This tutorial includes:

In this tutorial you will learn about:

Importing a CCL file in CFX-Pre.

High-speed multicomponent, multiphase flow with interphase mass transfer.

Model customization using CEL.

Handling mass sources based on species transfer.

Source linearization.

Component | Feature | Details |

|---|---|---|

CFX-Pre | User Mode | General mode |

Domain Type | Single Domain | |

Analysis Type | Steady State | |

Fluid Type | Continuous Fluid | |

Dispersed Fluid | ||

CCL File | Import | |

Boundary Conditions | Inlet Boundary | |

Opening Boundary | ||

Outlet Boundary | ||

Steam Jet Default | ||

Symmetry Boundary | ||

Timestep | Physical Timescale | |

CFD-Post | Plots | Default Locators |

Line Locator | ||

Other | Chart Creation |

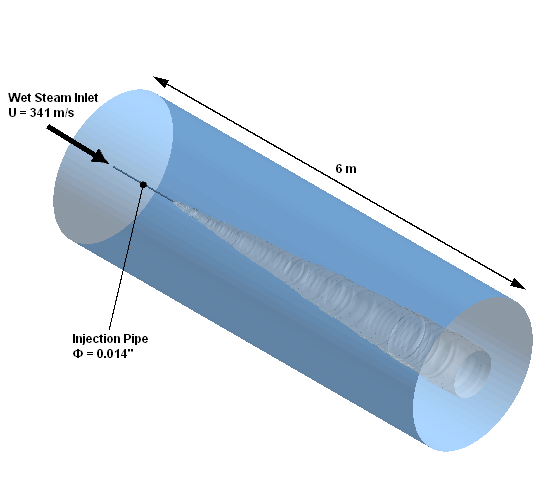

This tutorial investigates the simulation of a high-speed steam jet from a pipe. Steam at 373 K leaves the pipe at 341 m s^-1 and contains some liquid water. The surrounding air temperature is 25 °C.

Evaporation and condensation of water are modeled using mass sources and sinks applied to two subdomains; one is used for evaporation and the other is used for condensation. The rate of mass transfer is modeled using Sherwood number-based mass diffusion at the surface of liquid drops.

To take advantage of the symmetrical nature of the domain, a thin slice of the flow field is modeled and symmetry boundaries are used to represent the rest of the flow field. An opening boundary is used around the outside edges of the domain; the flow direction is restricted to be normal to this boundary in order to provide sufficient constraints on the flow solution.

It is strongly recommended that you complete the previous tutorials before trying this one. However, if this is the first tutorial you are working with, it is important to review the following topics before beginning:

Create a working directory.

Ansys CFX uses a working directory as the default location for loading and saving files for a particular session or project.

Download the

steam_jet.zipfile here .Unzip

steam_jet.zipto your working directory.Ensure that the following tutorial input files are in your working directory:

steam_jet.gtmsteam_jet_expressions.cclsteam_jet_additional_variables.ccl

Set the working directory and start CFX-Pre.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

This section describes the step-by-step definition of the flow physics in CFX-Pre for a steady-state simulation.

In CFX-Pre, select File > New Case.

Select General and click .

Select File > Save Case As.

Set File name to

SteamJet.cfx.Click .

Right-click

Meshand select Import Mesh > CFX Mesh.The Import Mesh dialog box appears.

Configure the following setting(s):

Setting

Value

File name

steam_jet.gtm

Click Open.

CFX Command Language (CCL) consists of commands used to

carry out actions in CFX-Pre, CFX-Solver Manager, and CFD-Post. Expressions

and Additional Variables required for the steam jet simulation will

be imported from CCL files. This section outlines the steps to analyze steam_jet_expressions.ccl and steam_jet_additional_variables.ccl, and then import them into the simulation.

Note: The physics for a case can be saved to a CCL (CFX Command Language) file at any time by selecting File > Export > CCL.

Select CCL files from your working directory, and open them one at a time with a text editor and take the time to look at the information they contain. The information contained in the CCL files is outlined below:

The CCL file

steam_jet_expressions.cclcreates expressions required for setting up the following data:Liquid/gas interface

Interphase diffusive transport coefficient

Heats of vaporization

Liquid-gas mass transfer rate for water [1]

Local false step linearization of the interphase mass transfer (IPMT).

