The following topics are discussed:

For a detailed discussion of the derivation of turbulence equations please consult one of the available text books ([2]–[7]). In this section only a very basic model descriptions will be provided to allow the connection between the best Practice discussions and the turbulence model formulations.

The following topics are discussed:

Due to the high cost of DNS, the engineering approach to CFD lies in the Reynolds-Averaged Navier-Stokes (RANS) equations. These equations are obtained from the exact Navier-Stokes equations through time (or ensemble) averaging.

Time averaging is defined by:

(12–42) |

(12–43) |

In other words, the instantaneous quantity is split into a time-mean value

and a fluctuating part

. The simulation is then only concerned with the time-mean

part. More generally, one can also perform an ensemble-averaging over many instances of an

experiment:

Ensemble averaging is defined by:

(12–44) |

(12–45) |

The advantage of ensemble averaging is that it can also be applied to inherently unsteady flows (e.g. the flow in an internal combustion engine with moving parts). Both forms of averaging lead to the same equations and turbulence models, so the same overbar is used for simplicity.

When these averaging processes are applied to the Navier-Stokes equations, one obtains the RANS momentum equations:

(12–46) |

where () ?is the vector of the averaged velocity field,

is the density (assumed

constant in this brief overview),

is the averaged pressure and

is the Stokes (laminar)

stress tensor. For incompressible flows:

(12–47) |

with being the dynamic molecular viscosity.

The last term in the above equation ( ) is so-called 'Reynolds Stress

Tensor' and results from the averaging of the non-linear convection terms. This tensor

represents the influence of the turbulent fluctuations on the mean velocity field. The above

momentum equations are 'unclosed' as no equations are yet available for the Reynolds Stress

Tensor. Turbulence models are needed to provide formulations for this tensor.

The RANS momentum equations above are derived under the assumption that there are no significant density variations due to turbulence – this is typically the case for flows with Mach numbers below 3. Note that density variations on the mean flow occur much earlier, starting as low as M~0.1.

The most widely applied assumption in turbulence modeling is the eddy-viscosity assumption. It is based on the concept that turbulent stresses can be represented in a similar fashion as the laminar stress tensor:

(12–48) |

The last term on the right represents the turbulent kinetic energy, , and accounts for

the requirement that the sum of the diagonals of the Reynolds Stress Tensor must amount to

.

This term is not essential and can be avoided/ignored (e.g. in one-equation models where

is

not available)

The original problem of providing closure equations for the six (due to symmetry of

tensor) unknowns of the Reynolds Stress Tensor is thereby now reduced to providing a suitable

eddy-viscosity (also called turbulent viscosity). It is important to note that

is not a

property of the fluid, but a property of the local turbulence. The eddy-viscosity has

dimension:

(12–49) |

where and

are the length- and time-scales of turbulence, respectively.

Contrary to the eddy-viscosity assumption, there are methods, which aim at computing the individual Reynolds Stresses individually. For this purpose, exact transport equations for each Reynolds Stress are derived (6 equations). These exact equations, however, contain again new unknown terms which need to be modeled (see e.g. [5]). Different modeling assumptions for these terms then leads to a large variety of Reynolds Stress Models (RSM). The exact RSM equations read:

(12–50) |

The terms in these equations are: Line 1: time derivative, convection, production. Line

2: pressure strain (PS), dissipation. Line 3: turbulent diffusion and molecular diffusion. All

terms in Line 1 are exact and need no modeling. This is true also for the last term in Line 3.

All other terms require models to close the equations. In addition, there is a need for

information on the turbulent scale required e.g. in the dissipation term. This information is

typically obtained from an additional transport equation (e.g. -equation of

-equation). All

in all, RSM closure therefore requires the solution of seven additional equations. Proposed RSM

differ mostly by the way they model the pressure-strain term.

Simplified versions of RSM models can be obtained where the Reynolds stresses are computed from algebraic formulations instead of transport equations. Such models are generically of the form:

(12–51) |

with

(12–52) |

and being the turbulent kinetic energy and

a turbulent frequency scale. Note that the

eddy-viscosity formulation (Eq. (9.7)) is the simplest form of such a model. The main model in

Ansys CFD is the version of Wallin-Johansson (19).

All industrial relevant two-equation models use the equation for the turbulent kinetic

energy, , to provide one of the two scales required. The

-equation can be derived by summing

up half of the diagonal of the exact RSM equations (Eq.(9.9)).

(12–53) |

with:

(12–54) |

(12–55) |

(12–56) |

The term is the production term. When inserting the eddy-viscosity formulation (Equation

(9.7)) it can be formulated as:

(12–57) |

with

The term is the turbulence energy dissipation rate, which converts turbulent kinetic energy into heat

(typically small enough to be neglected in the overall energy balance).

The term is called turbulent diffusion. In an integral sense, it does not contribute to

the overall production or dissipation of turbulent kinetic energy, but does only smooths out

the

-distribution. It is typically modeled by a simple gradient-diffusion hypothesis:

(12–58) |

The modeled -equation therefore reads:

(12–59) |

With these formulations, the only term missing (unclosed) in the -equation is the

dissipation term

. It needs to be provided from a separate scale-equation (e.g. the

-equation

or the

-equation with

).

What is meant by 'turbulent scales' in the context of RANS modeling? As discussed in the introduction, turbulence consists of a spectrum of scales – so identifying a single length- or time-scale is not trivial. However, the mixing processes which are of foremost engineering interest are driven by the largest scales of turbulence.

