In addition to the general support parameters, parameters specific to line supports allow you to control:

Tooth-shaped cutouts at the upper edges of supports

Perforations in the support walls

How far the supports intrude into the part

Struts in the support walls

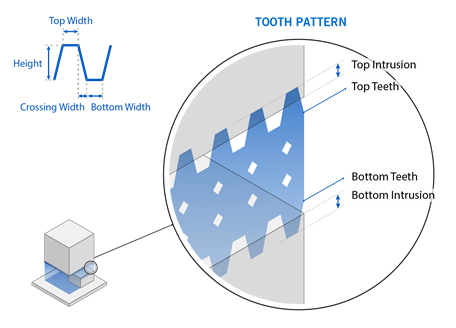

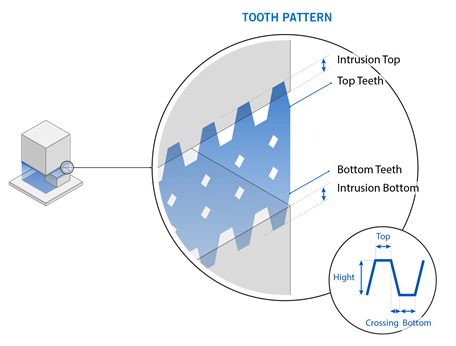

Tooth Pattern

Tooth patterns are tooth-shaped cut-outs at the upper and/or lower edges of each support wall. They can be generated between a part and the baseplate or between part areas. Their main purpose is to make it easier to remove supports.

Create Top Tooth Pattern: If enabled, cut-outs are generated at

the upper edge of the support walls in the form of teeth. This is at the connection between the

support walls and the underlying part surface.

Create Top Tooth Pattern: If enabled, cut-outs are generated at

the upper edge of the support walls in the form of teeth. This is at the connection between the

support walls and the underlying part surface.

Bottom Width: The lower width of each tooth, in millimeters.

Crossing Width: The distance between the end of the top width and the start of the lower width, in millimeters. This affects the distance between teeth.

Top Width: The upper width of each tooth, in millimeters. A value of zero will produce a pointed tooth at the top, subject to intrusion settings.

Height: The height of the top tooth, in millimeters.

Create Bottom Tooth Pattern: If enabled, cut-outs are generated

at the lower edge of the support walls in the form of teeth. This is at the connection between

the support walls and the baseplate (or lower part surface).

Create Bottom Tooth Pattern: If enabled, cut-outs are generated

at the lower edge of the support walls in the form of teeth. This is at the connection between

the support walls and the baseplate (or lower part surface).

Bottom Width: The lower width of each tooth, in millimeters. A value of zero will produce a pointed tooth at the intersection of the support walls and the baseplate (or lower part), subject to intrusion settings.

Crossing Width: The distance between the end of the top width and the start of the lower width, in millimeters. This affects the distance between teeth.

Top Width: The upper width of each tooth, in millimeters.

Height: The height of the bottom tooth, in millimeters.

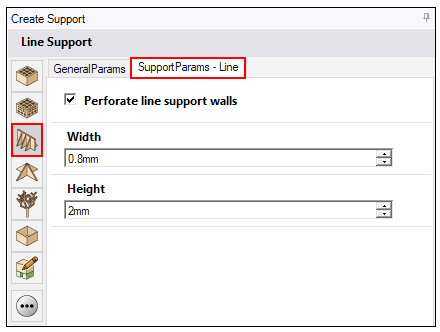

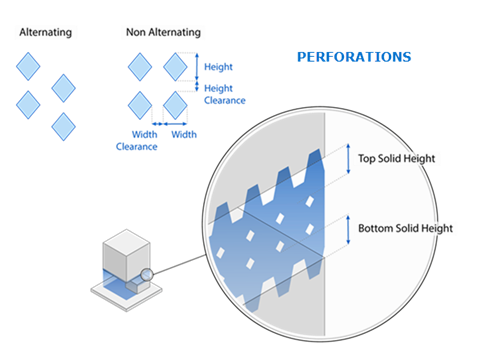

Perforate Support Walls

Here you can define settings for perforations in line support walls. Settings for the perforations are applied to both the external contour (if being generated) and the internal line support walls.

