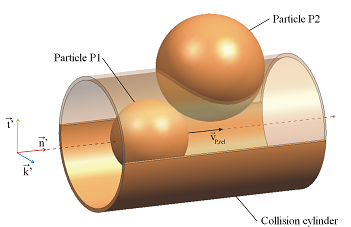

The main idea behind the stochastic collision model is the creation of a virtual collision partner, which is done by using local size and velocity distributions of the droplet phase. Hence, the virtual droplet is a representative of the local droplet population. This approach avoids the need to know the locations of neighboring droplets and the time consuming search for collision partners in order to decide whether a collision takes place or not. Only the droplet size- and velocity-distribution functions must be stored for each computational element, see Sommerfeld, M. (1996) [152]. The following illustration shows a virtual collision partner, Particle P2, whose position is determined using the following considerations:

Stochastic determination

Probability equally distributed over cross-section

For the calculation of the instantaneous velocity of the virtual

collision partner, a partial correlation of the turbulent fluctuation

velocities between the real and the virtual particle is taken into

account, as proposed by Sommerfeld, M. (2001) [154]. The correlation

is a function of the turbulent Stokes number , which is the ratio

of the aerodynamic relaxation time and a characteristic eddy lifetime,

the latter provided by the turbulence model. Small particles being

able to follow the gas flow easily have Stokes numbers below unity;

the Stokes numbers of large inertial particles exceed unity.

Sommerfeld’s correlation function,

(6–172) |

which was adapted to LES-data of a homogeneous isotropic turbulence field by Lavieville, J., E. Deutsch, and O. Simonin (1995) [153], is used to determine the fluctuating velocity of the virtual collision partner as given below:

(6–173) |

where the index 1 stands for the real particle and index 2 for

the virtual particle, index represents the three coordinate

directions and the prime indicates a fluctuating part of the velocity.

is the

-th component of the mean fluctuation

velocity in the control volume.

is a Gaussian random number with

zero mean and a standard deviation of unity. It represents the uncorrelated

part of the fluctuation velocity of the virtual particle. Its instantaneous

velocity is the sum of the fluctuating part described above and the

local mean value. The collision frequency is then determined in analogy

to the Kinetic Theory of Gases [151], by the following equation:

(6–174) |

where and

represent the instantaneous velocities of the real

particle 1 and its collision partner 2. The diameter of the latter

is sampled from a Gaussian distribution around the local average value.

The collision probability is a simple function of the collision frequency

and the Lagrangian time step and is calculated as follows:

(6–175) |

The time step can be altered in the collision subroutine to

ensure accuracy and stability of the calculation by limiting it to . This allows for at most one binary collision per

time step, as derived by Sommerfeld, M. [152].

A uniformly distributed random number, , is then generated and compared to the collision

probability

. If

, the inter-particle collision is calculated deterministically. For

, no collision occurs and the velocity

components of the real particle remain unchanged. In case of a collision,

the location of the virtual particle is determined in a stochastic

way. The calculation of the position of the collision partner relative

to the real particle is done in a local coordinate system. The position

is sampled randomly from a uniform distribution on the collision cylinder

cross-section and a distance of the center point according to the

sum of the two particle radii. Subsequently, the position of the virtual

particle is transformed back to the global system. A more detailed

description is given by Frank, Th. (2002) [149].

At this stage, information on location, size and velocity of

the virtual collision partner is known. The next step is to determine

the change in the velocity components caused by the collision. To

identify the post-collision velocities, the momentum transferred between

the particles has to be determined. For this purpose, it is again

suitable to use a local coordinate system, different to the one mentioned

above and fixed to the real particle. To identify the post-collision

velocities, the momentum transferred between the particles has to

be determined. Here a distinction is made between a sliding and a

non-sliding collision, if particle rotation is accounted for which

affects the tangential components of

. During a non-sliding collision,

the relative movement at the point of contact ceases; whereas during

a sliding collision, relative motion of the contact surfaces is maintained

under the influence of sliding friction.

