This tutorial includes:

In this tutorial you will learn about:

Modeling flow with cavitation.

Using vector reduction in CFD-Post to clarify a vector plot with many arrows.

Importing and exporting data along a polyline.

Plotting computed and experimental results.

Component | Feature | Details |

|---|---|---|

CFX-Pre | User Mode | General mode |

Analysis Type | Steady State | |

Fluid Type | General Fluid | |

Domain Type | Single Domain | |

Turbulence Model | k-Epsilon | |

Heat Transfer | Isothermal | |

Multiphase | ||

Boundary Conditions | Inlet (Subsonic) | |

Outlet (Subsonic) | ||

Symmetry Plane | ||

Wall: No-Slip | ||

Wall: Free-Slip | ||

| Timestep | Physical Time Scale | |

| CFX-Solver Manager | Restart | |

| CFD-Post | Plots | Contour |

Line Locator | ||

Polyline | ||

Slice Plane | ||

Streamline | ||

Vector | ||

Other | Chart Creation | |

Data Export | ||

Printing | ||

Title/Text | ||

Variable Details View |

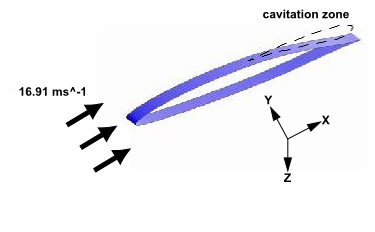

This example demonstrates cavitation in the flow of water around a hydrofoil. A two-dimensional solution is obtained by modeling a thin slice of the hydrofoil and using two symmetry boundary conditions.

In this tutorial, an initial solution with no cavitation is generated to provide an accurate initial guess for a full cavitation solution, which is generated afterwards.

If this is the first tutorial you are working with, it is important to review the following topics before beginning:

Create a working directory.

Ansys CFX uses a working directory as the default location for loading and saving files for a particular session or project.

Download the

hydrofoil.zipfile here .Unzip

hydrofoil.zipto your working directory.Ensure that the following tutorial input files are in your working directory:

HydrofoilExperimentalCp.csvHydrofoilGrid.def

Set the working directory and start CFX-Pre.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

This section describes the step-by-step definition of the flow physics in CFX-Pre.

In CFX-Pre, select File > New Case.

Select General and click .

Select File > Save Case As.

Under File name, type

HydrofoilIni.Click .

Right-click

Meshand select Import Mesh > CFX-Solver Input.The Import Mesh dialog box appears.

Configure the following setting(s):

Setting

Value

File name

HydrofoilGrid.def

Click Open.

Right-click a blank area in the viewer and select Predefined Camera > View From -Z.

Since this tutorial uses Water Vapour at 25 C and Water at 25 C, you need to load these materials.

In the Outline tree view, right-click

Materialsand select Import Library Data.The Select Library Data to Import dialog box is displayed.

Expand Water Data.

Select both

Water Vapour at 25 CandWater at 25 Cby holding Ctrl when selecting.Click .

The fluid domain used for this simulation contains liquid water and water vapor. The volume fractions are initially set so that the domain is filled entirely with liquid.

Edit

Case Options>Generalin the Outline tree view and ensure that Automatic Default Domain is turned on.A domain named

Default Domainshould now appear under theSimulation>Flow Analysis 1branch.Double-click

Default Domain.Under Fluid and Particle Definitions, delete

Fluid 1and create a new fluid definition calledLiquid Water.Use the

button to create another fluid named

button to create another fluid named Water Vapor.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Fluid and Particle Definitions

Liquid Water

Fluid and Particle Definitions

> Liquid Water

> Material

Water at 25 C [a]

Fluid and Particle Definitions

Water Vapor

Fluid and Particle Definitions

> Water Vapor

> Material

Water Vapour at 25 C [a]

Domain Models

> Pressure

> Reference Pressure

0 [atm]

Fluid Models

Multiphase

> Homogeneous Model

(Selected)

Heat Transfer

> Option

Isothermal

Heat Transfer

> Fluid Temperature

300 [K]

Turbulence

> Option

k-Epsilon

Click .