The derivation of the scale equation (typically or

) is one of the weakest steps in

RANS modeling. While exact transport equations can be derived e.g. for

, such equations

represent the small scales of turbulence (where dissipation takes place) and do not provide

information on the large scales required in RANS closure. One could argue that in RANS

is not

trying to model 'dissipation' but rather the destruction of large scales into smaller scales

– which are no longer relevant for the mixing processes.

To arrive at a suitable model equation, the assumption is made that the scale equation has

a form similar to the -equation:

(12–60) |

with the ratio introduced for dimensional correctness. The coefficients

,

,

are model coefficients which need to be tuned by experimental data. The coefficients of the

standard

model are:

An equation for the turbulent frequency, can be derived with the same arguments:

(12–61) |

With this set of equations, the eddy-viscosity can be computed:

(12–62) |

using

Since and

are related, one can investigate the differences between the

and the

equations. This can be achieved e.g. by transforming the exact

equation to an

equation.

Assuming for simplicity

one gets:

(12–63) |

With the cross-diffusion term:

(12–64) |

The transformation of the coefficients gives the relation:

(12–65) |

In other words, the -equation when derived on the same dimensional arguments as the

-equation results in Equation ((9.20), whereas the transformation of the

-equation into a

-equation gives Equation (9.22). The difference lies mainly in the cross-diffusion term

.

What is the effect of the term? There are two main effects, one positive and one negative. The negative

effect is discussed in detail by Wilcox [7] and is manifested in an improved performance of the

-equation based models not utilizing the

term in adverse pressure gradient boundary layers. Such models predict an

improved response to the pressure gradient and a higher sensitivity to predict flow separation,

compared to

-equation based models. In other words, the inclusion of the

term in the

-equation in the near wall region would inhibit correct

separation prediction.

The second effect of including the is desirable, as it avoids the strong sensitivity of the standard

-equation (models without

) based model to freestream values. As discussed in detail in [52] the

standard model produces a wide variation in results in case the level of

changes outside the boundary or free shear layer (freestream). This is

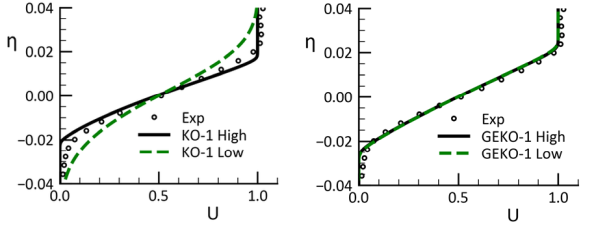

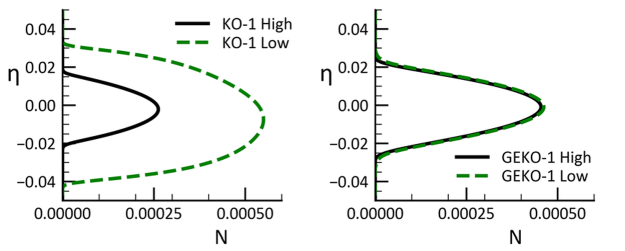

illustrated in Figure 12.161: Effect of freestream omega-levels on velocity profile for free mixing layer solution.

Left: std. k-omega model without CD term. Right: GEKO model including CD term. for a mixing layer. The left part of the

Figures shows the reaction of the Wilcox

model to changes in freestream

on the velocity profile and the right part shows the same test using the GEKO

model (which includes the

term). Figure 12.162: Effect of freestream

-levels on non-dimensional eddy viscosity profiles for free mixing layer solution. Left: standard

model without CD term. Right: GEKO model including CD term. shows the same effect on the

eddy-viscosity profiles, where the difference in the standard

model is more than a factor 2 between the low and the high freestream values.

Since the level of freestream values cannot easily be controlled and is often based on roughly

estimated inlet values, solution independence from these values is essential for reliable

simulations.

Figure 12.161: Effect of freestream omega-levels on velocity profile for free mixing layer solution. Left: std. k-omega model without CD term. Right: GEKO model including CD term.

Figure 12.162: Effect of freestream -levels on non-dimensional eddy viscosity profiles for free mixing layer solution. Left: standard

model without CD term. Right: GEKO model including CD term.

The equations discussed so far form the basis of all industrially and

based

turbulence models.

The motivation behind two-equation models originates from the need to obtain the two scales

required to compute the eddy-viscosity. Based on dimensional arguments, a length-scale,, and

a time-scale,

, are required for that purpose. Note that any two other scales are equivalent

as there are only two independent mechanical scales. These requirements naturally lead to

two-equation models as a basis for providing these scales. However, two-equation models also

form the basis for all further developments, like One-equation models, Reynolds Stress Models

(RSM) or Explicit Algebraic Reynolds Stress models (EARSM). Two-equation models are also the

optimal platform for including additional physics, like laminar-turbulent transition, rough

walls, buoyancy, as well as hybrid RANS-LES concepts.

Two-equation models are composed of the following elements:

Turbulent kinetic energy equation

Scale equation (

or

)

Eddy-viscosity formulation

Near-wall treatment

Limiters

Each one of these elements can have a substantial influence of accuracy and robustness of the simulations.

The following topics are discussed:

The BSL/SST Models

Based on the investigation of the freestream dependency of the Wilcox model [52], Menter

proposed model formulations which are composed of a blend of and

model elements (17).

