Two topics are available:

The Hall-Petch effect is shown as observed from the four microstructures with decreasing average grain sizes. A mesh with 125000 elements is used.

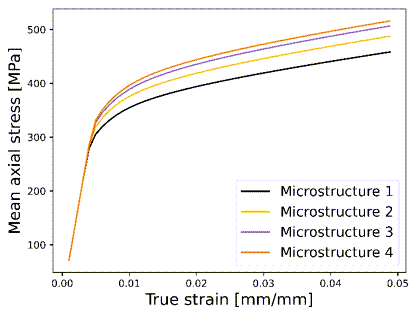

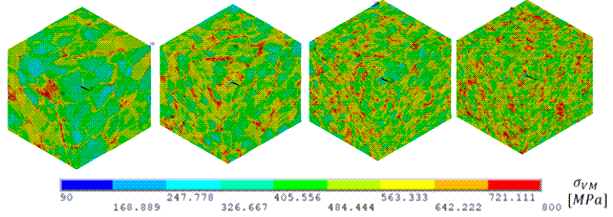

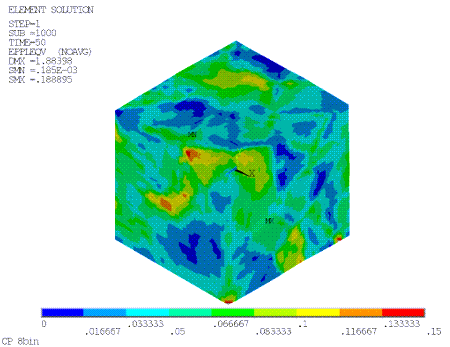

Following are the stress-strain curves and von Mises stress contour plots from the microstructures:

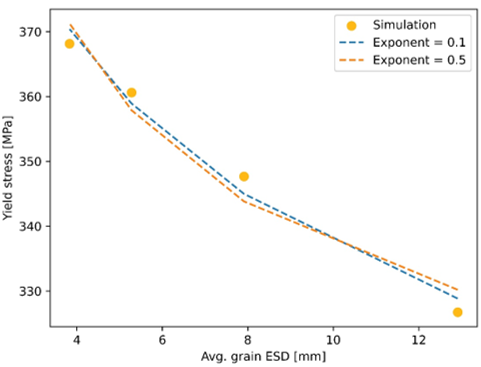

The yield stresses are extracted from the simulated stress-strain curves and are fitted to the following relationship:

where:

Following are the fitted material parameters and the values for two different strengthening exponents:

| 0.1 | 415.5 | 7.1 | 0.980 |

| 0.5 | 176.5 | 281.1 | 0.955 |

The values (calculated using a strengthening exponent between 0.1 and 0.5) are

> 0.955.

Following are the fitted relationships and the simulated datapoints:

The results show that, with a nonuniform distribution of initial hardness higher near the grain boundary and lower at the grain interior, the crystal plasticity model can capture the increasing yield stress with decreasing average grain size.

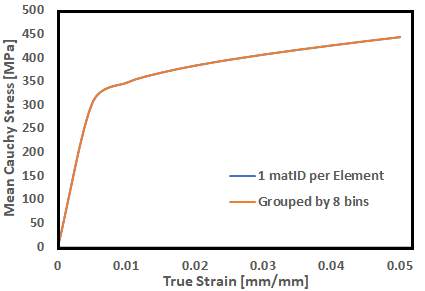

Two material-assignment options are compared. Unlike the 125000-element mesh used to demonstrate the Hall-Petch effect, a coarser mesh with 27000 elements is used here to limit the total number of material assignments needed for the one-material-ID-per-element assignment option.

For the binning option, a total of 8 bins per grain is used.

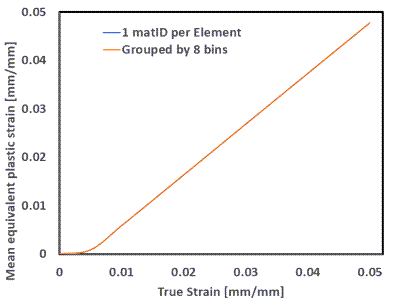

The stress-strain curves and evolution of equivalent plastic strain show the effect of binning the initial hardness values:

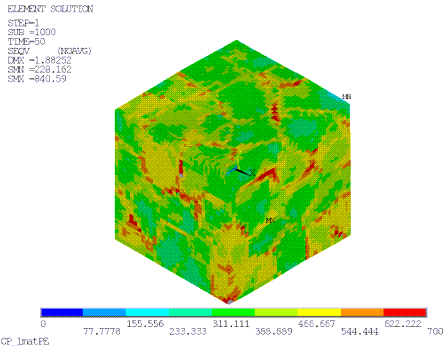

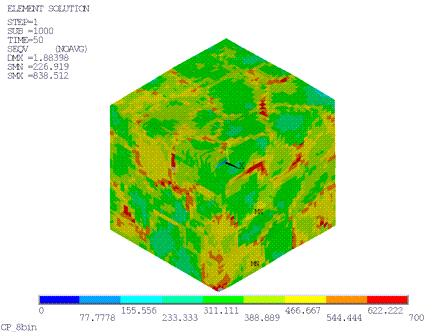

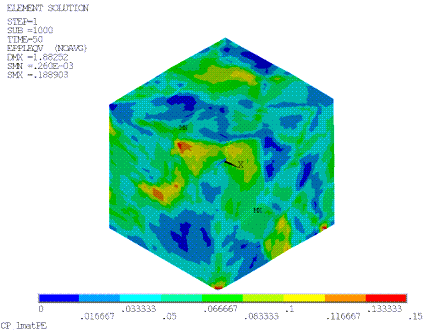

The contour plots for von Mises stress and equivalent plastic strain are also compared:

| Von Mises Stress | |

|---|---|

| 1 material per element |

|

| Grouped into 8 bins |

|

| Equivalent Plastic Strain | |

|---|---|

| 1 material per element |

|

| Grouped into 8 bins |

|

As shown, grouping the hardness values into bins does not significantly affect simulation results provided that a sufficient number of bins are used.

Grouping the hardness values into 8 bins reduces the .dat file (for material assignment) size by a factor of 29 in this case.