The CCL file

steam_jet_additional_variables.cclcreates the following Additional Variables:Pressure linearization coefficient

PCoefWater IPMT flux liquid-to-gas

WaFluxLGWater IPMT flux gas-to-liquid

WaFluxGLLocal IPMT false timestep

FalseDtSaturation temperature

SatTempSaturation pressure

SatPresLatent heat at saturation

SatLHeat

These variables are recognizable by CFD-Post to enable plotting and further analysis during postprocessing.

Select File > Import > CCL

The Import CCL dialog box appears.

Under Import Method, select Append. This option appends the changes to the existing case.

Note: The Replace option is useful if you have defined the physics and want to update or replace the existing physics using the newly imported CCL.

From your working directory, select

steam_jet_expressions.ccl.Click Open. The CCL is now loaded as indicated by the status bar in the bottom right corner of the window. After a short pause, the CCL and the Outline tree view will be updated.

Repeat steps 2 to 5 to import

steam_jet_additional_variables.ccl.In the Outline tree view, expand the

Additional VariablesandExpressionsbranches underSimulation>Expressions, Functions and Variablesto confirm that new objects have been added after importing the CCL files.

The characteristics of this case do not change as a function of time, and therefore a steady-state analysis is appropriate.

Right-click

Analysis Typein the Outline tree view and select Edit.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Analysis Type

> Option

Steady State

Click .

In addition to providing template fluids, CFX allows you to create custom fluids for use in all your CFX models. A custom fluid may be defined as a pure substance, but may also be defined as a mixture, consisting of a number of transported fluid components. This type of fluid model is useful for applications involving mixtures, reactions, and combustion.

In order to define custom fluids, CFX-Pre provides the Material details view. This tool allows you to define your own fluids as pure substances, fixed composition mixtures or variable composition mixtures using a range of template property sets defined for common materials.

The steam jet application requires two fluids: a variable-composition

mixture containing the materials Steam3v (which

is dry steam) and Air Ideal Gas; a fixed-composition

mixture containing only the material Steam3l (which

is liquid water). In a variable composition mixture, the proportion

of each component material will change throughout the simulation;

while in a fixed composition mixture, the proportion of each component

material is fixed.

You are first going to load some of the materials that take

part in the process (Steam3v, Steam3l). The only other material that takes part in the process, Air Ideal Gas, is already loaded.

Load the materials Steam3v and Steam3l from the CFX-Pre Materials Library by loading Steam3vl.

In the Outline tree view, right-click

Simulation>Materialsand select Import Library Data.The Select Library Data to Import dialog box appears.

Click the browse button

next to File to Import.

next to File to Import. The Import CCL dialog box appears. If the dialog box opens behind any existing windows, reposition it so that it is completely visible in order to complete the next step.

Under Import Method, select Append. This option appends the CCL changes to the existing case.

Select

MATERIALS-iapws.cclfrom theetc/materials-extradirectory and click Open.In the Select Library Data to Import dialog box, expand

Wet Steamand selectSteam3vl.Click .

In the Outline tree view, expand

Simulation>Materialsto confirm thatSteam3vandSteam3lhave been added to the list.

In the next sections you will create the variable-composition mixture and the fixed-composition mixture.

Create a new material named Gas mixture that will be composed of Air Ideal Gas and Steam3v. This material will be injected into the gas inlet

during the steady-state simulation.

Create a new material named

Gas mixture.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Option

Variable Composition Mixture

Materials List

Air Ideal Gas, Steam3v [a]

Click .

Create a new material named Liquid mixture that will be composed of Steam3l.

Create a new material named

Liquid mixture.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Option

Fixed Composition Mixture

Materials List

Steam3l

Child Materials

> Steam3l

> Mass Fraction

1.0

Click .

This section outlines the steps to create a new domain Steam Jet.

Select Insert > Domain from the menu bar, or click Domain

.

.In the Insert Domain dialog box, set the name to

Steam Jetand click .On the Basic Settings tab, configure the following setting(s) under Location and Type:

Setting

Value

Location

B26

Domain Type

Fluid Domain

Coordinate Frame

Coord 0

On the Basic Settings tab, delete any existing items under Fluid and Particle Definitions by selecting them and clicking Remove selected item

.

