Engineering turbulence transition predictions are based mainly on two modeling concepts. The first is the use of low-Reynolds number turbulence models, where the wall damping functions of the underlying turbulence model trigger turbulent transition onset. This concept is attractive because it is based on transport equations and can therefore be implemented without much effort. However, experience has shown that this approach is not capable of reliably capturing the influence of the many different factors that affect transition, such as free-stream turbulence, pressure gradients and separation.

The second approach is the use of experimental correlations.

The correlations usually relate the turbulence intensity, , in the free-stream to the momentum-thickness Reynolds number,

, at transition onset. Ansys

has developed a locally formulated transport equation for intermittency,

which can be used to trigger transition. The full laminar-turbulent transition model is based on

two transport equations, one for the intermittency and one for the

transition onset criteria in terms of momentum thickness Reynolds

number. It is called the Gamma Theta model and is

the recommended transition model for general-purpose applications.

It uses an empirical correlation (Langtry and Menter) that has

been developed to cover standard bypass transition as well as flows

in low free-stream turbulence environments. This built-in correlation

has been extensively validated together with the SST turbulence model

for a wide range of transitional flows. The transition model can also

be used with the BSL or SAS-SST turbulence models. A description

of the full Gamma Theta model can be found in Two Equation Gamma Theta Transition Model in the CFX-Solver Theory Guide.

In addition, a very powerful option has been included to enable you to enter your own user defined empirical correlation together with the Gamma Theta model, which can then be used to control the transition onset momentum thickness Reynolds number equation. The method is driven by CCL and as a result any valid CCL expression can be used to define the correlation. A simple example is shown below where the transition Reynolds number was specified as a function of the x-coordinate:

FLUID MODELS:

TURBULENCE MODEL :

Option = SST

TRANSITIONAL TURBULENCE :

Option = Gamma Theta Model

TRANSITION ONSET CORRELATION:

Option = User Defined

Transition Onset Reynolds Number = 260.0*(1.0 + x/(1.0 [m]))

END

END

END

END

Besides the two-equation Gamma Theta transition model, other reduced models are available:

Specified Intermittency

A zero-equation model, where you can prescribe the intermittency directly as a CEL expression.

The best way to specify the intermittency is with a user defined subroutine that is based on the x, y and z coordinates. This way, conditional statements can be used to define geometric bounds where the intermittency can be specified as zero (laminar flow) or one (turbulent flow). This method can be used to prescribe laminar regions at the leading edges of the wings, for example.

Gamma Model

A one-equation model that solves only the intermittency equation (of the two-equation Gamma Theta transition model) using a user specified value of the transition onset momentum thickness-based Reynolds number.

Intermittency Model

A one-equation model. For details, see One Equation Intermittency Transition Model in the CFX-Solver Theory Guide.

Note:

The Gamma Theta transition model is not Galilean invariant and should therefore not be applied (unless with caution) to walls that move relative to the coordinate system for which the velocity field is computed. For this purpose the Intermittency Model should be used.

Both Gamma Theta and Intermittency models are currently not linked to the buoyancy production terms. Therefore the models should not be used in conjunction with non-zero buoyancy forces.

More details can be found in Ansys CFX Laminar-Turbulent Transition Models in the CFX-Solver Theory Guide.

The following topics are discussed:

Because the transition model requires the solution of two extra

transport equations, there are additional CPU costs associated with

using it. A rough estimate is that for the same grid the transition

model solution requires approximately 18 percent additional CPU time

compared to a fully turbulent solution. As well, the transition model

requires somewhat finer grids than are typically used for routine

design purposes. This is because the max grid must be approximately equal to one (that is, wall-function

grids cannot be used because they cannot properly resolve the laminar

boundary layer) and sufficient grid points in the streamwise direction

are needed to resolve the transitional region. For this reason, it

is important to be able to estimate when the additional cost of using

the transition model in terms of CPU and grid generation time is justified.

The relative percentage of laminar flow on a device can be estimated

using the following formula, which is based on the Mayle [104] empirical correlation

for transition onset.