As discussed in Section 9.2.2, the main difference between these models is the cross-diffusion

term (CD) which appears when transforming the

model to a

model. This term avoids the

freestream sensitivity near the shear/boundary layer edge. However, while it is desirable to

include the term near the shear/boundary layer edge, it is not desirable to activate it near

the wall, as it negatively affects the adverse pressure gradient behavior of the model. The BSL

model was therefore built on the blending function

, which is based on wall distance,

. The

function has a value of

inside the wall boundary layer and gradually blends to

in the

outer part of the boundary layer and beyond. This function blends the

term into the

-equation but also blends the coefficients from those of the

to those of the

model.

(12–66) |

(12–67) |

(12–68) |

(12–69) |

(12–70) |

There are two model variants. The BSL (baseline model) and the SST (Shear Stress

Transport) model. The SST model is based on the BSL model, but in addition limits the

eddy-viscosity inside the boundary layer (using a second blending function ) to achieve

improved model performance for flows under adverse pressure gradients and separation.

The two blending functions and

read:

(12–71) |

(12–72) |

The BSL model can also be used as the basis for combination with EARSM and RSM models - where the limiter on the eddy-viscosity is not required, as improved stress prediction is achieved through the EARSM/RSM formulation. The SST model on the other hand is calibrated for accurate prediction of separation and aerodynamic flows when used as an eddy-viscosity model.

There is a clear increase in complexity from the Wilcox model to the BSL/SST models, mainly through the need for blending functions, which in turn require the wall-distance. Wall-distance is not problematic if the mesh/geometry are fixed (as is the case in most CFD simulations). In case of varying mesh/geometry however, the wall distance computation can become expensive as it needs to be repeated for every time-step. Particularly for massively parallel simulations, the wall distance computation can dominate the CPU costs as the algebraic operation does not scale well on such machines. The GEKO model (Section 3.3.2) has therefore been developed with an option avoiding the wall distance.

The SST model allows variation of the coefficient without affecting the calibration of

the logarithmic layer. Its value can be increased, thereby reducing the sensitivity to adverse

pressure gradient flows and delaying/reducing flow separation. The value cannot be decreased

however, as that would interfere with the log-law behavior and would thereby negatively affect

the flat plat calibration.

The Generalized  model (GEKO)

model (GEKO)

The main characteristics of the GEKO model is that it has several free parameters for tuning the model to different flow scenarios. The starting point for the formulation is:

(12–73) |

(12–74) |

(12–75) |

(12–76) |

(12–77) |

(12–78) |

There is a provision for corner flows which amounts to adding a quadratic term to the stress-strain relation. The terms is essentially the same as the Quadratic Closure Relation (QCR) proposed by Spalart [53]:

(12–79) |

The GEKO model formulation is otherwise conventional, it involves the cross-diffusion term

which typically is derived from a transformation of the model to a

. This term is

included in most of the more recent

models in various ways. It is generally understood that

this term is required at the edge of turbulent layers to maintain the

model behavior and

avoid freestream sensitivities.

The main difference of GEKO to existing models is the introduction of free parameters which can be tuned by the user to achieve different goals in different parts of the simulation domain. The details of the GEKO model formulation are not published at this point, but the effect of the free parameters will be described. Note that an entire 'Best Practice Guide' exists for the GEKO model: [1].

Currently there are the following parameters included for tuning:

– Parameter to optimize flow separation from smooth surfaces

– Parameter to optimize flow in non-equilibrium near wall regions (heat transfer,

, ….)

– Parameter to optimize strength of mixing in free shear flows

– Parameter to optimize free shear layer mixing (optimize free jets independent of mixing layer)

– Parameter to optimize flows with streamline curvature and rotation

– Parameter to optimize anisotropic flow in corners

All these parameters are designed so that they do not negatively affect the basic model

calibration for flat plate flows. In other words, the logarithmic layer formulation is

preserved despite the changes in these parameters. Note that the two last parameters can also

be combined with other models.

All parameters (except ) are available through User Defined Functions (UDF) access.

This means that they can be defined either with a global value (in the GUI/TUI) or as

zonal/local values via UDFs.

The function is defined using the blending function

:

(12–80) |

Inside wall boundary layers, the term is de-activated (=1) to ensure that the

/

coefficient only affects free shear flows. It is also seen, that the coefficient

only affects the impact of

(e.g. in case

=0 also

has no effect).

essentially

reduced the impact of

on jet flows (where

would otherwise cause an over-prediction of

jet spreading rates).

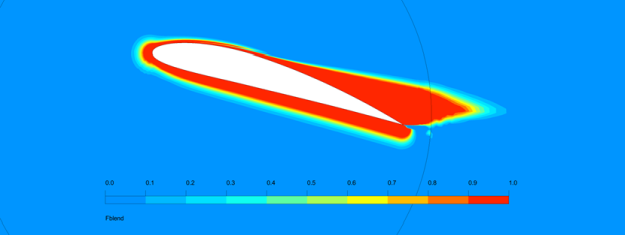

Figure 12.163: Blending function FBlend for introducing addtional mixing through coefficients /

. shows the function

for a NACA 4412 airfoil at

=12° angle of attack. The function is

=1 (red) inside the boundary layer and

=0 (blue) away from the wall. Especially at the trailing edge, where the wake

(free shear flow) leaves the wall (boundary layer) the function switches swiftly to activate

the

-term.

The free coefficients should be in the range:

The coefficient can in principle be increased beyond

=1, in cases with very

strong mixing.