Perforate the support walls: If enabled, perforations are generated.

Perforate the support walls: If enabled, perforations are generated.

Type: The shape of the perforations. A simple diamond shape is

available.

Type: The shape of the perforations. A simple diamond shape is

available.Width: The width of the diamond, in millimeters.

Height: The height of the diamond, in millimeters.

Height Clearance: The distance between the diamonds in height –

the height interval, in millimeters.

Height Clearance: The distance between the diamonds in height –

the height interval, in millimeters. Width Clearance: The distance between the diamonds in width – the

width interval, in millimeters.

Width Clearance: The distance between the diamonds in width – the

width interval, in millimeters. Top Solid Height: The distance between the uppermost diamonds and the

part at the top of the support wall, in millimeters.

Top Solid Height: The distance between the uppermost diamonds and the

part at the top of the support wall, in millimeters. Bottom Solid Height: The distance between the lowest diamonds and the

baseplate (or lower part) at the bottom of the support wall, in millimeters.

Bottom Solid Height: The distance between the lowest diamonds and the

baseplate (or lower part) at the bottom of the support wall, in millimeters.

Alternate diamonds: If enabled, the diamonds will be

positioned offset to each other.

Alternate diamonds: If enabled, the diamonds will be

positioned offset to each other.

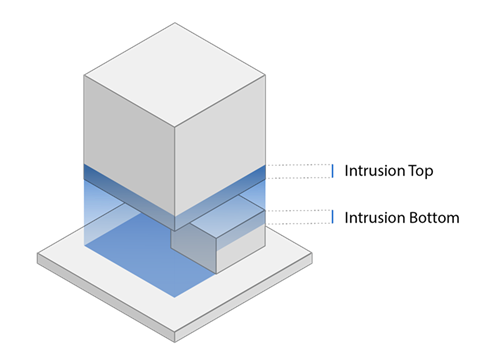

Intrusion into Part

Intrusion Top: The distance the top of the support walls

penetrate into the part, in millimeters.

Intrusion Top: The distance the top of the support walls

penetrate into the part, in millimeters.

Intrusion Bottom: The distance the bottom of the support walls

penetrate into the part (for part-to-part supports), in millimeters.

Intrusion Bottom: The distance the bottom of the support walls

penetrate into the part (for part-to-part supports), in millimeters.

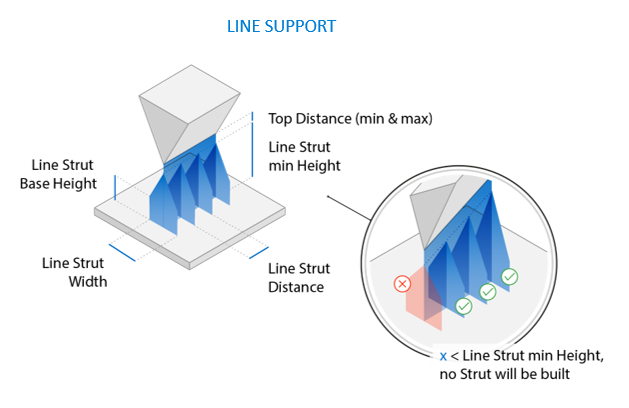

Include Struts

Line has Struts: If enabled, struts are generated.

Line has Struts: If enabled, struts are generated.

Struts Distance: The distance between the individual struts, in millimeters.

Strut Min Height: The height of the struts, in millimeters. Struts that are smaller than the defined value are not generated.

Strut Min Top Distance: The minimum distance between the uppermost end of the strut and the part, in millimeters.

Strut Max Top Distance: The maximum distance between the uppermost end of the strut and the part, in millimeters.

Strut Base Height: The height of the strut up to which the struts run upwards at a 90° angle to the baseplate, in millimeters. After this height, the struts buckle and point directly upwards.

Strut Half Min Width: The minimum width of the strut halves on the baseplate, in millimeters.

Strut Max Width: The maximum width of the struts on the baseplate, in millimeters.

Strut Mesh Clearance: The distance between the struts and a nearby part surface, in millimeters.

Strut Max Slope on Part: The angle up to which struts are generated, in degrees.