(4–1) |

Where is the transition Reynolds number,

is the device Reynolds number,

is the length of the device,

is a representative

velocity, and

is the freestream

turbulence intensity, which can be calculated, as follows:

(4–2) |

where is the turbulent kinetic energy.

The fraction of laminar flow for some representative devices is shown

in Table 4.1: Fraction of laminar flow for a variety of different devices. Clearly, there are

many cases where the assumption of fully turbulent flow is not correct

and a significant amount of laminar flow could be present.

Table 4.1: Fraction of laminar flow for a variety of different devices

|

Case |

Rex |

Tu (%) |

Fraction Laminar Flow |

|---|---|---|---|

|

LP Turbine blade |

150 000 |

2.5 |

0.80 |

|

HP Turbine blade |

500 000 |

6.0 |

0.10 |

|

Compressor blade |

1 000 000 |

1.0 |

0.38 |

|

Small Aircraft wing |

5 000 000 |

0.2 |

0.57 |

|

F1 Race Car Spoiler |

2 000 000 |

0.3 |

0.86 |

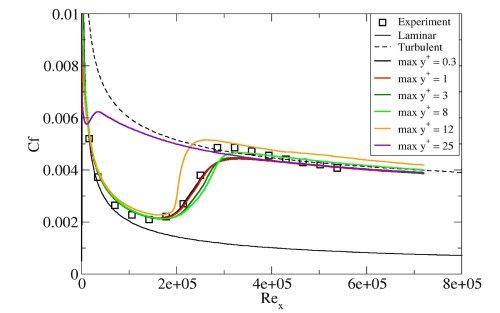

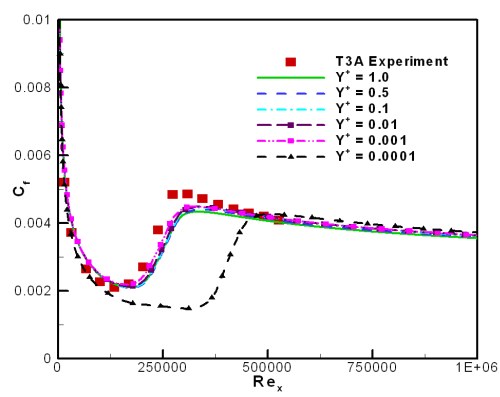

The effect of increasing and decreasing for a flat plate test case (T3A) is shown in Figure 4.1: Effect of increasing y+ for the flat plate T3A test case and Figure 4.2: Effect of decreasing y+ for the flat plate T3A test case. For

values between

0.001 and 1, there is almost no effect on the solution. Once the maximum

increases above 8, the transition onset location

begins to move upstream. At a maximum

of 25, the boundary layer is almost completely turbulent.

For

values below

0.001, the transition location appears to move downstream. This is

presumably caused by the large surface value of the specific turbulence

frequency

, which scales with the first grid

point height. Additional simulations on a compressor test case have

indicated that at very small

values the

SST blending functions switch to

in the boundary

layer. For these reasons, very small (below 0.001)

values should be avoided at all costs.

(Figure 4.2: Effect of decreasing y+ for the flat plate T3A test case provided by Likki, Suzen and Huang [102])

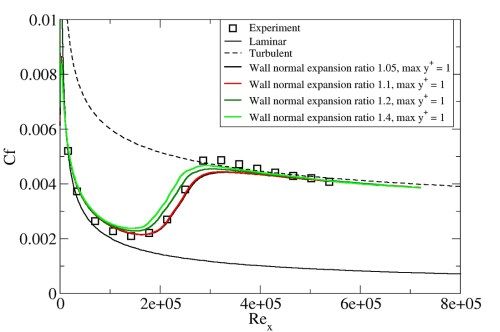

The effect of wall normal expansion ratio from a value of 1 is shown in Figure 4.3: Effect of wall normal expansion ratio for the flat plate T3A

test case. For expansion factors of 1.05 and 1.1, there

is no effect on the solution. For larger expansion factors of 1.2

and 1.4, there is a small but noticeable upstream shift in the transition

location. Because the sensitivity of the solution to wall-normal grid

resolution can increase for flows with pressure gradients, it is recommended

that you apply grids with

and

expansion factors smaller than 1.1.