The main tuning parameter for the GEKO model is the coefficient . When increasing

, boundary layer separation will be predicted more aggressively. However, in addition, the

spreading rates of all free shear flows will be affected by changes in

as it generally

decreases the eddy-viscosity level in the entire domain. This is not convenient for users, as

they would have to tune 2 parameters simultaneously. To maintain the spreading rate for the

most important free shear flow, namely the mixing layer, while changing

, a correlation was

developed, which maintains the mixing layer spreading rates under changes of

:

(12–81) |

This correlation is set as default – however users can also optimize by hand,

independently of

.

The parameter is designed to reduce the spreading rate for round jets, which is over-predicted

with all cnventional turbulence models. To achieve optimal performance for round jets, one needs to set

to values

~1.75-2.00 and

=0.9 (default). With reduction in

and the corresponding reduction in

, the effect of

vanishes (see [Generalized k-omega Two-Equation Turbulence Model (GEKO) in Ansys CFD ].). There is another parameter CJET_AUX which

also has an influence on the jet flow. It defines the limit between mixing layers and jet flows.

The larger the value, the sharper the 'demarcation' and stronger the effect of

. The default value is CJET_AUX=2.0. It is suitable for jet flow

simulations to set the CJET_AUX=4.0. This is not done by default, as it can lead to oscillations

on poor meshes. For more details and test cases, see the Best Practices Guidelines for the GEKO

model [Generalized k-omega Two-Equation Turbulence Model (GEKO) in Ansys CFD ].

At first, the versatility of the model seems to pose a challenge to the user as to the

optimal selection of coefficients. However, there are strong defaults and there are certain

combinations of coefficients, which can be applied to most flows, so that the user would only

interfere on specific cases, where the model does not lead to satisfactory results. The

selection of results in an exact transformation to the

model, albeit with

improved sub-layer treatment and limiters activated.

The standard  -Model

-Model

In order to explain the preference for -equation based models, it is important to

critically discuss the

-equation. It needs to be emphasized that the

-equation has been used

in many CFD simulations in the past which is a clear indication that the issues discussed below

are not present in all or even the majority of

-equation model simulations. However, these

deficiencies are frequent enough to preclude the

-equation as a turbulence model integration

platform.

The standard model without Viscous Sublayer Model (VSM) terms is given by:

(12–82) |

(12–83) |

(12–84) |

The model provides a 'middle of the road' calibration which covers many flows with

sensible accuracy – which might explain its popularity over the years.

A well-published deficiency of the -equation is the lack of response to adverse pressure

gradient flows [7], (17). The model produces too large turbulence length scales near the wall

and thereby delays or even suppresses flow separation when compared to experimental data. This

in turn leads to overly optimistic design choices as the model predicts attached flow under

conditions, where the real flow can already be severely separated.

This effect can be seen for a diffuser flow [54]. It consists of a straight wall on one

side and an inclined wall on the other. The flow in the experiment separates from the inclined

wall. Figure 12.164: Flow topology for Obi [54] diffuser. Top - SST model. Bottom model. shows the different flow topologies predicted by the

SST and the

model. Figure 12.165: Velocity profiles for Obi diffuser [54]. Comparison of SST,

and experimental data. provides a comparison of the model

predictions with the exp. velocity profiles which clearly shows that the flow is separated as

predicted by the SST model. In case where the design engineer would base the decision of the

opening angle of the diffuser on the

model, the real performance (pressure loss) would be much more optimistic

than later observed when the device is built.

It is important to emphasize that similar pictures of failure could be produced for almost

any turbulence model, as there are always flows where models struggle. However, the ability to

accurately predict separation onset is essential for many applications, and the based

models have never been able to overcome their deficiencies in this respect.

The Realizable  Model (RKE)

Model (RKE)

The RKE model is a variation of the standard model. Its derivation is somewhat

curious, involving a mix of small and large scale arguments (15), but this is of no relevance

in the current document. The equations read:

(12–85) |

(12–86) |

(12–87) |

(12–88) |

(12–89) |

One of the lesser appreciated

deficiencies of two-equation models is their behavior in inviscid regions with non-zero strain

rates. In such regions the vorticity is zero, but the strain-rate is not. A typical example is

the stagnation region of an airfoil (outside the boundary layer). As the inviscid flow

approaches the airfoil, there is an increasing level of shear, , but not due to a shear layer, but due to non-zero velocity gradients of the

inviscid flow. Similar regions exist when inviscid flow is accelerated. Observations show that

two-equation models can exhibit excessively high levels of eddy-viscosity there (Buoyancy Flows). From a physical standpoint, there is very little turbulence

production in such areas, so that this is likely an artefact of the eddy-viscosity formulation.

The introduction of the eddy-viscosity assumption into the production term of the turbulent

kinetic energy equation changes the characteristics of that term. While in the exact

-equation it is a product of turbulent stresses times a velocity gradient (see

Equation (9.9)) (and therefore linear in terms of the velocity gradients), it becomes a product

of the eddy-viscosity times the strain rate square (and therefore quadratic in the velocity

gradients). It is believed that this difference is responsible for the observation of high

turbulence production.

To avoid such unphysical behavior, different types of limiters have been developed. Each has their pros and cons, but all are better than running the model without limiters.

Kato-Launder Limiter

The Kato-Launder limiter (21) is based on the observation that in the inviscid region, the vorticity is zero, whereas in plane shear layers it is equal to the shear strain rate:

(12–90) |

With

(12–91) |

(12–92) |

The Kato-Launder limiter is formulated as a change to the (incompressible

portion of the) production term :

(12–93) |

Since most model calibrations are carried out for shear flows with this does not change the model calibration for such flows. On the other hand,

the modification turns off the production term in inviscid flows where

=0. The downside of the Kato-Launder limiter is that it does affect non-trivial

flows with 3D effects and or streamline curvature and rotation where

.

