This tutorial includes:

In this tutorial you will learn about:

Setting up an immersed solids domain.

Applying a counter-rotating wall boundary.

Monitoring an expression during a solver run.

Creating an XY-transient chart in CFD-Post.

Creating a keyframe animation.

Component | Feature | Details |

|---|---|---|

CFX-Pre | User Mode | General mode |

Domain Type | Immersed Solid | |

Fluid Domain | ||

Analysis Type | Transient | |

Fluid Type | Continuous Fluid | |

Boundary Conditions | Inlet Boundary | |

Outlet Boundary | ||

Domain Interface | Fluid Fluid | |

CFD-Post | Chart | Mass Flow Rate |

Animation | Keyframe |

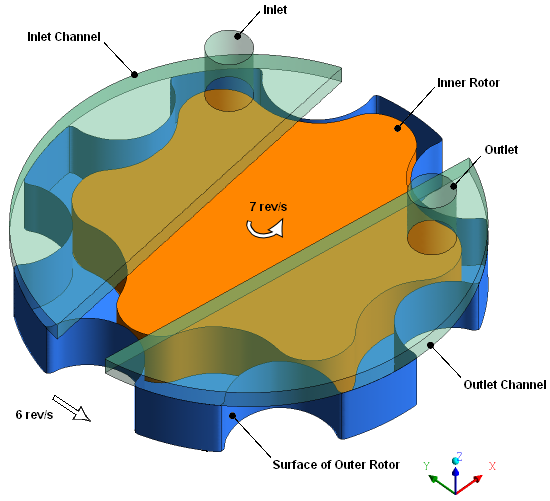

In this tutorial, you will simulate a gear pump that drives a flow of water. This tutorial makes use of the Immersed Solids capability of Ansys CFX in order to model a solid that moves through a fluid.

The outlet has an average relative static pressure of 1 psi; the relative total pressure at the inlet is 0 psi. The inner rotor (gear) rotates at a rate of 7 revolutions per second; the outer rotor rotates at 6 revolutions per second. The diameter of the fluid region between the rotors is approximately 7.3 cm.

You will use an immersed solid domain to model the inner rotor, a rotating fluid domain to model the water immediately surrounding the inner rotor, and a stationary fluid domain to model the water in the inlet and outlet channels. To model the stationary pump housing (not shown in the figure), you will apply a counter-rotating wall condition to the top (high Z) surface of the rotating fluid domain, on the non-overlap portion (which lies between the inlet and outlet channels). To model the upper surfaces of the teeth of the outer rotor, you will apply a rotating wall condition on the non-overlap portions of the lower (low Z) surfaces of the inlet and outlet chambers.

The following conditions will be met to promote the establishment of a cyclic flow pattern:

The mesh of the rotating domain should be rotationally periodic so that it looks the same after each (outer) rotor tooth passes.

The mesh on the outer boundary of the immersed solid domain should be rotationally periodic so that it looks the same after each (inner) rotor tooth passes. (The mesh inside the immersed solid domain has no effect in this tutorial.)

An integer number of time steps should pass as one rotor tooth passes.

If this is the first tutorial you are working with, it is important to review the following topics before beginning:

Create a working directory.

Ansys CFX uses a working directory as the default location for loading and saving files for a particular session or project.

Download the

immersed_solid.zipfile here .Unzip

immersed_solid.zipto your working directory.Ensure that the following tutorial input file is in your working directory:

ImmersedSolid.gtm

Set the working directory and start CFX-Pre.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

This section describes the step-by-step definition of the flow physics in CFX-Pre for a steady-state simulation.

In CFX-Pre, select File > New Case.

Select General and click .

Select File > Save Case As.

Under File name, type

ImmersedSolid.Click .

Right-click

Meshand select Import Mesh > CFX Mesh.The Import Mesh dialog box appears.

Configure the following setting(s):

Setting

Value

File name

ImmersedSolid.gtm

Click Open.

Next, you will create an expression defining the time step size for this transient analysis. One tooth of the inner (or outer) rotor passes every 1/42 s. Choose a time step that resolves this motion in 30 intervals.

From the main menu, select Insert > Expressions, Functions and Variables > Expression.

In the Insert Expression dialog box, type

dt.Click .

Set Definition, to

(1/42)[s]/30.Click Apply to create the expression.

Next, you will create an expression defining the total simulation time. Make the simulation run long enough for 3 rotor teeth to pass: 3/42 s. This will give the solution time to establish a periodic nature.

Create an expression called

total time.Set Definition to

(3/42)[s].Click Apply.

Define the simulation as transient, using the expressions you created earlier.