The simulation requires inlet, outlet, wall and symmetry plane boundaries. The regions for these boundaries were imported with the grid file.

Create a new boundary named

Inlet.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Inlet

Location

IN

Boundary Details

Mass And Momentum

> Normal Speed

16.91 [m s^-1]

Turbulence

> Option

Intensity and Length Scale

Turbulence

> Fractional Intensity

0.03

Turbulence

> Eddy Length Scale

0.0076 [m]

Fluid Values

Boundary Conditions

Liquid Water

Boundary Conditions

> Liquid Water

> Volume Fraction

> Volume Fraction

1

Boundary Conditions

Water Vapor

Boundary Conditions

> Water Vapor

> Volume Fraction

> Volume Fraction

0

Click .

Create a new boundary named

Outlet.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Outlet

Location

OUT

Boundary Details

Mass And Momentum

> Option

Static Pressure

Mass And Momentum

> Relative Pressure

51957 [Pa]

Click .

Create a new boundary named

SlipWalls.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Wall

Location

BOT, TOP

Boundary Details

Mass And Momentum

> Option

Free Slip Wall

Click .

Create a new boundary named

Sym1.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Symmetry

Location

SYM1

Click .

Create a new boundary named

Sym2.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Symmetry

Location

SYM2

Click .

Click Global Initialization

.

.Configure the following setting(s):

Tab

Setting

Value

Global Settings

Initial Conditions

> Cartesian Velocity Components

> Option

Automatic with Value

Initial Conditions

> Cartesian Velocity Components

> U

16.91 [m s^-1]

Initial Conditions

> Cartesian Velocity Components

> V

0 [m s^-1]

Initial Conditions

> Cartesian Velocity Components

> W

0 [m s^-1]

Fluid Settings

Fluid Specific Initialization

Liquid Water

Fluid Specific Initialization

> Liquid Water

> Initial Conditions

> Volume Fraction

> Option

Automatic with Value

Fluid Specific Initialization

> Liquid Water

> Initial Conditions

> Volume Fraction

> Volume Fraction

1

Fluid Specific Initialization

Water Vapor

Fluid Specific Initialization

> Water Vapor

> Initial Conditions

> Volume Fraction

> Option

Automatic with Value

Fluid Specific Initialization

> Water Vapor

> Initial Conditions

> Volume Fraction

> Volume Fraction

0

Click .

Click Solver Control

.

.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Convergence Control

> Max. Iterations

100

Convergence Control

> Fluid Timescale Control

> Timescale Control

Physical Timescale

Convergence Control

> Fluid Timescale Control

> Physical Timescale

0.01 [s]

Note: For the Convergence Criteria, an

RMSvalue of at least 1e-05 is usually required for adequate convergence, but the default value is sufficient for demonstration purposes.Click .

Click Define Run

.

.Configure the following setting(s):

Setting

Value

File name

HydrofoilIni.def

Click .

CFX-Solver Manager automatically starts and, on the Define Run dialog box, Solver Input File is set.

Quit CFX-Pre, saving the simulation (

.cfx) file at your discretion.

While the calculations proceed, you can see residual output for various equations in both the text area and the plot area. Use the tabs to switch between different plots (for example, Momentum and Mass, Turbulence Quantities, and so on) in the plot area. You can view residual plots for the fluid and solid domains separately by editing the workspace properties.

Ensure that the Define Run dialog box is displayed.

Click Start Run.

CFX-Solver runs and attempts to obtain a solution. At the end of the run, a dialog box is displayed stating that the simulation has ended.

Select Post-Process Results.

If using stand-alone mode, select Shut down CFX-Solver Manager.

Click .

The following topics will be discussed:

In this section, you will create a plot of the pressure coefficient distribution around the hydrofoil. The data will then be exported to a file for later comparison with data from the cavitating flow case, which will be run later in this tutorial.

Right-click a blank area in the viewer and select Predefined Camera > View From -Z.