Besides the coefficient of restitution considering the

losses normal to the plane of contact, the coefficients of sliding

and static friction have to be supplied for the particle material,

if particle rotation is taken into account. Hence, in the case of

rotating particles, a decision between the two collision modes is

made based on the coefficient of static friction. The respective components

of the transferred momentum are determined and the post-collision

velocity components are calculated in the local coordinate system.

Finally these values are transformed back to the global coordinate

system and passed to the Lagrangian solver. Because the computational

particles (parcel) represent a number of real particles, it is assumed

that all the real particles inside the parcel collide with the same

number of virtual particles.

The parameters used for the particle collision model are outlined below:

- Sommerfeld Collision Model

Coefficient of Restitution: Enter a numerical quantity or CEL based expression to specify the value of coefficient of restitution for inter-particle collisions. A value of ‘1.0’ means a fully elastic collision, while a value of ‘0.0’ would result in an inelastic collision.Static Friction CoefficientandKinetic Friction Coefficient: Enter a numerical quantity or CEL based expression to specify values of coefficients of friction for inter-particle collisions.See Implementation Theory in the CFX-Solver Theory Guide for more information on setting up

Coefficient of Restitution,Static Friction Coefficient, andKinetic Friction Coefficient.

- User Defined

This option is available only if you have created a particle user routine to set up the model. Specify the name of Particle User Routine and select input arguments and type of particle variables returned to the user routine from the Arguments and Variable List drop-down list, respectively. See Particle User Routines in the CFX-Pre User's Guide for information on setting up a particle user routine.

The friction coefficient values are dependent on particle material and should be obtained from experimental investigations. As another example, a suitable (static and kinetic) friction coefficient for the collision of steel particles can be assumed to be equal to 0.15, while a value of about 0.4 is mentioned in literature for glass particles. Furthermore, these values are dependent on the surface roughness of the particle material and the degree of sphericity of the particle material in the flow and are therefore subject to uncertainty.

The calculation of particle collisions with the Sommerfeld

collision model uses instantaneous and averaged fluid and

particle quantities as well as the following additional quantities:

The particle number density, , describes the number of particles per

unit volume and is calculated as follows:

(6–176) |

In this expression, the sum is taken over all particles and

all time-steps taken in the control volume of each vertex. Here is the particle integration timestep and

is the number rate for

the particle.

is the volume of the control volume associated with

the vertex.

The turbulent Stoke number, , is used for the calculation of the fluctuating

velocity of the collision partner of a droplet. The turbulent Stokes

number is defined as the ratio of the aerodynamic relaxation time,

, and a characteristic

eddy lifetime,

.

(6–177) |

With

(6–178) |

and

(6–179) |

The calculation of the collision partner requires the instantaneous, the mean, and the standard deviation values of particle quantities. The standard deviations of the following variables are calculated and are available for solver internal use, as well as for Particle User Fortran and postprocessing.

Particle Velocity

Particle Temperature

Particle Diameter

Particle Number Rate

The standard deviation of a particle variable, , is

calculated within the "vertex variable" machinery and

uses the following definition:

(6–180) |

For information on vertex and RMS particle variables, see Particle Field Variables in the CFX Reference Guide.

The particle integration time-step is passed to the collision model routine that is provided by the user. The timestep size is required to calculate the collision frequency for that particular integration.

Note: The particle-integration timestep can be accessed by you

but it can not be changed. The only exception is made for the particle

collision model when using Particle User Fortran. In this case, the

solver allows users to overwrite the Particle Integration

Timestep variable. This extension is required, as the integration

timestep computed from the particle tracker is typically 2 to 4 orders

of magnitude larger than the one computed (and usually needed) by

the collision model routine. This ensures an accurate calculation

of the droplet collision in regions with high particle concentration.

For details, see Implementation of a Stochastic Particle-Particle Collision

Model in Ansys CFX.

|

Name |

Meaning |

Dimension |

|---|---|---|

|

Size of the current integration time-step | [Time] | |

|

Turbulent Particle Stokes number |

[ ] | |

|

Particle number density |

[1/Length^3] | |

|

Standard deviation of the particle number rate |

[1/Time] | |

|

Standard deviation of particle velocity |

[Velocity] | |

|

Standard deviation of particle diameter |

[Length] |