Under the Outline tab, edit Analysis Type

.

. Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Analysis Type

> Option

Transient

Analysis Type

> Time Duration

> Option

Total Time

Analysis Type

> Time Duration

> Total Time

total time [a]

Analysis Type

> Time Steps

> Option

Timesteps

Analysis Type

> Time Steps

> Timesteps

dt

Analysis Type

> Initial Time

> Option

Automatic with Value

Analysis Type

> Initial Time

> Time

0 [s]

Click .

This simulation requires three domains: two fluid domains and one immersed solid domain. First you will create an immersed solid domain.

Create the immersed solid domain as follows:

Select Insert > Domain from the main menu, or click Domain

.

.In the Insert Domain dialog box, set the name to

ImmersedSolidand click .Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Location and Type

> Location

Inner Rotor

Location and Type

> Domain Type

Immersed Solid

Location and Type

> Coordinate Frame

Coord 0

Domain Models

> Domain Motion

> Option

Rotating

Domain Models

> Domain Motion

> Angular Velocity

7 [rev s^-1]

Domain Models

> Domain Motion

> Axis Definition

> Option

Two Points

Domain Models

> Domain Motion

> Axis Definition

> Rotation Axis From

0.00383, 0, 0

Domain Models

> Domain Motion

> Axis Definition

> Rotation Axis To

0.00383, 0, 1

Click .

Create the stationary fluid domain according to the problem description:

Create a new domain named

StationaryFluid.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Location and Type

> Location

Channels

Location and Type

> Domain Type

Fluid Domain

Location and Type

> Coordinate Frame

Coord 0

Fluid and Particle Definitions

Fluid 1

Fluid and Particle Definitions

> Fluid 1

> Option

Material Library

Fluid and Particle Definitions

> Fluid 1

> Material

Water

Fluid and Particle Definitions

> Fluid 1

> Morphology

> Option

Continuous Fluid

Domain Models

> Pressure

> Reference Pressure

0 [psi]

Domain Models

> Buoyancy Models

> Option

Non Buoyant

Domain Models

> Domain Motion

> Option

Stationary

Domain Models

> Mesh Deformation

> Option

None

Fluid Models

Heat Transfer

> Option

None

Turbulence

> Option

k-Epsilon

Turbulence

> Wall Function

Scalable

Combustion

> Option

None

Thermal Radiation

> Option

None

Initialization

Domain Initialization

(Selected)

Domain Initialization

> Initial Conditions

> Velocity Type

Cartesian

Domain Initialization

> Initial Conditions

> Cartesian Velocity Components

> Option

Automatic with Value

Domain Initialization

> Initial Conditions

> Cartesian Velocity Components

> U

0 [m s^-1]

Domain Initialization

> Initial Conditions

> Cartesian Velocity Components

> V

0 [m s^-1]

Domain Initialization

> Initial Conditions

> Cartesian Velocity Components

> W

0 [m s^-1]

Domain Initialization

> Initial Conditions

> Static Pressure

> Option

Automatic with Value

Domain Initialization

> Initial Conditions

> Static Pressure

> Relative Pressure

1 [psi] * step(-y/1 [cm]) [a]

Domain Initialization

> Initial Conditions

> Turbulence

> Option

Medium (Intensity = 5%)

Click .

Create the rotating fluid domain according to the problem description:

In the Outline tree view, right-click

Simulation>Flow Analysis 1>StationaryFluidand select Duplicate.Right-click

Simulation>Flow Analysis 1>Copy of StationaryFluidand select Rename.Rename the domain to

RotatingFluid.Edit

RotatingFluid.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Location and Type

> Location

Gear Chamber

Domain Models

> Domain Motion

> Option

Rotating

Domain Models

> Domain Motion

> Angular Velocity

6 [rev s^-1]

Domain Models

> Domain Motion

> Axis Definition

> Option

Coordinate Axis

Domain Models

> Domain Motion

> Axis Definition

> Rotation Axis

Global Z

Click .

Add a domain interface that connects the StationaryFluid and RotatingFluid domains:

Click Insert > Domain Interface from the main menu or click Domain Interface

.

.Accept the default domain interface name and click .

Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Interface Type

Fluid Fluid

Interface Side 1

> Domain (Filter)

StationaryFluid

Interface Side 1

> Region List

Channel Side

Interface Side 2

> Domain (Filter)

RotatingFluid

Interface Side 2

> Region List

Chamber Side

Interface Models

> Option

General Connection

Interface Models

> Frame Change/Mixing Model

> Option

Transient Rotor Stator

Interface Models

> Pitch Change

> Option[i]

None

Additional Interface Models

Mass and Momentum

> Option

Conservative Interface Flux

Mass and Momentum

> Interface Model

> Option

None

Mesh Connection

Mesh Connection Method

> Mesh Connection

> Option

GGI

Click .

