Two different parametrizations of the Hill yield criterion with respect to the principal values of the orientation tensor are available:

Following [Launay 2013], we adopt the following phenomenological parametrization of the Hill yield criterion:

(3–65) |

where

denotes the i-th eigenvalue of the second order fiber orientation tensor

is a parameter describing the sensitivity of the yield criterion to the orientation distribution

is a regularization parameter.

Note that the regularization term was not present in the original model by

[Launay

2013], in which case no plastic flow can develop along the fiber

direction of a unidirectionally aligned composite– that is,

for

. Since this assumption does not hold for short fiber

reinforced composites, the term

is added here, where the constant

(3–66) |

depends on the volume fraction and the aspect ratio

of the fibers.

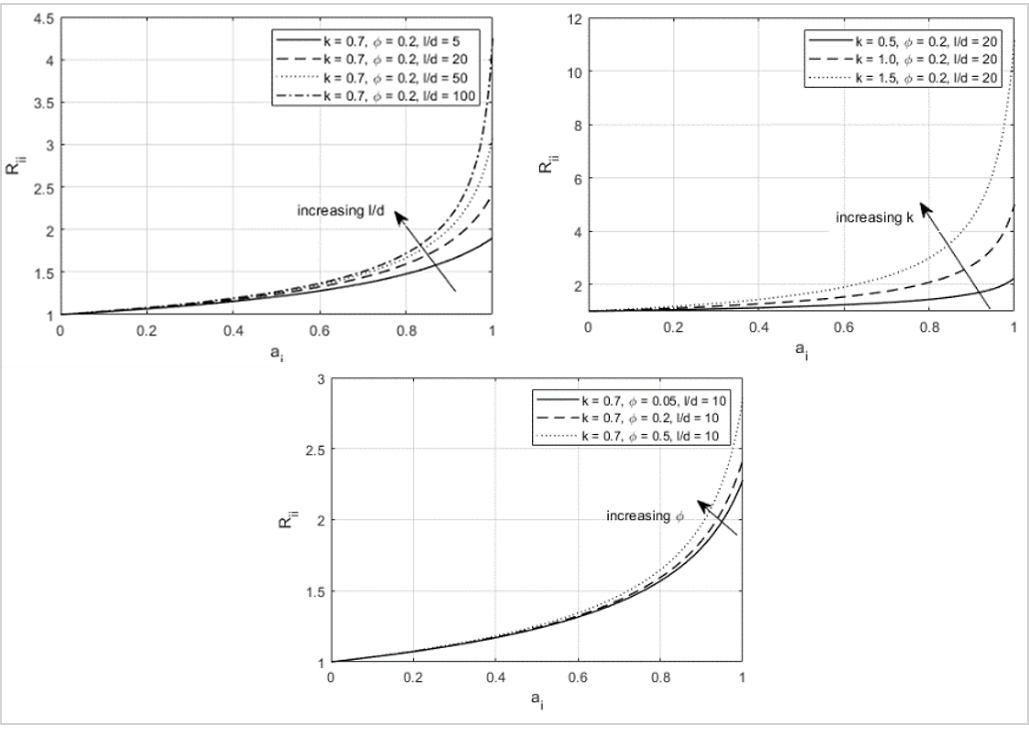

The directional yield ratios then read

(3–67) |

Some comments are in order:

The yield ratios in shear direction are independent of the fiber orientation.

For

, which is in the limit of high fiber volume fraction and/or high fiber aspect ratio, the expression for the yield ratios in normal direction reduces to the original one in [Launay 2013]. See the figure below.

For

, it reduces to the von Mises Yield criterion.

For a generic

and a completely random fiber orientation distribution

up to a scaling factor, it reduces to the von Mises criterion in the limit of

.

Figure 3.2: Effect of the aspect ratio, fiber volume fraction, and orientation sensitivity parameter on the yield ratio in normal direction

Assume that the Hill yield strength of a unidirectional short fiber composite is known. To predict the strength of a composite with arbitrary fiber orientations, we can follow an approach similar to that used for the homogenization of linear elastic properties.

Let denote the Hill strength tensor of a unidirectional

composite with inclusions aligned along the direction

. Following [Van Hattum et al., 1999], we rewrite the yield criterion (Equation 3–59 to Equation 3–61) in strain

space:

(3–68) |

where and

is the stiffness tensor of the unidirectional composite.

The strength properties of a composite with arbitrary fiber orientations are

computed as an average of unidirectional composite properties over all

directions, weighted by the orientation distribution function

(3–69) |

The tensor admits the same representation as in Equation 3–5 and can be easily

computed in terms of the second and fourth-order fiber orientation tensors.

The final orientation averaged yield strength tensor (in stress form) is

obtained as

(3–70) |

This procedure relies on the assumption of knowing

the strength of the unidirectional composite. In such case, the Hill yield

tensor is transversely isotropic and only depends on three

independent parameters: the yield stress in the longitudinal and transverse

directions (

and

, respectively), and the longitudinal shear stress

. For instance, for a unidirectional composite with fibers

aligned along the material 1 direction, the yield stresses in Equation 3–64 are given by

|

|

The values of ,

, and

can be, for instance, predicted from micro-mechanical

considerations (see for example [Van Hattum

et al., 1999]. In Material Designer, they are reverse-engineered from

experimental stress-strain curves as described in Hill Yield Criterion.