After using NLAD-ETCHG to remesh all elements in a hex-dom component to tetrahedral elements, standard nonlinear mesh adaptivity recommendations apply.

Following are a few general recommendations for the initial phase of the NLAD-ETCHG process (where the hex-dom element components are present):

The mesh-quality-based criterion (NLADAPTIVE,,,MESH) as applied to NLAD-ETCHG uses two options simultaneously:

To enable both options to work properly together, it is often necessary to adjust the remeshing frequency and the remeshing time intervals (

VAL1,VAL2,VAL3) for both options separately.If using the same component to define both options under the same criterion (MESH), however, only the remeshing frequency and time interval defined last for the component will be active. To avoid this behavior, and to ensure correct control over the remeshing process, use two different component names (one for SHAPE and one for SKEWNESS) and apply a separate remeshing frequency and time interval for both.

Geometrically, the components are defined identically (in terms of nodes and elements), differing only in name.

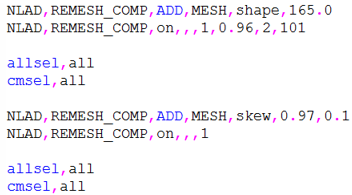

Example 4.7: Wrong Setup

In this case, only the remeshing-control command NLADAPTIVE,REMESH_COMP,ON,,,1 (defined last) is used for the component REMESH_COMP during remeshing. (The NLADAPTIVE,REMESH_COMP,ON,,,1,0.96,2,101 command is ignored.)

Example 4.8: Correct Setup

Set up properly, the separately-named components REMESH_COMP and REMESH_COMP_2 have the same elements.

For cases with mesh distortion using the mesh-quality-based criterion (NLADAPTIVE,,,MESH), adjust the remeshing frequency and the remeshing time intervals (

VAL1,VAL2,VAL3). Seek a compromise solution where the hex-dom elements can model as much of the deformation as possible without causing divergence issues when the remeshing to tetrahedral elements occurs.If the new tetrahedral mesh requires refinement (energy-based (NLADAPTIVE,,,ENERGY) and position-based (NLADAPTIVE,,,BOX)), a better gradation of the initial hex-dom mesh ensures that the tetrahedral mesh follows that gradation, too.

The default maximum angle value for hex-dom meshes using the SHAPE mesh-quality-based criterion is 155 degrees. If mapping difficulties occur, try reducing the limiting value and rerun the problem.

If solution divergence occurs after generating the tetrahedral mesh, check the stability of materials and contact pairs to ensure that they have optimal settings and are not causing the divergence. Comparing analysis runs with and without nonlinear mesh adaptivity is not necessarily a like-to-like comparison, as even one remeshing can change the path of nonlinear deformation and make the final results difficult to compare.

Nonlinear mesh adaptivity cannot automatically resolve problems caused by model instabilities or bifurcations. It is also more sensitive to such perturbations after a refinement due to remeshing, resulting in divergence and/or unrepeatable solutions.

If severe deformation occurs at every substep on a global scale for the nonlinear adaptive component (as most elements in the component tend to become distorted), it is better to reduce the minimum time-step so that more remeshing can repair the large distortion.

Remeshing controls (NLMESH) may require adjustment depending on the model and physical deformation pattern:

Do not adjust the global size ratio (NLMESH,SRAT) before the first remesh of the NLAD-ETCHG procedure occurs.

In cases when the initial mesh is graded for the component activated in nonlinear adaptivity, retain the mesh-sizing gradient (that is, do not issue NLMESH,GRAD,0). For refinement-based operations, the hex-to-tet remeshing maintains the element edge size closely. Generally, excessive element-volume change during this procedure often causes convergence difficulties.

Avoid high thresholds for the boundary angle (NLMESH,BDRA). In most cases, the default threshold values are acceptable. If solution divergence occurs due to an inadequate new mesh quality, try increasing the threshold values by a few degrees. Understand that the loss of features due to the larger angles (especially at contact boundaries) may affect mapping, cause rebalancing difficulties, or generate errors immediately after remeshing.

For a nonlinear adaptive component using SOLID186 elements with hyperelastic material and contact, it may be necessary to increase the contact normal penalty-stiffness factor (FKN), or to decrease the penetration-tolerance factor (FTOLN), for the respective contiguous pairs to achieve stable convergence. To further aid convergence in such cases, you can also try increasing the minimum number of substeps (NSUBST,,,NSBMN), or decreasing the maximum time-step size (DELTIM,,,DTMAX)..

SOLID185 is preferred for large deformation with hyperelastic materials. SOLID186 is preferred for large deformation with elastoplastic materials.

Using the mesh-quality-based criterion (NLADAPTIVE,,,MESH) with small-deflection effects (NLGEOM,OFF) is not recommended, as only the initial mesh shape distortion is handled.

Nonlinear adaptivity in a transient analysis is recommended for low- or moderate-speed dynamic applications, or for quasi-static applications. Due to the mass redistribution from remeshing, it is not recommended for impact problems or high-speed dynamic applications.