Numerical simulation of composite structures is challenging due to the differences in involved length scales. Consider a wind turbine rotor blade made of glass fiber reinforced composite materials: the diameter of the glass fibers is a few micrometers, while the diameter of the turbine is 100 meters. This is a scale difference of roughly eight orders of magnitude.

While the finite element method could be used to simulate the structural mechanics of this system (resolving all length scales), it is not practical. The number of elements required would be astronomically large, and computing the finite element solution would be infeasible, both on modern and near-future computing hardware.

This scale difference is also a problem in additive manufacturing. 3-D printing allows the generation of parts on the meter scale, with complex microstructures. The ratio of the involved length scales is smaller than in the example of the composite blade, but still presents a significant computing challenge with a single finite element model resolving all length scales.

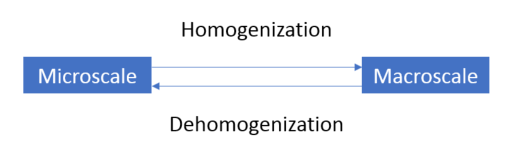

The standard approach to eliminate this problem of scale in finite element analysis for composite materials is homogenization. Material properties for a composite material are averaged, rather than simulating the full complex microstructure. With homogenized material data, structures only need to be simulated at the macroscopic scale, making composite simulation significantly less computationally expensive.

The simplest way to perform homogenization is to use an analytic approach: rules-of-mixture or mean-field homogenization (see for instance [Younes et. al (2012)]). Material Designer allows you to perform analytical homogenization for short fiber (see the section below, Analytical Homogenization). A more accurate approach is finite element analysis of the microscale structure of the material, which is the approach implemented in Material Designer in all other instances. The following sections describe the finite element analysis approach to performing material homogenization.

It should also be mentioned that there is a reverse process called dehomogenization or localization. In order to investigate why a structure fails at a certain location, analysis is shifted from the macroscopic to the microscopic scale. On the finer level, the cause of failure is determined.

If both length scales are fully coupled in a numerical simulation, it is called a multi-scale simulation. The most common approach is often called FE2, as there is a separate microscopic finite element simulation for every integration point of the macroscopic finite element simulation (see for instance [Kouznetsova] for an overview of this approach). In general, multi-scale simulation is very computationally expensive and should be avoided (if possible). Instead, Material Designer performs a single computationally expensive preprocessing step that leads to variable, homogenized material data, and results in a macroscopic simulation that is significantly less computationally expensive.

Following this approach, Material Designer can compute homogenized linear elastic and thermal material properties. As a Beta feature, Material Designer can also compute stress-strain curves for micro-structures with nonlinear constituent materials. You will find the Beta documentation here. For Short Fiber Composites, in addition to the microscale-based approaches, you can also characterize the nonlinear response of the material by fitting a phenomenological plasticity model against experimental data. See Hill Plasticity Curve Fitting for Short Fiber Reinforced Composites for more details.

In all of the simulation approaches described, there is an assumption of scale separation. The microscale structures must be significantly smaller than the macroscale (compare also [Geers et. al (2010)]). If this assumption is violated, the micro- and macroscale cannot be modeled independently. However, this assumption is reasonable for both composite materials and additive manufacturing, and is assumed in all computations.