Insert a new plane named

Slice.Configure the following setting(s):

Tab

Setting

Value

Geometry

Definition

> Method

XY Plane

Definition

> Z

5e-5 [m]

Render

Show Faces

(Cleared)

Click Apply.

Create a new polyline named

Foilby selecting Insert > Location > Polyline from the main menu.Configure the following setting(s):

Tab

Setting

Value

Geometry

Method

Boundary Intersection

Boundary List

Default Domain Default

Intersect With

Slice

Click Apply.

Zoom in on the center of the hydrofoil (near the cavity) to confirm the polyline wraps around the hydrofoil.

Define the following expressions, remembering to click Apply after entering each definition:

Name

Definition

PCoef

(Pressure-51957[Pa])/(0.5*996.2[kg m^-3]*16.91[m s^-1]^2)

FoilChord

(X-minVal(X)@Foil)/(maxVal(X)@Foil-minVal(X)@Foil) [a]

Create a new variable named

Pressure Coefficient.Configure the following setting(s):

Setting

Value

Method

Expression

Scalar

(Selected)

Expression

PCoef

Click Apply.

Create a new variable named

Chord.Configure the following setting(s):

Setting

Value

Method

Expression

Scalar

(Selected)

Expression

FoilChord

Click Apply.

Note: Although the variables that were just created are only needed at points along the polyline, they exist throughout the domain.

Now that the variables Chord and Pressure Coefficient exist, they can be associated with

the previously defined polyline (the locator) to form a chart line.

This chart line will be added to the chart object, which is created

next.

Select Insert > Chart from the main menu.

Set the name to

Pressure Coefficient Distribution.Configure the following setting(s):

Tab

Setting

Value

General

Title

Pressure Coefficient Distribution

Data Series

Name

Solver Cp

Location

Foil

X Axis

Data Selection

> Variable

Chord

Axis Range

> Determine ranges automatically

(Cleared)

Axis Range

> Min

0

Axis Range

> Max

1

Axis Labels

> Use data for axis labels

(Cleared)

Axis Labels

> Custom Label

Normalized Chord Position

Y Axis

Data Selection

> Variable

Pressure Coefficient

Axis Range

> Determine Ranges Automatically

(Cleared)

Axis Range

> Min

-0.5

Axis Range

> Max

0.4

Axis Range

> Invert Axis

(Selected)

Axis Labels

> Use data for axis labels

(Cleared)

Axis Labels

> Custom Label

Pressure Coefficient

Click Apply.

The chart appears in the Chart Viewer.

You will now export the chord and pressure coefficient data along the polyline. This data will be imported and used in a chart later in this tutorial for comparison with the results for when cavitation is present.

Select File > Export > Export.

The Export dialog box appears

Configure the following setting(s):

Tab

Setting

Value

Options

File

NoCavCpData.csv

Locations

Foil

Export Geometry Information

(Selected) [a]

Select Variables

Chord, Pressure Coefficient

Click .

The file

NoCavCpData.csvwill be written in the working directory.

If you are running CFD-Post in stand-alone mode, you will need to save the postprocessing state for use later in this tutorial, as follows:

Select File > Save State As.

Under File name type

Cp_plot, then click .

In the next part of this tutorial, the solver will be run with cavitation turned on. Similar postprocessing follows, and the effect of cavitation on the pressure distribution around the hydrofoil will be illustrated in a chart.

Earlier in this tutorial, you ran a simulation without cavitation. The solution from that simulation will serve as a starting point for the next simulation, which involves cavitation.

Ensure that the following tutorial input file is in your working directory:

HydrofoilIni_001.res

Set the working directory and start CFX-Pre if it is not already running.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

Select File > Open Case.

Select

HydrofoilIni_001.resand click Open.Save the case as

Hydrofoil.cfx.