Apply a counter-rotating no-slip wall condition to the non-overlap portion of the domain interface on the rotating domain side, because this surface represents part of the stationary housing of the pump.

Edit

RotatingFluid>Domain Interface 1 Side 2.If this object does not appear in the tree view, then edit

Case Options>General, select Show Interface Boundaries in Outline Tree, and click .Configure the following setting(s):

Tab

Setting

Value

Nonoverlap Conditions

Nonoverlap Conditions

(Selected)

Nonoverlap Conditions

> Mass and Momentum

> Option

No Slip Wall

Nonoverlap Conditions

> Mass and Momentum

> Wall Velocity

(Selected)

Nonoverlap Conditions

> Mass and Momentum

> Wall Velocity

> Option

Counter Rotating Wall

Click OK.

Apply a rotating no-slip wall condition to the non-overlap portions of the domain interface on the stationary domain side, because these surfaces represent faces of the rotor teeth of the outer rotor, and the latter rotates at 6 rev/s about the Z axis.

Edit

StationaryFluid>Domain Interface 1 Side 1.Configure the following setting(s):

Tab

Setting

Value

Nonoverlap Conditions

Nonoverlap Conditions

(Selected)

Nonoverlap Conditions

> Mass and Momentum

> Option

No Slip Wall

Nonoverlap Conditions

> Mass and Momentum

> Wall Velocity

(Selected)

Nonoverlap Conditions

> Mass and Momentum

> Wall Velocity

> Option

Rotating Wall

Nonoverlap Conditions

> Mass and Momentum

> Wall Velocity

> Angular Velocity

6 [rev s^-1]

Nonoverlap Conditions

> Mass and Momentum

> Wall Velocity

> Axis Definition

> Option

Coordinate Axis

Nonoverlap Conditions

> Mass and Momentum

> Wall Velocity

> Axis Definition

> Rotation Axis

Global Z

Click OK.

This section outlines the steps to create the inlet and outlet boundary conditions, as specified in the problem description.

Create a total pressure inlet at a relative pressure of 0 psi:

In the Outline tree view, right-click

StationaryFluidand select Insert > Boundary.Set Name to

inand click OK.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Inlet

Location

Inlet

Boundary Details

Mass And Momentum

> Option

Total Pressure (stable)

Mass And Momentum

> Relative Pressure

0 [psi]

Flow Direction

> Option

Normal to Boundary Condition

Turbulence

> Option

Medium (Intensity = 5%)

Click .

Create an outlet with a relative average static pressure of 1 psi:

Create a boundary named

outin theStationaryFluiddomain.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Outlet

Location

Outlet

Boundary Details

Mass And Momentum

> Option

Average Static Pressure

Mass And Momentum

> Relative Pressure

1 [psi]

Mass And Momentum

> Pres. Profile Blend

0.05

Pressure Averaging

> Option

Average Over Whole Outlet

Click .

Click Solver Control

.

.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Advection Scheme

> Option

High Resolution

Transient Scheme

> Option

Second Order Backward Euler

Transient Scheme

> Timestep Initialization

> Option

Automatic

Turbulence Numerics

> Option

First Order

Convergence Control

> Min. Coeff. Loops

1

Convergence Control

> Max. Coeff. Loops

10

Convergence Control

> Fluid Timescale Control

> Timescale Control

Coefficient Loops

Convergence Criteria

> Residual Type

RMS

Convergence Criteria

> Residual Target

1.0 E −4

Click .

Set up the solver to output transient results files that record pressure, velocity, and velocity in the stationary frame, on every time step:

Click Output Control

.

.Click the Trn Results tab.

In the Transient Results list box, click Add new item

, set Name to

, set Name to Transient Results 1, and click OK.Configure the following setting(s) of

Transient Results 1:Setting

Value

Option

Selected Variables

File Compression

Default

Output Variables List

Pressure, Velocity, Velocity in Stn Frame

Output Boundary Flows

(Selected)

Output Boundary Flows

> Boundary Flows

All

Output Frequency

> Option

Every Timestep

Click the Monitor tab.

Select Monitor Objects.

Under Monitor Points and Expressions:

Click Add new item

.

.Accept the default name and click .

Set Option to

Expression.Set Expression Value to

massFlow()@in.

Click .

Click Define Run

.

.Configure the following setting(s):

Setting

Value

File name

ImmersedSolid.def

Click .

