This tutorial includes:

In this tutorial you will learn about:

Mesh motion and deformation.

Rigid body simulation.

Fluid structure interaction (without modeling solid deformation).

Animation creation.

Component | Feature | Details |

|---|---|---|

CFX-Pre | User Mode | General mode |

Analysis Type | Transient | |

Fluid Type | General Fluid | |

Domain Type | Single Domain | |

Turbulence Model | k-Epsilon | |

Heat Transfer | Isothermal | |

Boundary Conditions | Opening | |

Symmetry | ||

Wall | ||

Rigid Body | 1 Degree of Freedom | |

Mesh Motion | Unspecified | |

Stationary | ||

Rigid Body Solution | ||

CFD-Post | Plots | Slice Plane |

Point | ||

Vector | ||

Animation |

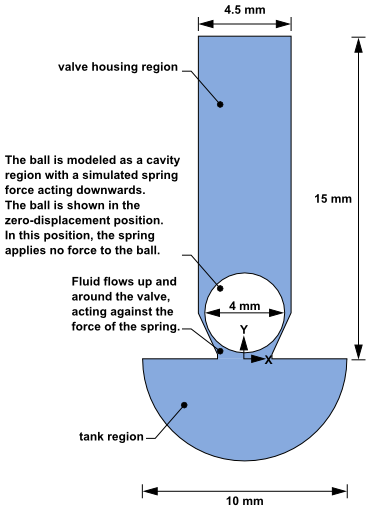

This tutorial uses an example of a ball check valve to demonstrate two-way Fluid-Structure Interaction (FSI) between a ball and a fluid, as well as mesh deformation capabilities using Ansys CFX. A sketch of the geometry, modeled in this tutorial as a 2D slice (0.1 mm thick), is shown below.

Check valves are commonly used to enforce unidirectional flow of liquids and act as pressure-relieving devices. The check valve for this tutorial contains a ball connected to a spring with a stiffness constant of 300 N/m. The ball is made of steel with a density of 7800 kg/m3 and is represented as a cavity region in the mesh with a diameter of 4 mm. Initially the center of mass of the ball is located at the coordinate point (0, 0.0023, 5e-05); this point is the spring origin, and all forces that interact with the ball are assumed to pass through this point. The tank region, located below the valve housing, is filled with Methanol (CH4O) at 25°C. High pressure from the liquid at the tank opening (6 atm relative pressure) causes the ball to move up, therefore enabling the fluid to escape through the valve to the atmosphere at an absolute pressure of 1 atm. The forces on the ball are: the force due to the spring (not shown in the figure) and the force due to fluid flow. Gravity is neglected here for simplicity. The spring pushes the ball downward to oppose the force of the pressure when the ball is raised above its initial position. The pressure variation causes the ball to oscillate along the Y axis as a result of a dynamic imbalance in the forces. The ball eventually stops oscillating when the forces acting on it are in equilibrium.

In this tutorial the deformation of the ball itself is not modeled; mesh deformation is employed to modify the mesh as the ball moves. A rigid body simulation is used to predict the motion of the ball, and will be based on the forces that act on it.

If this is the first tutorial you are working with, it is important to review the following topics before beginning:

Create a working directory.

Ansys CFX uses a working directory as the default location for loading and saving files for a particular session or project.

Download the

valve_fsi.zipfile here .Unzip

valve_fsi.zipto your working directory.Ensure that the following tutorial input file is in your working directory:

ValveFSI.out

Set the working directory and start CFX-Pre.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

This section describes the step-by-step definition of the flow physics in CFX-Pre.

In CFX-Pre, select File > New Case.

Select General and click .

Select File > Save Case As.

Under File name, type

ValveFSI.Click .

Right-click

Meshand select Import Mesh > Other.The Import Mesh dialog box appears.

Configure the following setting(s):

Setting

Value

Files of type

PATRAN Neutral (*out *neu)

File name

ValveFSI.out

Options

> Mesh Units

mm [a]

Click Open.

