VM218

VM218

Hyperelastic Circular Plate

Test Case

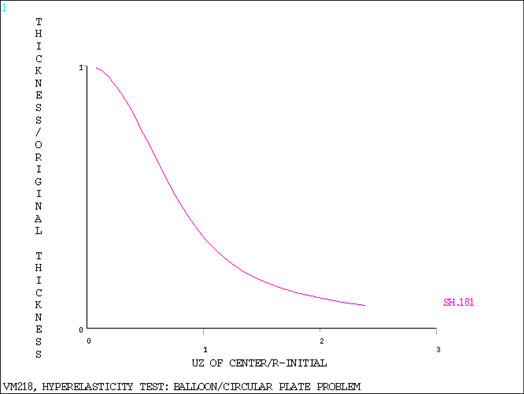

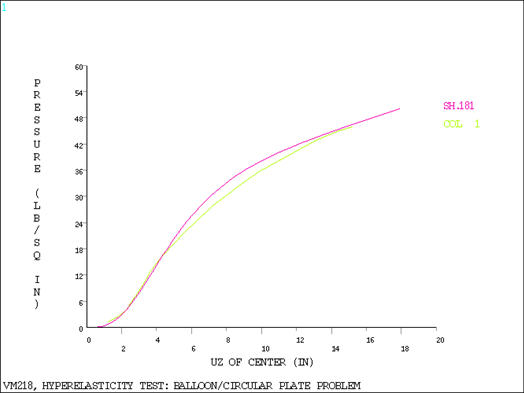

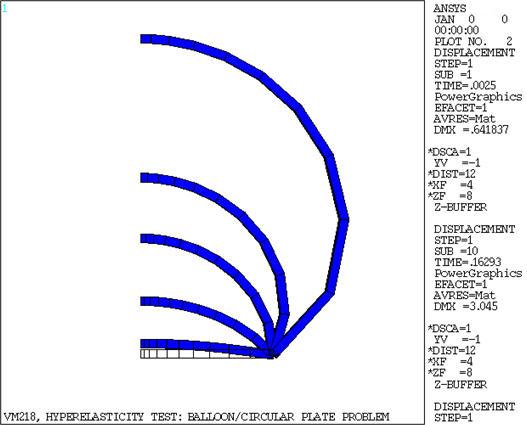

A flat circular membrane made of a rubber material is subjected

to uniform water pressure. The edges of the membrane are fixed.

Determine the response as pressure is increased to 50 psi.

Analysis Assumptions and Modeling Notes

The full circular plate is reduced to a 7.5° sector for

analysis. The midplane of the outer edge of the circle is considered

to be fixed. A pressure of 50 psi is applied to the bottom surface

of the shell sector. The SHELL181 and SHELL281 models are solved using standard formulation

using reduced integration.

Four different analyses are performed using SHELL181, SHELL208, SHELL209, and SHELL281 elements, respectively.