Note: A warning message will appear due to the global warning that was mentioned earlier in Creating the Domain Interface. Click Yes.

CFX-Solver Manager automatically starts and, on the Define Run dialog box, Solver Input File is set.

If using stand-alone mode, quit CFX-Pre, saving the simulation (

.cfx) file at your discretion.

When CFX-Pre has shut down and the CFX-Solver Manager has started, obtain a solution to the CFD problem by following the instructions below:

In CFX-Solver Manager, ensure that the Define Run dialog box is displayed.

If CFX-Solver Manager is launched from CFX-Pre, the information required to perform a solver run is entered automatically in the Define Run dialog box.

Click Start Run.

The solver run begins and the progress is displayed in a split screen.

Click the User Points tab (which appears after the first time step has been computed) and monitor the value of

Monitor Point 1as the solution proceeds.Rescale the monitor plot so that you can readily see the time-periodic oscillations in mass flow that occur after the initial transient phase:

Right-click anywhere in the User Points plot and select Monitor Properties.

In the Monitor Properties: User Points dialog box, on the Range Settings tab, select Set Manual Scale (Linear).

Set the lower and upper bounds to 0.015 and 0.055 respectively.

Click OK.

Select the check box next to Post-Process Results when the completion message appears at the end of the run.

If using stand-alone mode, select the check box next to Shut down CFX-Solver Manager.

Click .

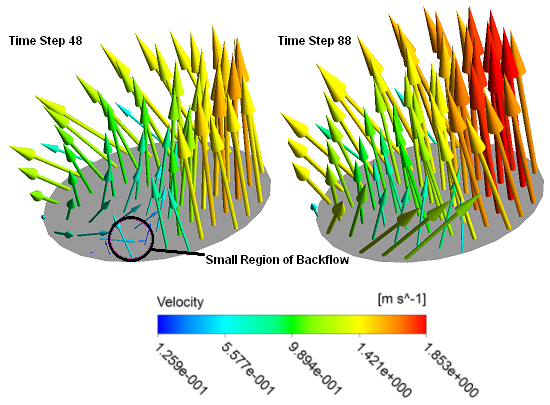

Note: During the Solver Manager run, you may observe a notice at the 47th and 48th time steps warning you that "A wall has been placed at portion(s) of an OUTLET boundary condition ... to prevent fluid from flowing into the domain." The mass flow at the inlet drops to its lowest level throughout the cycle at this point, causing a reduction in the velocity at the outlet. Because there is turbulence at the outlet, this reduced velocity allows a tiny vortex to produce a small, virtually negligible, amount of backflow at the outlet. Figure 25.1: Velocity Vectors on the Outlet shows velocity vectors at the outlet when the mass flow at the inlet is lowest (48th time step) and when the mass flow is greatest (88th time step). In the figure, you can see where this slight backflow occurs for the 48th time step.

In this section, you will generate a chart to show the mass flow rate through the machine as a function of time. You will also prepare an animation of the machine in operation, complete with velocity vectors.

During the solver run, you observed a monitor plot that showed mass flow versus time step. Here, you will make a similar plot of mass flow versus time. As you did in the monitor plot, adjust the vertical axis range to focus on the time-periodic oscillations in mass flow that occur after the initial transient phase.

When CFD-Post starts, the Domain Selector dialog box might appear. If it does, ensure that the

ImmersedSolid,RotatingFluidandStationaryFluiddomains are selected, then click OK to load the results from these domains.A dialog box will notify you that the case contains immersed solid domain. Click to continue.

Create a new chart named

Mass Flow Rate.The Chart Viewer appears.

Configure the following setting(s):

Tab

Setting

Value

General

Type

XY-Transient or Sequence

Title

Mass Flow Rate at the Inlet over Time

Click the Data Series tab.

If the Data Series list box is empty, right-click in it and select New, or click New

.

.Configure the following setting(s):

Tab

Setting

Value

Data Series

Series 1

(Selected)

Name

Inlet Mass Flow

Data Source

> Expression

(Selected)

Data Source

> Expression

massFlow()@in [a]

Y Axis

Axis Range

> Determine ranges automatically

(Cleared)

Axis Range

> Min

0.015

Axis Range

> Max

0.055

Click Apply.

The mass flow rate settles into a repeating pattern with a period of 1/42 s, which is the time it takes a rotor tooth to pass.

Create a slice plane and then make a vector plot on the slice plane as follows:

Click the 3D Viewer tab.

Create a new plane named

Plane 1.Configure the following setting(s):

Tab

Setting

Value

Geometry

Domains

RotatingFluid

Definition

> Method

XY Plane

Definition

> Z

0.003 [m]

Click Apply.