Production Limiter

A limiter with much less impact on complex flows was proposed in (17). The limiter is applied to the production term in relation to the dissipation.

(12–94) |

Typically, the limiter is set to a value of =10, which is far away from typical calibration flows for which one has

.

Generic Realizability Limiter

The realizability limiter is based on the demand that the Reynolds stresses computed from the eddy-viscosity model should adhere to known restrictions to the Reynolds Stresses [2] (e.g. non-negativity etc.). It reads:

(12–95) |

with . This limiter is similar to the production limiter but corresponds more

closely to a

. It is therefore activated sooner than the production limiter.

Realizability Limiter of RKE Model

The realizability limiter of the RKE (Equation (9.47)) model is quite different from the

classical realizability limiter. It depends not only on the strain rate but also on the

vorticity and the third invariant of the strain rate tensor. Since can become negative, it is not even ensured that the eddy-viscosity is

limited. In addition, the production term in the

-equation is formulated as a conventional quadratic term in strain rate (

), whereas the production in the

-equation is formulated as a linear term in

. This all makes it very difficult to judge the activation limit of this

limiter and therefore its effectiveness.

The wall treatment in a CFD method is necessary to allow the prediction of the wall

shear-stress, required in the wall cells in the momentum equations as a wall-force. The wall

shear-stress is computed from the known solution for the velocity (and possibly

and other quantities) at point j=1 (known e.g. from the previous iteration).

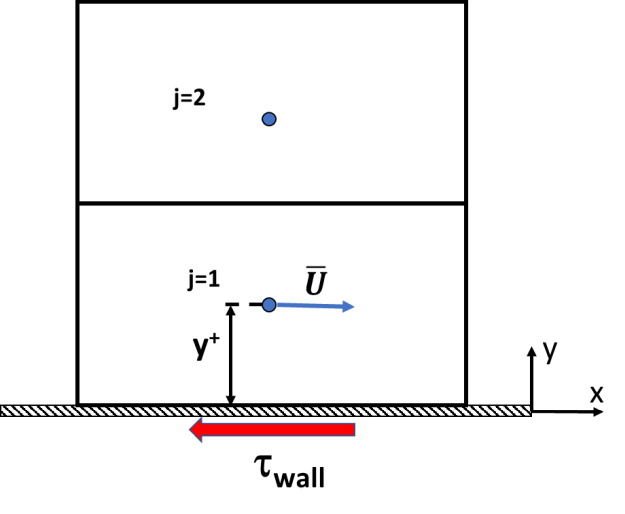

This is depicted in Figure 12.166: Near wall grid cells for a finite volume cell-centered method. for a cell-centered finite volume method.

The task is therefore, given

at j=1, compute the wall shear-stress to close the discretization of the

momentum equations.

Figure 103: Near wall grid cells for a finite volume cell-centered method.

Near the wall of equilibrium flows (zero pressure gradient boundary layer, channel flow,

pipe flow, Couette flow), the solution variables follow universal laws which scale with the

wall-shear stress ?wall and the near wall molecular kinematic viscosity, ?. In other words, one

can collapse all equilibrium near wall profiles onto a single curve if the near wall variables

are non-dimensionalized by these quantities. The non-dimensionalization is based on the

wall-friction velocity (computed from

), the turbulent kinetic energy

(note that in the logarithmic layer one has

) and the kinematic viscosity

? in the following way:

(12–96) |

Using these variables, one obtains a universal velocity profile of the form:

(12–97) |

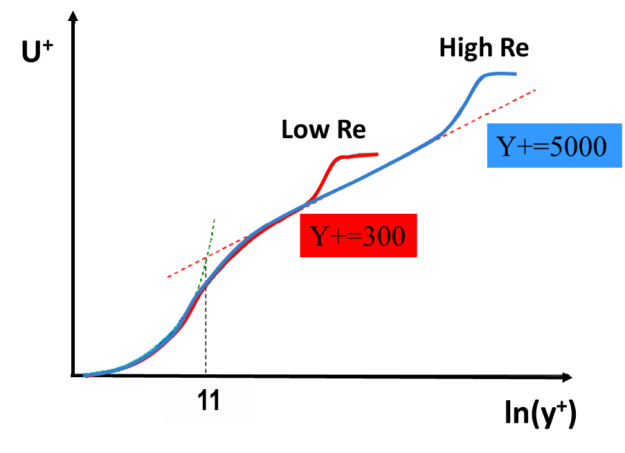

Such profiles are depicted in Figure 104 for two Reynolds number of a boundary layer. For both Reynolds numbers, the profiles are identical near the wall and differ in the outer part. The extent to which the universal profile is followed depends on the Reynolds number.

Assuming a universal velocity profile does exist, what is the benefit for CFD? Suppose the

velocity is known in the near wall cell (j=1) e.g. from the last iteration. Since the location

of the first cell center is also known and so are the viscosity and density, they can all be

inserted into Equation (9.56). The only unknown is then the friction velocity , which can

therefore be calculated (iteratively due to the non-linearity of the equation). From

follows

the wall-shear-stress

, which is required to close the discretization of the near

wall cell. Once this achieved, a new global iteration can be started until convergence. The

details are slightly different for each model (involving e.g.

