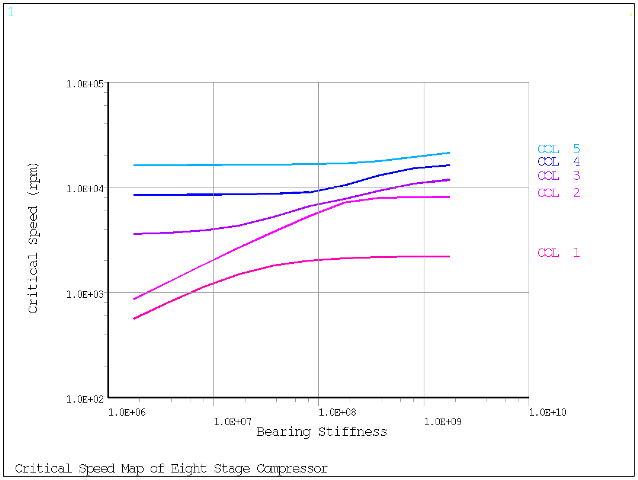

The example consists of an eight stage centrifugal compressor supported by two tilting pad bearings. It is modeled with beam (BEAM188), bearing elements (COMBI214), and points masses (MASS21). APDLMath commands are used to directly calculate the critical speeds and generate the critical speed map.