.Under Fluid and Particle Definitions, create two fluid definitions named

GasandLiquidby using the Add new item icon.

icon.The new fluids named

GasandLiquidappear under Fluid and Particle Definitions.On the Basic Settings tab, configure the following setting(s) under Fluid and Particle Definitions:

Setting

Value

(List Box)

Gas

Gas

> Material

Gas mixture

Gas

> Morphology

> Option

Continuous Fluid

(List Box)

Liquid

Liquid

> Material

Liquid mixture

Liquid

> Morphology

> Option

Dispersed Fluid

Liquid

> Morphology

> Mean Diameter

liqLength [a]

On the Fluid Models tab, configure the following setting(s):

Setting

Value

Heat Transfer

> Option

Fluid Dependent

Turbulence

> Option

Fluid Dependent

Combustion

> Option

None

Thermal Radiation

> Option

None

On the Fluid Models tab under Additional Variable Models > Additional Variable, select

FalseDtand select the FalseDt check box.Make sure that Additional Variable Models > Additional Variable > FalseDt > Option is set to

Fluid Dependent.Repeat the previous two steps for the rest of the Additional Variables (PCoef, SatLheat, SatPres, SatTemp, WaFluxGL, WaFluxLG).

On the Fluid Specific Models tab, select

Gasin the list box, then configure the following setting(s):Setting

Value

Heat Transfer Model

> Option

Total Energy

Turbulence

> Option

k-Epsilon

Turbulence

> Wall Function

> Wall Function

Scalable

Component Models

> Component

Air Ideal Gas

Component Models

> Component

> Air Ideal Gas

> Option

Constraint

Component Models

> Component

Steam3v

Component Models

> Component

> Steam3v

> Option

Transport Equation

Component Models

> Component

> Steam3v

> Kinematic Diffusivity

(Selected)

Component Models

> Component

> Steam3v

> Kinematic Diffusivity

> Kinematic Diffusivity

KinDiff

Additional Variable Models

PCoef

Additional Variable Models

> PCoef

(Selected)

Additional Variable Models

> PCoef

> Add. Var. Value

dFLUXwadp

On the Fluid Specific Models tab, select

Liquidin the list box, then configure the following setting(s):Setting

Value

Heat Transfer Model

> Option

Total Energy

Turbulence

> Option

Dispersed Phase Zero Equation

Under Additional Variable Models (for Liquid), select

FalseDtin the list box, then configure the following setting(s):Setting

Value

FalseDt

(Selected)

FalseDt

> Add. Var. Value

DtFalseMf

Repeat the previous step for the rest of the Additional Variables (PCoef, SatLheat, SatPres, SatTemp, WaFluxGL, WaFluxLG) using the following values:

Additional Variable

Expression

PCoef

dFLUXwadp

SatLheat

HtVapwa

SatPres

VpWat

SatTemp

SatT

WaFluxGL

FLUXwa1

WaFluxLG

FLUXwa2

On the Fluid Pair Models tab, select

Gas | Liquidin the list box, then configure the following setting(s):Setting

Value

Surface Tension Coefficient

(Selected)

Surface Tension Coefficient

> Surf. Tension Coeff.

srfTenCoef

Interphase Transfer

> Option

Particle Model

Momentum Transfer

> Drag Force

> Option

Schiller Naumann

Turbulence Transfer

> Option

None

Mass Transfer

> Option

None

Heat Transfer

> Option

Ranz Marshall

Click .

To model evaporation and condensation, mass sources and sinks

are defined for the materials Steam3v and Steam3l, according to the expressions imported earlier.

In the next two sections you will set up two subdomains; one is used

for evaporation and the other is used for condensation.

This section outlines the steps to create the subdomain GastoLiq. This subdomain will be defined in a manner consistent

with the process of condensation.

Create a subdomain named

GastoLiq.On the Basic Settings tab, configure the following setting(s):

Setting

Value

Location

B26

Coordinate Frame

Coord 0

On the Fluid Sources tab, select

Gasin the list box, then select the Gas check box and configure the following setting(s):Setting

Value

Equation Sources

Continuity

Equation Sources

> Continuity

(Selected)

Equation Sources

> Continuity

> Option

Fluid Mass Source

Equation Sources

> Continuity

> Source

-Liquid.WaFluxGL

Equation Sources

> Continuity

> MCF/Energy Sink Option

(Selected)

Equation Sources

> Continuity

> MCF/Energy Sink Option

> Sink Option

Spec. Mass Frac. and Loc. Temp.