) and can be found in the user

documentation. However, the principle is as outlined here.

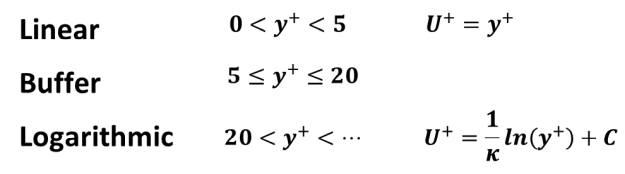

The universal profile consists of different parts. Very close to the wall, turbulence is damped, and the velocity profile is linear (viscous sublayer). In the fully-turbulent near wall layer, the profile follows a logarithmic form (log-law). These two regions are bridged by a 'buffer layer'. This is illustrated in Figure 12.167: Universal non-dimensional velocity-profile near the wall. which depicts two flat plate boundary layer profiles (at different Reynolds numbers) in a logarithmic plot. The velocity profile can roughly be split as follows:

The log-profile has two constants - the von Karman constant which is typically selected to

be and an additive constant of approximately

.

Important: while the velocity profile follows a universal law near the wall, the thickness

of the log-layer in terms of depends on the Reynolds number. A

resolution of say

=50

will therefore be sufficient for a high Reynolds number flow, but not for a Low Reynolds number

flow. In the high Re case, there are plenty of cells between the wall cell and the boundary

layer edge (which is say at

=5000), compared to a low-Re case where the boundary layer edge

might be at say

=200.

Important: Even for high Re number flows, the inner layers (sub+ buffer+ log-law) cover only 10-20% of the entire boundary layer thickness.

The following topics are discussed:

Historically, many turbulence models have been combined with a 'wall-function' (WF) approach. WF do not allow/require to integrate the equations through the viscous sublayer. Instead, the user needs to provide a grid, where the first grid point (cell center) lies in the log-layer. The wall shear stress is then computed from the log-layer formulation alone. Details of specific WF formulations can be more elaborate and can be found in the code documentation.

Wall function treatment has the advantage that simulations can be carried out on

relatively coarse grids (in wall normal direction). However, the user must ensure that the

first cell center lies in the log-layer. As depicted in Figure Figure 104, this is not trivial,

as the upper limit of the log-layer depends on the Reynolds number of the boundary layer

profile. One can therefore not define a universal upper limit, as to where the log layer is

applicable. Especially for low to moderate Reynolds number (device Re numbers of -

) the

thickness of the log-layer might be narrow, and the first grid point can easily be placed

either too close or too far from the wall, missing the layer. In addition, at the lower

Reynolds numbers, even if the first cell center is placed in the log-layer, there might be not

enough resolution to cover the rest of the boundary layer with enough cells.

Standard wall functions are highly problematic, as the solution depends on the ability of the user to:

Ensure that the cell center point is not too close to the wall so not to fall into the buffer/sublayer.

Ensure that the cell center point is not too far from the wall to not fall into the outer layer.

Ensure that the boundary layer is resolved with enough cells.

The violation of any of these conditions can result in substantial errors. Most

problematic is that mesh refinement beyond a certain level leads to a deterioration of results.

This is counter to the principles of numerical methods, where grid refinement should eventually

lead to more consistent and grid-converged solutions. The above requirements are hard to

achieve, especially at low-moderate Reynolds numbers. One needs also not to forget that the

mesh is created before a solution is available, so placing the first grid cell into the

log-layer is a difficult job. The use of standard wall functions is therefore discouraged

– it is not available when using based models for that reason.

Users are often under the false impression that wall functions 'take care of the boundary

layer' – meaning that a grid with a properly placed near wall cell is all that is

needed for an accurate boundary layer simulation. This is not the case. Wall functions are just

a special type of boundary conditions – the boundary layer itself still needs to be

resolved with a sufficient number of cells.

Important:

With standard wall functions, one can easily create incorrect solutions, either by overly coarse or overly fine meshes. The usage of standard wall functions is therefore not recommended.

Having a proper

is not sufficient for accurate boundary layer simulations. One also needs a sufficient number of cells inside the boundary layer.

A simple trick can be employed to avoid the solution deterioration under mesh refinement

with standard wall functions, by applying a limiter onto [55]:

(12–98) |

This limiter prevents the wall functions to move into the viscous sublayer and thereby

guarantees a consistent wall shear-stress (and wall heat-transfer) even under mesh refinement.

While the scalable wall function is a substantial improvement, it still entails significant

assumptions, as the mesh is no longer refined towards the wall, but towards a fictitious

location at =11, thereby slightly altering the geometry. This change is more noticeable at

low Reynolds numbers as the gap between

=0 and

=11 becomes a larger portion of the overall

geometry (e.g. the height of the channel or boundary layer) than for high Reynolds numbers.

A more consistent, albeit more expensive method is to integrate the equations all the way

to the wall. This requires a near-wall grid with a resolution of ~1 or finer. However, such

an integration can only be performed if the turbulence models is calibrated to represent the

sublayer. Since turbulence is damped by viscosity in the buffer- and sublayer, most turbulence

models require additional damping terms and/or specific boundary conditions to account for this

effect.

Historically models which can be integrated to the wall have been termed 'Low-Reynolds

number' models or 'low-Re' models. This is a highly confusing nomenclature, as the term

'low-Re' refers not to the device Reynolds number, but to the turbulent Reynolds number

where

is the turbulent kinetic energy,

is the wall distance and

is the

kinematic viscosity. As

is damped by the presence of the wall, the turbulent kinetic energy

approaches zero for low

levels and so does the turbulent Re number. This is the case for all

flows close to the wall, at all device Reynolds numbers! In the following, the term 'low-Re

model' will therefore be replaced by the terminology 'Viscous Sublayer Model – VSM'.