Turn off the visibility of

Plane 1.Create a new vector plot named

Vector 1.Configure the following setting(s):

Tab

Setting

Value

Geometry

Domains

All Domains

Definition

> Locations

Plane 1

Definition

> Sampling

Rectangular Grid

Definition

> Spacing

0.03

Definition

> Variable

Velocity

Color

Mode

Use Plot Variable

Range

User Specified

Min

0 [m s^-1]

Max

0.8 [m s^-1]

Symbol

Symbol

Arrow3D

Symbol Size

15

Normalized Symbols

(Cleared)

Click Apply.

Make the inlet and outlet visible as follows:

Edit

StationaryFluid>in.Configure the following setting(s):

Tab

Setting

Value

Render

Show Faces

(Cleared)

Show Mesh Lines

(Selected)

Show Mesh Lines

> Edge Angle

105 [degree]

Show Mesh Lines

> Line Width

2

Show Mesh Lines

> Color Mode

Default

Click Apply.

Apply the same settings to

StationaryFluid>out.

Make the inlet and outlet channels visible as follows:

Edit

StationaryFluid>StationaryFluid Default.Configure the following setting(s):

Tab

Setting

Value

Render

Show Faces

(Selected)

Show Faces

> Transparency

0.8

Show Mesh Lines

(Cleared)

Click Apply.

Make the walls of the rotating fluid domain visible as follows:

Edit

RotatingFluid>RotatingFluid Default.Configure the following setting(s):

Tab

Setting

Value

Color

Mode

Constant

Color

(White)

Render

Show Faces

(Selected)

Show Faces

> Transparency

0.0

Show Mesh Lines

(Cleared)

Click Apply.

Make the walls of the immersed solid domain visible as follows:

Edit

ImmersedSolid>ImmersedSolid Default.Configure the following setting(s):

Tab

Setting

Value

Color

Mode

Constant

Color

(Blue)

Render

Show Faces

(Selected)

Show Faces

> Transparency

0.0

Show Mesh Lines

(Cleared)

Click Apply.

Make the following other changes in preparation for the animation that you will create in the next section:

Right-click a blank area in the viewer and select Predefined Camera > View From +Z.

Rotate the view a few degrees so that you can see the 3D nature of the geometry.

Turn off the visibility of

User Locations and Plots>Wireframe.

In this section, you will generate an animation that shows the

changing velocity field on Plane 1. To take advantage

of the periodic nature of the solution, you will record a short animation

that can be played in a repeating loop in an MPEG player. Start the

animation at the 61st time step (a time

at which the flow has settled into a repeating pattern) and end it

at the 90th time step. The 60th time step corresponds with 2/42 s, and the 90th corresponds with 3/42 s; the 1/42 s interval is

the period over which the solution repeats. Because the 60th and 90th time steps look

the same, the 60th time step is omitted

to avoid having a pair of adjacent identical frames in the animation

when the latter is played in a repeating loop.

Click Timestep Selector

and load the 61st time step.

and load the 61st time step.Click Animation

.

.The Animation dialog box appears.

Set Type to Keyframe Animation.

Click New

to create

to create KeyframeNo1.Select

KeyframeNo1, then set # of Frames to28, then press Enter while the cursor is in the # of Frames box.Tip: Be sure to press Enter and confirm that the new number appears in the list before continuing.

Use the Timestep Selector to load the 90th time step.

In the Animation dialog box, click New

to create

to create KeyframeNo2.Ensure that More Animation Options

is pushed down to show more animation settings.

is pushed down to show more animation settings.Select Loop.

Ensure that the Repeat forever button

next to Repeat is not selected

(not pushed down).

next to Repeat is not selected

(not pushed down).Select Save Movie.

Set Format to

MPEG1.Click Browse

next

to Save Movie.

next

to Save Movie.Set File name to

ImmersedSolid.mpg.If required, set the path location to a different directory.

Click .

The movie file name (including path) has been set, but the animation has not yet been produced.

Click To Beginning

.

.This ensures that the animation will begin at the first keyframe.

After the first keyframe has been loaded, click Play the animation

.

.The MPEG will be created as the animation proceeds.

This will be slow, since results for each time step will be loaded and objects will be created.

To view the movie file, you need to use a viewer that supports the MPEG format.

Note: To explore additional animation options, click the Options button. On the Advanced tab of the Animation Options dialog box, there is a Save Frames As Image Files check box. By selecting this check box, the JPEG or PPM files used to encode each frame of the movie will persist after movie creation; otherwise, they will be deleted.

When you have finished, quit CFD-Post.