As a complex vehicle subsystem, the tire plays a crucial role in vehicle ride and handling performance, affecting accelerating, braking, cornering, and other maneuvers. Simulations using a robust, accurate tire model help engineers to predict the mechanical response of vehicles under various operating conditions, and they help designers to shorten the development cycle of new performance features.

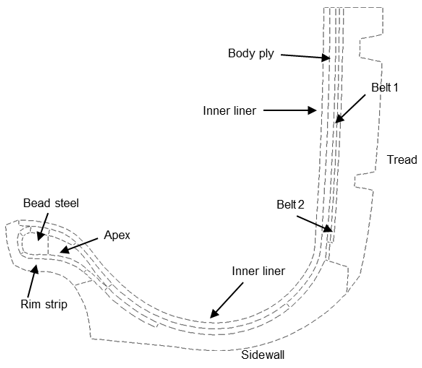

Typically, a tire has the following components:

Tread

Belt region

Inner wall

Sidewall region

Inner carcass region

Bead-fill region

Apex/chafer region

Beads

Reinforcing (belts and body ply)

Tires are made primarily of hyperelastic material such as rubber; however, they are reinforced in some locations (such as the belt, body-ply, and bead-fill regions) with steel or other stiff materials.

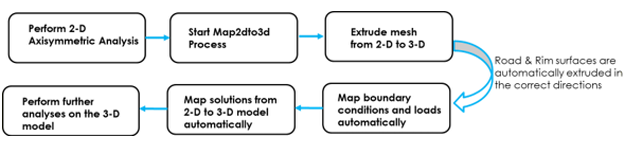

Tire geometry is almost an axisymmetric structure (except occasionally for the tread blocks), so tire simulation generally begins with a 2D axisymmetric analysis. The initial analyses (for rim-mounting and inflation analyses, for example) are performed on the 2D axisymmetric tire model.

After the 2D analyses, the 2D axisymmetric tire model is extruded to the 3D model, and further analyses (such as footprint and steady-state rolling) are continued on the 3D model.

A successful tire-performance simulation requires the following:

A 2D axisymmetric tire model capable of handling torsion due to reinforcing. The PLANE182 2D 4-node structural solid element with torsion effects enabled (KEYOPT(3) = 6) is used to model the 2D axisymmetric tire model.

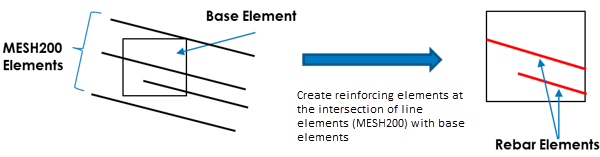

Accurate and straightforward reinforcing modeling. The mesh-independent method is used to create reinforcing elements:

Efficient and accurate transformation of the 2D model into a 3D model.

Effective steady-state rolling analysis on the 3D model.

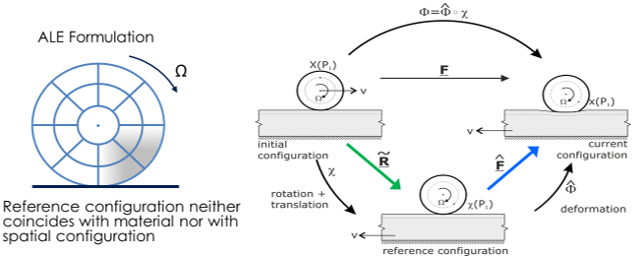

Simulation of steady-state rolling is performed using Arbitrary Lagrangian Eulerian (ALE) formulation.