Double-click

Default Domainin the Outline tree view.Configure the following setting(s):

Tab

Setting

Value

Fluid Pair Models

Fluid Pairs

> Liquid Water | Water Vapor

> Mass Transfer

> Option

Cavitation

Fluid Pairs

> Liquid Water | Water Vapor

> Mass Transfer

> Cavitation

> Saturation Pressure

(Selected)

Fluid Pairs

> Liquid Water | Water Vapor

> Mass Transfer

> Cavitation

> Saturation Pressure

> Saturation Pressure

3574 [Pa] [a]

Click .

Click Solver Control

.

.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Convergence Control

> Max. Iterations

150 [a]

Click .

Click Execution Control

.

.Configure the following setting(s):

Tab

Setting

Value

Run Definition

Input File Settings

> Solver Input File

Hydrofoil.def [a]

Confirm that the rest of the execution control settings are set appropriately.

Click .

Ensure the Define Run dialog box is displayed.

Solver Input File should be set to

Hydrofoil.def.Configure the following setting(s) for the initial values file:

Tab

Setting

Value

Initial Values

Initial Values Specification

Selected

Initial Values Specification

> Initial Values

Initial Values 1

Initial Values Specification

> Initial Values

> Initial Values 1 Settings

> File Name [a]

HydrofoilIni_001.resThis is the solution from the starting-point run.

Click Start Run.

CFX-Solver runs and attempts to obtain a solution. At the end of the run, a dialog box is displayed stating that the simulation has ended.

Select Post-Process Results.

If using stand-alone mode, select Shut down CFX-Solver Manager.

Click .

You will restore the state file saved earlier in this tutorial

while preventing the first solution (which has no cavitation) from

loading. This will cause the plot of pressure distribution to use

data from the currently loaded solution (which has cavitation). Data

from the first solution will be added to the chart object by importing NoCavCpData.csv (the file that was exported earlier).

A file containing experimental data will also be imported and added

to the plot. The resulting chart will show all three sets of data

(solver data with cavitation, solver data without cavitation, and

experimental data).

Note: The experimental data is provided in HydrofoilExperimentalCp.csv which must be in your working directory before proceeding with this

part of the tutorial.

Note: If using Ansys Workbench, CFD-Post will already be in the state in which you left it in the first part of this tutorial. In this case, proceed to step 5 below.

Select File > Load State.

Clear Load results.

Select

Cp_plot.cst.Click Open.

Click the Chart Viewer tab.

Edit

Report>Pressure Coefficient Distribution.Click the Data Series tab.

Configure the following setting(s):

Tab

Setting

Value

Data Series

Name

Solver Cp - with cavitation

This reflects the fact that the user-defined variable

Pressure Coefficientis now based on the current results.Click Apply.

You will now add the chart line from the first simulation.

Create a new polyline named

NoCavCpPolyline.Configure the following setting(s):

Tab

Setting

Value

Geometry

File

NoCavCpData.csv

Click Apply.

The data in the file is used to create a polyline with values of

Pressure CoefficientandChordstored at each point on it.Edit

Report>Pressure Coefficient Distribution.Click the Data Series tab.

Click New

.

.Select

Series 2from the list box.Configure the following setting(s):

Tab

Setting

Value

Data Series

Name

Solver Cp - no cavitation

Location

NoCavCpPolyline

Custom Data Selection

(Selected)

X Axis

> Variable

Chord on NoCavCpPolyline

Y Axis

> Variable

Pressure Coefficient on NoCavCpPolyline

Click Apply.

The chart line (containing data from the first solution) is created, added to the chart object, and displayed in the Chart Viewer.

You will now add a chart line to show experimental results.

Click New

.

.Configure the following setting(s):

Tab

Setting

Value

Data Series

Name

Experimental Cp - with cavitation

Data Source

> File

(Selected)

Data Source

> File

HydrofoilExperimentalCp.csv

Line Display

Line Display

> Line Style

Automatic

Line Display

> Symbols

Rectangle

Click Apply.

The chart line (containing experimental data) is created, added to the chart object, and displayed in the Chart Viewer.

If you want to save an image of the chart, select File > Save Picture from the main menu while the Chart Viewer is displayed. This will enable you to save the chart to an image file.

When you are finished, close CFD-Post.