Equation Sources

> Continuity

> Mass Source Volume Fraction Coefficient

(Selected)

Equation Sources

> Continuity

> Mass Source Volume Fraction Coefficient

> Volume Frac. Coeff.

-Gas.density/DtFalseMf

Equation Sources

> Continuity

> Variables

> Steam3v.mf

> Option

Value

Equation Sources

> Continuity

> Variables

> Steam3v.mf

> Value

1

Equation Sources

> Continuity

> Variables

> Temperature

> Option

Value

Equation Sources

> Continuity

> Variables

> Temperature

> Value

Gas.T

Equation Sources

> Continuity

> Variables

> Turbulence Eddy Dissipation

> Option

Value

Equation Sources

> Continuity

> Variables

> Turbulence Eddy Dissipation

> Value

Gas.ed

Equation Sources

> Continuity

> Variables

> Turbulence Kinetic Energy

> Option

Value

Equation Sources

> Continuity

> Variables

> Turbulence Kinetic Energy

> Value

Gas.ke

Equation Sources

> Continuity

> Variables

> Velocity

> Option

Cartesian Vector Components

Equation Sources

> Continuity

> Variables

> Velocity

> U

Gas.Velocity u

Equation Sources

> Continuity

> Variables

> Velocity

> V

Gas.Velocity v

Equation Sources

> Continuity

> Variables

> Velocity

> W

Gas.Velocity w

Equation Sources

Steam3v.mf

Equation Sources

> Steam3v.mf

(Selected)

Equation Sources

> Steam3v.mf

> Option

Source

Equation Sources

> Steam3v.mf

> Source

0 [kg m^-3 s^-1]

Equation Sources

> Steam3v.mf

> Source Coefficient

(Selected)

Equation Sources

> Steam3v.mf

> Source Coefficient

> Source Coefficient

dFLwadYG [a]

This source coefficient is required only for the mass transfer rates between gas and liquid phases. The source is set to 0 [kg m^3 s^-1] because there is no external source and therefore no additional mass is transferred into the system. The source is defined only to enable setting a linearization coefficient.

On the Fluid Sources tab, select

Liquidin the list box, then select theLiquidcheck box and configure the following setting(s):Setting

Value

Equation Sources

Continuity

Equation Sources

> Continuity

(Selected)

Equation Sources

> Continuity

> Option

Fluid Mass Source

Equation Sources

> Continuity

> Source

Liquid.WaFluxGL

Equation Sources

> Continuity

> Mass Source Volume Fraction Coefficient

(Selected)

Equation Sources

> Continuity

> Mass Source Volume Fraction Coefficient

> Volume Frac. Coeff.

-Liquid.density/DtFalseMf

Equation Sources

> Continuity

> Variables

> Temperature

> Option

Value

Equation Sources

> Continuity

> Variables

> Temperature

> Value

Gas.T

Equation Sources

> Continuity

> Variables

> Velocity

> Option

Cartesian Vector Components

Equation Sources

> Continuity

> Variables

> Velocity

> U

Gas.Velocity u

Equation Sources

> Continuity

> Variables

> Velocity

> V

Gas.Velocity v

Equation Sources

> Continuity

> Variables

> Velocity

> W

Gas.Velocity w

Equation Sources

Energy

Equation Sources

> Energy

(Selected)

Equation Sources

> Energy

> Option

Source[a]

Equation Sources

> Energy

> Source

Liquid.WaFluxGL*HtVapwa

Equation Sources

> Energy

> Source Coefficient

(Selected)

Equation Sources

> Energy

> Source Coefficient

> Source Coefficient

-Liquid.vf*Liquid.density*Liquid.Cp/DtFalseMf

Click .

This section outlines the steps to create the subdomain LiqtoGas. This subdomain will be defined in a manner consistent

with the process of vaporization.