Right-click

Analysis Typein the Outline tree view and select Edit.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Analysis Type

> Option

Transient

Analysis Type

> Time Duration

> Option

Total Time

Analysis Type

> Time Duration

> Total Time

7.5e-3 [s]

Analysis Type

> Time Steps

> Option

Timesteps

Analysis Type

> Time Steps

> Timesteps

5.0e-5 [s]

Analysis Type

> Initial Time

> Option

Automatic with Value

Analysis Type

> Initial Time

> Time

0 [s]

Click .

Note: You may ignore the physics validation message regarding the lack of definition of transient results files. You will set up the transient results files later.

In this section you will create the fluid domain, define the fluid and enable mesh motion.

If

Default Domaindoes not currently appear under Flow Analysis 1 in the Outline tree,edit

Case Options>Generalin the Outline tree view and ensure that Automatic Default Domain is turned on and click .In the tree view, right-click

Default Domainand select Edit.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Location and Type

> Location

CV3D REGION, CV3D SUB [a]

Location and Type

> Domain Type

Fluid Domain

Fluid and Particle Definitions

Fluid 1

Fluid and Particle Definitions

> Fluid 1

> Material

Methanol CH4O [b]

Domain Models

> Pressure

> Reference Pressure

1 [atm]

Domain Models

> Mesh Deformation

> Option

Regions of Motion Specified [c]

Domain Models

> Mesh Deformation

> Displacement Rel. To

Previous Mesh

Domain Models

> Mesh Deformation

> Mesh Motion Model

> Option

Domain Models

> Mesh Deformation

> Mesh Motion Model

> Mesh Stiffness

> Option

Increase near Small Volumes

Domain Models

> Mesh Deformation

> Mesh Motion Model

> Mesh Stiffness

> Model Exponent

1[f]

Domain Models

> Mesh Deformation

> Mesh Motion Model

> Mesh Stiffness

> Reference Volume

> Option

Mean Control Volume

Fluid Models Heat Transfer

> Option

Isothermal

Heat Transfer

> Fluid Temperature

25 [C]

Turbulence

> Option

k-Epsilon

Click the Multi-select from extended list icon

to open the Selection

Dialog dialog box, then hold the Ctrl key

while selecting both

to open the Selection

Dialog dialog box, then hold the Ctrl key

while selecting both CV3D REGIONandCV3D SUBfrom this list. Click .To make Methanol an available option:

Click the Select from extended list icon

to open the Material dialog box.

to open the Material dialog box.Click the Import Library Data icon

to open the Select Library Data to

Import dialog box.

to open the Select Library Data to

Import dialog box. In that dialog box, expand

Constant Property Liquidsin the tree, selectMethanol CH4Oand click .Select

Methanol CH4Oin the Material dialog box and click .

The

Regions of Motion Specifiedoption permits boundaries and subdomains to move, and makes mesh motion settings available.To see the additional mesh motion settings, you may need to click Roll Down

located beside Mesh Motion Model.

located beside Mesh Motion Model.The Displacement Diffusion model for mesh motion attempts to preserve the relative mesh distribution of the initial mesh.

An exponent value of 1 is chosen in order to limit the distortion of the coarse mesh. If a finer mesh were used, the default value of 2 would most likely be appropriate.

Click .

In this section, a secondary coordinate system will be created to define the center of mass of the ball. This secondary coordinate system will be used to define certain parameters of the rigid body in the next section.

In the Outline tree view, right-click Coordinate Frames and select Insert > Coordinate Frame.

Set the name to

Coord 1and click .Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Option

Axis Points

Origin

(0, 0.0023, 5e-05)

Z Axis Point

(0, 0.0023, 1)

X-Z Plane Pt

(1, 0.0023, 0)

Select .

A rigid body is a non-deformable object described by physical parameters: mass, center of mass, moment of inertia, initial velocities and accelerations, and orientation. The rigid body solver uses the interacting forces between the fluid and the rigid body and calculates the motion of the rigid body based upon the defined physical parameters. The rigid body may have up to six degrees of freedom (three translational and three rotational). You may also specify external forces and torques acting on the rigid body.

