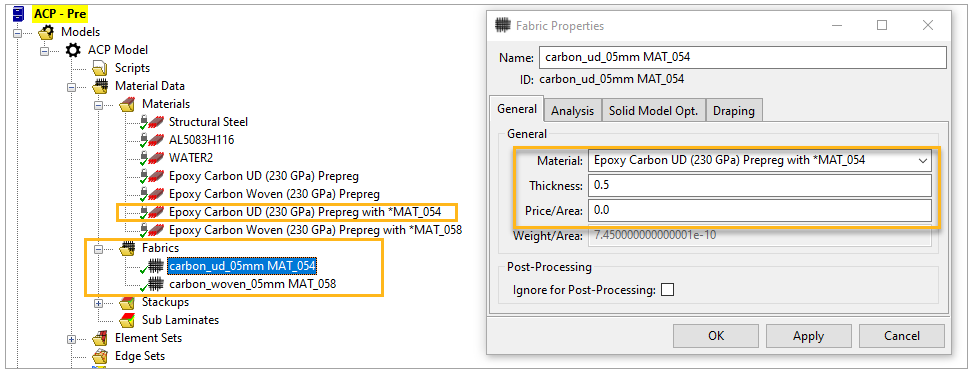

Material Assignment

Because each LS-DYNA material model in Engineering Data has its own definition, you can assign specific materials to each individual ply. If a material without an LS-DYNA definition is used, it is automatically converted to the preset LS-DYNA material card. The workflow for defining Fabrics, Stackups, and Sub-Laminates in ACP does not differ from standard composite model generation. The model in this example uses two different Fabrics, one for the woven and another for the unidirectional material. You must define Fabric Thickness in the Fabric Properties dialog. Additional but optional controls are available for draping computation and solid model material handling for degenerated elements.

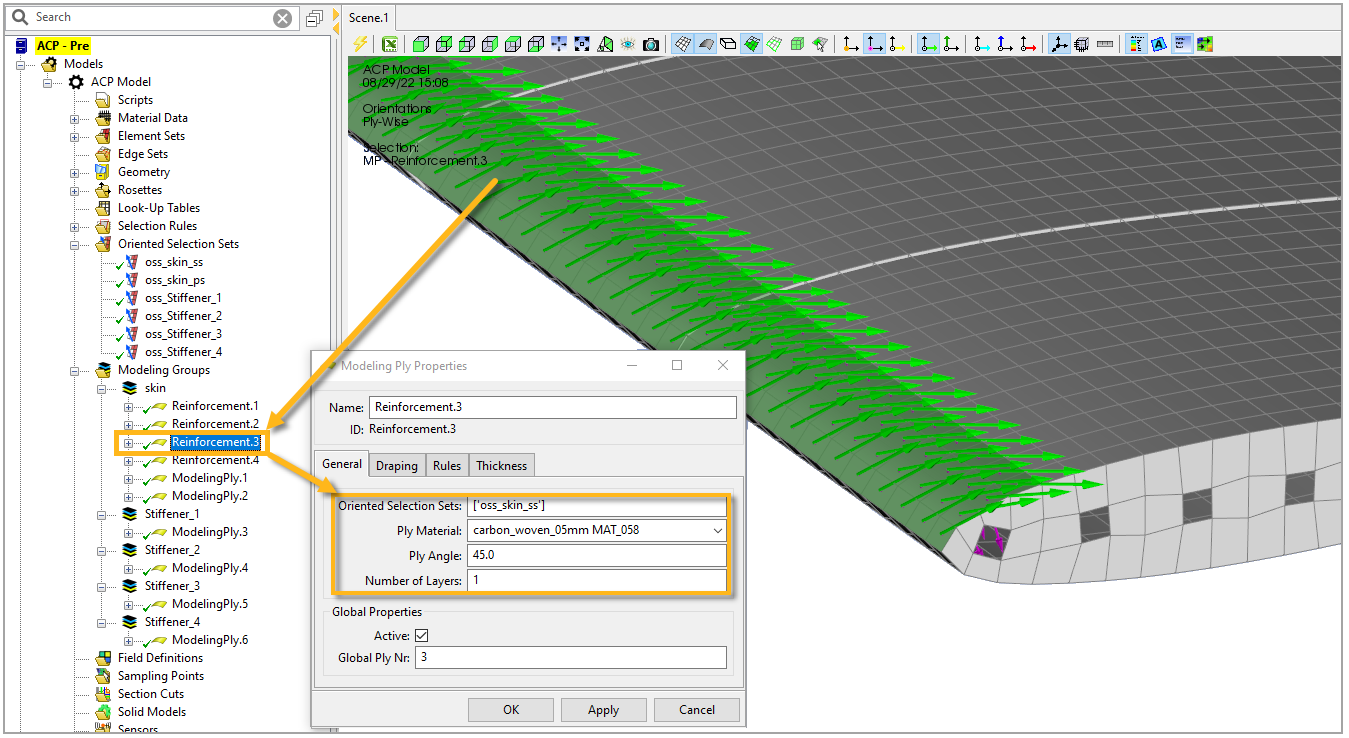

Lay-Up

The composite lay-up contains the two different materials previously defined. The stiffeners and the base lay-up of the skins are made from the unidirectional material. Additional woven materials are applied to the trailing edge of the wing as a local reinforcement. The ply stacking direction of the skin points inward as defined through the underlying Oriented Selection Set of the modeling plies.