/filename,tutor-rag07s /prep7 ! *** material mp, ex, 1, 1.33414e+11 mp, dens, 1, 7833.3834 mp, prxy, 1, 0.3 ! *** rotor geometry et, 1, beam188,,, 2 nbdiam = 34 *dim, diam, array, nbdiam diam(1) = 0.06985 diam(2) = 0.110744 diam(3) = 0.127 diam(4) = diam(3) diam(5) = 0.1651 diam(6) = 0.168148 diam(7) = 0.157988 diam(8) = 0.182372 diam(9) = 0.17018 diam(10) = diam(9) diam(11) = diam(9) diam(12) = diam(9) diam(13) = diam(9) diam(14) = diam(9) diam(15) = diam(9) diam(16) = diam(9) diam(17) = diam(9) diam(18) = diam(9) diam(19) = diam(9) diam(20) = diam(9) diam(21) = diam(9) diam(22) = diam(9) diam(23) = diam(9) diam(24) = diam(9) diam(25) = diam(9) diam(26) = 0.1778 diam(27) = 0.168148 diam(28) = diam(27) diam(29) = 0.1651 diam(30) = 0.127 diam(31) = diam(30) diam(32) = 0.118872 diam(33) = 0.094996 diam(34) = 0.093472 *do,i,1,nbdiam sectype, i, beam, csolid secdata, diam(i)/2 *enddo ! *** point masses et, 2, mass21 r,101,72.1224,72.1224,72.1224 r,102,3.22056,3.22056,3.22056 r,103,4.58136,4.58136,4.58136 r,104,2.54016,2.54016,2.54016 r,105,4.39992,4.39992,4.39992 r,106,5.57928,5.57928,5.57928 r,107,5.67,5.67,5.67 r,108,7.4844,7.4844,7.4844 r,109,6.66792,6.66792,6.66792 r,110,33.3396,33.3396,33.3396,0.1805617,0.09042717,0.09042717 ! disk r,111,7.80192,7.80192,7.80192,0.00992065,0.00520907,0.00520907 r,112,33.3396,33.3396,33.3396,0.1805617,0.09042717,0.09042717 ! disk r,113,7.80192,7.80192,7.80192,0.00992065,0.00520907,0.00520907 r,114,33.3396,33.3396,33.3396,0.1805617,0.09042717,0.09042717 ! disk r,115,7.80192,7.80192,7.80192,0.00992065,0.00520907,0.00520907 r,116,36.69624,36.69624,36.69624,0.1805617,0.09042717,0.09042717 ! disk r,117,13.19976,13.19976,13.19976 r,118,36.92304,36.92304,36.92304,0.1805617,0.09042717,0.09042717 ! disk r,119,9.5256,9.5256,9.5256,0.01436885,0.00793067,0.00793067 r,120,34.33752,34.33752,34.33752,0.1805617,0.09042717,0.09042717 ! disk r,121,9.5256,9.5256,9.5256,0.01436885,0.0079014,0.0079014 r,122,34.33752,34.33752,34.33752,0.1805617,0.09042717,0.09042717 ! disk r,123,9.5256,9.5256,9.5256,0.01436885,0.00793067,0.00793067 r,124,36.56016,36.56016,36.56016,0.1805617,0.09042717,0.09042717 ! disk r,125,17.14608,17.14608,17.14608,0.04799371,0.03540999,0.03540999 r,126,5.62464,5.62464,5.62464 r,127,5.94216,5.94216,5.94216 r,128,5.71536,5.71536,5.71536 r,129,5.53392,5.53392,5.53392 r,130,4.39992,4.39992,4.39992 r,131,1.99584,1.99584,1.99584 r,132,3.58344,3.58344,3.58344 r,133,7.39368,7.39368,7.39368 r,134,9.43488,9.43488,9.43488 r,135,4.71744,4.71744,4.71744 ! *** bearing (YZ plane) et, 3, 214 keyopt, 3, 2, 1 keyopt, 3, 3, 0 *dim, kb, array, 10, 1, 1 kb(1,1) = 1751181.1, 3772744.57, 8128282.20, 17511811.02, 37717971.02, 81282646.93, 175118110.24, 377280585.83, 812826294.17, 1751181102.36 r,3, kb(1,1), kb(1,1) ! *** nodes (shaft along X) n, 1 , 0. n, 2 , 0.034544 n, 3 , 0.20574 n, 4 , 0.24384 n, 5 , 0.287274 n, 6 , 0.375412 n, 7 , 0.429768 n, 8 , 0.51943 n, 9 , 0.60579 n, 10, 0.668274 n, 11, 0.747014 n, 12, 0.809498 n, 13, 0.888238 n, 14, 0.950722 n, 15, 1.029462 n, 16, 1.091946 n, 17, 1.251966 n, 18, 1.411986 n, 19, 1.484122 n, 20, 1.575054 n, 21, 1.64719 n, 22, 1.738122 n, 23, 1.810258 n, 24, 1.90119 n, 25, 2.028444 n, 26, 2.10185 n, 27, 2.160524 n, 28, 2.250694 n, 29, 2.30505 n, 30, 2.39268 n, 31, 2.436114 n, 32, 2.474214 n, 33, 2.61874 n, 34, 2.666238 n, 35, 2.806192 n, 40 , 0.24384 n, 310, 2.436114 ! *** mesh type, 1 mat, 1 *do,i,1,nbdiam secnum, i e, i, i+1 *enddo type, 2 *do,i,1,nbdiam+1 real, i+100 e, i *enddo type, 3 real, 3 e, 4, 40 e, 31, 310 ! *** boundary conditions d, all, ux ,,,,,rotx d, 40, all d, 310, all fini ! *** Example of how to determine critical speeds ! ------------------------------------------- ! ** modify the bearing stiffness /prep7 rmodif, 3, 1, kb(5,1), kb(5,1) finish ! ** write the full file /solu antype, modal modopt, damp, 2 coriolis, on,,, on omega, 1.0 ! unit rotational velocity to get [G1] wrfull, 1 ! stop solve when the full file is written solve fini ! ** read matrices on the full file *smat, K , D,IMPORT,FULL,tutor-rag07s.full, STIFF *smat, M , D,IMPORT,FULL,tutor-rag07s.full, MASS *smat, G1, D,IMPORT,FULL,tutor-rag07s.full, DAMP ! ** obtain the new eigenproblem matrices alpha = 1.0 *smat, zMbar, Z, COPY, M *axpy,, -1/alpha, G1, 1,, zMbar *smat, zK, Z, COPY, K *free,K *free,M *free,G1 ! ** solve the new eigenproblem /solu antype, modal modopt, unsym , 10 *eigen, zK, zMbar,, eigenVal, eigenVec fini *free,zK *free,eigenVec ! ** store the critical speeds *dim, critspeed1, ARRAY, 5 _coefunit = 60/alpha ! Hz -> rpm *do,_iloop,1,5 xx = eigenVal(_iloop*2,1)*_coefunit ! real part of the eigenvalue (FW) critspeed1(_iloop) = xx *enddo *free,eigenVal *status,critspeed1 ! ** Obtain the complete critical speed map ! Macro CRITSPEEDMAP.MAC ! ARG1 Number of critical speeds ! ARG2 Number of excitations per revolution ! =0 Defaults to 1.0 (synchronous excitation) ! Bearings stiffness ! ARG3 Lowest value ! ARG4 Highest value ! ARG5 Number of steps ! =0 Defaults to 10 ! Rotational velocity direction (normalized to unity) ! ARG6 X component ! ARG7 Y component ! ARG8 Z component ! ! Eigensolver parameter ! ARG9 Beginning of the frequency range (defaults to 1 Hz) !-------------------------------------------- /show,JPEG critspeedmap, 5,, kb(1,1), kb(10,1),, 1,0,0 /show,CLOSE

The critical speed map is shown in Figure 7.11: Critical Speed Map.