Create a new subdomain named

LiqtoGas.On the Basic Settings tab, configure the following setting(s):

Setting

Value

Location

B26

Coordinate Frame

Coord 0

On the Fluid Sources tab, select

Gasin the list box, then select the Gas check box and configure the following setting(s):Setting

Value

Equation Sources

Continuity

Equation Sources

> Continuity

(Selected)

Equation Sources

> Continuity

> Option

Fluid Mass Source

Equation Sources

> Continuity

> Source

Liquid.WaFluxLG

Equation Sources

> Continuity

> Variables

> Steam3v.mf

> Option

Value

Equation Sources

> Continuity

> Variables

> Steam3v.mf

> Value

1

Equation Sources

> Continuity

> Variables

> Temperature

> Option

Value

Equation Sources

> Continuity

> Variables

> Temperature

> Value

SatT

Equation Sources

> Continuity

> Variables

> Turbulence Eddy Dissipation

> Option

Value

Equation Sources

> Continuity

> Variables

> Turbulence Eddy Dissipation

> Value

Gas.ed

Equation Sources

> Continuity

> Variables

> Turbulence Kinetic Energy

> Option

Value

Equation Sources

> Continuity

> Variables

> Turbulence Kinetic Energy

> Value

Gas.ke

Equation Sources

> Continuity

> Variables

> Velocity

> Option

Cartesian Vector Components

Equation Sources

> Continuity

> Variables

> Velocity

> U

Liquid.Velocity u

Equation Sources

> Continuity

> Variables

> Velocity

> V

Liquid.Velocity v

Equation Sources

> Continuity

> Variables

> Velocity

> W

Liquid.Velocity w

On the Fluid Sources tab, select

Liquidin the list box, then select the Liquid check box and configure the following setting(s):Setting

Value

Equation Sources

Continuity

Equation Sources

> Continuity

(Selected)

Equation Sources

> Continuity

> Option

Fluid Mass Source

Equation Sources

> Continuity

> Source

-Liquid.WaFluxLG

Equation Sources

> Continuity

> MCF/Energy Sink Option

(Selected)

Equation Sources

> Continuity

> MCF/Energy Sink Option

> Sink Option

Spec. Mass Frac. and Temp.

Equation Sources

> Continuity

> Variables

> Temperature

> Option

Value

Equation Sources

> Continuity

> Variables

> Temperature

> Value

SatT

Equation Sources

> Continuity

> Variables

> Velocity

> Option

Cartesian Vector Components

Equation Sources

> Continuity

> Variables

> Velocity

> U

0 [m s^-1]

Equation Sources

> Continuity

> Variables

> Velocity

> V

0 [m s^-1]

Equation Sources

> Continuity

> Variables

> Velocity

> W

0 [m s^-1]

Equation Sources

Energy

Equation Sources

> Energy

(Selected)

Equation Sources

> Energy

> Option

Source[a]

Equation Sources

> Energy

> Source

-Liquid.WaFluxLG*HtVapwa

Equation Sources

> Energy

> Source Coefficient

(Selected)

Equation Sources

> Energy

> Source Coefficient

> Source Coefficient

-Liquid.vf*Liquid.density*Liquid.Cp/DtFalseMf

Click .

This section outlines the steps to create the following boundaries:

an inlet boundary, Gas Inlet, for the location

where the steam is injected, an opening boundary, Opening, for the outer edges of the domain, and two symmetry boundaries.

The wall of the injection pipe will assume the default boundary (a

smooth, no-slip wall).

At the gas inlet, create an inlet boundary that injects wet steam at a normal speed and static temperature set consistent with the problem description. The steam contains a liquid and vapor component whose sum of volume fractions is unity.

Create a new boundary named

Gas Inlet.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Inlet

Location

gas inlet

Boundary Details

Mass And Momentum

> Option

Normal Speed

Mass And Momentum

> Normal Speed

341 [m s^-1]

Turbulence

> Option

Fluid Dependent

Heat Transfer

> Option

Static Temperature

Heat Transfer

> Static Temperature

373 K

Fluid Values

Boundary Conditions

Gas

Boundary Conditions

> Gas

> Turbulence

> Option

Low (Intensity = 1%)

Boundary Conditions

> Gas

> Volume Fraction

> Option

Value

Boundary Conditions

> Gas

> Volume Fraction

> Volume Fraction

1-0.45*0.4/1000 [a]

Boundary Conditions

> Gas

> Component Details

Steam3v

Boundary Conditions

> Gas

> Component Details

> Steam3v

> Option

Mass Fraction

Boundary Conditions

> Gas

> Component Details

> Steam3v

> Mass Fraction

1

Boundary Conditions

Liquid

Boundary Conditions

> Liquid

> Volume Fraction

> Option

Value

Boundary Conditions

> Liquid

> Volume Fraction

> Volume Fraction

0.45*0.4/1000 [a]

Click .

