The following parameters of the constitutive model (described in the above section Material Modeling) must be fitted against experimental data:

The parameters entering the Hill yield criterion

The parameters of the isotropic hardening model

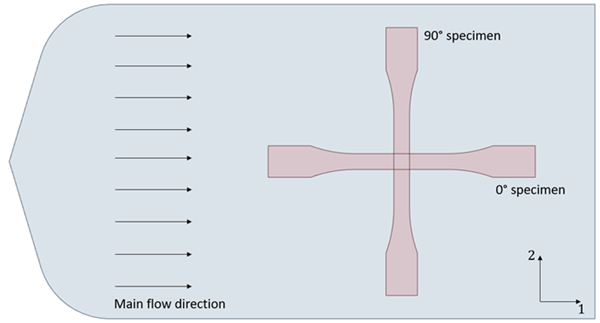

To this end, stress-strain curves from uniaxial tension experiments on two types of specimens must be collected: one prepared from an injection molded plate in the direction of the suspension flow and another type prepared from a similar plate perpendicular to the suspension flow. See the figure below.

Since the present constitutive model ignores rate-dependent effects due to polymer viscosity, experiments should be performed at very low test speeds (quasi-static testing).

In addition, we assume the average second-order fiber orientation tensor in the

injection molded plate is known. The fiber orientation field can be obtained one of

two ways: by microscopic computed tomography (CT) scans or by injection molding

simulation. When defining a cartesian coordinate system as shown in the figure below, we assume

the first principal fiber direction is aligned with the x axis (along the flow

direction) and the second principal fiber direction is aligned with the y axis (in

plane, transversely to the flow). We denote the corresponding eigenvalues by

and

.

The fitting process is split into two sequential steps: First, we determine the parameters of the Hill yield criterion and then calibrate the isotropic hardening model. To this end, we first need to derive an expression for the equivalent accumulated plastic strain.