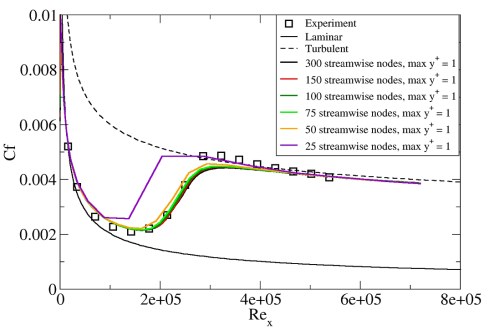

The effect of streamwise grid refinement is shown in Figure 4.5: Effect of streamwise grid density for the flat plate T3A test case. Surprisingly, the model was not very sensitive to the number of streamwise nodes. The solution differed significantly from the grid independent one only for the case of 25 streamwise nodes where there was only one cell in the transitional region. Nevertheless, the grid independent solution appears to occur when there are approximately 75 - 100 streamwise grid points. As well, better streamwise resolution is most likely necessary if separation induced transition takes place. In this case, the number of nodes has to be sufficient to resolve the separation bubble. A general rule is that at least 20 nodes should cover the bubble length. For low Reynolds numbers (<105) the bubble size is comparable to the blade chord length and this requirement is easy to satisfy. Even the recommended 75-100 grid points from the leading to the trailing edge are typically sufficient. However, the bubble decreases as the Reynolds number increases; therefore the grid has to be refined in the regions of the expected separation. An example of how the mesh density influences the resolution of a separation bubble near the leading edge of a wind turbine airfoil is illustrated in Figure 4.4: Effect of streamwise grid density for resolving the separation-induced transition due to a leading edge separation bubble for a wind turbine airfoil. The two meshes shown differ by the number of nodes in streamwise direction in the region covered by the bubble. On Mesh 1, the bubble is resolved by just a few nodes and appears to be much smaller compared to that for the finer mesh, Mesh 2. Clearly, if there are not enough streamwise nodes, the model cannot resolve the rapid separation-induced transition and the boundary layer on the suction side stays laminar, which might have a large influence on the lift coefficient and stall angle predictions.

Note that the high resolution advection scheme has been used for all equations including the turbulent and transition equations and this is the recommended default setting for transitional computations. In CFX, when the transition model is active and the high resolution scheme is selected for the hydrodynamic equations, the default advection scheme for the turbulence and transition equations is automatically set to high resolution.

Figure 4.4: Effect of streamwise grid density for resolving the separation-induced transition due to a leading edge separation bubble for a wind turbine airfoil

One point to note is that for sharp leading edges, often transition can occur due to a small leading edge separation bubble. If the grid is too coarse, the rapid transition caused by the separation bubble is not captured.

Based on the grid sensitivity study the recommended best practice

mesh guidelines are a max of 1, a wall

normal expansion ratio of 1.1 and about 75 - 100 grid nodes in the

streamwise direction. Note that if separation induced transition is

present, additional grid points in the streamwise direction are most

likely needed. For a typical 2D blade assuming an H-O-H type grid,

the above guide lines result in an inlet H-grid of 15x30, an O-grid

around the blade of 200x80 and an outlet H-grid of 100x140 for a total

of approximately 30 000 nodes, which has been found to be grid independent

for most turbomachinery cases. It should also be noted that for the

surfaces in the out of plane z-direction, symmetry planes should always

be used, not slip walls. The use of slip walls has been found to result

in an incorrect calculation of the wall distance, which is critical

for calculating the transition onset location accurately. Another

point to note is that all the validation cases for the transition

model have been performed on hexahedral meshes. At this point, the

accuracy of the transition model on tetrahedral meshes has not been

investigated.