Developing VSMs for -equation based models has been a major challenge. Many such models

have been developed over time (e.g. [56]), but they typically suffer from one or more of the

following deficiencies:

Lack of robustness.

Multiple solutions depending on initial conditions.

Pseudo-transitional behavior not calibrated against data.

Excessive wall shear and heat transfer at reattachment/stagnation points/lines.

There are some remedies to this. The first and most widely applied is the usage of a

so-called 2-Layer formulation ([57], [58]). In this method, the epsilon equation is not solved

through the buffer and sublayer but an algebraic formulation is used instead. The -equation is

then dominated by a source term which enforces the algebraic relations.

A second approach is to add additional differential equations to the -equations based

models which account for the near wall damping. These models are typically called

'elliptic-blending' or V2F models [59]. The downside of this approach is the significantly

increased complexity due to two additional equations and the associated complex boundary

conditions. In addition, such models still allow for pseudo-transitional behavior, meaning an

artificially non-calibrated laminar-turbulent transition process, which is undesirable. For

these reasons V2F-like models are not perused in Ansys-CFD.

One of the strengths of the -equation based models is that they do not require additional

damping terms. Integration to the wall can be obtained by a simple switch in boundary

conditions. These models also avoid pseudo-transition for all practical purposes and do not

lead to excessive wall shear and heat transfer at reattachment/stagnation points/lines. For

this reason,

-equation based models are the preferred option in Ansys CFD.

Important: -equation based models are much harder to integrate to the wall than ?-based models.

Classical VSM require always a fine near wall mesh with ~1 or smaller. This cannot be achieved for all walls in complex applications.

It is therefore desirable to be able to provide formulations which maintain consistency for a

variation in

. Such models are termed

-insensitive models (or all-

models). When computing a flow on a series of grids with different

-resolution, such models provide wall shear-stress (and heat transfer) levels

which are approximately independent of the

-value. Note that this statement is only correct in case of a sufficient

number of cells inside the boundary layer. Simulations with such a formulation can be seen in

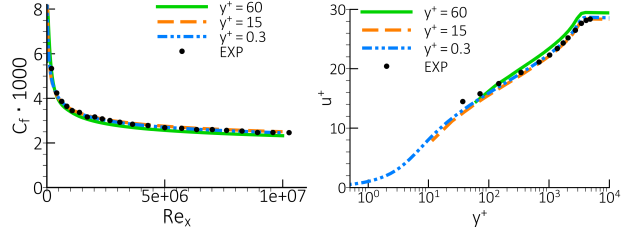

Figure 12.168: Comparison of the skin friction coefficient and velocity profiles at

on different meshes for the flat plate boundary layer (28)., where a flat plate zero pressure gradient boundary layer

(28) is computed on three different grids. The computed velocity profiles follow closely the

fine grid solution. On meshes with

>20, the formulation essentially switches back to a wall function.

Figure 12.168: Comparison of the skin friction coefficient and velocity profiles at on different meshes for the flat plate boundary layer (28).

In Ansys Fluent, -insensitive wall formulations are available for the Spalart-Allmaras

one-equation model and

models (using a 2-Layer VSM formulation and the ML VSM). In both

codes (Ansys Fluent and Ansys CFX) all

-equations based models are based on a

-insensitive

formulation. The details of such formulations are model and numerics dependent and are given in

more detail in the Theory Documentation of the corresponding codes.

Y+-Insensitive Near Wall Treatment for  -based

Models

-based

Models

Near the wall, the -equation reduces to (in the viscous sublayer production and turbulent

diffusion can also be neglected):

(12–99) |

This equation has the following near-wall solutions for in the viscous sub-layer and the

log-layer:

(12–100) |

(12–101) |

where is the (typically high) value specified for

at the wall. This formulation is

sufficient to provide proper near wall damping and the correct logarithmic layer. The

-equations

-insensitive formulation blends smoothly between these two solutions.

The simple and robust near wall formulation without the need for complex damping functions

(or new additional transport equations like in the V2F model) makes the model the most

attractive option as a basis for industrial turbulence models.

The  Two-Layer Formulation

Two-Layer Formulation

To avoid the complication and robustness limitations of historic VSM (low-Re) models,

but still enable CFD users to integrate these models through the viscous sublayer, the

so-called 'two-layer' (2L) formulation was introduced [57], [58]. The 2L formulation is today

one of the more widely used turbulence near-wall formulations in industrial codes for the

model. Its principal idea is to avoid the complexities of the

-equation near the wall entirely

and to replace it with an algebraic formulation, using a mixing-length model there. This

algebraic formulation is then blended with the

-equation away from the wall.

In the 2L model the near-wall -distribution is computed from an algebraic

equation:

(12–102) |

where is the mixing-length based on wall-distance, y:

(12–103) |

In addition, the eddy-viscosity is also blended between the standard formulation and

an algebraic mixing length model:

(12–104) |

Using the blending function:

(12–105) |

The blending is required as the distributions resulting from the algebraic formulation and

from the transport equation will not match at a pre-specified location. To prevent

discontinuities and convergence problems, a smooth variation is required.