In this section, you will define a rigid body with 1 degree of freedom, translation in the Y direction. The rigid body definition will be applied to the wall boundary of the ball to define its motion. Further, you will specify an external spring force by defining a spring constant and the initial origin of the spring; in this simulation the origin is the center of mass of the ball. The force caused by the tank pressure will cause an upward translation and the defined external spring force will resist this translation.

In the Outline tree view, right-click Flow Analysis 1 and select Insert > Rigid Body.

Set the name to

rigidBalland click .Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Mass

9.802e-6 [kg]

Location

BALL

Coordinate Frame

Coord 1

Mass Moment of Inertia

> XX Component

0 [kg m^2] [a]

Mass Moment of Inertia

> YY Component

0 [kg m^2]

Mass Moment of Inertia

> ZZ Component

0 [kg m^2]

Mass Moment of Inertia

> XY Component

0 [kg m^2]

Mass Moment of Inertia

> XZ Component

0 [kg m^2]

Mass Moment of Inertia

> YZ Component

0 [kg m^2]

Dynamics

External Force Definitions

Create a new external force named

Spring Force[b].External Force Definitions

> Spring Force

> Option

Spring

External Force Definitions

> Spring Force

> Equilibrium Position

> X Component

0 [m]

External Force Definitions

> Spring Force

> Equilibrium Position

> Y Component

0 [m]

External Force Definitions

> Spring Force

> Equilibrium Position

> Z Component

0 [m]

External Force Definitions

> Spring Force

> Linear Spring Constant

> X Component

0 [N m^-1]

External Force Definitions

> Spring Force

> Linear Spring Constant

> Y Component

300 [N m^-1]

External Force Definitions

> Spring Force

> Linear Spring Constant

> Z Component

0 [N m^-1]

Degrees of Freedom

> Translational Degrees of Freedom

> Option

Y axis

Degrees of Freedom

> Rotational Degrees of Freedom

> Option

None

Click .

Select Insert > Subdomain from the main menu or click Subdomain

.

.Set the subdomain name to

Tankand click .Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Location

CV3D SUB

Mesh Motion

Mesh Motion

> Option

Stationary [a]

Click .

In the following subsections, you will create the required boundary conditions, specifying the appropriate mesh motion option for each.

In this tutorial, mesh motion specifications are applied to

two and three dimensional regions of the domain. For example, the Ball boundary specifies the mesh motion in the form of

the rigid body solution. However, mesh motion specifications are also

used in this tutorial to help ensure that the mesh does not fold,

as set for the Tank subdomain earlier in the

tutorial, and the TankOpen boundary below. Two

regions, VALVE HIGHX and VALVE LOWX, remain at the default boundary condition: smooth, no slip walls

and no mesh motion (stationary).

Create a new boundary named

Ball.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Wall

Location

BALL

Boundary Details

Mesh Motion

> Option

Rigid Body Solution

Mesh Motion

> Rigid Body

rigidBall

Mass And Momentum

> Option

No Slip Wall

Mass And Momentum

> Wall Vel. Rel. To

Mesh Motion

Click .

Because a 2D representation of the flow field is being modeled (using a 3D mesh, one element thick in the Z direction), you must create symmetry boundaries on the low and high Z 2D regions of the mesh.

Create a new boundary named

Sym.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Symmetry

Location

SYMP1, SYMP2 [a]

Boundary Details

Mesh Motion

> Option

Unspecified

Click .

Create a new boundary named

ValveVertWalls.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Wall

Location

VPIPE HIGHX, VPIPE LOWX [a]

Boundary Details

Mesh Motion

> Option

Unspecified [b]

Mass And Momentum

> Option

No Slip Wall

Mass And Momentum

> Wall Vel. Rel. To

Boundary Frame

Hold the Ctrl key while selecting both

VPIPE HIGHXandVPIPE LOWXfrom the list.The

Unspecifiedsetting allows the mesh nodes to move freely. The motion of the mesh points on this boundary will be strongly influenced by the motion of the ball. Because the ball moves vertically, the surrounding mesh nodes should also move vertically, at a similar rate to the ball. This mesh motion specification helps to preserve the quality of the mesh on the upper surface of the ball.

Click .