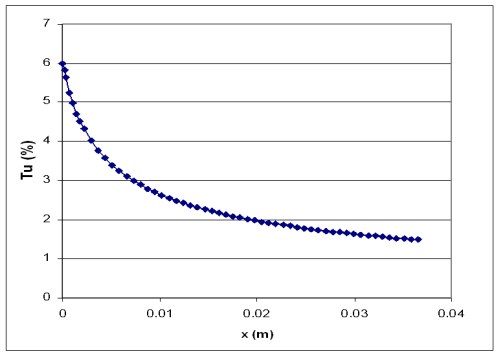

It has been observed that the turbulence intensity specified

at an inlet can decay quite rapidly depending on the inlet viscosity

ratio (and hence turbulence

eddy frequency). As a result, the local turbulence intensity downstream

of the inlet can be much smaller than the inlet value (see Figure 4.6: Decay of turbulence intensity (Tu) as a function of streamwise

distance (x)). Typically, the larger the

inlet viscosity ratio, the smaller the turbulent decay rate. However,

if too large a viscosity ratio is specified (that is, >100), the skin

friction can deviate significantly from the laminar value. There is

experimental evidence that suggests that this effect occurs physically;

however, at this point it is not clear how accurately the transition

model reproduces this behavior. For this reason, if possible, it is

desirable to have a relatively low (that is

1 - 10) inlet

viscosity ratio and to estimate the inlet value of turbulence intensity

such that at the leading edge of the blade/airfoil, the turbulence

intensity has decayed to the desired value.

The decay of turbulent kinetic energy can be calculated with the following analytical solution:

(4–3) |

For the SST turbulence model in the freestream the constants are:

(4–4) |

The time scale can be determined as follows:

(4–5) |

where is the streamwise distance downstream

of the inlet and

is the mean convective velocity.

The eddy viscosity is defined as:

(4–6) |

The decay of turbulent kinetic energy equation can be rewritten

in terms of inlet turbulence intensity () and eddy viscosity ratio (

) as follows:

(4–7) |

You should ensure that the values

around the body of interest roughly satisfy

. For smaller values of

, the

reaction of the SST model production terms to the transition onset

becomes too slow and transition can be delayed past the physically

correct location.

Simulations of external aerodynamic flows typically require

a computational domain with remote outer boundaries. In such cases,

it might be necessary to specify excessively high values of turbulence

intensity and eddy viscosity ratio at the inlet in order to get the

desired value at the airfoil. In addition, numerical grids around

aerodynamic bodies typically feature very coarse grids at the far-field

boundary. For such coarse grids, Equation 4–7 is no longer accurately resolved and the numerical decay can differ

substantially from the analytical one. Alternatively, sensible inlet

values can be obtained if the onset of the decay

is shifted closer to the airfoil. This can be implemented via adding

source terms into the

and

equations, which keep the inlet values

of the transported variables unchanged until the specified coordinate.

These source terms read as:

where is an arbitrary coordinate between the computational domain inlet

and the airfoil. The two source terms are actually the inverted sign

sink terms for the SST model when it is working in the

regime. Adding these terms prevents

and

values from undergoing any

decay in the freestream until the

location

is reached. The streamwise distance in Figure 4.6: Decay of turbulence intensity (Tu) as a function of streamwise

distance (x) counts

then from the

coordinate. More

general

functions can be used, but it needs to be ensured

that

is zero in the vicinity of the wall boundary layers

around the aerodynamic body.

Proper grid refinement and specification of inlet turbulence levels is crucial for accurate transition prediction. In general, there is some additional effort required during the grid generation phase because a low-Re grid with sufficient streamwise resolution is needed to accurately resolve the transition region. As well, in regions where laminar separation occurs, additional grid refinement is necessary in order to properly capture the rapid transition due to the separation bubble. Finally, the decay of turbulence from the inlet to the leading edge of the device should always be estimated before running a solution as this can have a large effect on the predicted transition location.