The constants are:

(12–106) |

The turbulent Reynolds number is also used to blend between the algebraic model and

the transport equation for

. The details of these blending are typically code-dependent and

are therefore not provided here. Such blending between alg. and transport equations can lead to

robustness problems and therefore needs to be performed gradually over a significant portion of

the inner portion of the boundary layer (

<200).

The 2L-blending can cause problems in low-Re number flows, where the model can be

dominated by the algebraic formulation. There is also a considerable Reynolds-number effect for

non-equilibrium flows, where the 2L mixing length model part and the -equation produce

different results, which are then stitched together with the blending function. The relative

portion across the boundary layer where the mixing length model is active depends on the Re

number of the boundary layer. For low Re, a substantial part of the boundary layer will be

covered by the alg. part of the model, whereas for high Re, the 2L model is active only in a

small near-wall portion (relative to the boundary layer thickness). As both models behave

differently for non-equilibrium flows, this mean that the combined model will lean towards a

mixing length model for low

and towards a

model for high

.

Another problematic issue results from the observation that the blending function based on

can switch back to 'near-wall mode' even outside the boundary layer in case

of low freestream values for

, causing non-physical distributions of the turbulence variables outside the

boundary layer. By this mechanism, a layer of high turbulence viscosity can be created

artificially, as the eddy-viscosity is also switched to the mixing length formulation (with

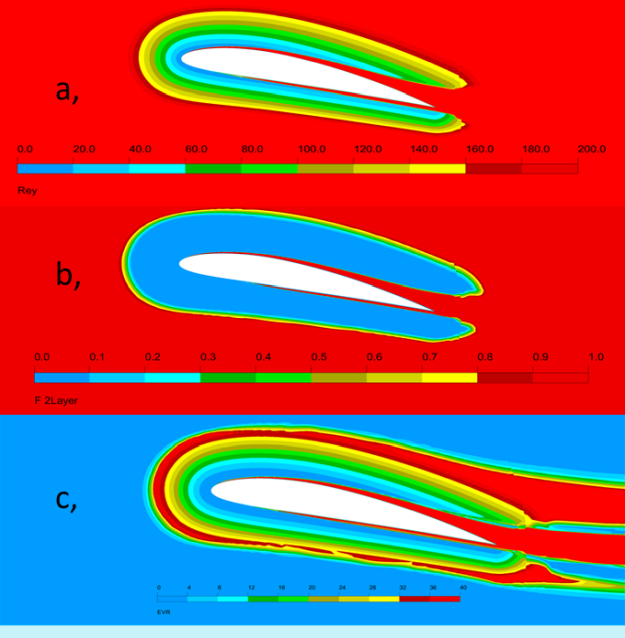

obviously a large mixing length due to the large wall distance). Figure 12.169: Contours of the

(Top, a,) and the Blending Function (Middle, b,) and the ratio of eddy-viscosity/molecular viscosity

(Bottom, c,) of the 2L formulation for flow around the NACA-4412 airfoil at AoA = 12

shows a simulation around a NACA 4412 airfoil. The

distribution used inside the blending function is shown in part a, of the

Figure.

is zero at the wall, increases rapidly inside the boundary layer (hard to see

in this scale), but then decreases again outside the boundary layer. The effect on the blending

function is shown in the middle Figure 106. The function is

=0 close to the wall (not seen on this scale) and then switches to

=1 inside the boundary layer as desired. However, outside the boundary layer,

the formulation switches back to the algebraic form (

=0). This switch-back is problematic, as it also switches the eddy-viscosity

back to the alg. formulation, which can be seen in the lower part of Figure 106c, where

is plotted. This ratio reaches relatively high values outside the boundary

layer and the switches back to the low freestream values further away, as the function switches

back to

=1.

These examples demonstrate that the 2L model can cause issues due to its switching procedure. This is even more the case for flows with additional complexities like multi-phase flows and/or flows with large changes in physical properties, where the model has shown instabilities due to erratic switching between the mixing length and the transport equation, thereby preventing solver convergence. While the 2L formulation works well for many industrial flows, it is not strong enough to serve as a default turbulence model which needs to work for all combinations of physics.

Figure 12.169: Contours of the (Top, a,) and the Blending Function (Middle, b,) and the ratio of eddy-viscosity/molecular viscosity

(Bottom, c,) of the 2L formulation for flow around the NACA-4412 airfoil at AoA = 12

In order to create a high-quality mesh, it is helpful to have some approximate formulas for

the development of boundary layers for zero pressure gradient boundary layers. The Boundary

Layer develops in streamwise direction (-direction) for a flat plate with origin at x=0. The

boundary layer thickness is

, the freestream velocity is

and the wall shear stress is

.

The wall friction coefficient is

and

The following topics are discussed:

Wall shear stress coefficient:

(12–109) |

Boundary Layer thickness:

(12–110) |

Viscous sublayer thickness – -estimate:

(12–111) |

(12–112) |

(12–113) |

This formula provides the required wall spacing to achieve a desired

. For

it is

prudent to use half the running length of the boundary layer (e.g. half chord of an airfoil).

The good news from this equation is that

has only a very weak variation with

. It is

therefore possible to use a constant near wall grid spacing

for the entire body. Note that

the above

estimate is based on the grid distance between the surface and the first grid

node off the wall. The code can internally use another

definition – e.g. in a

cell-centered code like Ansys Fluent it would use half of that value.

![Flow topology for Obi [] diffuser. Top - SST model. Bottom model.](graphics/image273.png)

![Velocity profiles for Obi diffuser []. Comparison of SST, and experimental data.](graphics/image274.png)