For the outer edges of the domain, where dry air may be entrained into the flow, specify an opening boundary with a fixed pressure and flow direction. The direction specification is necessary to sufficiently constrain the velocity. At this opening boundary you need to set the temperature of air that may enter through the boundary. Set the opening temperature to be consistent with the problem description.

Create a new boundary named

Opening.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Opening

Location

air inlet,outer edge,outlet [a]

Boundary Details

Mass And Momentum

> Option

Opening Pres. and Dirn

Mass And Momentum

> Relative Pressure

0 [Pa]

Flow Direction

> Option

Normal to Boundary Condition

Turbulence

> Option

Medium (Intensity = 5%)

Heat Transfer

> Option

Opening Temperature

Heat Transfer

> Opening Temperature

25 [C] [b]

Fluid Values

Boundary Conditions

Gas

Boundary Conditions

> Gas

> Volume Fraction

> Option

Value

Boundary Conditions

> Gas

> Volume Fraction

> Volume Fraction

1

Boundary Conditions

> Gas

> Component Details

Steam3v

Boundary Conditions

> Gas

> Component Details

> Steam3v

> Option

Mass Fraction

Boundary Conditions

> Gas

> Component Details

> Steam3v

> Mass Fraction

0.0

Boundary Conditions

Liquid

Boundary Conditions

> Liquid

> Volume Fraction

> Option

Value

Boundary Conditions

> Liquid

> Volume Fraction

> Volume Fraction

0

Click .

Create a new boundary named

SymP1.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Symmetry

Location

F29.26

Click .

Create a new boundary named

SymP2.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Symmetry

Location

F27.26

Click .

Note: The gas-to-liquid and liquid-to-gas mass transfer model is not symmetric. Consequently, the boundary layer between the liquid and gas acts as an interface that is not explicitly simulated. For simplicity, the boundary layer is imagined to belong to the gas phase in which the mass transfer is driven by a departure from equilibrium. The equilibrium condition must therefore be known. For a pure liquid the equilibrium boundary layer vapor fraction is just the gas saturation value. For a multicomponent liquid the boundary layer vapor fraction is related to the liquid component mole fraction via Raoult’s law, for example. For this case the gas saturation value of the partial pressure is used, which is the same as the ratio of the partial pressure to the gas pressure if it is in terms of mole fraction.

The conditions at each boundary determine the size of the time scale used in the time step. Generally, you can estimate an effective time step by dividing the displacement by the velocity at which a fluid is traveling. In this case, however, the velocity at the gas inlet approaches the speed of sound and the time step must be calculated by taking the height of the inlet and dividing it by the velocity at which the steam enters the system. The lower velocities at the outlet and opening boundaries enable the time step to be increased after the gas inlet properties have converged. Once all the values at the inlet, outlet, and openings have converged, a much larger time step is used to enable the overall solution to settle. In order to account for all these time step changes, an expression will be created.

Since the flow velocities are high at the jet inlet, you need

to use a very small time step to capture the property variations at

this location. The flow velocity decreases as you move away from the

jet inlet, therefore the time step can be increased systematically

for better efficiency. You will now create a time step control expression

called Dtstep that ramps up the time scale in

stages:

Right-click

Expressionsin the Outline tree view and select Insert > Expression.Set the name to

Dtstepand click .In the Definition area, type or copy and paste the following expression:

if (aitern <= 20, 1.0E-5[s], 5.0E-3 [s])Click .

Click Solver Control

.

.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Advection Scheme

> Option

High Resolution

Convergence Control

> Max Iterations

1500

Convergence Control

> Fluid Timescale Control

> Timescale Control

Physical Timescale

Convergence Control

> Fluid Timescale Control

> Physical Timescale

Dtstep

Convergence Criteria

> Residual Type

RMS

Convergence Criteria

> Residual Target

1.0E-4

Convergence Criteria

> Conservation Target

(Selected)

Convergence Criteria

> Conservation Target

> Value

0.005

Dynamic Model Control

Global Dynamic Model Control

(Selected)

Advanced Options

Multiphase Control

(Selected)

Multiphase Control

> Volume Fraction Coupling

(Selected)

Multiphase Control

> Volume Fraction Coupling

> Option

Segregated

Click .

