There are several Design for Additive Manufacturing (DfAM) considerations to be aware of that affect the cost and quality of your part. Variables include:

Part design (thicknesses, overhangs, edges, holes, desired surface finish)

Orientation on the base plate (affects time to print and number of replicate parts that can be nested on a base plate)

Slicing

Slicing is required if you use the manual clustering in the DED process simulation. Slicing requires geometrical manipulation, using SpaceClaim, perhaps. Consider these hints for slicing:

Slicing height must follow layer height.

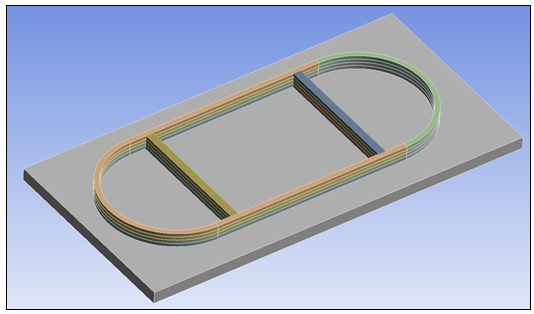

Closed loops must be split since each weld line requires a defined start face.

Here is the sliced geometry for a racetrack example.

Cleanup of Facets

If you have an .stl file, be sure to clean it up to eliminate gaps and slivers before importing it into Workbench.

In SpaceClaim:

Under Facets, the Check Facets and the Auto Fix tools are quick ways to find and fix problems in faceted bodies

Use Facets > Thickness to identify thin-walled features