down CFX-Solver Manager.

Click .

In this section, you will make a plot on the Periodic

Side 1 region showing the variation of concentration of

nitrogen oxide through the coal furnace.

Right-click a blank area in the viewer and select Predefined Camera > Isometric View (Z up).

Edit

Cases>CoalCombustion_noxcpp_swirl_001>Furnace>Periodic Side 1.Configure the following setting(s):

Tab

Setting

Value

Color

Mode

Variable

Variable

NO.Mass Fraction

Render

Show Faces

(Selected)

Lighting

(Cleared)

Click .

You can see that NO is produced in the high-temperature region near the inlet. Further downstream, the mass fraction of NO is more uniform.

Quit CFD-Post, saving the state (

.cst) file at your discretion.