When CFX-Pre has shut down and the CFX-Solver Manager has started, obtain a solution to the CFD problem by following the instructions below:

Ensure that the Define Run dialog box is displayed.

Solver Input File should be set to

SteamJet.defClick Start Run.

CFX-Solver runs and attempts to obtain a solution. At the end of the run, a dialog box is displayed stating that the simulation has ended.

Note the number of iterations required to obtain a solution.

Select Post-Process Results.

If using stand-alone mode, select Shut down CFX-Solver Manager.

Click .

In this section, the steam molar fraction in the gas fluid, the gas-to-liquid and liquid-to-gas mass transfer rates, and the false time step will be illustrated on various regions.

Right-click a blank area in the viewer and select Predefined Camera > View From -Z.

This ensures that the view is set to a position that is best suited to display the results.

From the menu bar, select Insert > Contour.

Under Name, type

Steam Molar Fractionand click .Configure the following setting(s):

Tab

Setting

Value

Geometry

Locations

SymP2

Variable

Gas.Steam3v.Molar Fraction

Click .

This will result in SymP2 shown colored by the molar fraction of steam.

Turn off the visibility of

Steam Molar Fraction.From the menu bar, select Insert > Contour.

Under Name, type

Gas to Liquid Fluxand click .Configure the following setting(s):

Tab

Setting

Value

Geometry

Locations

SymP2

Variable

Liquid.WaFluxGL

Click .

This will result in SymP2 shown colored by the gas-to-liquid mass transfer rate.

Turn off the visibility of

Gas to Liquid Flux.From the menu bar, select Insert > Contour.

Under Name, type

Liquid to Gas Fluxand click .Configure the following setting(s):

Tab

Setting

Value

Geometry

Locations

SymP2

Variable

Liquid.WaFluxLG

Click .

This will result in SymP2 shown colored by the liquid-to-gas mass transfer rate.

In the viewer toolbar, open the viewport drop-down menu and click the option with two horizontal viewports.

In the viewer toolbar, disable Synchronize visibility in displayed views

.

.Click a blank area in

View 2so that it becomes the active view.In the tree view, select the check box beside

Gas to Liquid Flux.

Note:You must disable Synchronize visibility in displayed views

to enable separate contours to

be displayed in each viewport

to enable separate contours to

be displayed in each viewportUnder

User Locations and Plotsin the tree view, ensure that onlyLiquid to Gas Fluxis visible inView 1, and onlyGas to Liquid Fluxis visible inView 2.

In

View 2, right-click a blank area in the viewer and select Predefined Camera > View From -Z.This ensures that the view is set to a position that is best suited to display the results.

You may want to zoom in near the gas inlet to view the differences between the gas-to-liquid and liquid-to-gas phase transfer rates.

In the tree view, right-click

User Locations and Plotsand select Insert > Location > Line.In the

Insert Linedialog box, use the default name and click .Configure the following setting(s):

Tab

Setting

Value

Geometry

Definition

> Method

Two Points

Definition

> Point 1

0, 0.005, 0.0002

Definition

> Point 2

5, 0.005, 0.0002

Line Type

> Cut

(Selected)

Click .

From the menu bar, select Insert > Chart.

Name the chart

False Time Stepand click .Configure the following setting(s):

Tab

Setting

Value

General

Title

False Time Step

Data Series

Data Source

> Location

Line 1

X Axis

Data Selection

> Variable

X

Y Axis

Data Selection

> Variable

Liquid.FalseDt

Axis Range

> Logarithmic Scale

(Selected)

Click .

The false time step peaks where the interphase mass transfer rate changes sign, and hence goes through zero. This is true because the false time step is inversely proportional to the absolute mass transfer rate.

When you have finished viewing the chart, quit CFD-Post.

[1] The expression to calculate the volumetric mass transfer rate of

the phase on which the mass transfer is based (CMwa) is multiplied

by the ratio between the molecular weight of the absorbing species

and the molecular weight of the phase on which the mass transfer is

based; that is, a two-component gas mixture and water, respectively.

However, due to the variable composition of the gas mixture (according

to Creating and Loading Materials), its molecular weight varies

with time. This causes the ratio of the molecular weights between

water and the gas mixture to vary also. Thus, an expression that is

used to calculate the molecular weight of the gas mixture depends

on the mole fractions of vapour and air in the gas mixture at any

given time (as seen in steam_jet_expressions.ccl).