The classic Drucker-Prager model[1] is approriate for granular (frictional) material such as soils, rock, and concrete and uses the outer cone approximation to the Mohr-Coulomb law. The input consists of only three constants:

Cohesion value (> 0)

Angle of internal friction

Dilatancy angle

The amount of dilatancy (the increase in material volume due to yielding) can be controlled via the dilatancy angle. If the dilatancy angle is equal to the friction angle, the flow rule is associative. If the dilatancy angle is zero (or less than the friction angle), there is no (or less of an) increase in material volume when yielding and the flow rule is nonassociated.

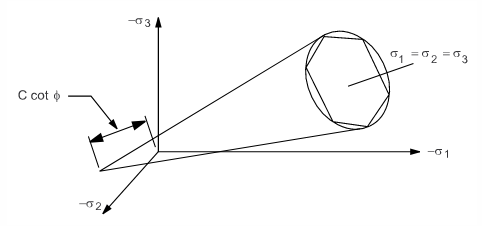

The model uses the Drucker-Prager yield criterion with either an associated or nonassociated flow rule. The yield surface does not change with progressive yielding; therefore, there is no hardening rule and the material is elastic-perfectly plastic (Figure 4.1: Stress-Strain Behavior of Each of the Plasticity Options (f) Drucker-Prager). The equivalent stress for Drucker-Prager is:

(5–1) |

where:

|

|

| {s} = deviatoric stress Equation 4–37 |

| β = material constant |

| [M] = as defined with Equation 4–36 |

This is a modification of the von Mises yield criterion (Equation 4–36 with {α} = {0}) that accounts for the influence of the hydrostatic stress component: the higher the hydrostatic stress (confinement pressure) the higher the yield strength. β is a material constant which is given as:

(5–2) |

where:

| φ = input angle of internal friction |

The material yield parameter is defined as:

(5–3) |

where:

| c = input cohesion value |

The yield criterion Equation 4–7 is then:

(5–4) |

This yield surface is a circular cone (Figure 4.2: Various Yield Surfaces-c) with the material parameters Equation 5–2 and Equation 5–3 chosen such that it corresponds to the outer aspices of the hexagonal Mohr-Coulomb yield surface:

is readily calculated as:

(5–5) |

is similar, however β is evaluated using φf

(the input dilatancy constant). When φf = φ, the flow rule is

associated and plastic straining occurs normal to the yield surface and there will be a

volumetric expansion of the material with plastic strains. If φf is

less than φ there will be less volumetric expansion and if φf

is zero, there will be no volumetric expansion.

The equivalent plastic strain (output as EPEQ) is defined by Equation 4–43 and the

equivalent stress parameter

(output as SEPL) is defined as:

(5–6) |

The equivalent stress parameter is interpreted as the von Mises equivalent stress at yield

at the current hydrostatic stress level. Therefore, for any integration point undergoing

yielding (stress ratio (output as SRAT) >1), should be close to the actual von Mises equivalent stress (output as SIGE) at

the converged solution.

[1] Drucker, D. C. & Prager, W. (1952). Soil mechanics and plastic analysis or limit design. Quarterly of Applied Mathematics. 10(2), 157-165.