Create a new boundary named

TankOpen.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Opening

Location

BOTTOM

Boundary Details

Mesh Motion

> Option

Stationary [a]

Mass And Momentum

> Option

Entrainment

Mass And Momentum

> Relative Pressure

6 [atm] [b]

Turbulence

> Option

Zero Gradient

The stationary option for the tank opening prevents the mesh nodes on this boundary from moving. If the tank opening had unspecified mesh motion, these mesh nodes would move vertically and separate from the non-vertical parts of the boundary.

As defined in the problem description. Note the units for this setting.

Click .

Create a new boundary named

ValveOpen.Configure the following setting(s):

Click .

Note: Opening boundary types are used to enable the flow to leave and reenter the domain. This behavior is expected due to the oscillatory motion of the ball and due to the potentially large region of flow recirculation that may occur downstream from the ball.

Because a transient simulation is being modeled, initial values are required for all variables.

Click Global Initialization

.

.Configure the following setting(s):

Tab

Setting

Value

Global Settings

Initial Conditions

> Cartesian Velocity Components

> U

0 [m s^-1]

Initial Conditions

> Cartesian Velocity Components

> V

0.1 [m s^-1] [a]

Initial Conditions

> Cartesian Velocity Components

> W

0 [m s^-1]

Initial Conditions

> Static Pressure

> Relative Pressure

0 [Pa]

Initial Conditions

> Turbulence

> Option

Medium (Intensity = 5%)

Click .

In this section you will edit the solver control settings to promote a quicker solution time and to enable the frequency of when the rigid body solver is run.

Click Solver Control

.

.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Transient Scheme

> Option

Second Order Backward Euler

Convergence Control

> Max. Coeff. Loops

5

Rigid Body Control

Rigid Body Control

(Selected)

Rigid Body Control

> Rigid Body Solver Coupling Control

> Update Frequency

Every Coefficient Loop [a]

Click .

This step sets up transient results files to be written at set intervals.

Click Output Control

.

.Click the Trn Results tab.

In the Transient Results tree view, click Add new item

, set Name to

, set Name to Transient Results 1, and click OK.Configure the following setting(s) of

Transient Results 1:Setting

Value

Option

Selected Variables

Output Variables List

Pressure, Velocity

Output Variable Operators

(Selected)

Output Variable Operators

> Output Variable Operators

All [a]

Output Frequency

> Option

Time Interval

Output Frequency

> Time Interval

5.0e-5 [s]

Click the Monitor tab.

Select Monitor Objects.

Under Monitor Points and Expressions:

Click Add new item

.

.Set Name to

Ball Displacementand click .Set Option to

Expression.Set Expression Value to

rbstate(Position Y)@rigidBall.

Click .

When CFX-Pre has shut down and the CFX-Solver Manager has started, obtain a solution to the CFD problem by following the instructions below.

Ensure that the Define Run dialog box is displayed.

Solver Input File should be set to

ValveFSI.def.Click Start Run.

CFX-Solver runs and attempts to obtain a solution. This can take a long time depending on your system.

Note: You can ignore the warning message indicating a negative sector volume in your mesh. This occurs as a result of large deformations in the mesh and will not significantly affect the results for this case.

While CFX-Solver Manager is running, you can check the progress of the monitor point you created in CFX-Pre by clicking the

User Pointstab in CFX-Solver Manager. The graph shows the Y position of the center of mass of the ball (in the global coordinate frame). Notice that the ball has a sinusoidal motion that diminishes in amplitude over time and that the maximum displacement of the ball occurs at around time step 17.Select Monitors > Rigid Body > Rigid Body Position from the main menu. The position of the rigid body will be shown in the X, Y and Z directions relative to the global coordinate frame.

Note: This graph is identical to the graph obtained from under the

User Pointstab (although the scale may be different). Normally, creating the monitor point for position is redundant since the rigid body positions are calculated automatically — the monitor point was created in this tutorial to demonstrate therbstatefunction.When a dialog box is displayed at the end of the run, select Post-Process Results.

Click .

In the following subsections, you will create a user location, point and vector plots, and an animation in CFD-Post. You will create an XY plane that lies midway between the two symmetry planes. The plane will be used to show the mesh motion; it will also serve as the location for a vector plot that will be used in the animation.

