VM172

VM172

Stress Analysis of a Long, Thick, Isotropic Solenoid

Test Case

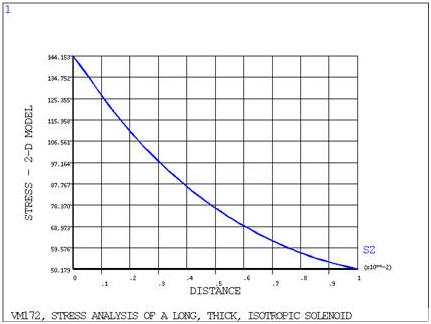

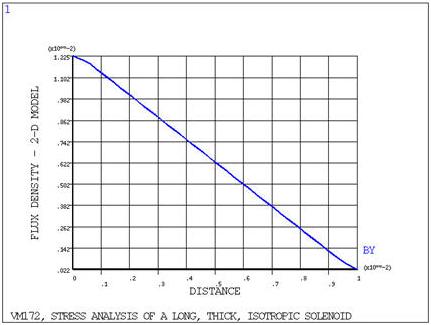

A long, thick solenoid carries a uniform current density distribution, J. Assuming that the turns of the solenoid can be modeled as a homogeneous isotropic material with modulus of elasticity E, and Poisson's ratio ν, determine the axial magnetic flux density distribution Bθ and the circumferential stress σo distribution in the solenoid.

| Material Properties | Geometric Properties | Loading | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

Analysis Assumptions and Modeling Notes

The problem is solved first using PLANE13 elements. The length of the

solenoid is assumed infinite (L = ), so only a section of the axisymmetric solenoid (t = .002 m, arbitrary) is

required for modeling. It is assumed that the magnetic field external to the solenoid is zero, so

the nodes at x = b are coupled (AZ = constant) such that the proper flux-parallel boundary

condition is imposed. The flux-parallel condition at x = 0 is imposed by setting A = 0.

Flux-normal boundary conditions are imposed naturally (no Ansys input necessary) at y = 0

and y = t.

Symmetric structural boundary conditions are applied to the solenoid elements at y = 0. The nodes at y = t on the solenoid are coupled in UY to ensure symmetry. The air is modeled with 5 elements in the radial direction while the solenoid is discretized with 20 elements in the radial direction to accurately model the stress distribution.