Right-click a blank area in the viewer and select Predefined Camera > View From +Z.

Select Insert > Location > Plane from the main menu. Accept the default name and click .

Configure the following setting(s):

Tab

Setting

Value

Geometry

Definition

> Method

XY Plane

Definition

> Z

5e-05 [m]

Render

Show Faces

(Cleared)

Show Mesh Lines

(Selected)

Click .

Select Insert > Location > Point from the main menu. Accept the default name and click .

Configure the following setting(s):

Tab

Setting

Value

Geometry

Definition

> Method

XYZ

Point

(0, 0.0003, 0)

Symbol

Symbol

Crosshair

Symbol Size

5

Click to create the point.

This is a reference point for the minimum Y value of the ball at time step 0. However the final time step is currently selected. This will be corrected in the proceeding steps.

Select Insert > Location > Point from the main menu. Accept the default name and click .

Configure the following setting(s):

Tab

Setting

Value

Geometry

Definition

> Method

XYZ

Point

(0, 0.001266, 0)

Symbol

Symbol

Crosshair

Symbol Size

5

Click to create the point.

This is a reference point for the minimum Y value of the ball in the positive Y direction at the time of maximum displacement.

Click Timestep Selector

and load the results for a few

different time steps, selecting one entry at a time.

and load the results for a few

different time steps, selecting one entry at a time.For example, double-click rows with the step values of 0, 10, 20, 50, and 90 to see the ball in different positions. The mesh deformation will also be visible.

Create a new vector named

Vector 1.Configure the following setting(s):

Tab

Setting

Value

Geometry

Locations

Plane 1

Variable

Velocity

Click to show the vector plot in the 3D Viewer.

You will create an animation showing the velocity in the domain as the ball moves.

Turn off the visibility of

Plane 1to better see the vector plot.Click the Timestep Selector

and load the 1st time step.

and load the 1st time step.Click Animate timesteps

in the Timestep Selector dialog box.

in the Timestep Selector dialog box.The Animation dialog box appears.

Set Type to Keyframe Animation.

Click New

to create

to create KeyframeNo1.Select

KeyframeNo1, then set # of Frames to149, then press Enter while the cursor is in the # of Frames box.Tip: Be sure to press Enter and confirm that the new number appears in the list before continuing.

Use the Timestep Selector to load the last time step.

In the Animation dialog box, click New

to create

to create KeyframeNo2.Tip: The # of Frames parameter has no effect on the last keyframe, so leave it at the default value.

Ensure that More Animation Options

is pushed down to show more animation settings.

is pushed down to show more animation settings.Select Loop.

Ensure that Repeat forever

(next to the Repeat setting)

is not selected (not pushed down).

(next to the Repeat setting)

is not selected (not pushed down).Click the Options button to open the Animation Options dialog box.

Configure the following setting(s):

Tab

Setting

Value

Options

Print Options

> Image Size

720 x 480 (NTSC)

Advanced

MPEG Options

> Quality

Custom

MPEG Options

> Variable Bit Rate

(Cleared)

MPEG Options

> Bit Rate

3000000 [a]

Click .

Select Save Movie.

Set Format to

MPEG1.Click Browse

(next

to Save Movie).

(next

to Save Movie).Set File name to

ValveFSI.mpg.If required, set the path to a different directory.

Click .

The movie file name (including the path) has been set, but the animation has not yet been produced.

Click To Beginning

.

.This ensures that the animation will begin at the first keyframe.

After the first keyframe has been loaded, click Play the animation

.

.The MPEG will be created as the animation proceeds.

This will be slow, since results for each time step will be loaded and objects will be created.

To view the movie file, you need to use a viewer that supports the MPEG format.

Note: To explore additional animation options, click the Options button. On the Advanced tab of the Animation Options dialog box, there is a Save Frames As Image Files check box. By selecting this check box, the JPEG or PPM files used to encode each frame of the movie will persist after movie creation; otherwise, they will be deleted.

Close the Animation dialog box when the animation is complete.

When you have finished, close the Timestep Selector dialog box and quit CFD-Post.